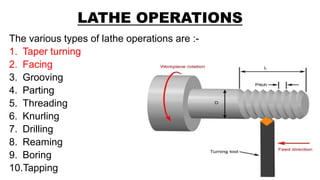

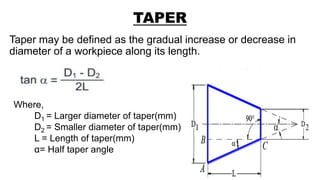

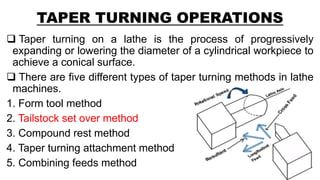

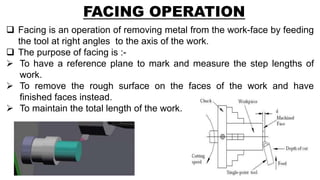

This document discusses taper turning and facing operations on a lathe machine. It defines taper as a gradual change in diameter along the length of a workpiece. There are different methods for turning tapers, including using a form tool, tailstock set over, compound rest, or taper turning attachment. The tailstock set over method involves shifting the tailstock axis at an angle to the lathe axis. Facing involves removing metal from a workpiece face using a tool fed at a right angle to the work axis, to create a flat reference surface. Taper turning and facing are important lathe operations for creating conical shapes and flat surfaces.