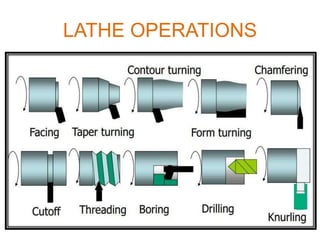

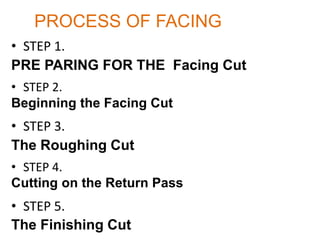

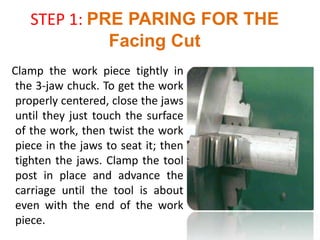

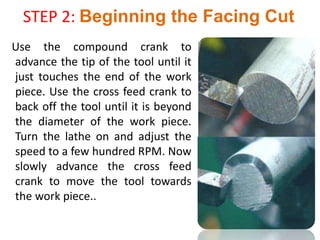

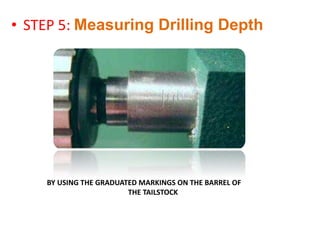

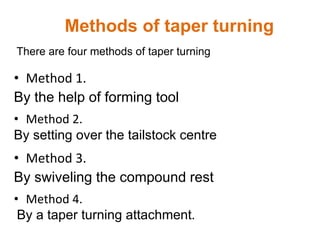

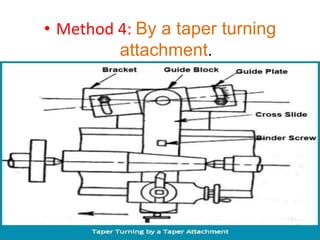

The document discusses various lathe operations including facing, turning, drilling, and taper turning. It provides step-by-step explanations of the processes with diagrams. Facing involves removing metal from the end of a workpiece to create a flat surface. Turning reduces the diameter of a rotating cylindrical workpiece. Drilling uses the lathe to drill holes before other internal operations. Taper turning creates a conical shape through various methods such as using a forming tool, setting over the tailstock, swiveling the compound rest, or a taper turning attachment.