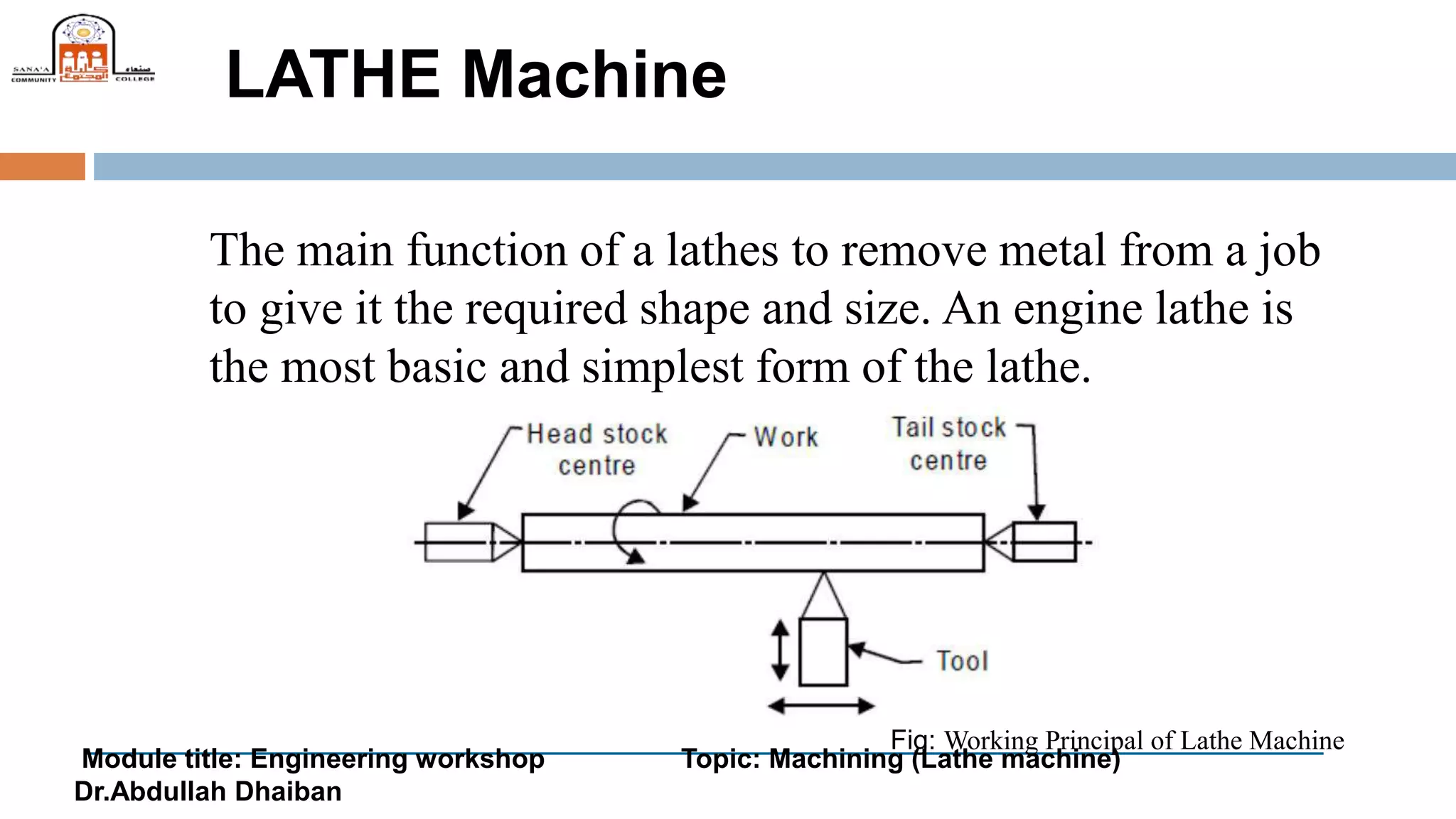

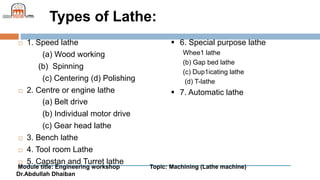

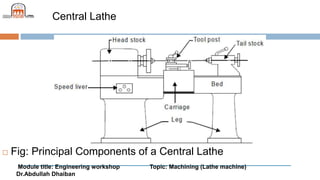

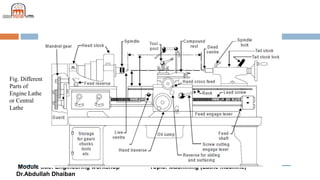

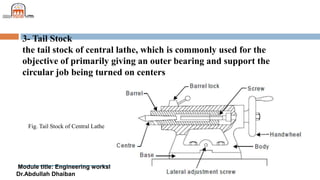

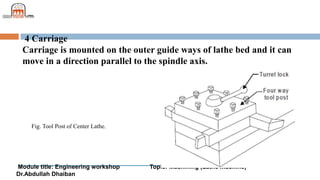

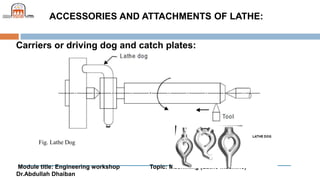

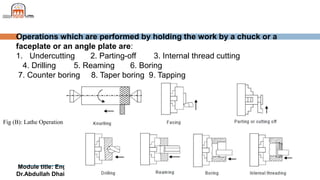

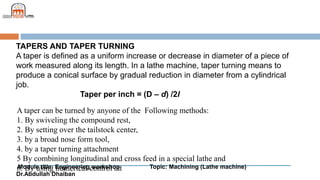

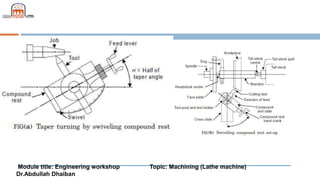

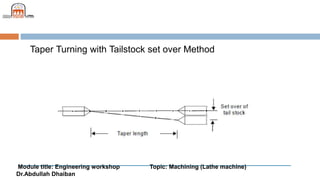

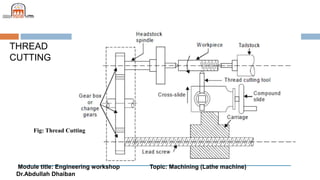

The document discusses the lathe machine, its main components and functions. It describes different types of lathes including speed lathes, center lathes, bench lathes, and special purpose lathes. It outlines the basic parts of a center lathe like the bed, headstock, tailstock, carriage and feed mechanism. The document also discusses lathe accessories, operations performed on lathes, taper turning methods and thread cutting.