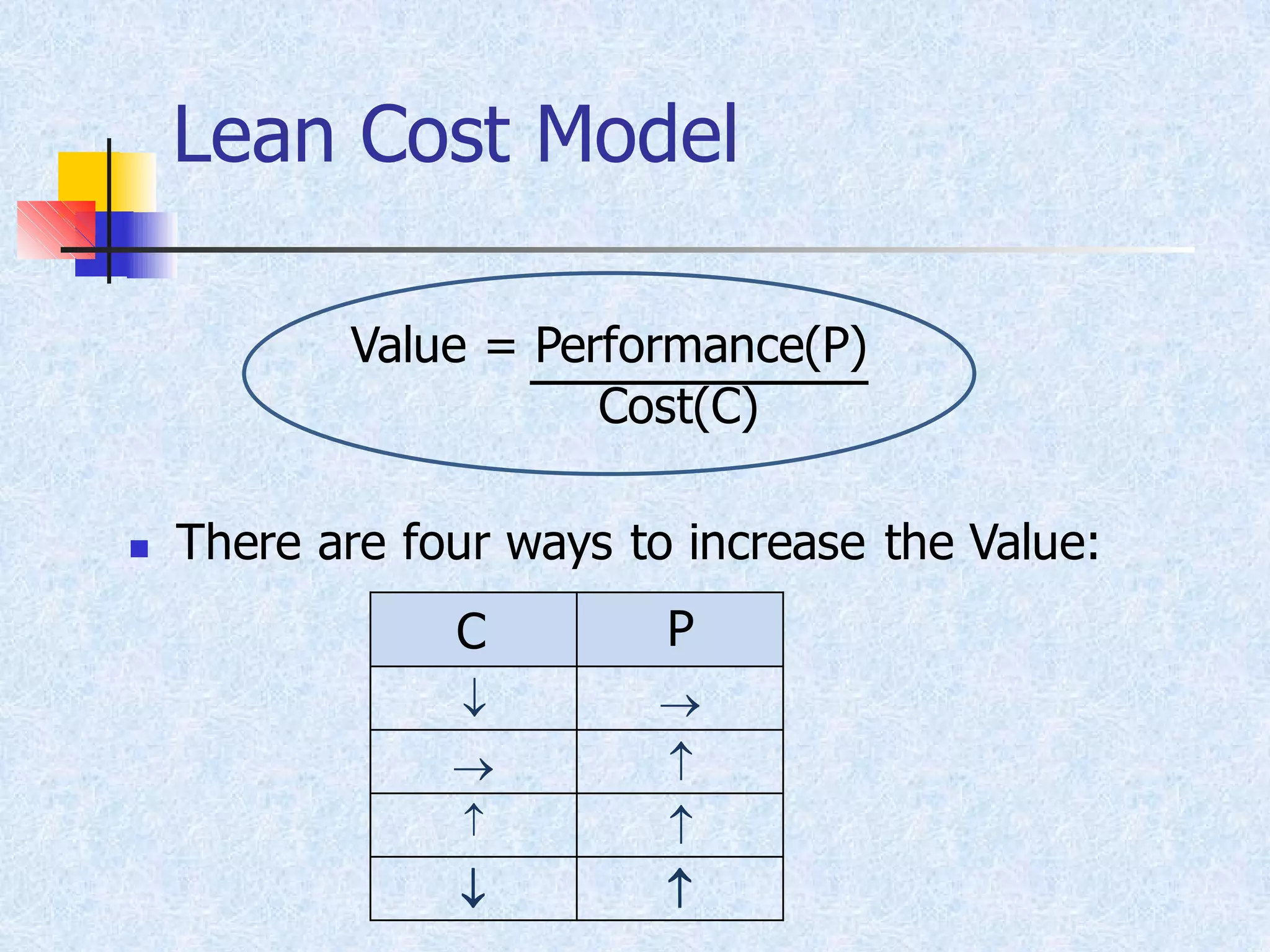

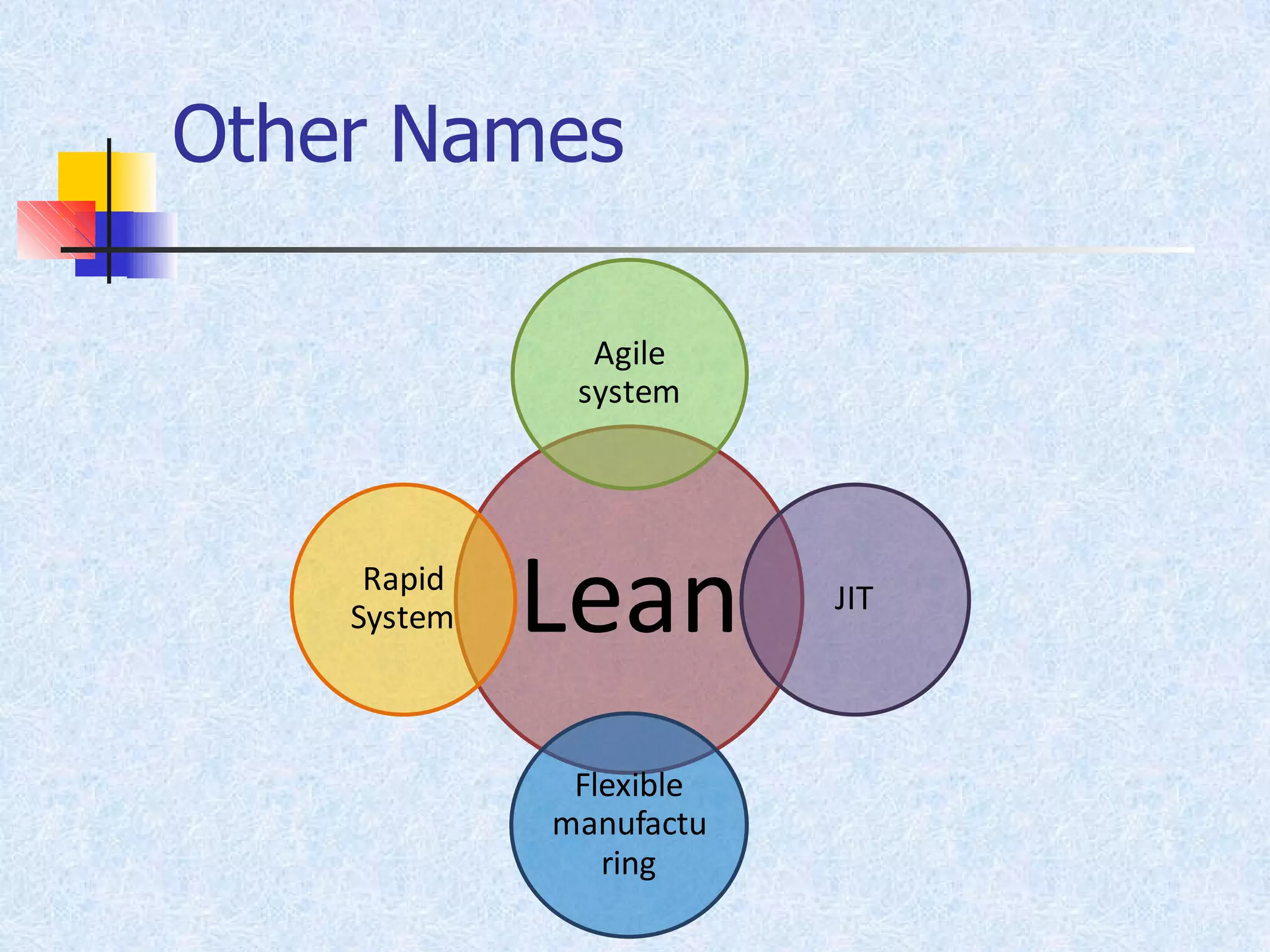

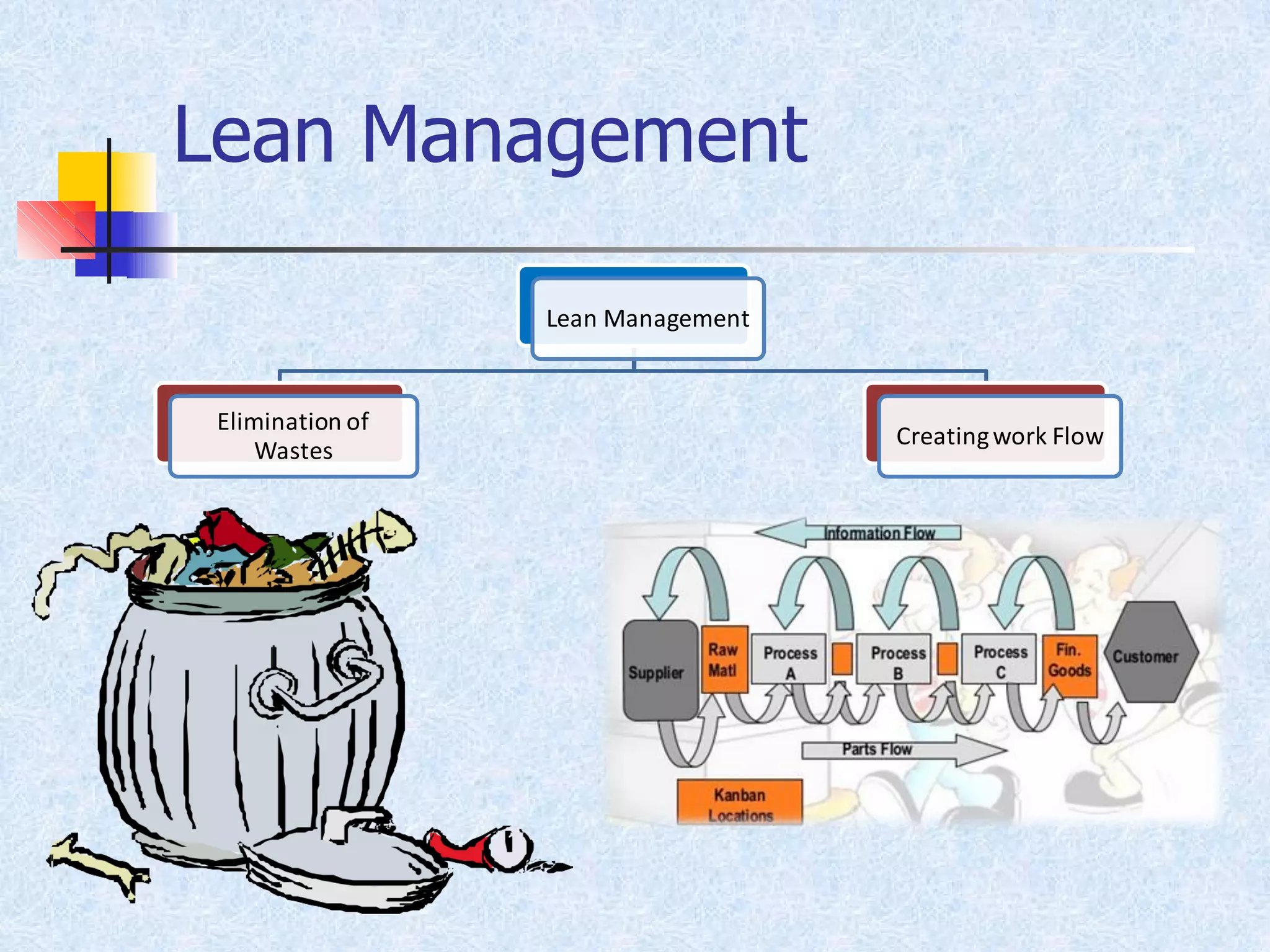

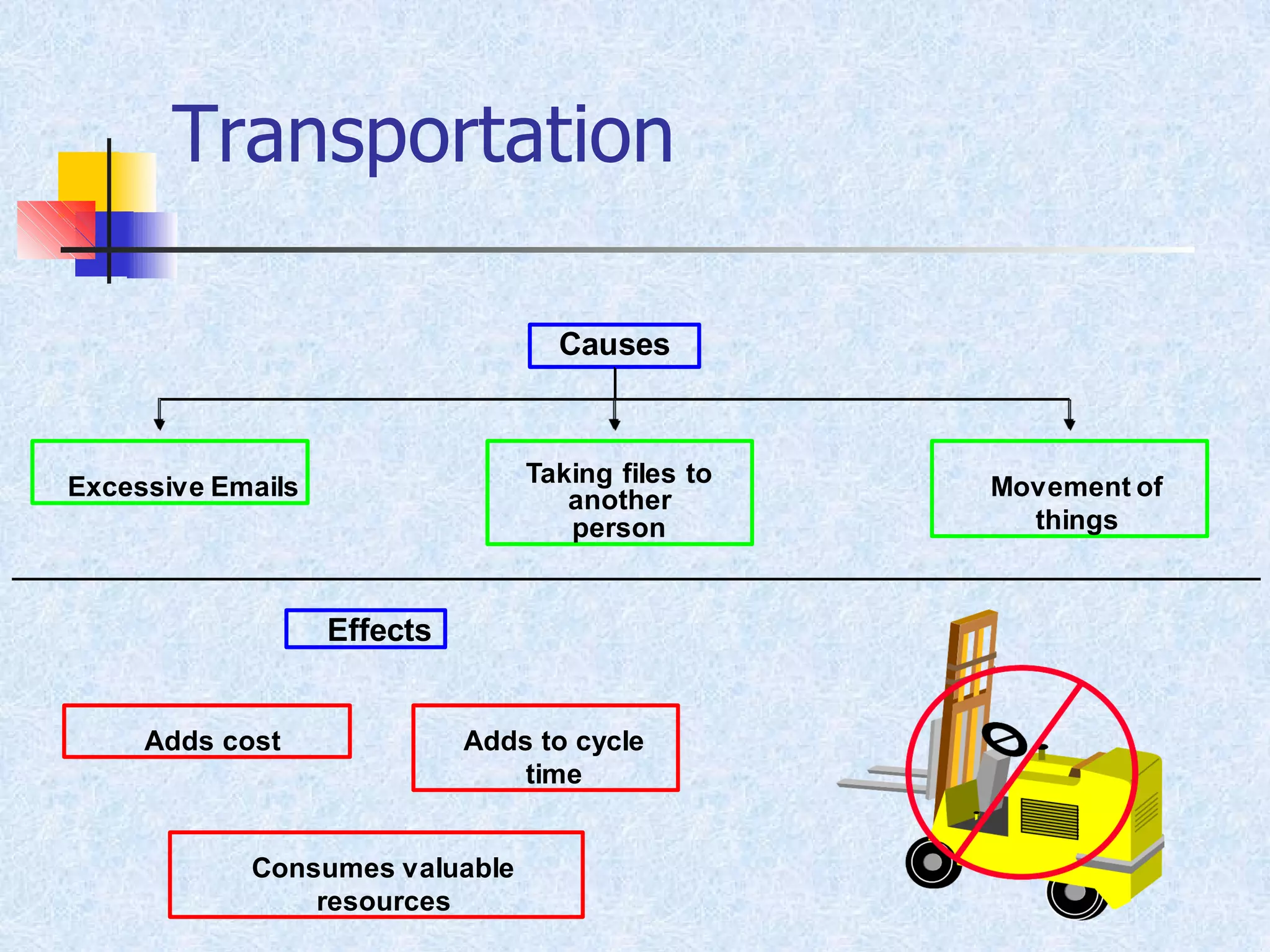

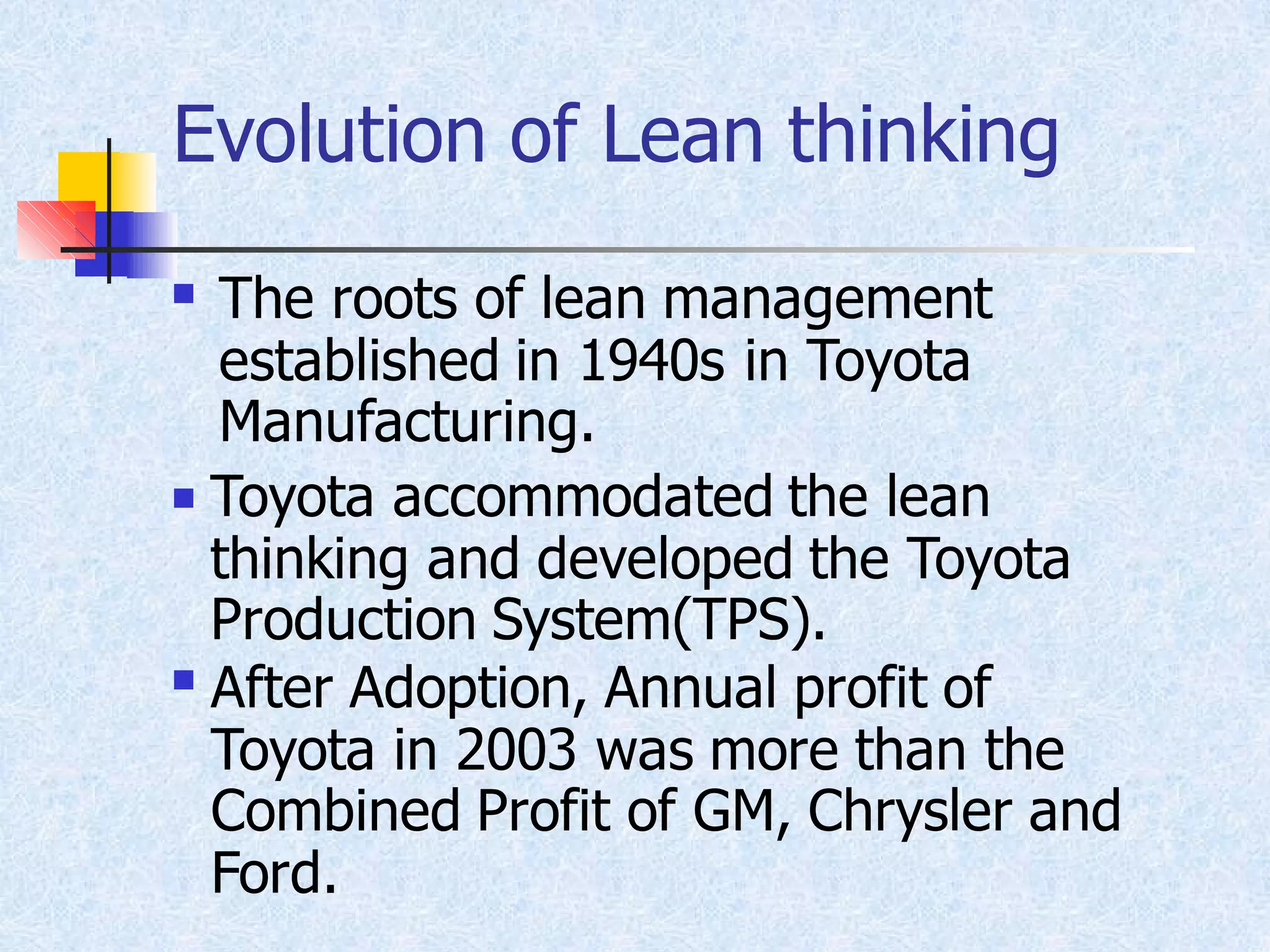

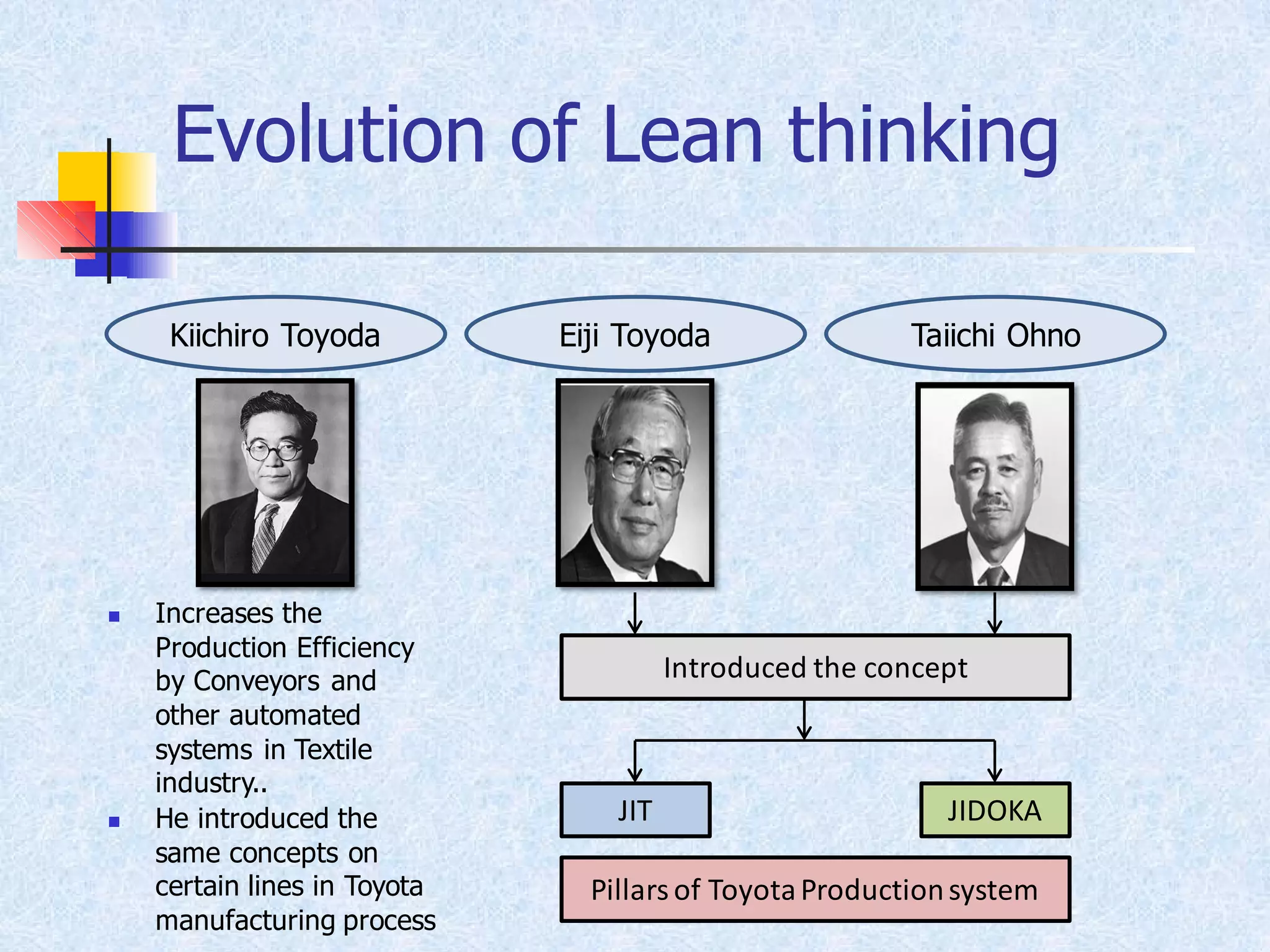

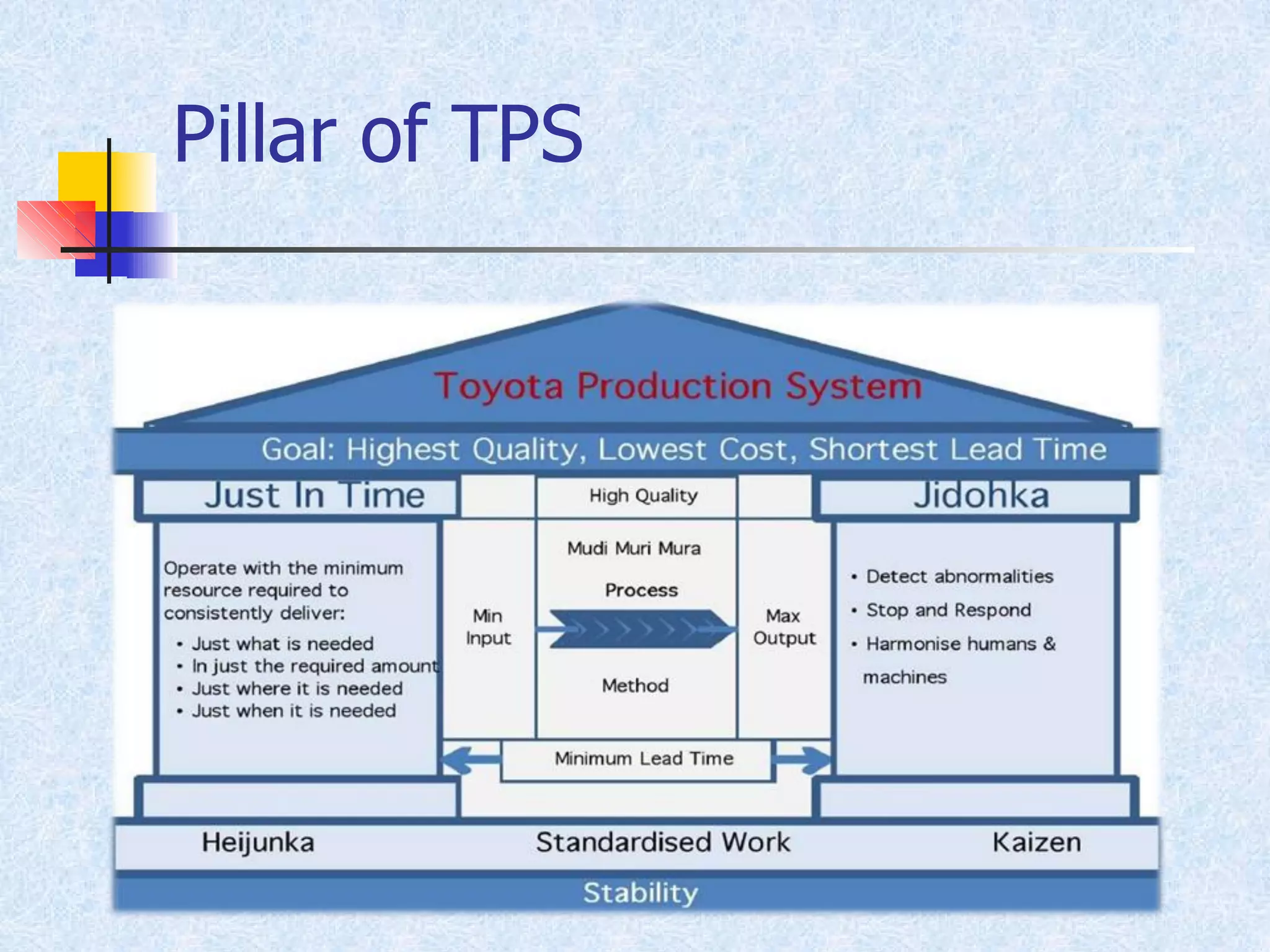

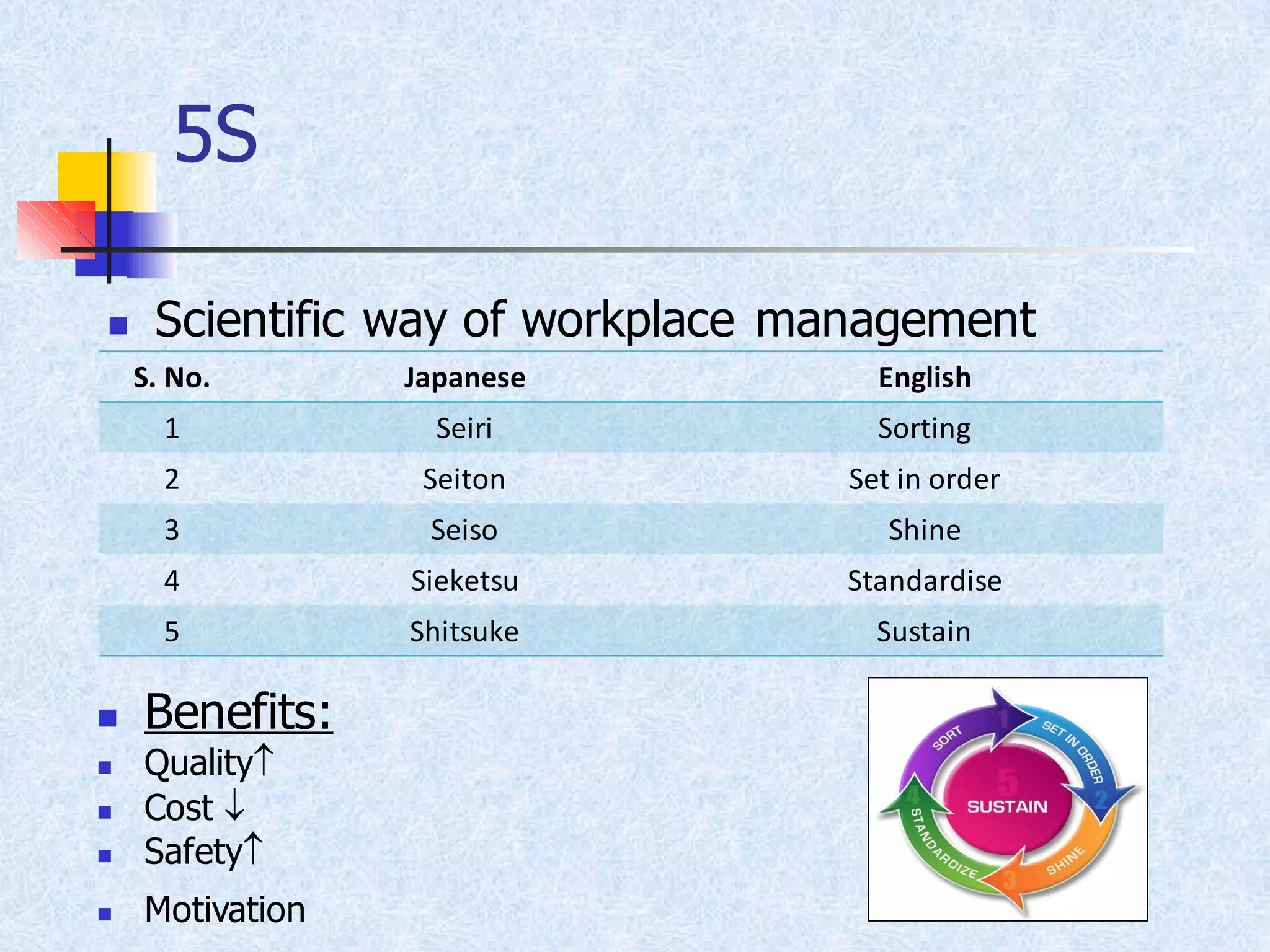

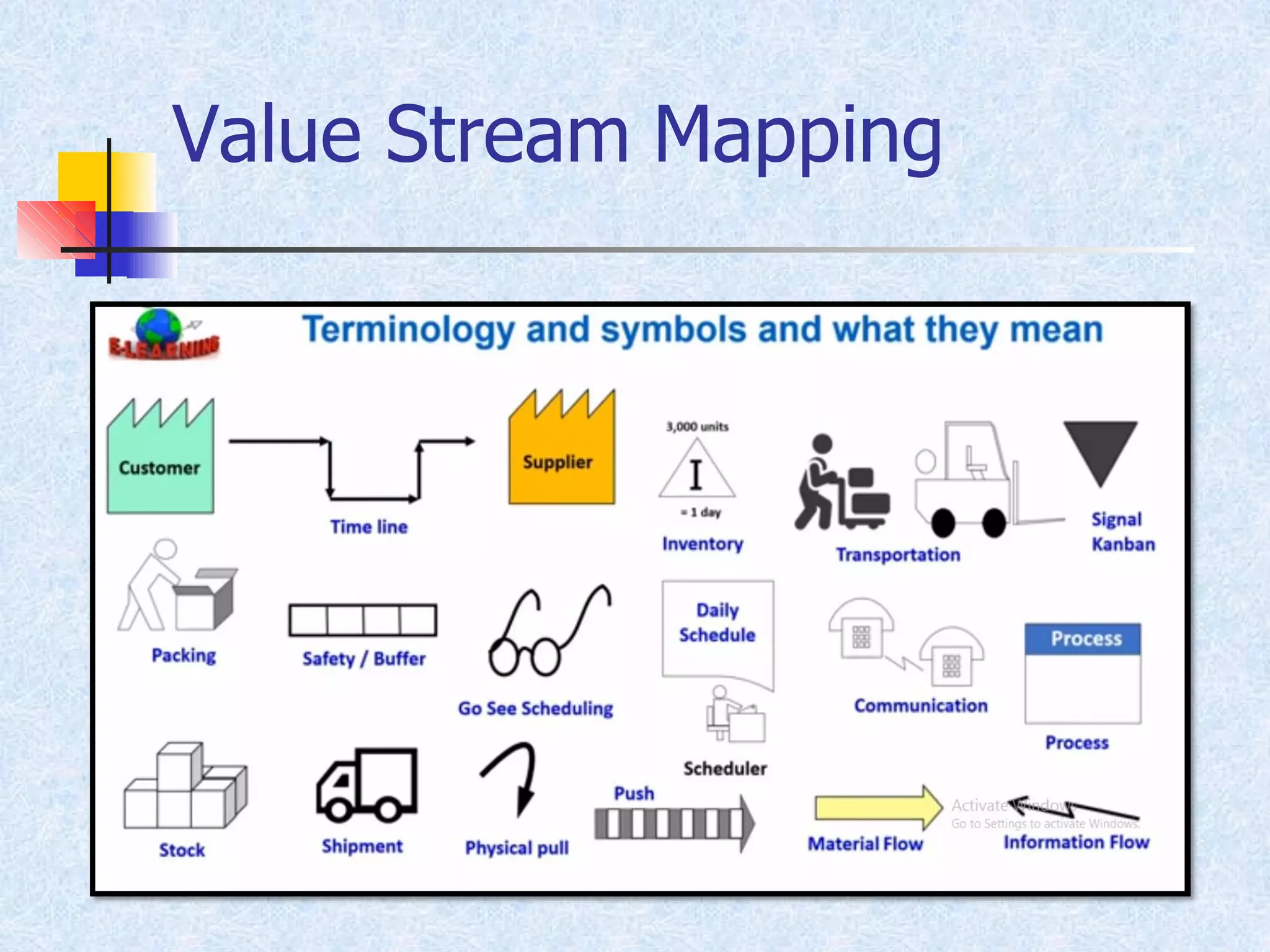

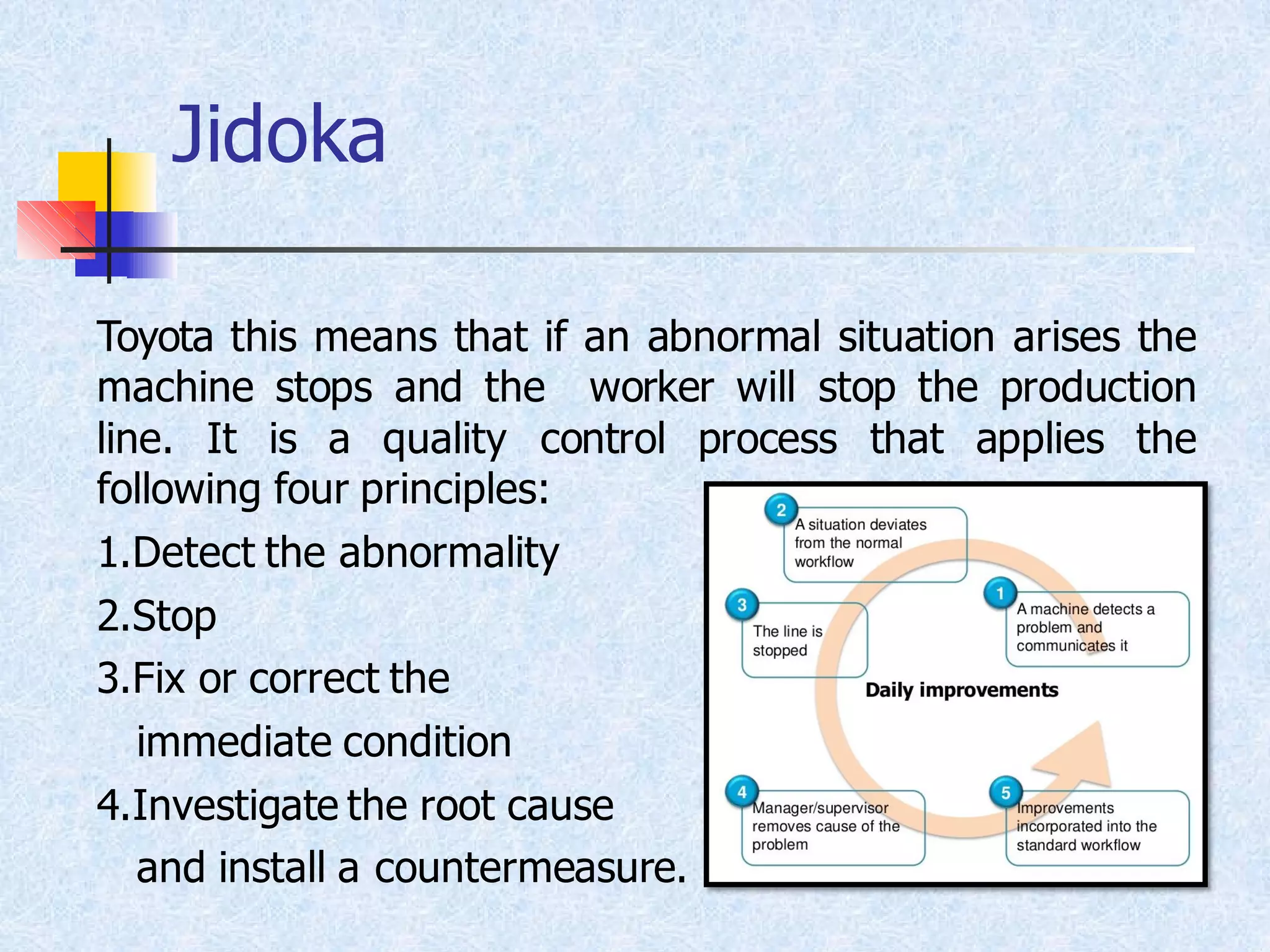

This document provides an overview of lean manufacturing principles and tools. It defines lean as eliminating waste ("muda") and focusing on value-added activities. The key components of lean thinking are specified as perfection, value, value streams, flow, and pull. Toyota Production System pillars of just-in-time ("JIT") and autonomation ("jidoka") are discussed. Common lean tools like 5S, kaizen, value stream mapping, standard work, SMED, and poka-yoke are summarized along with their benefits. The evolution of lean thinking from Henry Ford to Toyota is also outlined.