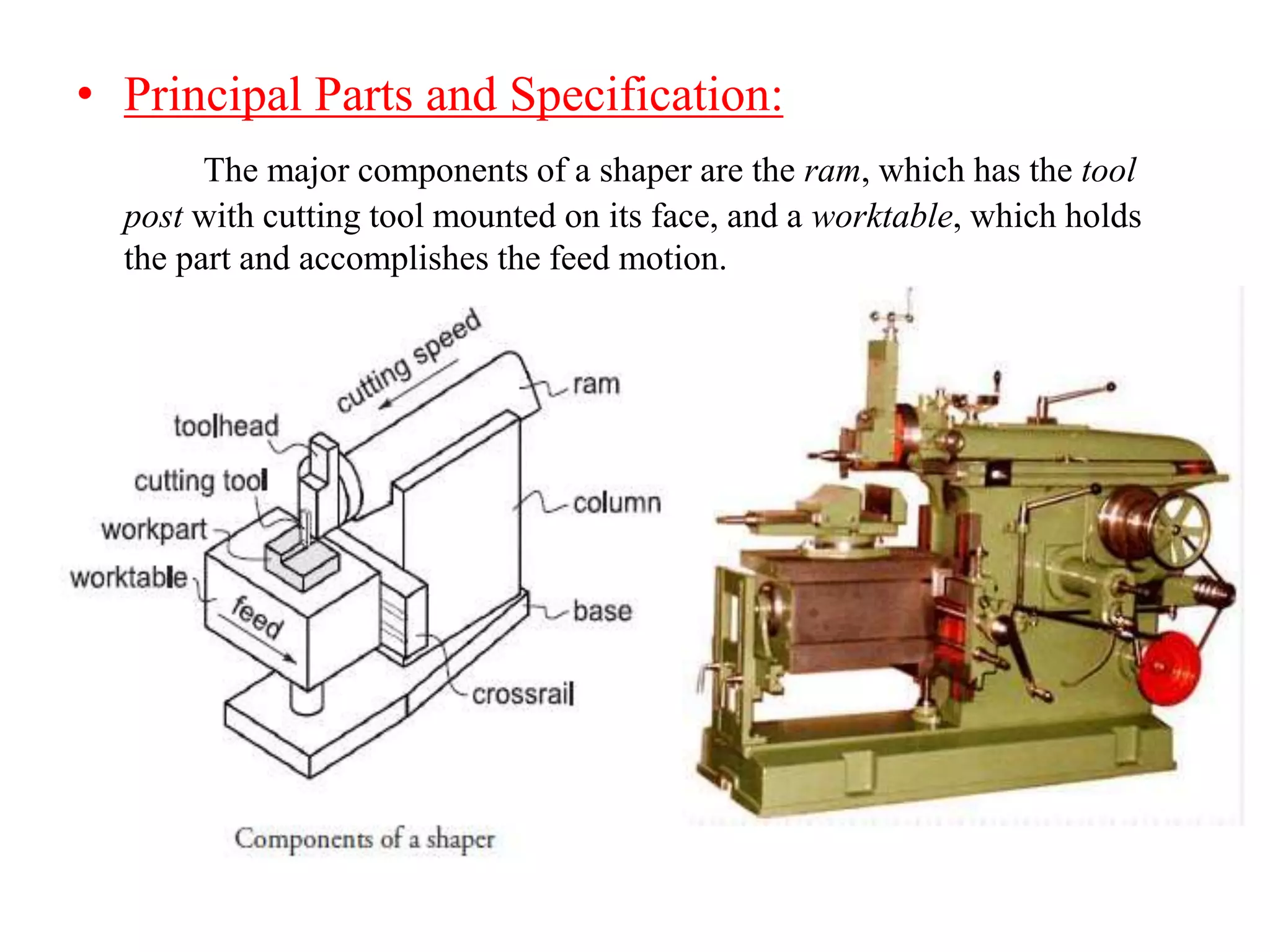

The document provides an overview of shaping, planning, and slotting machines, detailing their working principles and classifications. Shapers perform cutting using a reciprocating tool, with various types classified by mechanism, ram position, table design, and cutting stroke. Planning machines generate large flat surfaces and can handle heavier jobs, while slotting machines are primarily designed for internal surfaces.