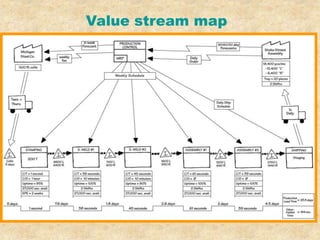

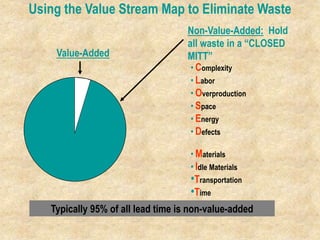

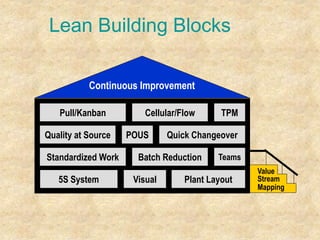

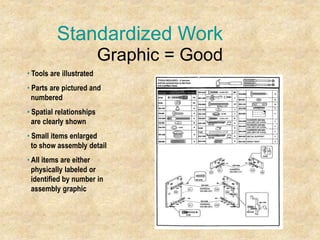

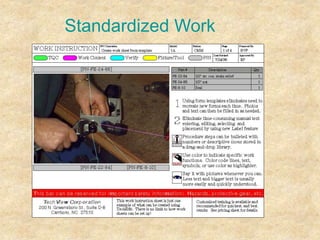

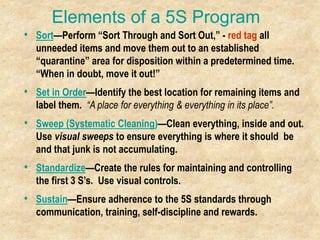

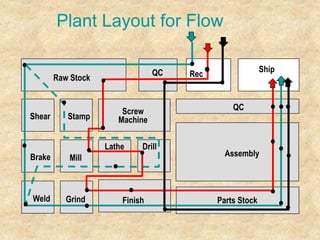

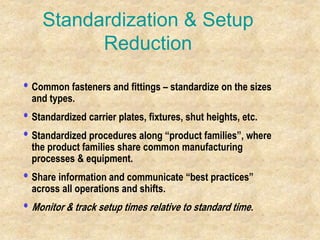

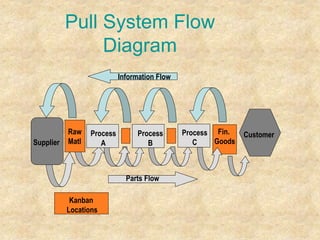

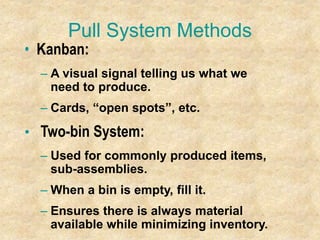

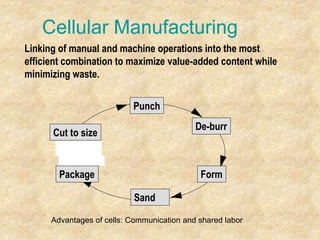

Lean manufacturing aims to maximize value and minimize waste in production. It was developed from Toyota's production system and focuses on eliminating non-value added activities. Key aspects of lean include identifying the value stream to reduce waste, using a pull system triggered by customer demand, cross-training employees to continuously improve processes, and implementing tools like 5S, standard work, and visual controls. The ultimate goal is to provide high quality, low cost products on time with minimal human effort, inventory, and space requirements.