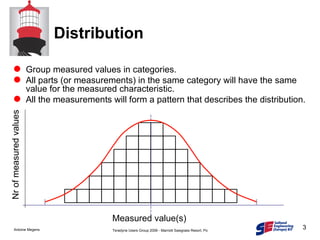

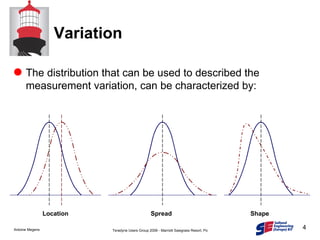

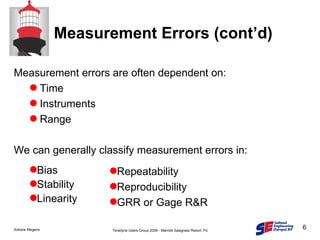

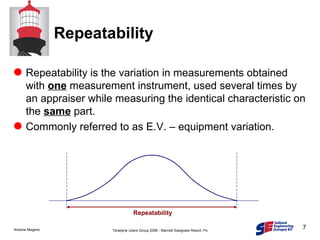

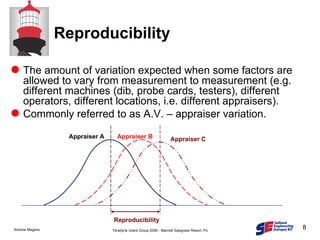

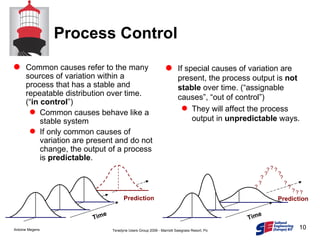

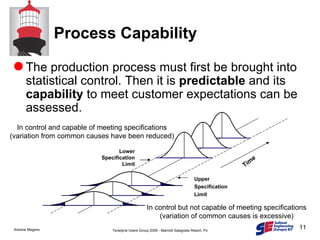

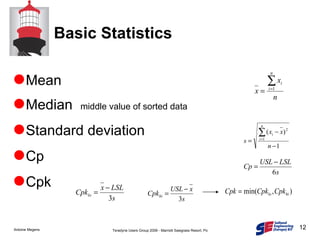

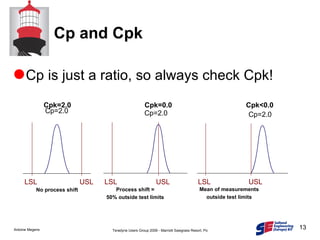

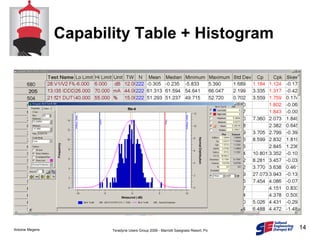

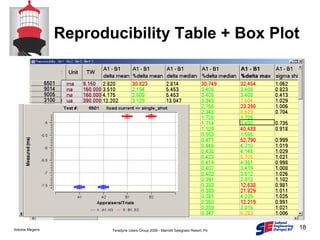

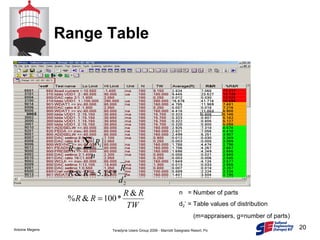

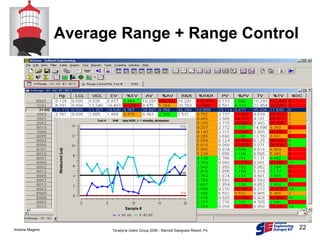

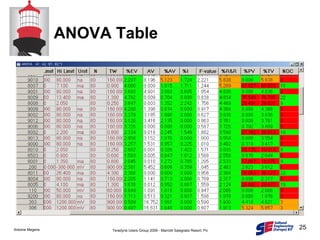

This document discusses standard data analysis tools for evaluating measurement repeatability and reproducibility (R&R) using statistical methods. It covers topics such as distribution and variation, measurement errors, process control and capability, basic statistics, and methods for evaluating repeatability, reproducibility, and gauge R&R including the range method, average/range method, and ANOVA method. Examples of tables and charts used in R&R studies are also presented.

![R&R Investigation Using Standard Data Analysis Tools Antoine Megens, Salland Engineering [email_address]](https://image.slidesharecdn.com/RRAnalysisusingSEDana-123516078114-phpapp02/75/R-R-Analysis-Using-SEDana-1-2048.jpg)