1. The document discusses the history and founding principles of Toyota Motor Corporation. It was founded in 1937 by Kiichiro Toyoda as a spin-off from his father's company, Toyota Industries.

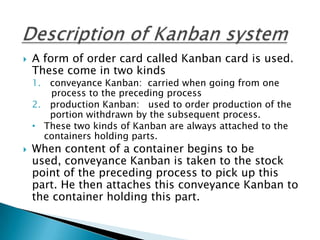

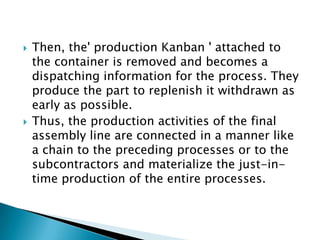

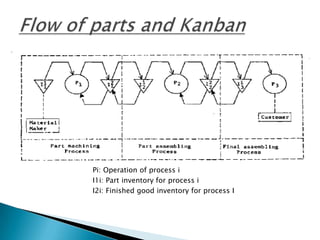

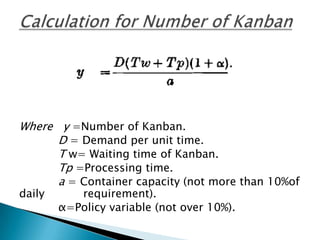

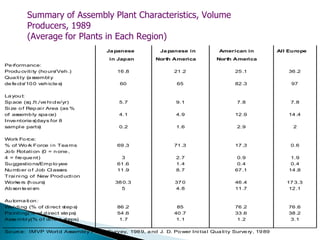

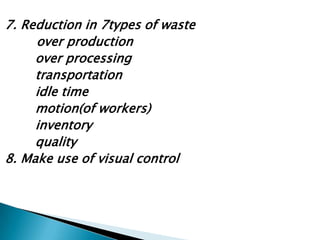

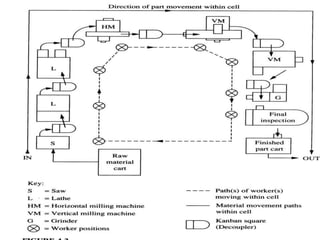

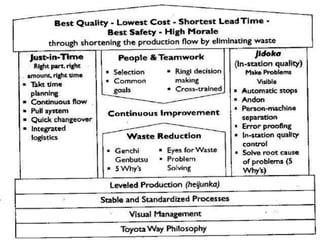

2. Toyota established the Toyota Production System (TPS) based on two concepts - reducing waste to lower costs, and making full use of workers' capabilities. This involved just-in-time production, jidoka, kanban systems, and other lean manufacturing principles.

3. TPS principles like jidoka aimed to stop production whenever a defect was detected, eliminate waste, and give workers more responsibility and autonomy. This improved quality, productivity and respect for humanity in the workplace.