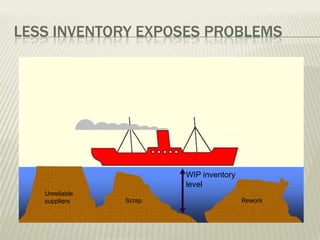

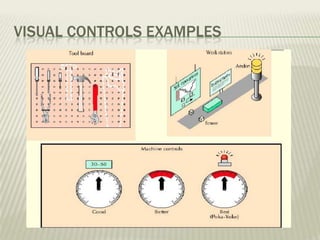

This document provides an introduction to Lean manufacturing concepts. It aims to help readers understand Lean, identify types of waste, and learn Lean tools and techniques. The core idea of Lean is maximizing customer value while minimizing waste. It defines seven types of waste including overproduction, waiting times, transportation, processing, inventory, motion, and defects. It also explains Lean tools and techniques for standardizing work, using visual controls, conducting quick changeovers, implementing total productive maintenance, and empowering self-inspection. The overall goal is to eliminate waste and continuously improve processes to provide value to customers.