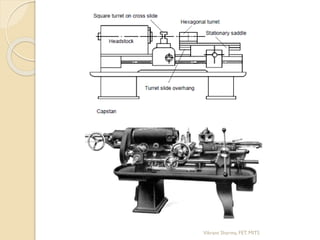

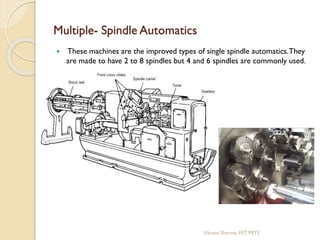

The document discusses different types of modified lathes, including capstan, turret, and automatic lathes. Capstan and turret lathes improve on center lathes by including an indexable turret holding multiple tools to allow for faster job set-up and overlapping of operations. Automatic lathes further automate the process by automatically controlling tool movement and sequencing. Single spindle automatics operate on one component at a time using either Swiss or turret screw machine designs, while multi-spindle automatics improve productivity further by processing multiple components simultaneously in parallel or progressively.