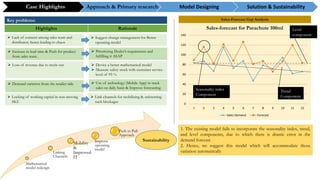

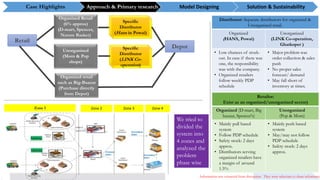

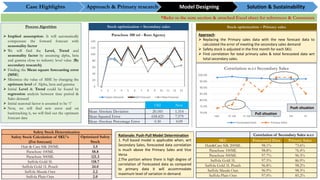

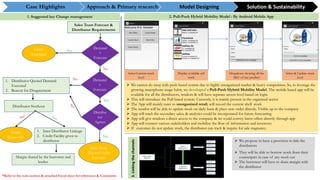

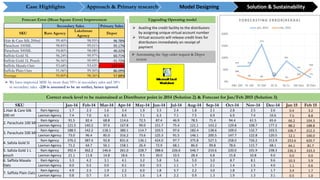

The document presents a detailed analysis and solution proposal for improving demand forecasting and inventory management for Marico's Parachute brand. It identifies key issues such as inaccurate sales forecasts due to a lack of seasonality and trend considerations, and introduces a pull-push hybrid mobility model utilizing a mobile app to enhance communication between distributors and retailers. Recommendations include mathematical model redesign, better stock management practices, and leveraging technology to improve forecasting accuracy and operational efficiency.