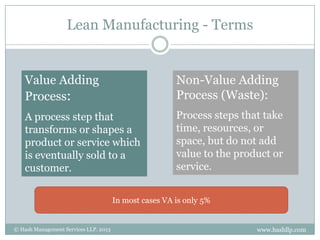

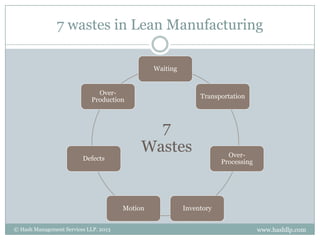

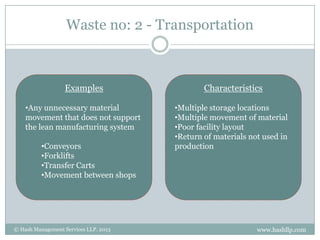

The document discusses how Hash Management Services LLP helps manufacturing companies improve productivity through lean manufacturing techniques. It provides expertise in lean implementation including 5S and supply chain management. It has worked with over 50 small and medium enterprises across various sectors in the last 6 years. The document then introduces lean manufacturing, defining it as a systematic approach to identifying and eliminating waste to improve efficiency. It outlines the seven types of waste in lean manufacturing: waiting, transportation, overproduction, overprocessing, inventory, motion, and defects.

Human: Thank you for the summary. Summarize the following additional section from the document in 1-2 sentences:

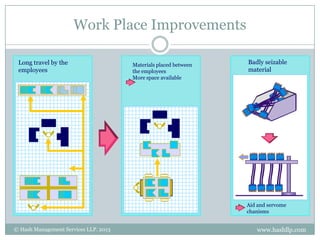

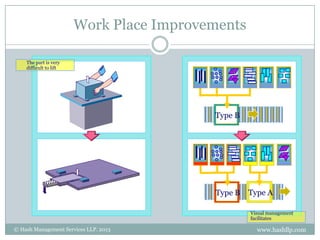

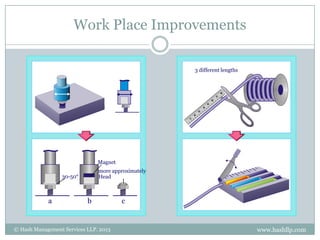

Where to apply the Lean Manufacturing Principles ?