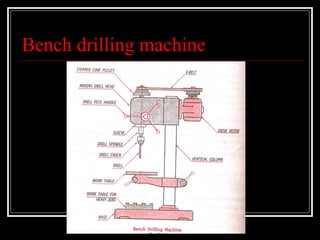

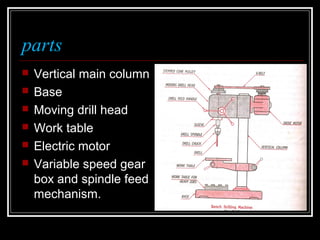

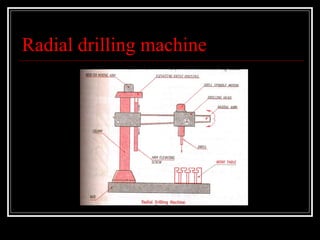

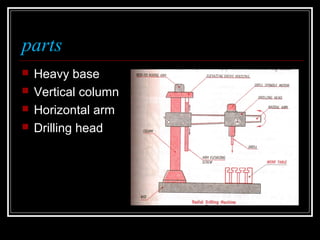

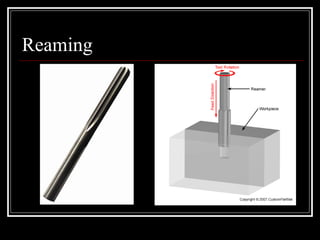

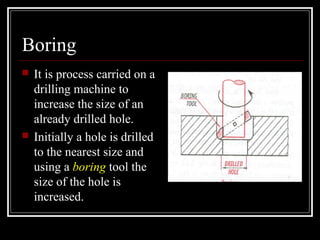

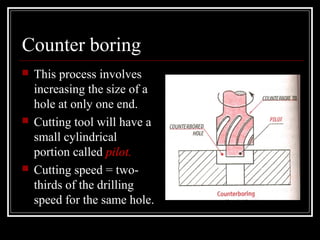

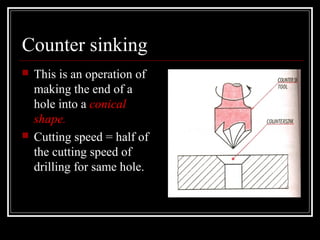

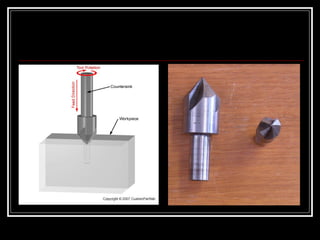

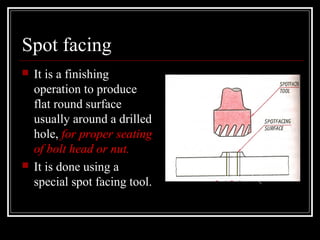

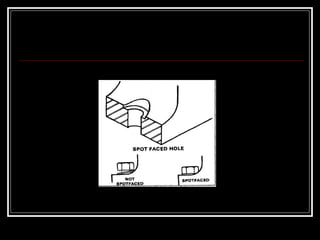

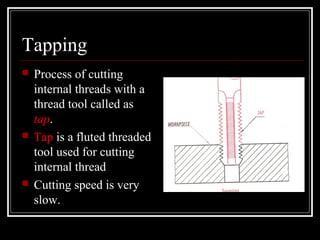

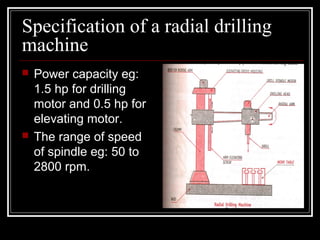

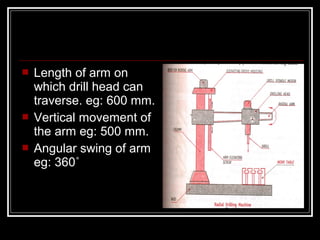

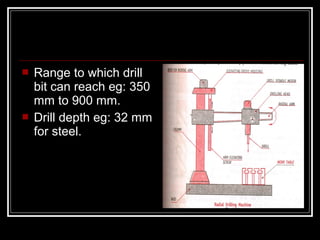

This document discusses different types of drilling machines and their functions. It describes bench drilling machines, which are light duty machines used in small workshops to drill holes from 1 to 15 mm in diameter. Radial drilling machines are heavy duty machines used to drill larger holes, up to 7.5 cm, in heavy workpieces. The document outlines the parts and working of bench drilling machines and radial drilling machines. It also covers drilling machine operations like reaming, boring, counterboring, countersinking, spot facing and tapping.