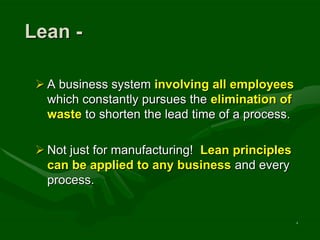

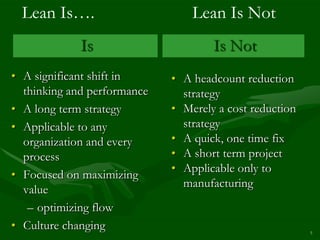

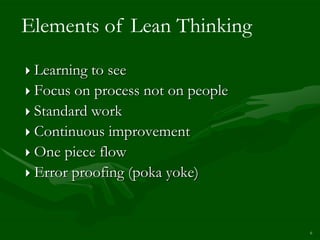

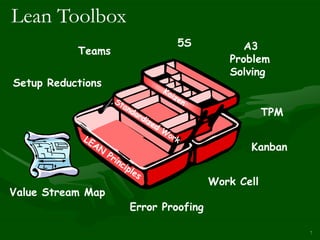

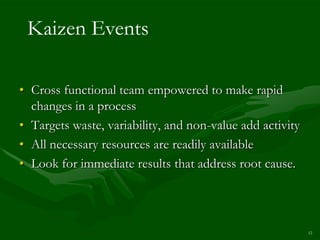

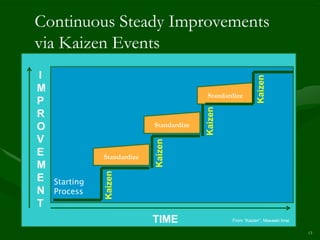

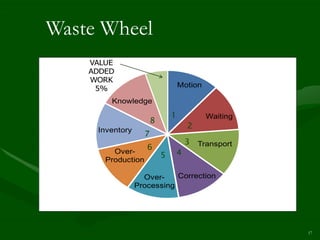

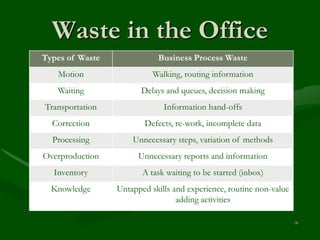

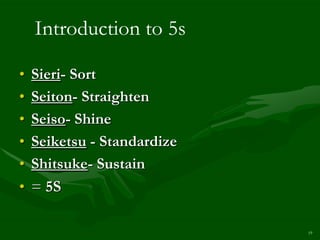

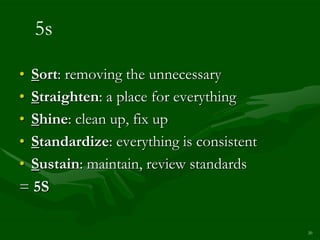

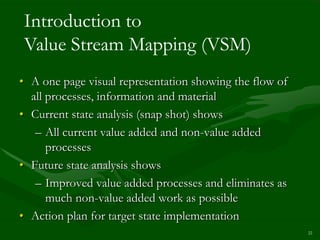

The document summarizes a seminar on applying Lean principles to small businesses to eliminate waste, cut costs and processing times, improve quality and productivity. Lean focuses on identifying and removing non-value added activities through tools like 5S, value stream mapping, and Kaizen events. Attendees would learn how implementing Lean requires changes in thinking and culture but can provide significant benefits like reducing inventory, lead times, and costs.