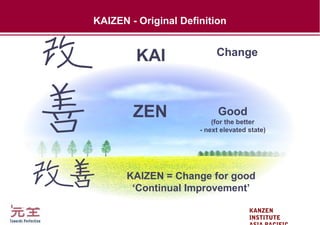

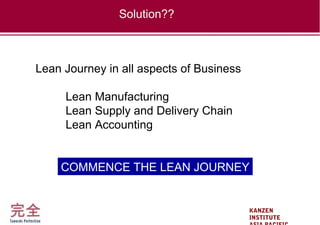

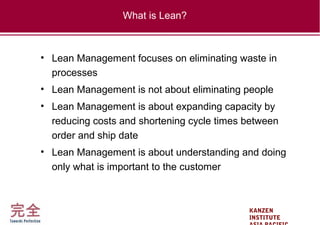

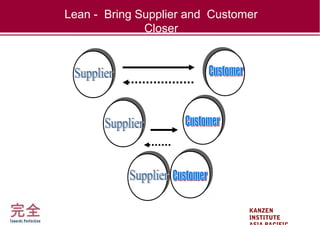

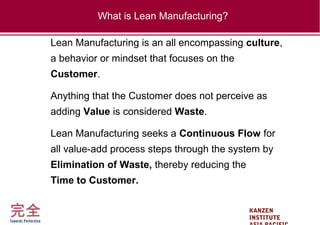

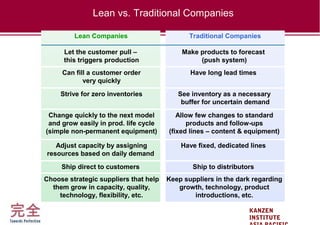

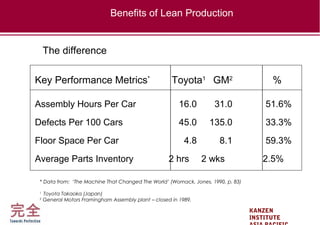

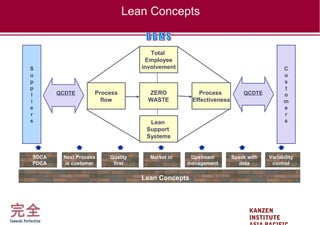

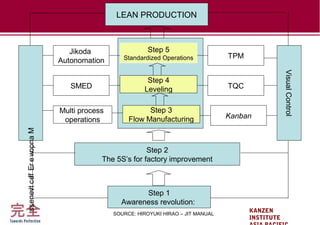

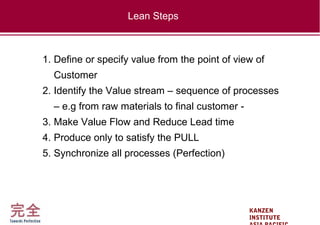

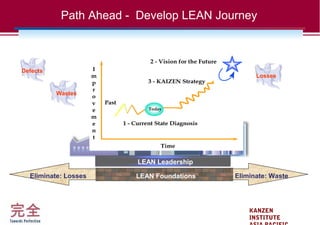

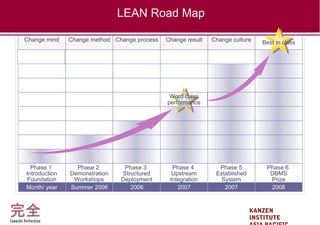

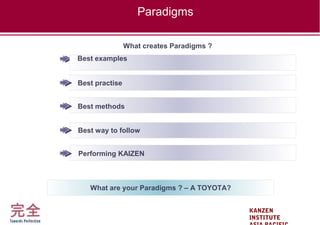

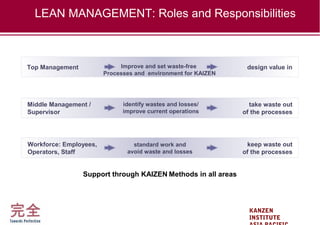

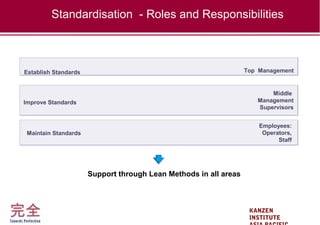

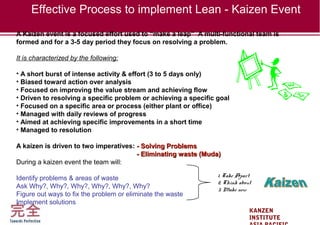

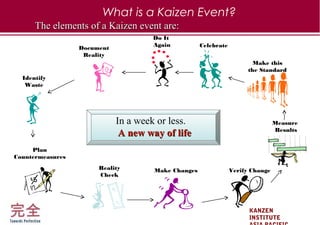

The document provides an overview of Lean manufacturing and the Toyota Production System. It discusses how Toyota implemented Lean principles beginning in the 1950s to become highly efficient and profitable. The core concepts of Lean include eliminating waste, reducing lead times, and continuous improvement. Lean aims to optimize flow and pull production using tools like just-in-time, standard work, and visual management. Kaizen events are used to rapidly improve processes by multidisciplinary teams identifying and eliminating sources of waste.