Embed presentation

Download as PDF, PPTX

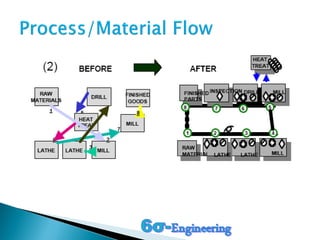

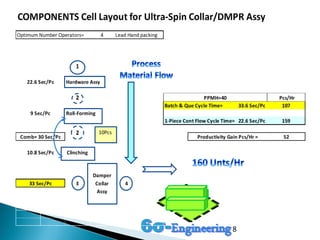

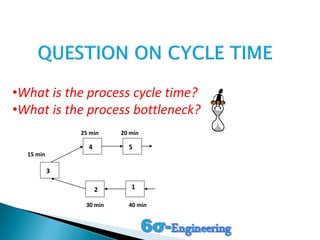

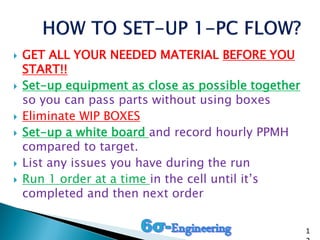

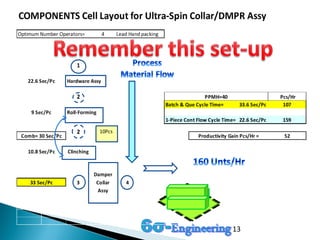

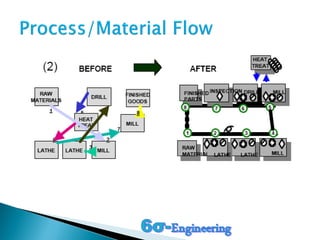

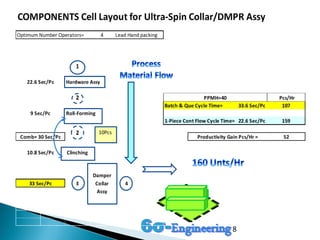

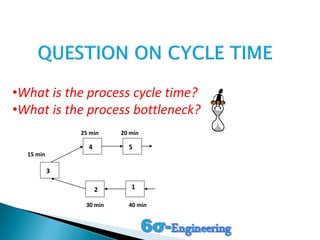

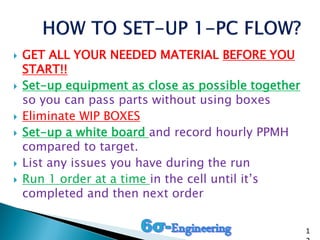

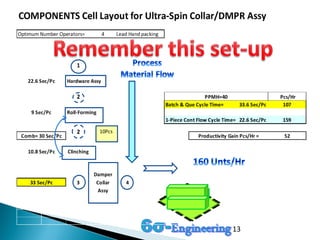

This document discusses lean production methods for 1-piece flow versus batch and queue production. It notes that a bottleneck will always exist in any process, and that bottlenecks can move. It recommends managing a buffer before the bottleneck and avoiding high work-in-process, which can mask the bottleneck. The document also discusses benefits of 1-piece flow such as workers being able to help each other and learn different tasks, and improving bottleneck operations.