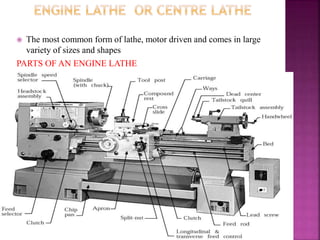

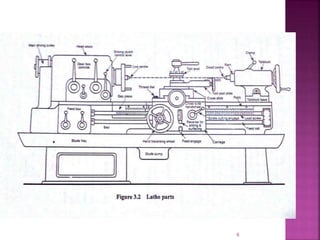

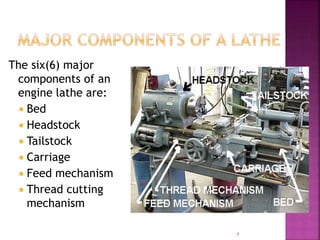

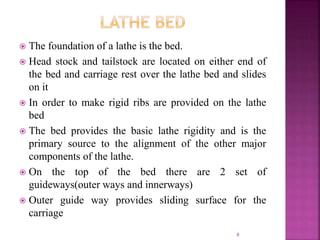

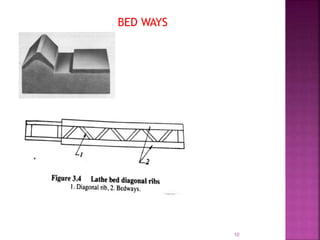

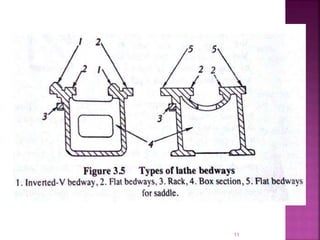

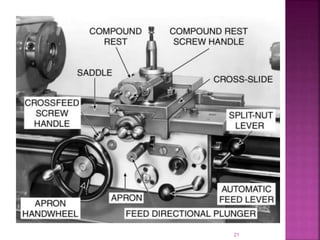

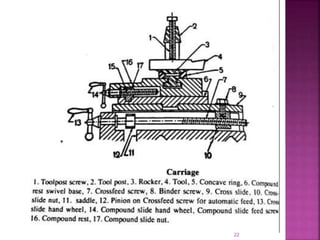

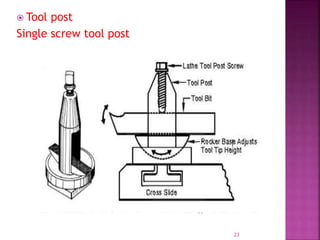

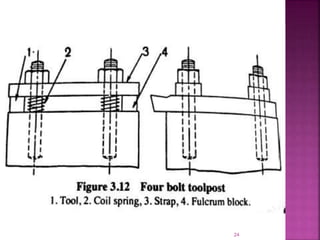

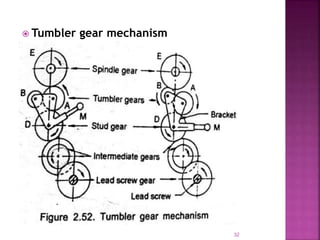

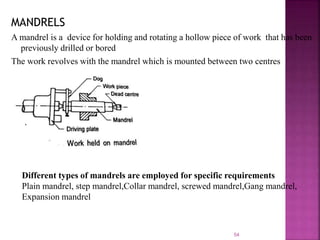

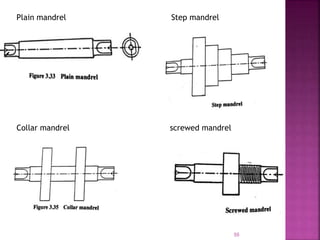

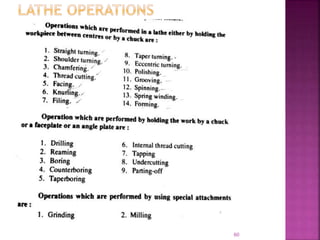

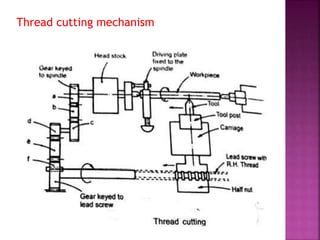

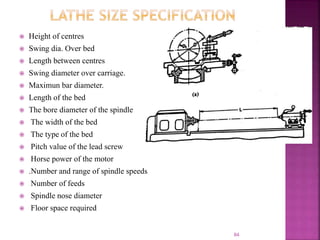

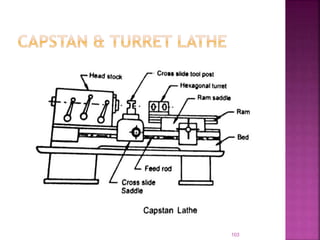

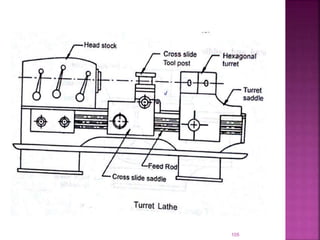

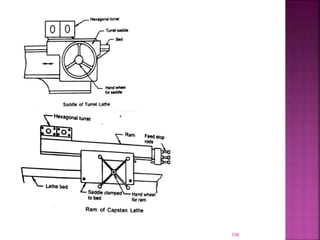

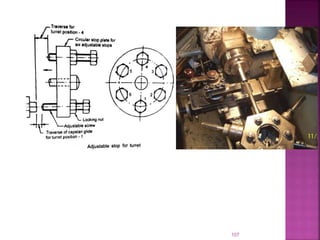

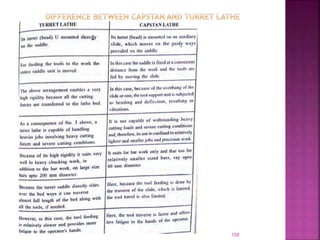

Machine tools are power-driven devices used to produce parts by removing material from preformed blanks through cutting tools. The document discusses lathes, which are machine tools that remove metal from a workpiece to achieve a desired size and shape. It describes the main components of an engine lathe, including the bed, headstock, tailstock, carriage, feed mechanism, and thread cutting mechanism. It also discusses other types of lathes, lathe accessories, and specifications used to describe lathe characteristics.