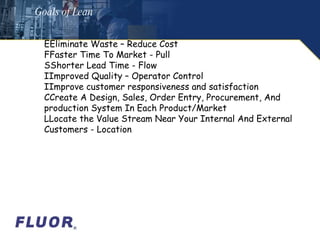

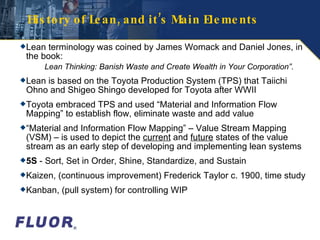

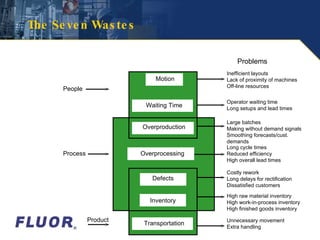

The document discusses lean methodology and its principles of eliminating waste and adding value. It defines lean as redefining work to positively contribute to value creation and meet customer needs. The goals of lean are to reduce costs, shorten lead times through flow, improve quality and customer responsiveness. Lean is based on the Toyota Production System and uses value stream mapping to eliminate waste and add value. The main lean elements discussed are 5S, continuous improvement (kaizen), pull systems (kanban), and identifying and reducing the seven wastes.