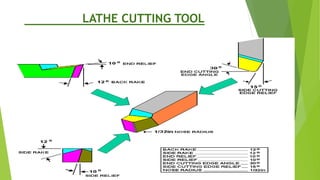

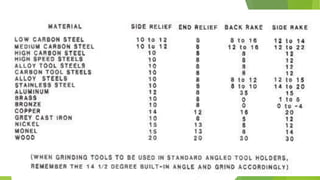

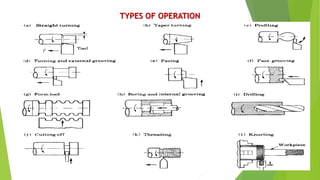

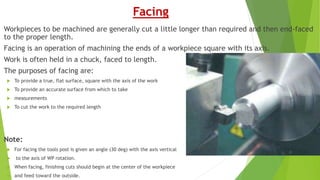

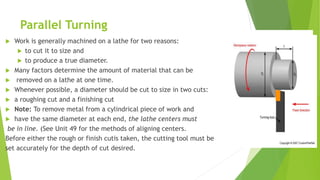

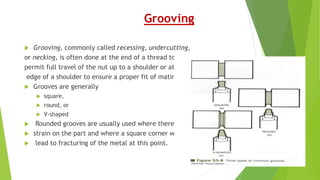

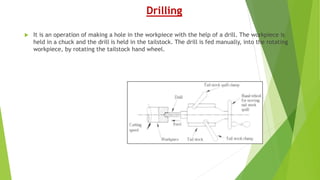

The document provides an overview of various lathe operations including facing, turning, knurling, grooving, and drilling. It describes the purpose and process for each operation. Facing involves machining the ends of a workpiece square to its axis to provide a true, flat surface. Turning cuts a workpiece to the proper diameter and involves roughing and finishing cuts. Knurling imprints a pattern to improve grip or increase diameter for press fits. Grooving cuts recesses or shoulders. Drilling makes holes in the workpiece using a drill held in the tailstock.