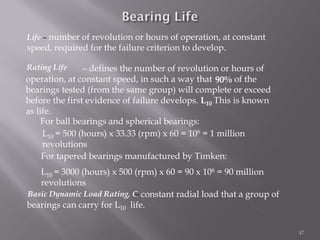

A bearing is a device that supports load and reduces friction between moving parts. There are two main types: plain/slider bearings and rolling/anti-friction bearings. Rolling bearings use balls or rollers to create separation between surfaces and are more commonly used. Common bearing materials include metals, alloys, and some non-metals. Bearings must be properly selected, mounted, lubricated, and maintained to maximize their lifespan and prevent premature failure.