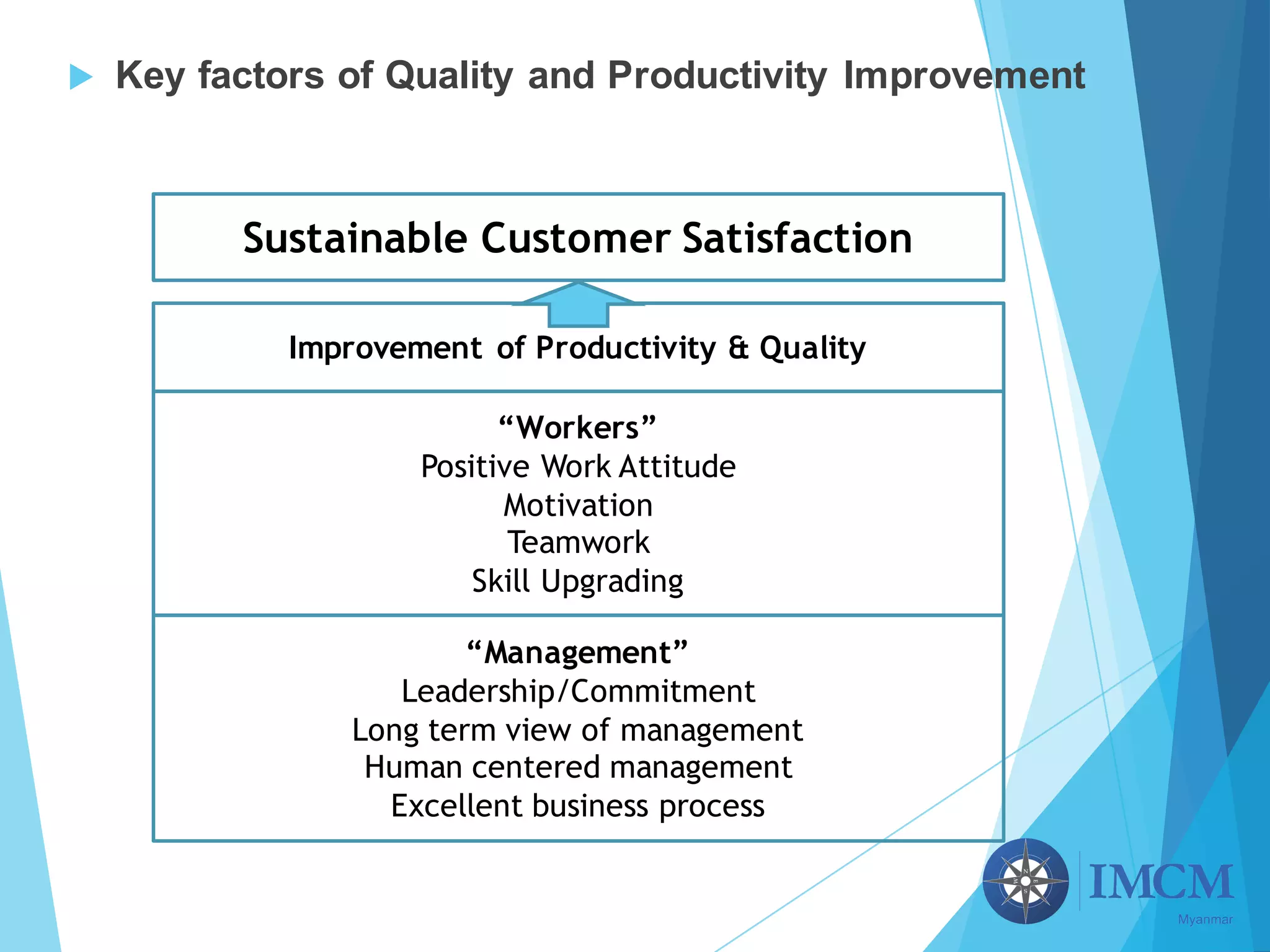

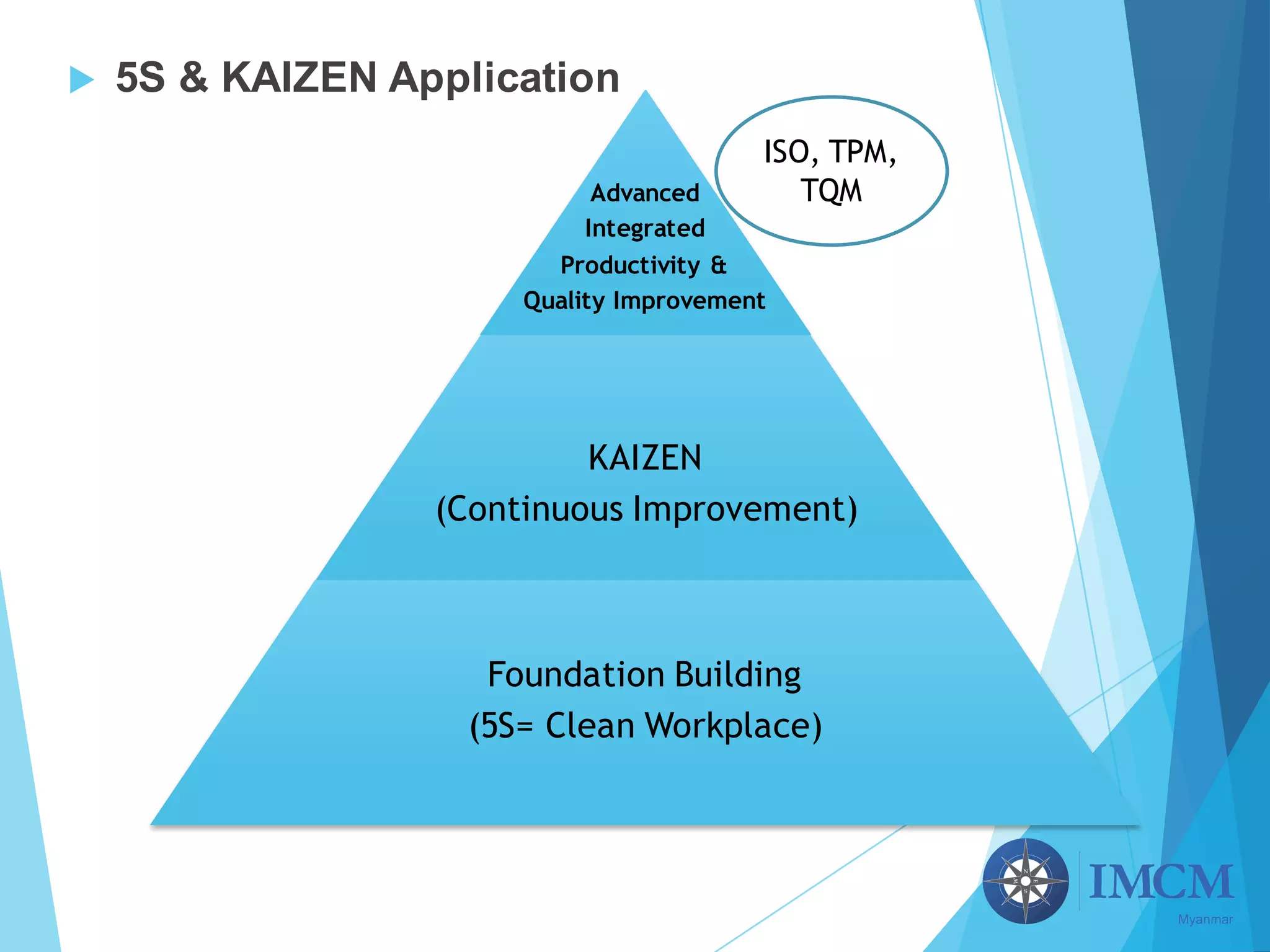

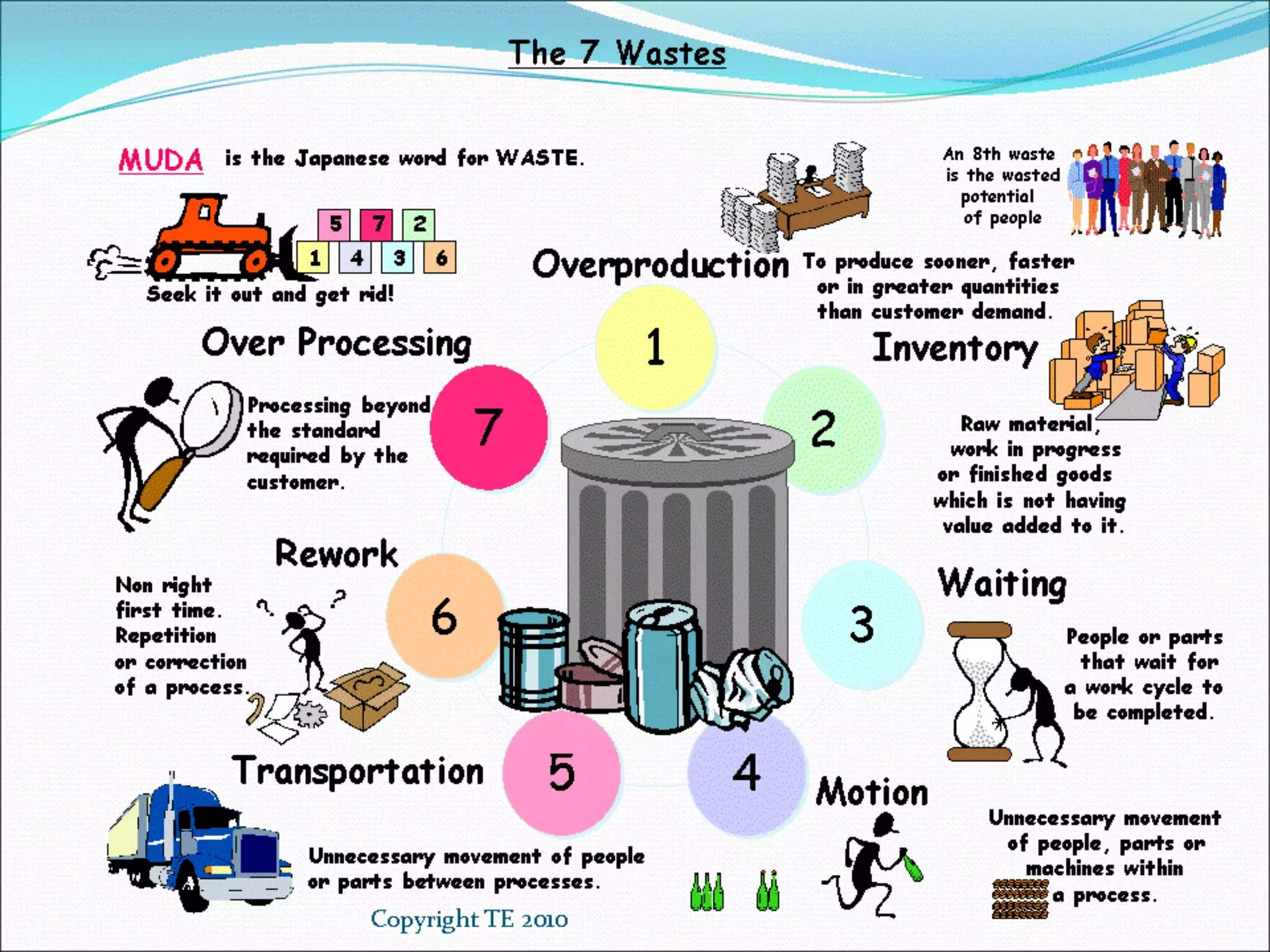

This document provides an overview of continuous improvement strategies like Kaizen, 5S, and the Toyota Production System (TPS). It discusses key aspects of each including:

- The 5 pillars of TPS: JIT, Jidoka, Kaizen, Heijunka, and respect for people.

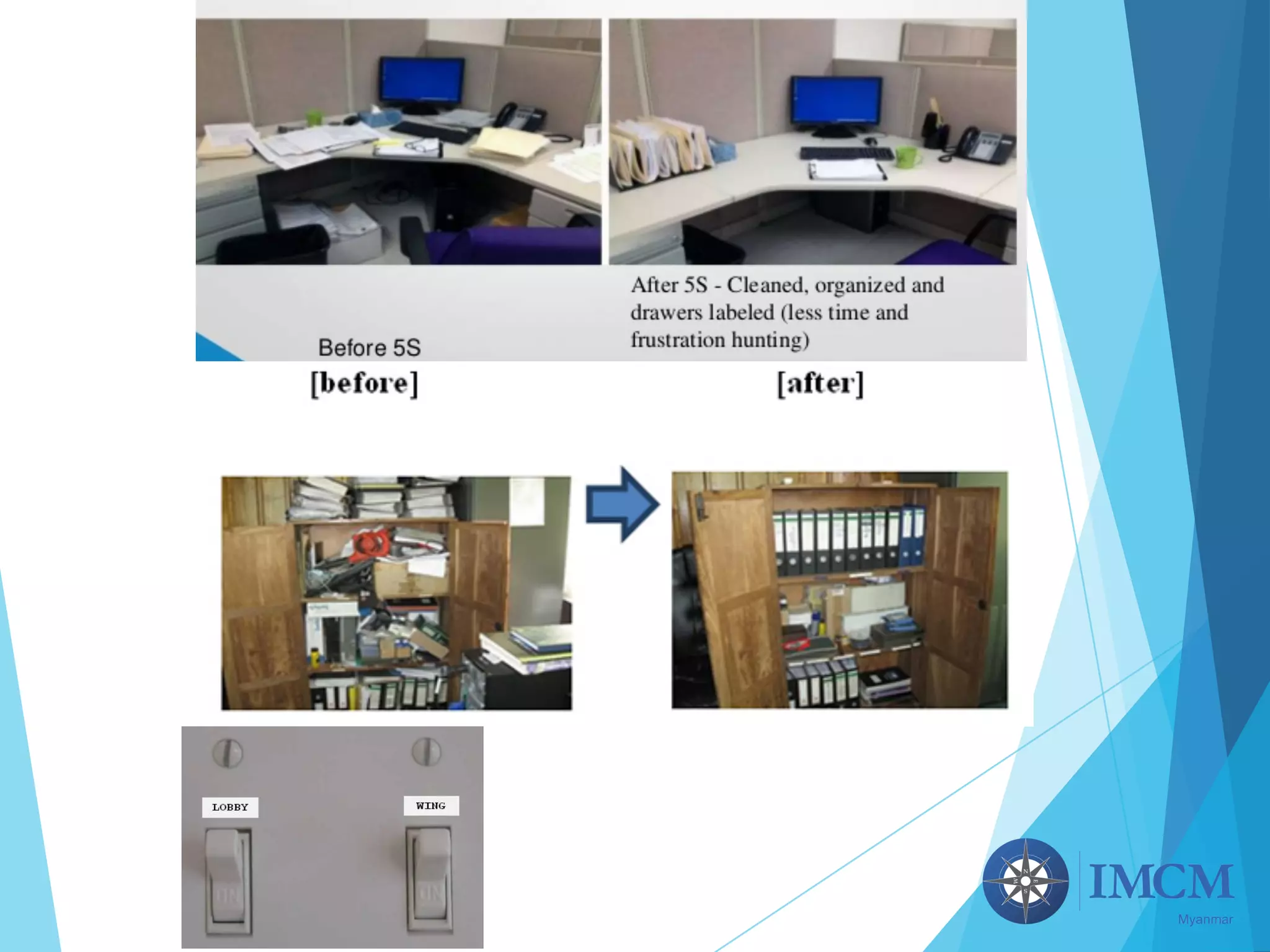

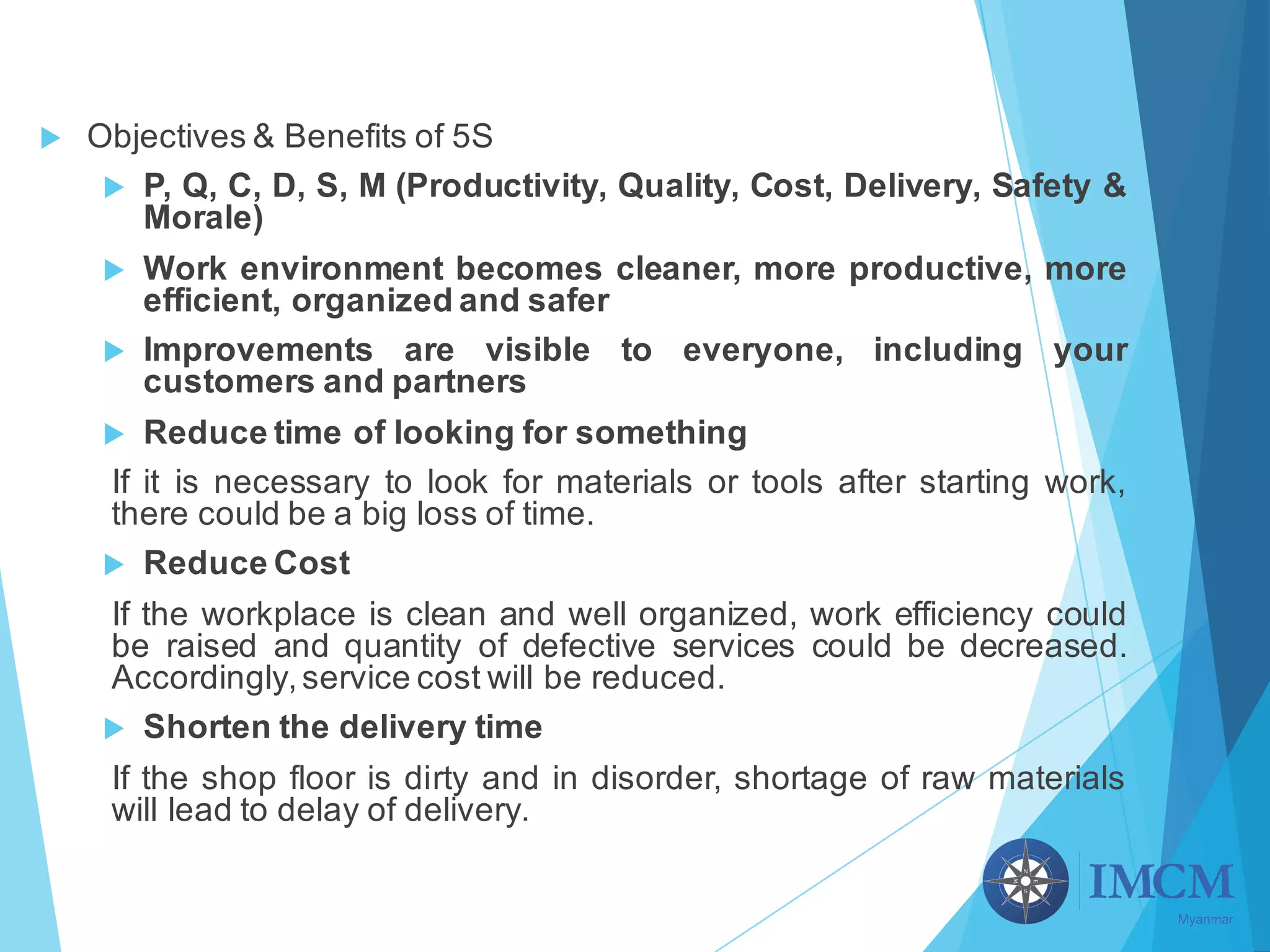

- Components and benefits of 5S including sort, set in order, shine, standardize, and sustain. 5S aims to create a clean and organized workplace.

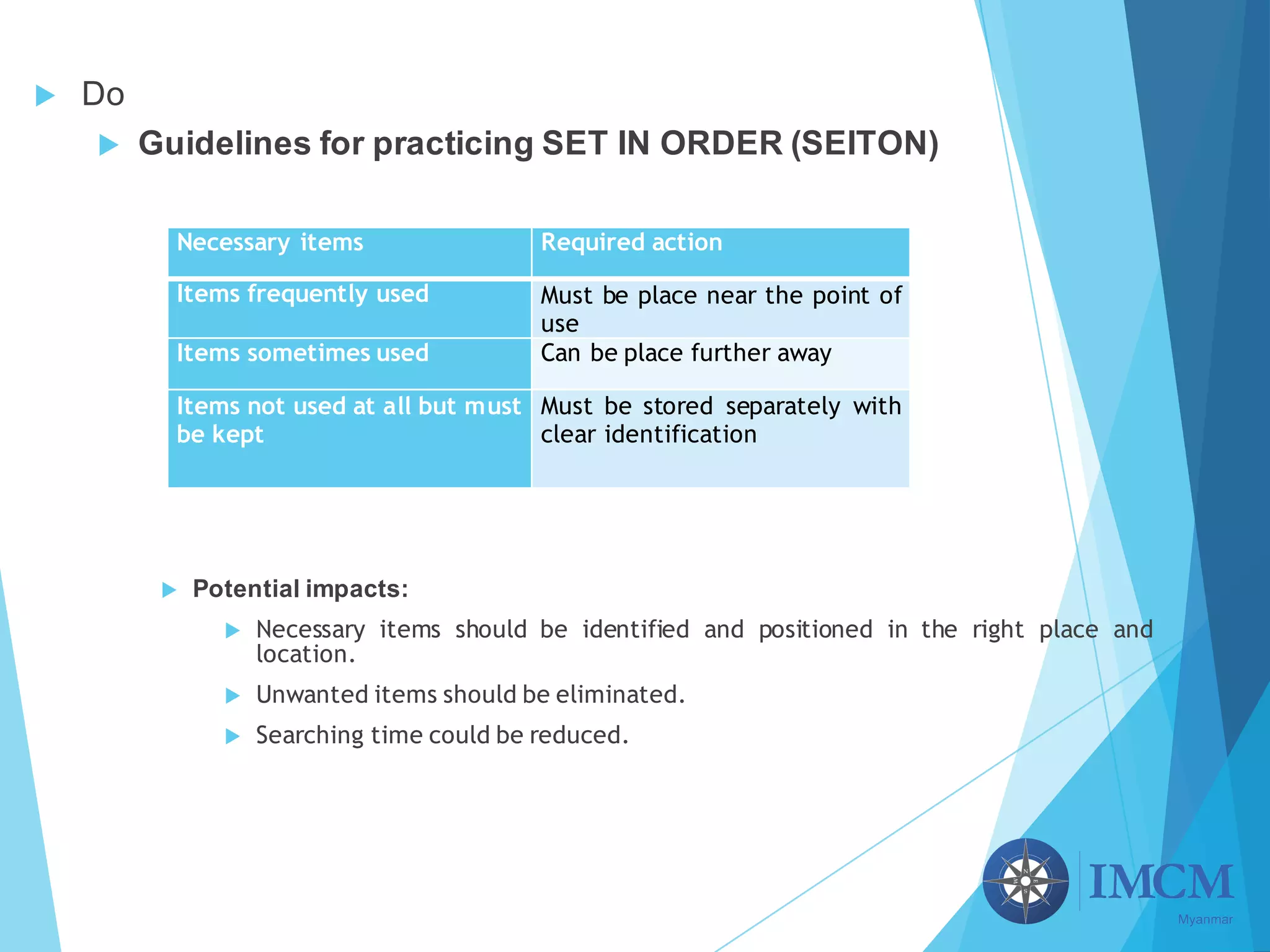

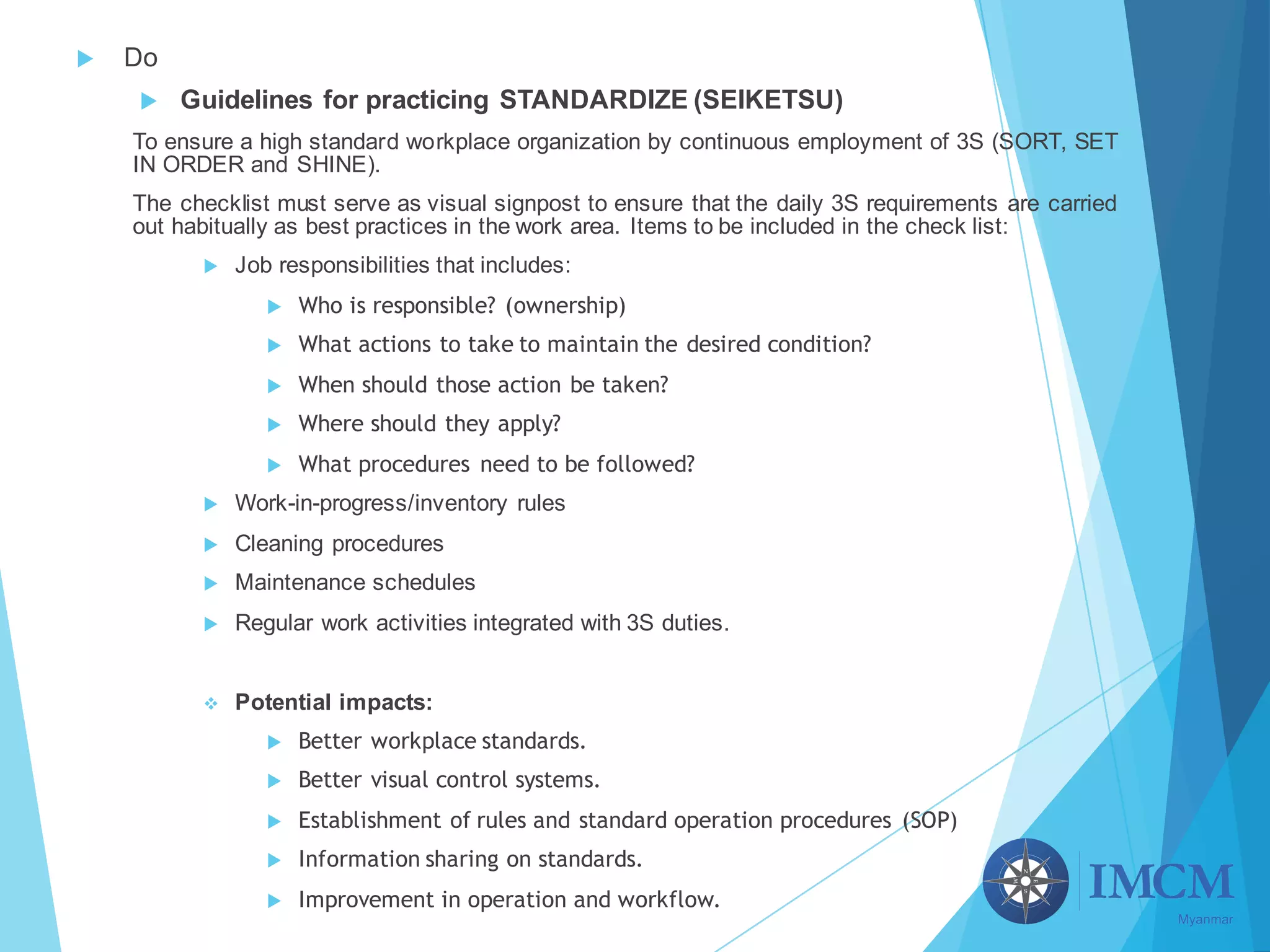

- Guidelines for implementing the different elements of 5S like sorting unnecessary items, clearly labeling storage areas, and establishing cleaning procedures and responsibilities.

- Using a PDCA approach for continuous 5S implementation including planning, doing, checking