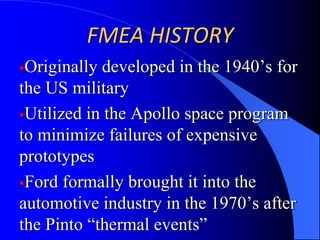

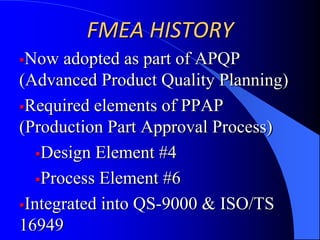

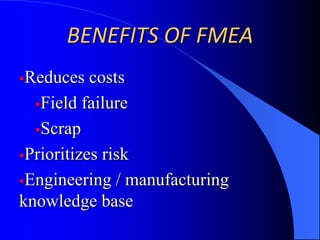

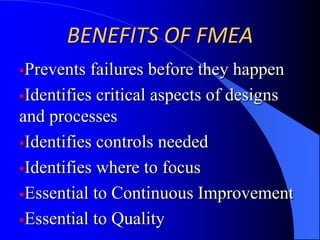

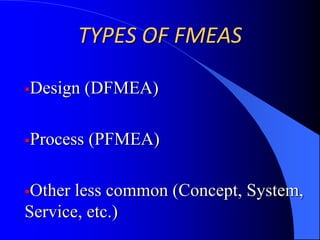

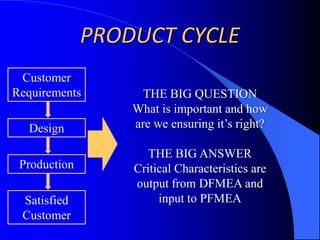

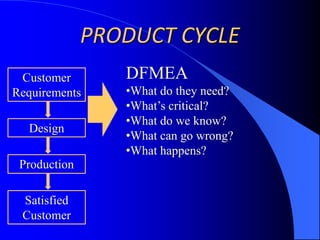

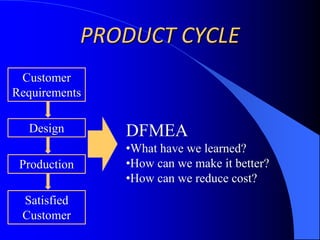

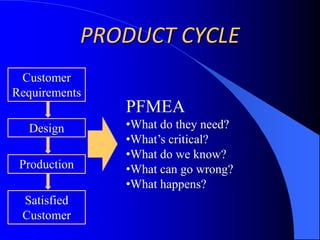

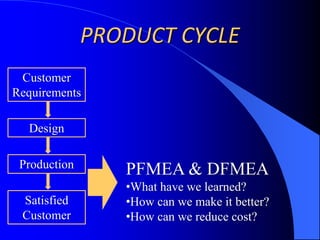

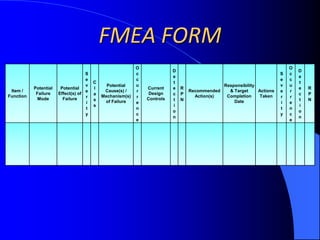

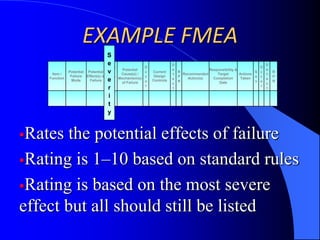

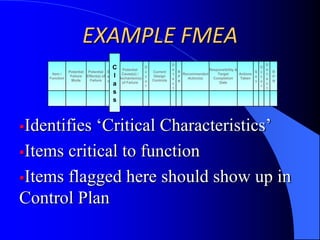

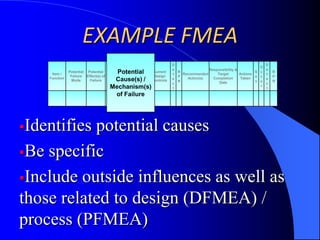

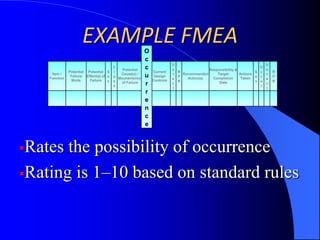

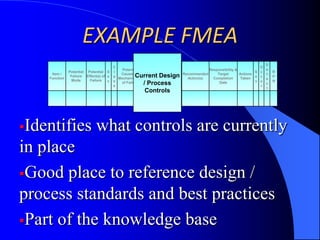

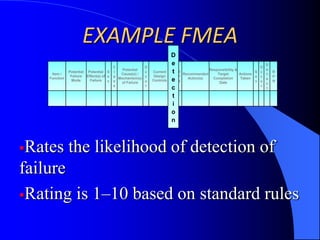

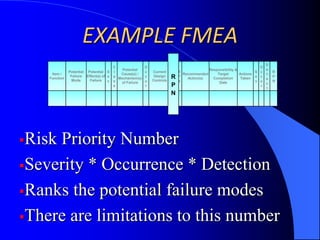

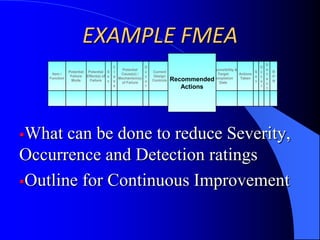

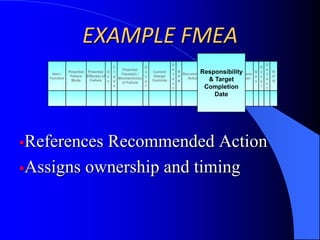

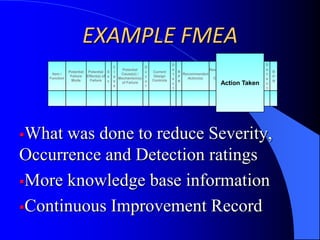

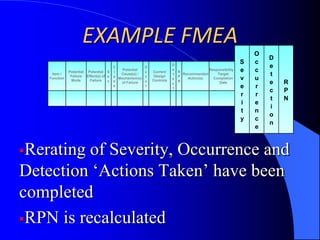

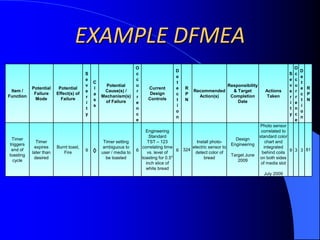

The document discusses Failure Mode and Effects Analysis (FMEA), a systematic method for evaluating potential failures in design, manufacturing, and production processes. It was originally developed in the 1940s for the military and is now commonly used in various industries. An FMEA involves analyzing how and how often a process might fail and classifying the failures by severity, occurrence, and detection. The analysis helps prioritize risks and identify actions needed to prevent failures.