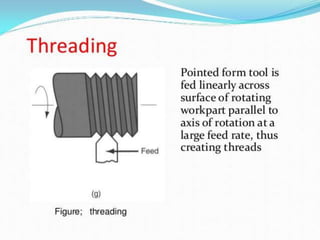

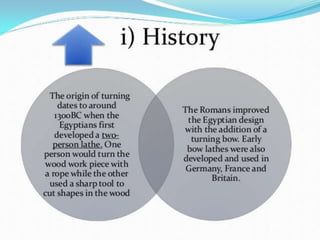

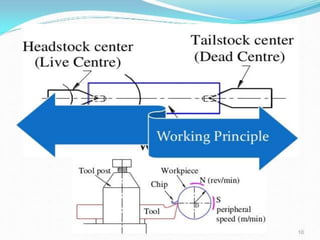

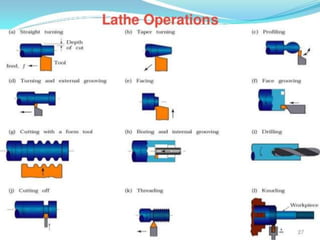

The presentation discusses the lathe machine, highlighting its significance as one of the oldest and most essential machine tools designed primarily for machining cylindrical surfaces. It details various operations possible on a lathe, such as turning, facing, and knurling, explaining the processes involved and their applications. The document emphasizes the lathe's fundamental role in manufacturing and acknowledges contributions from instructors and viewers.

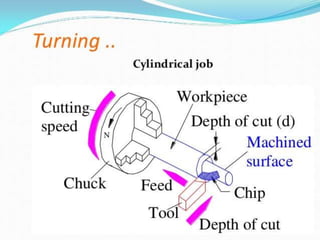

![Turning ..

This operation is one of the most

basic machining processes. That is,

the part is rotated while a single

point cutting tool is moved parallel

to the axis of rotation.[1] Turning can

be done on the external surface of

the part as well as internally

(boring). The starting material is

generally a workpiece generated by

other processes such

as casting, forging, extrusion,

or drawing.

Figure; Turning](https://image.slidesharecdn.com/mufeedpresentation-170214161329/85/presentation-on-lathe-machine-21-320.jpg)

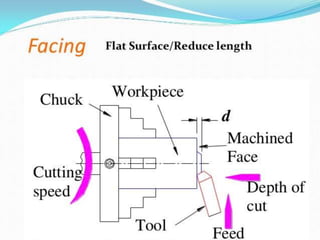

![Facing ..

Facing in the context of turning

work involves moving the cutting

tool at right angles to the axis of

rotation of the rotating

workpiece.[1] This can be performed

by the operation of the cross-slide,

if one is fitted, as distinct from the

longitudinal feed (turning). It is

frequently the first operation

performed in the production of the

workpiece, and often the last—

hence the phrase "ending up".

Figure; Facing](https://image.slidesharecdn.com/mufeedpresentation-170214161329/85/presentation-on-lathe-machine-24-320.jpg)