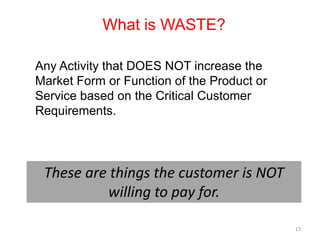

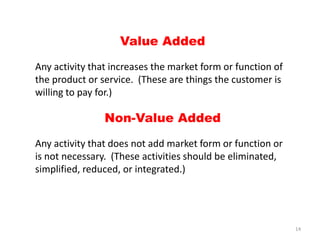

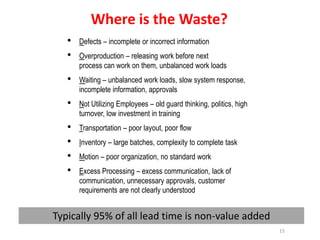

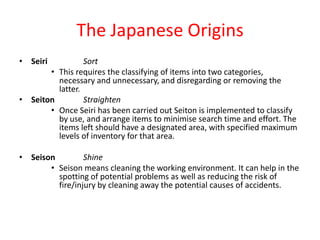

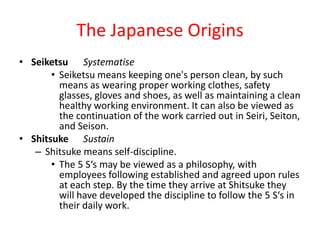

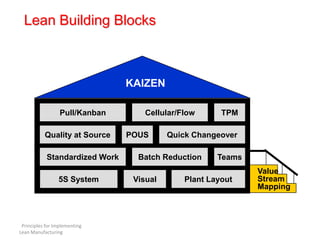

Lean manufacturing aims to eliminate waste by focusing on value-added activities. It was developed based on the Toyota Production System and considers seven types of waste. Key Lean principles include specifying value from the customer perspective, making value flow without interruptions, and continuously improving processes through eliminating waste. Techniques like 5S, standard work, visual management, and value stream mapping are used to implement Lean.