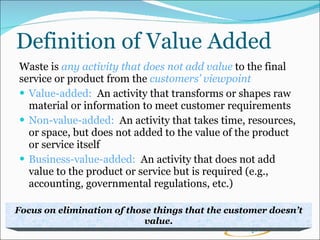

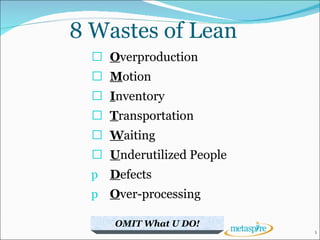

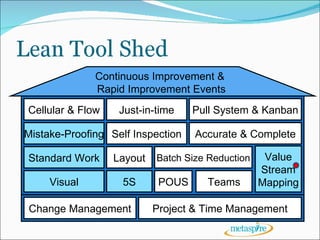

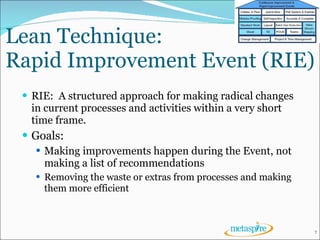

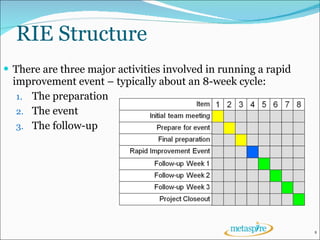

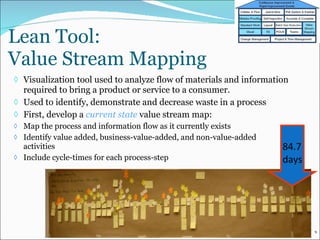

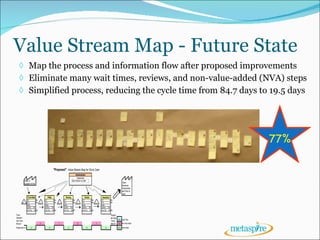

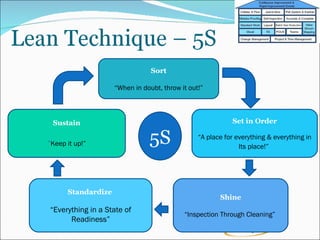

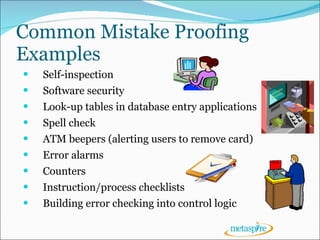

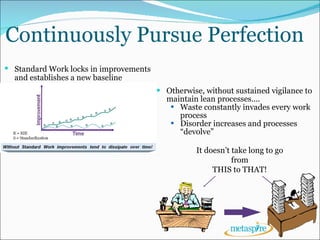

Lean is a systematic approach to eliminating waste through continuous improvement. It aims to provide customers what they want, when they want it, without wasting resources. The document outlines key Lean concepts like the eight wastes, tools like 5S and visual controls, and processes like rapid improvement events and value stream mapping that analyze and improve workflow. Implementing Lean can increase process speed, reduce costs, improve delivery, and simplify operations through waste elimination.