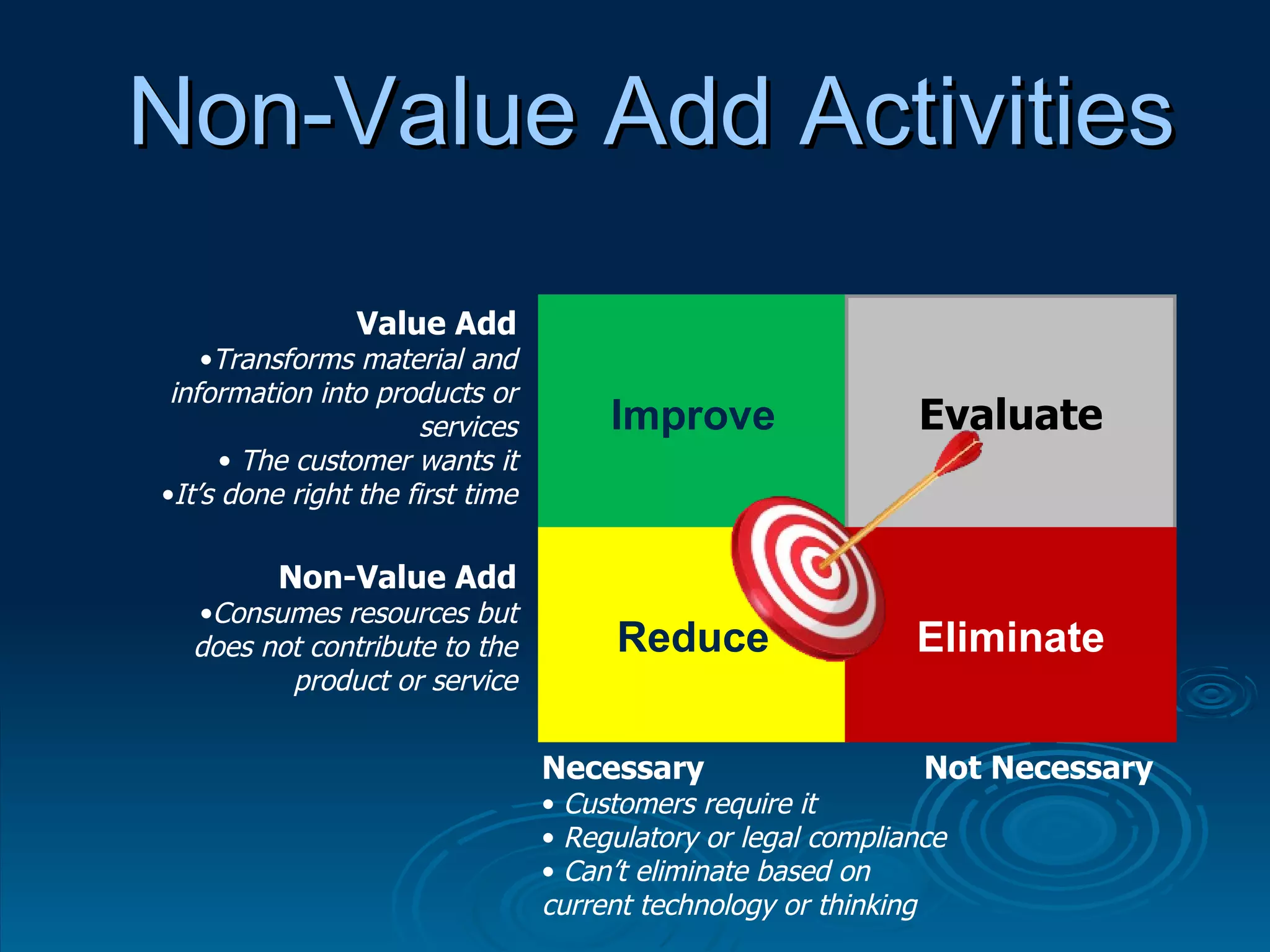

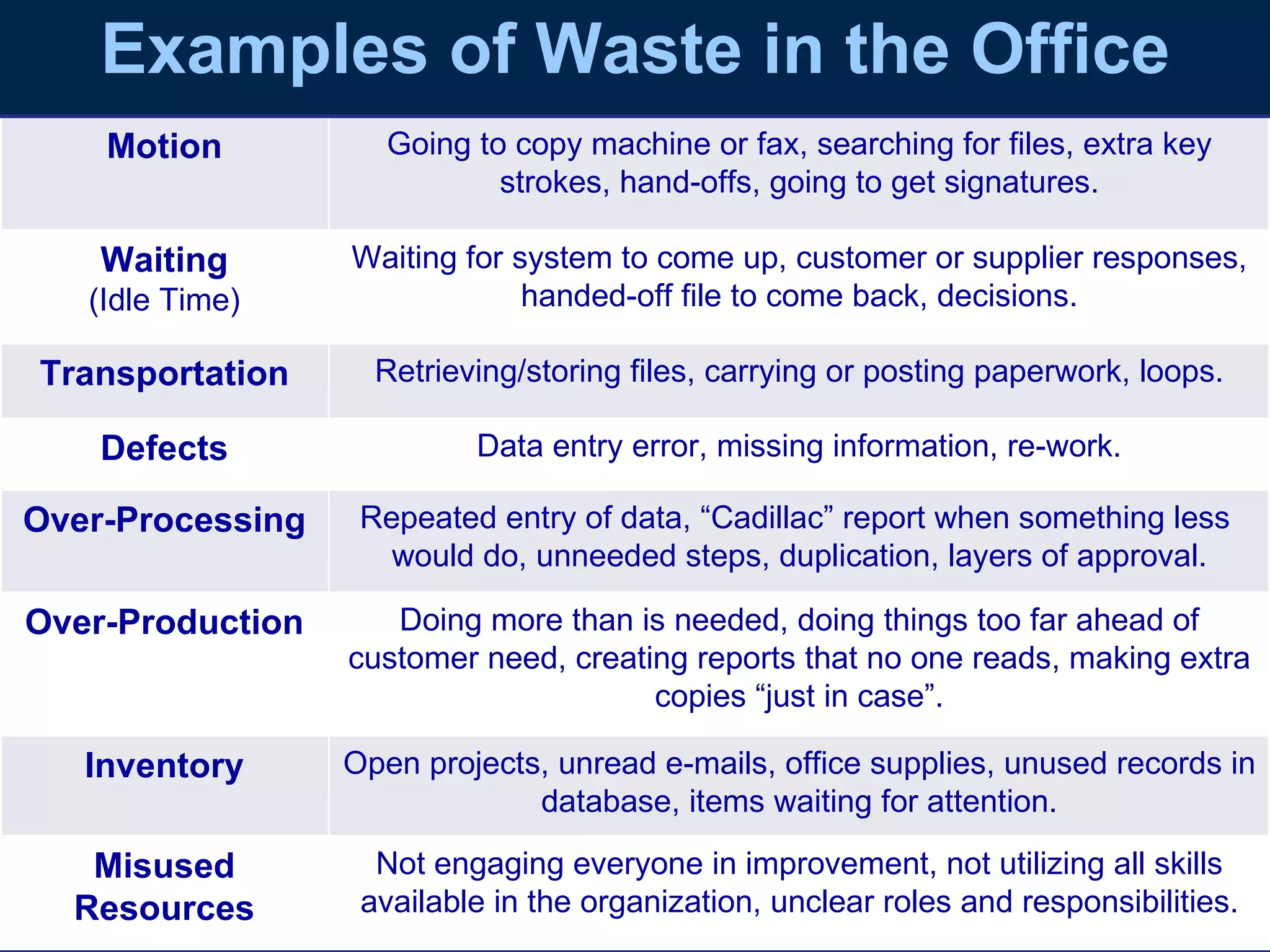

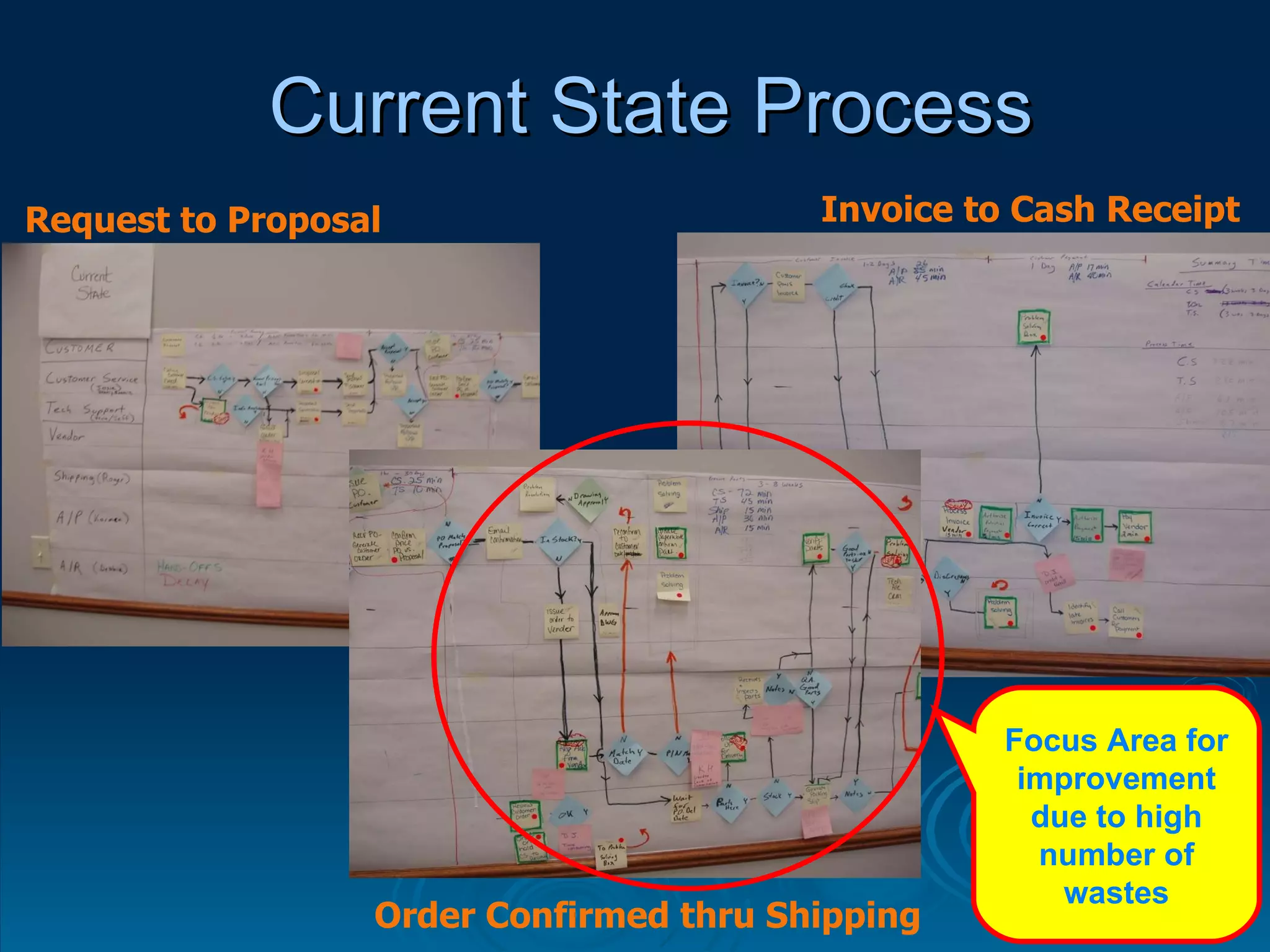

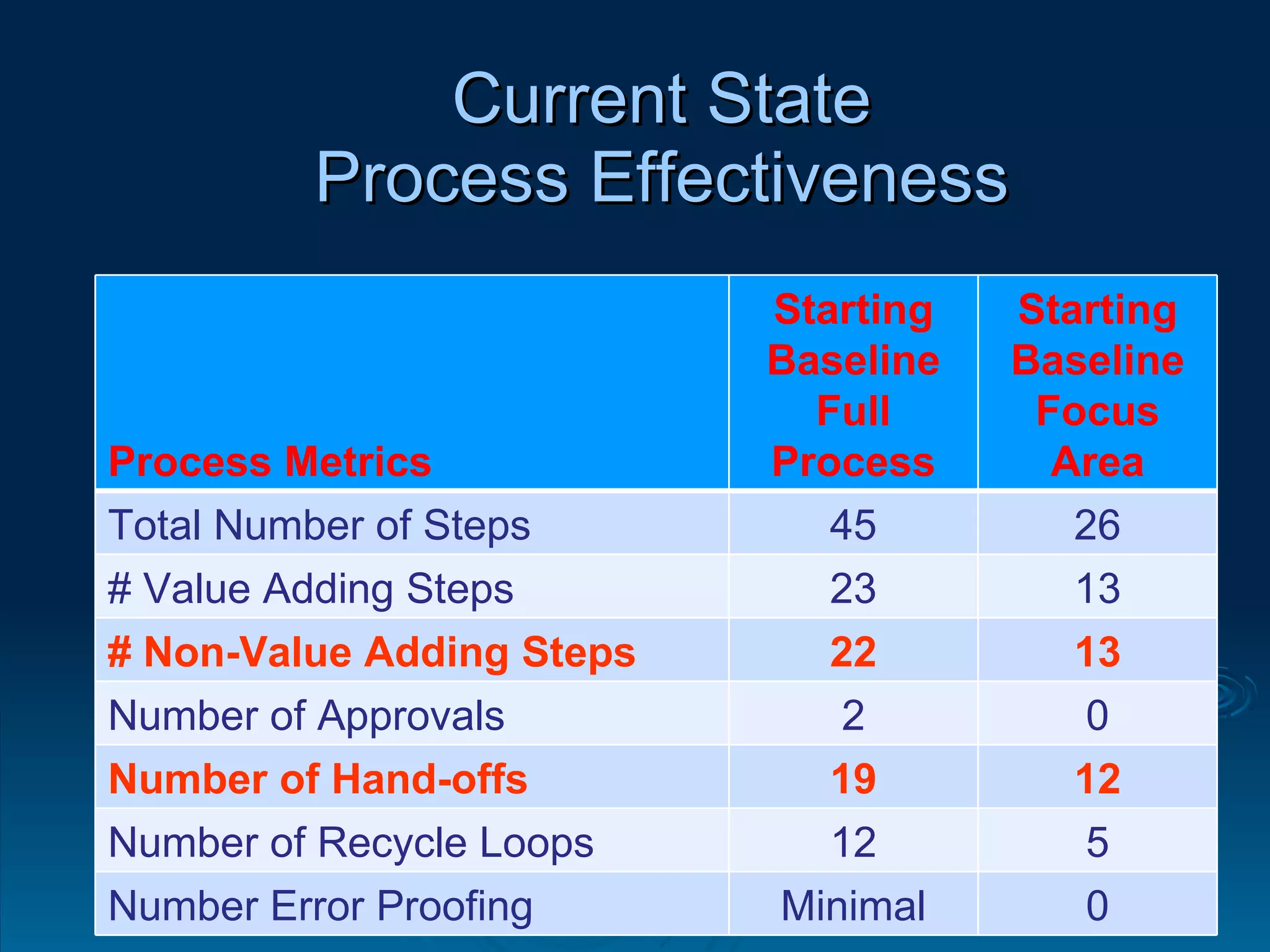

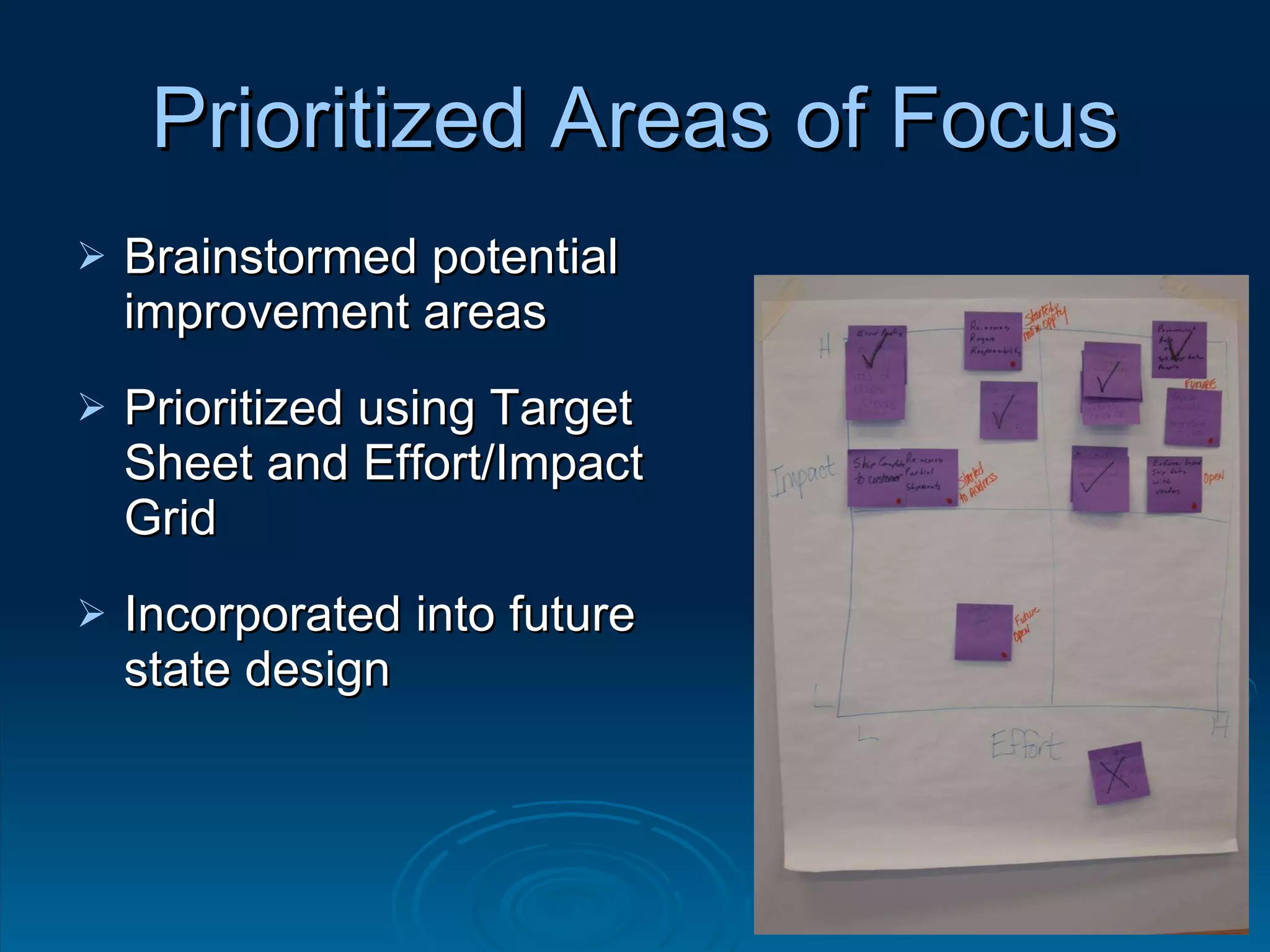

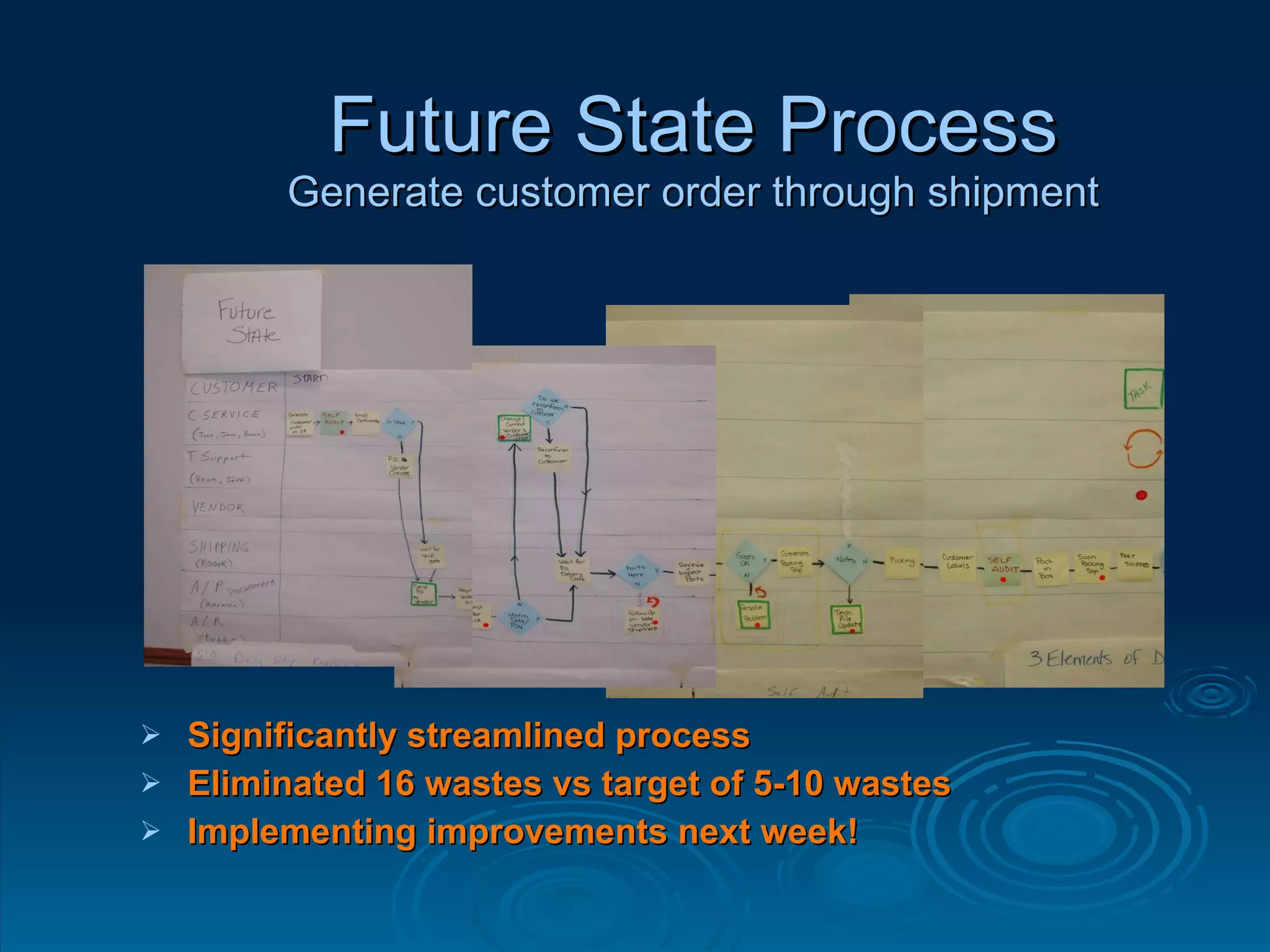

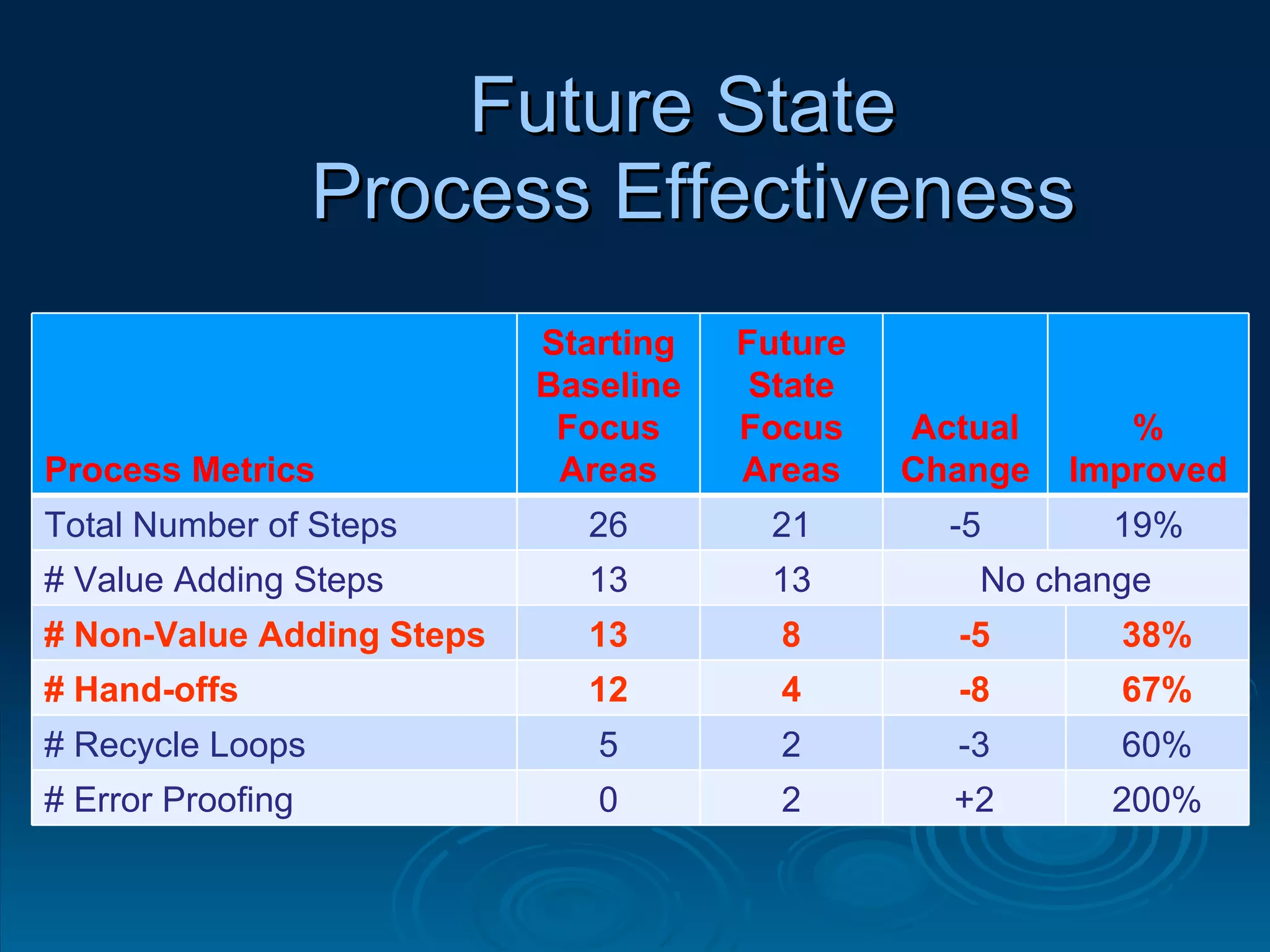

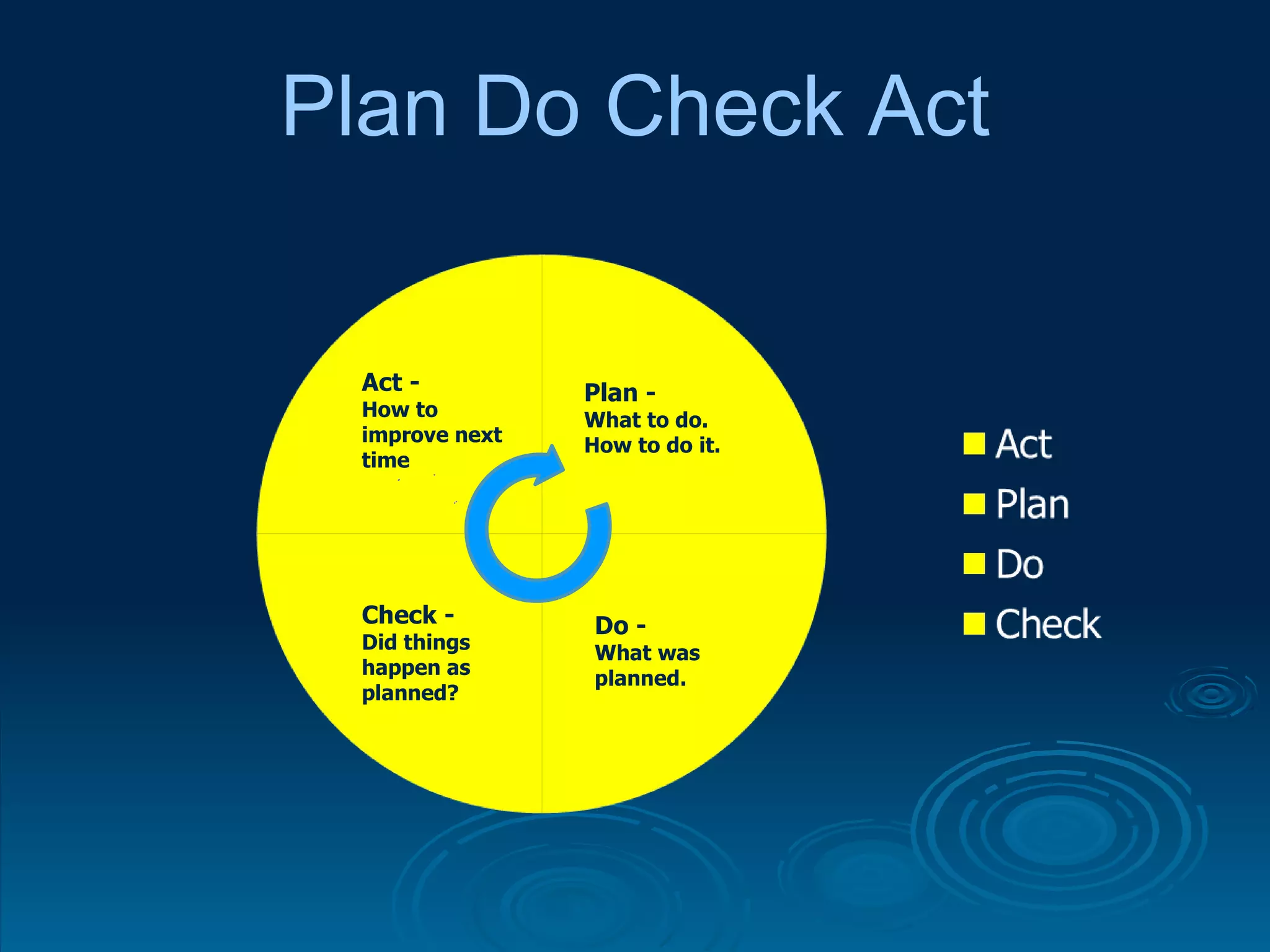

The document summarizes an upcoming value stream mapping event for a home healthcare services company. The 2-day agenda includes lean education, creating a current state map to understand existing processes, identifying improvement opportunities, designing an improved future state map, and developing an action plan. The goal is to streamline processes, eliminate waste, and improve customer satisfaction through applying lean principles like value stream mapping.