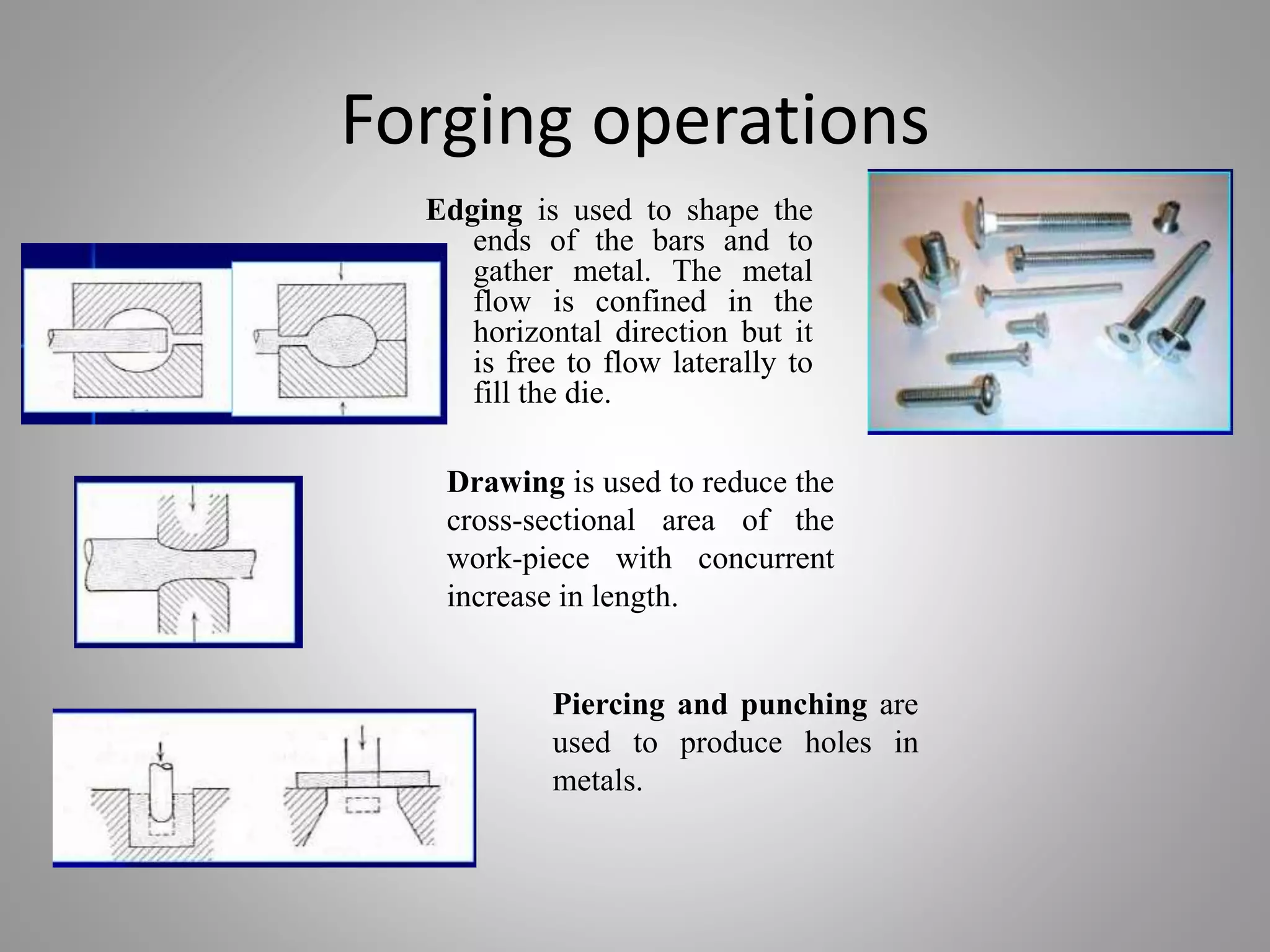

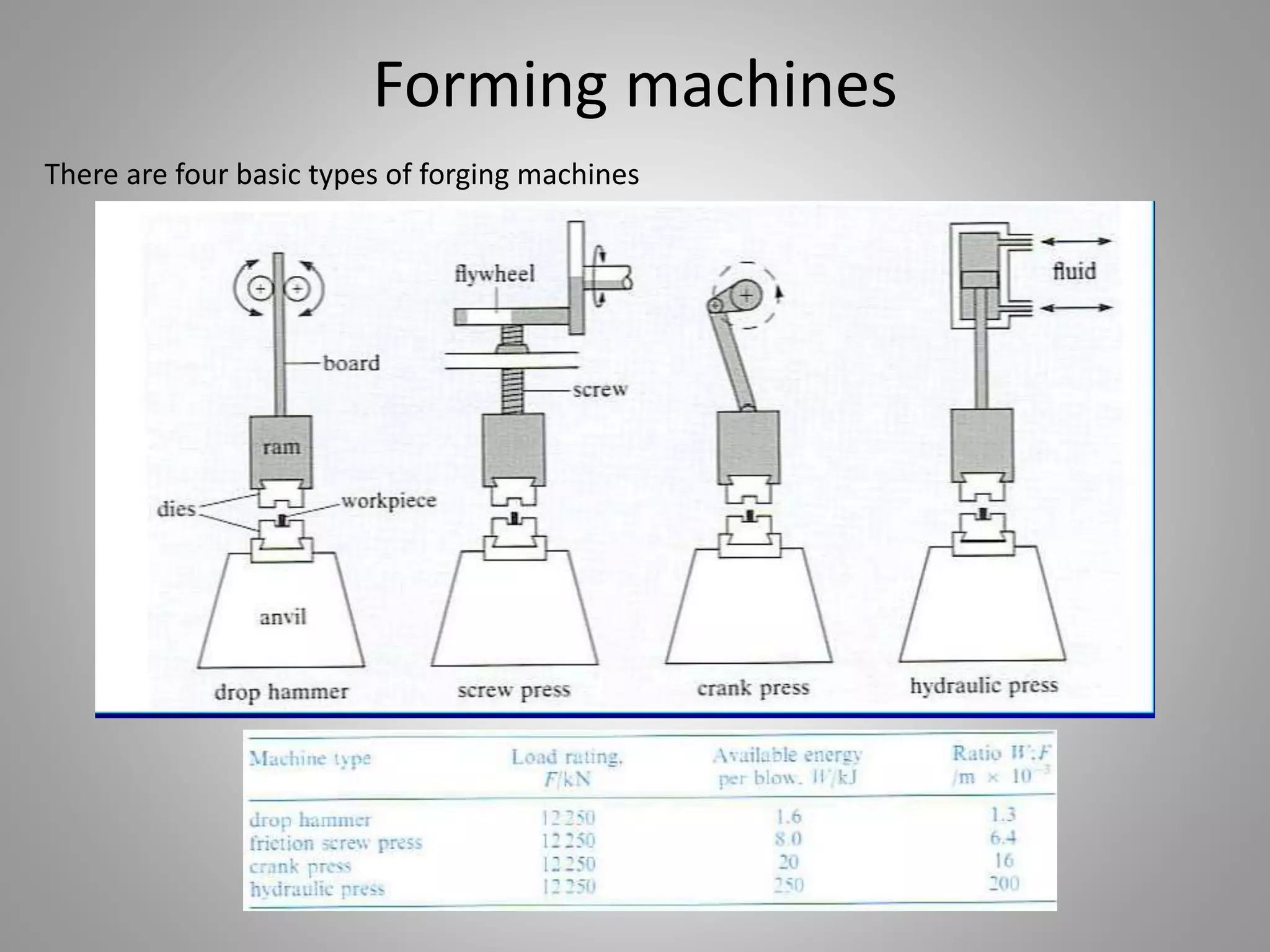

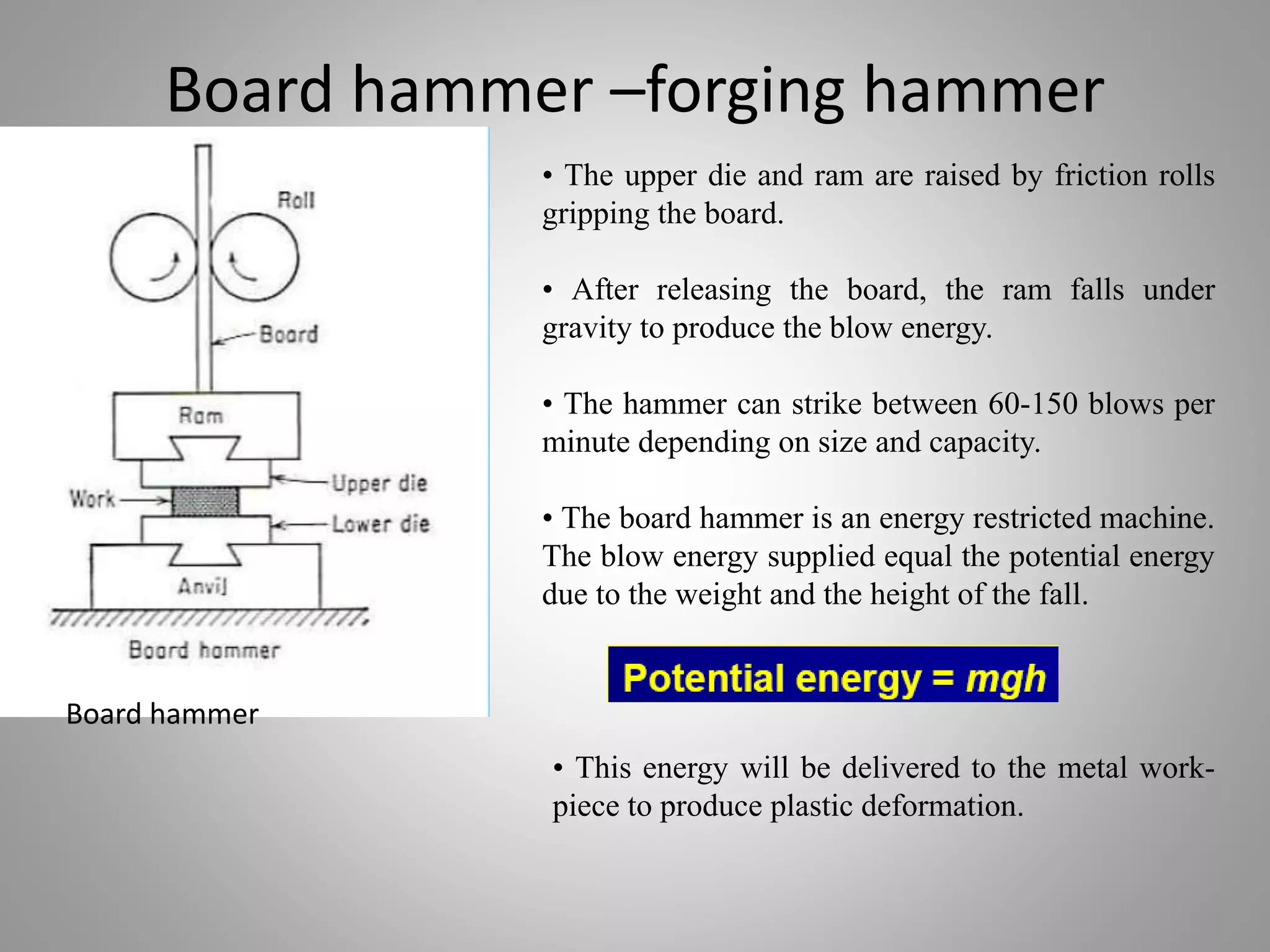

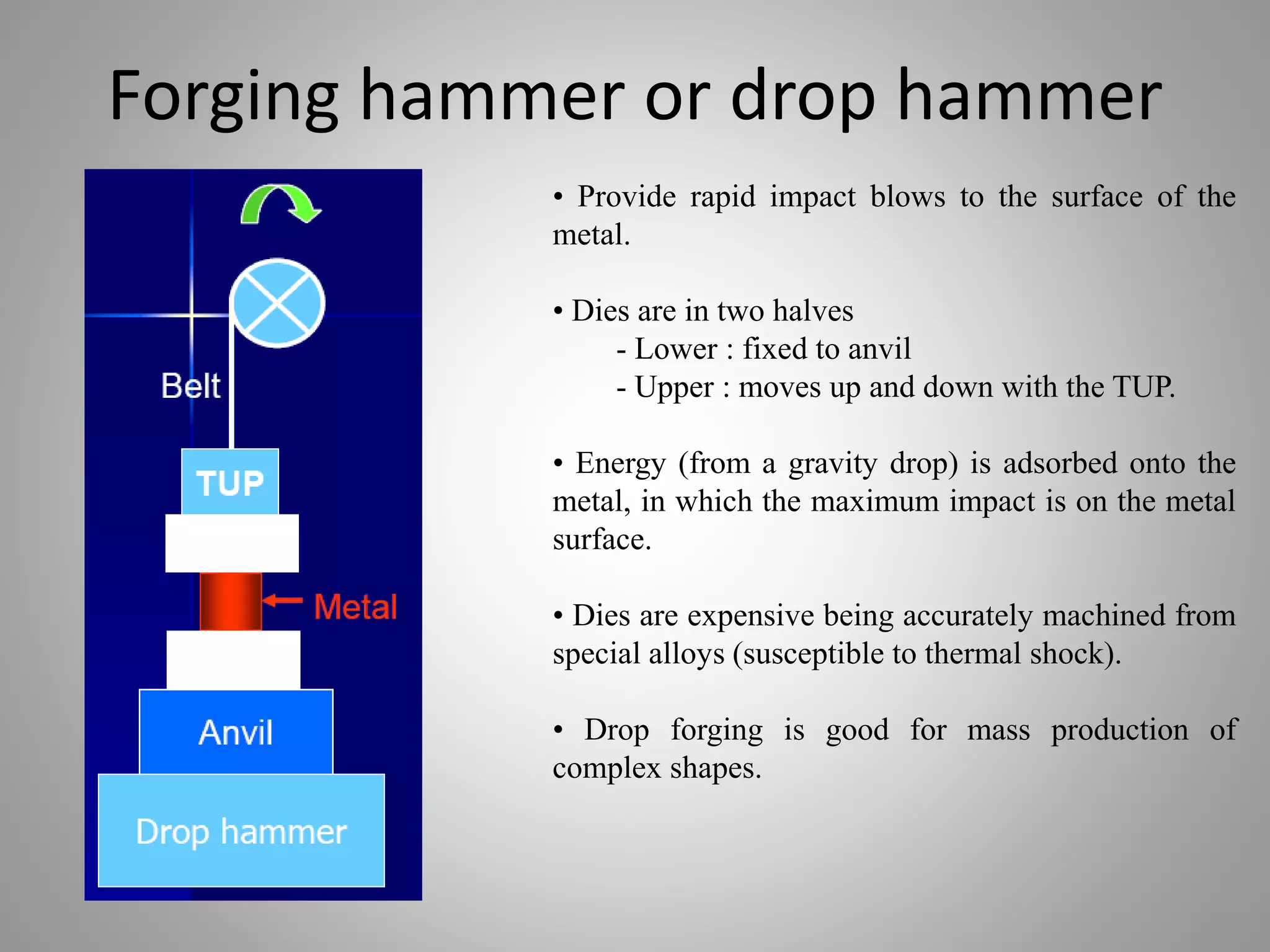

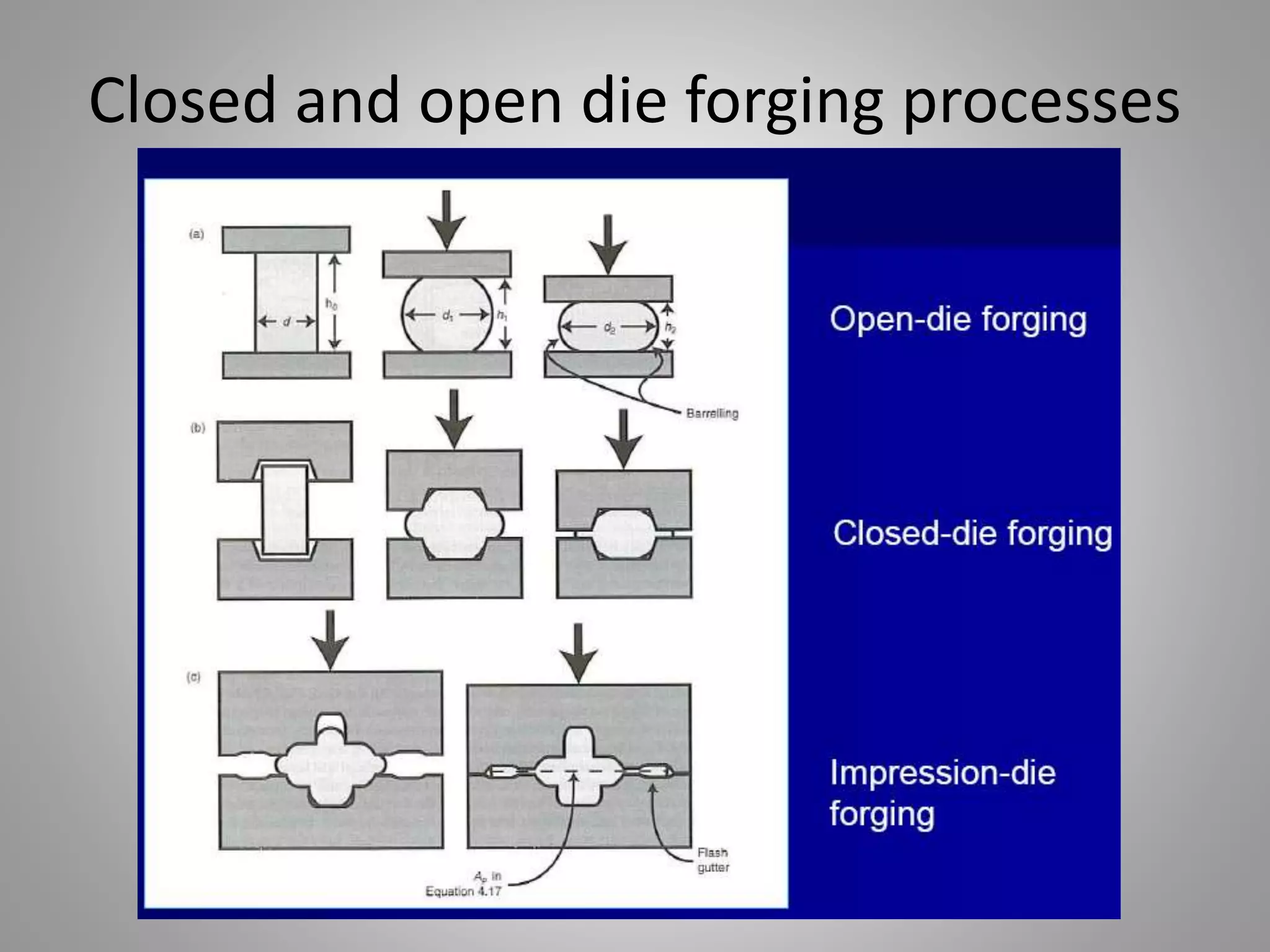

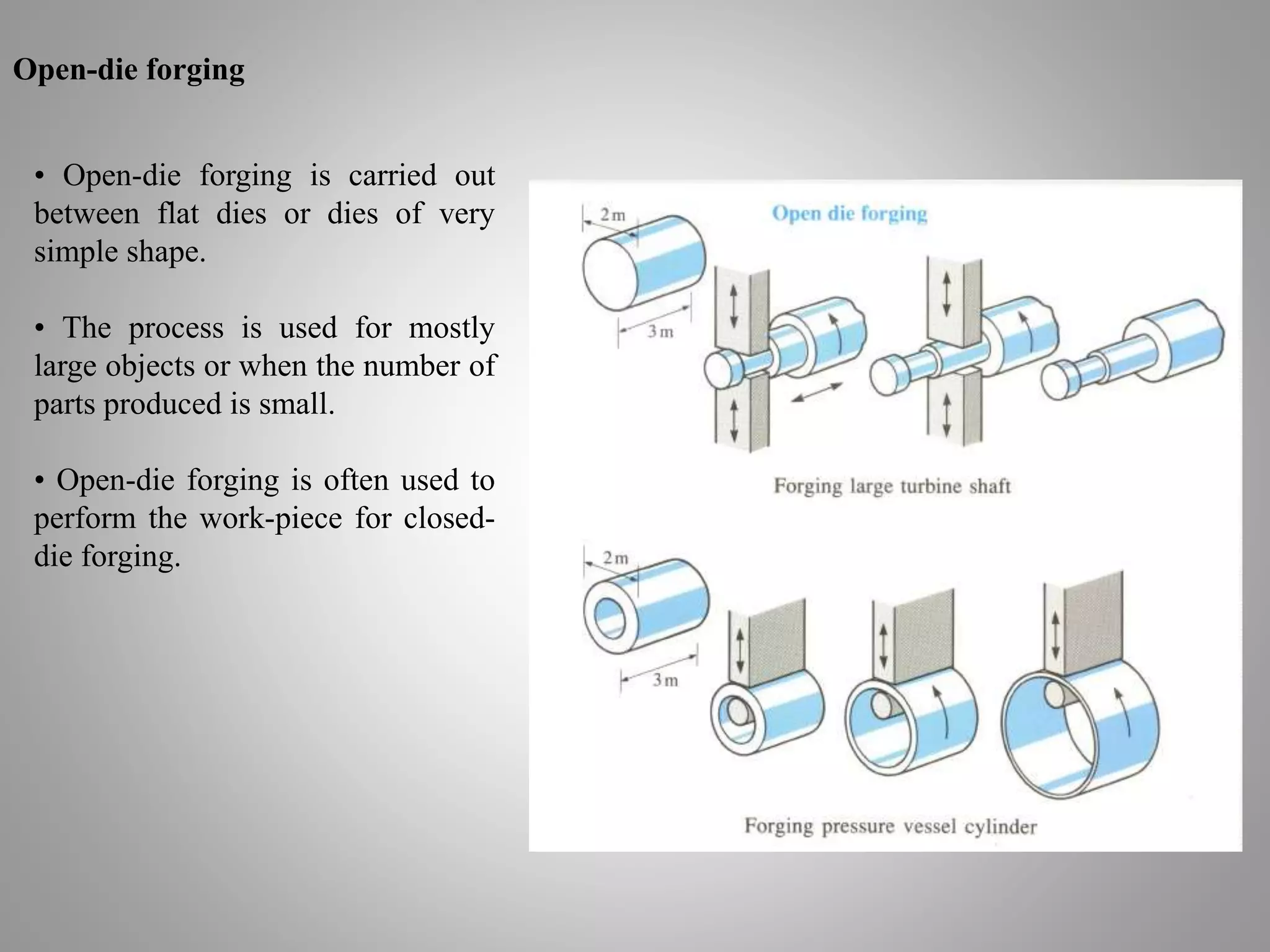

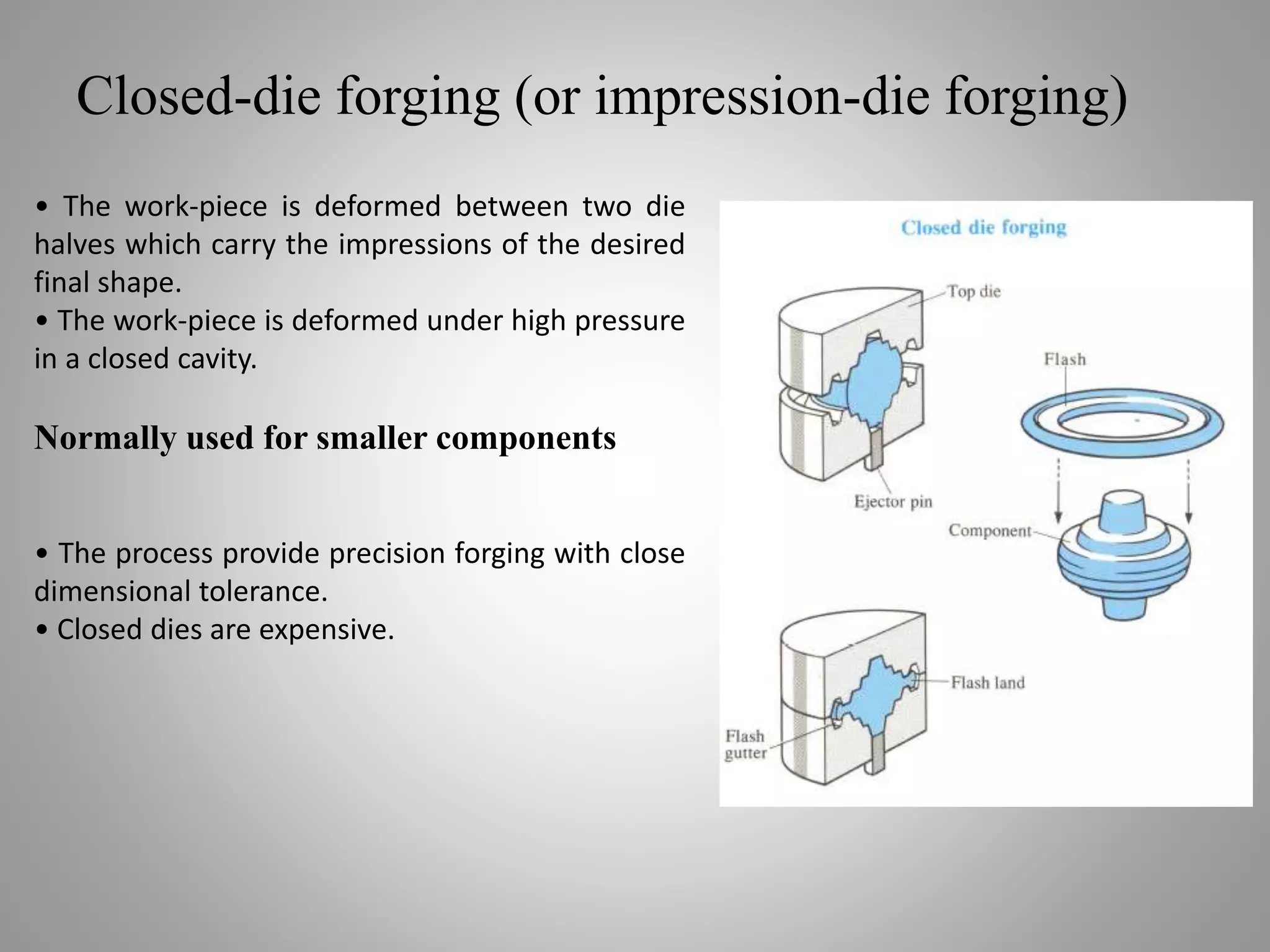

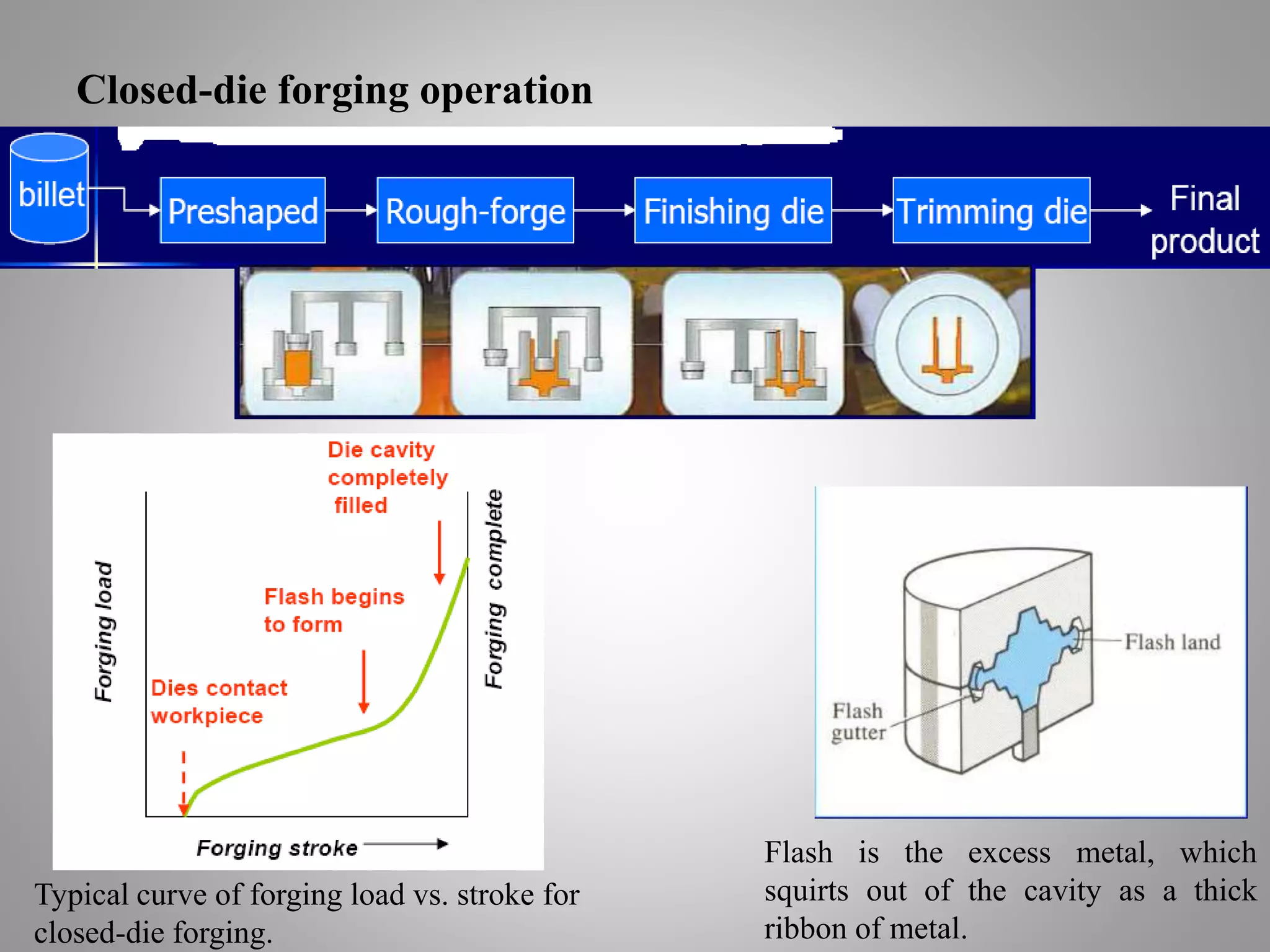

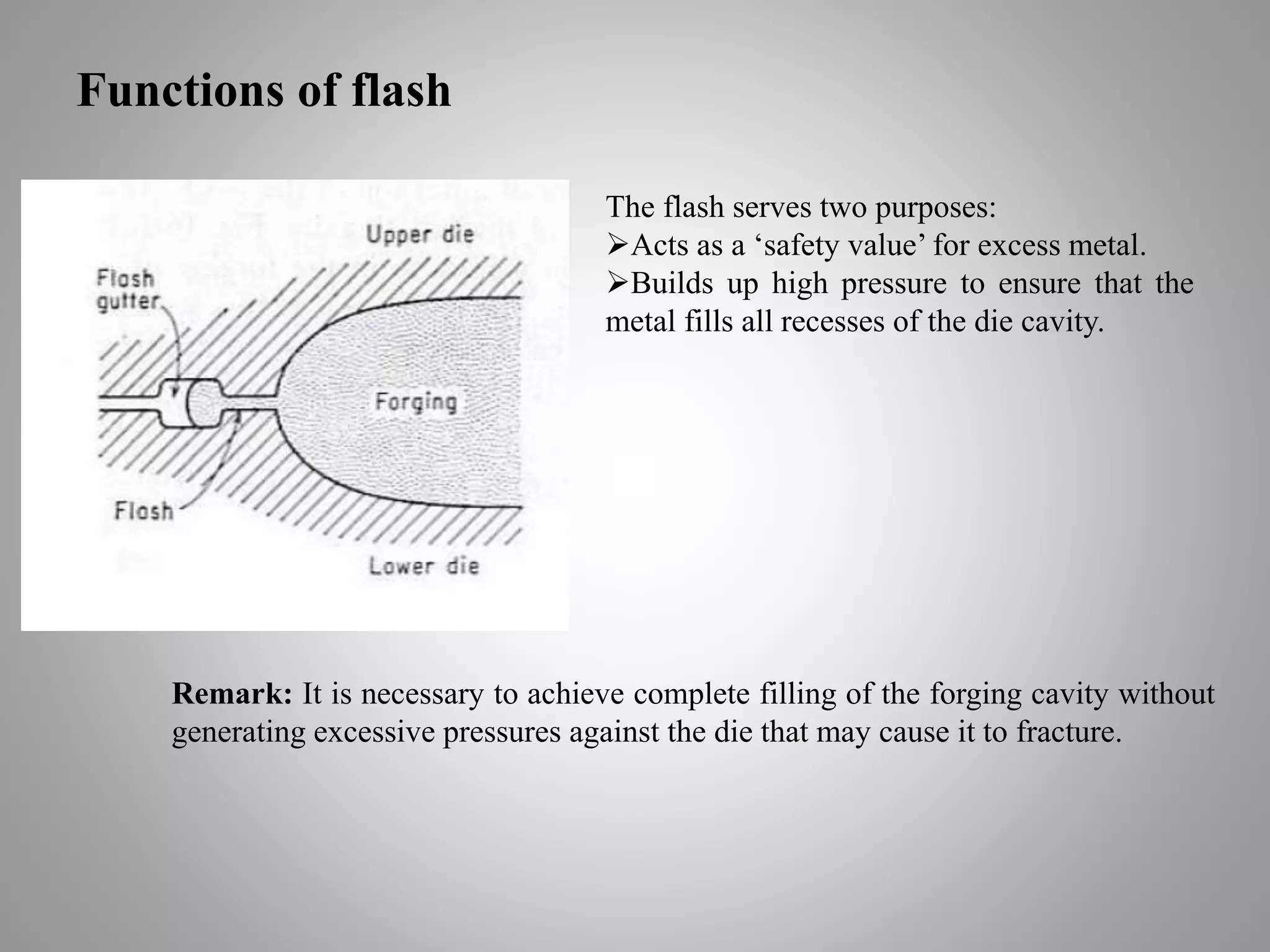

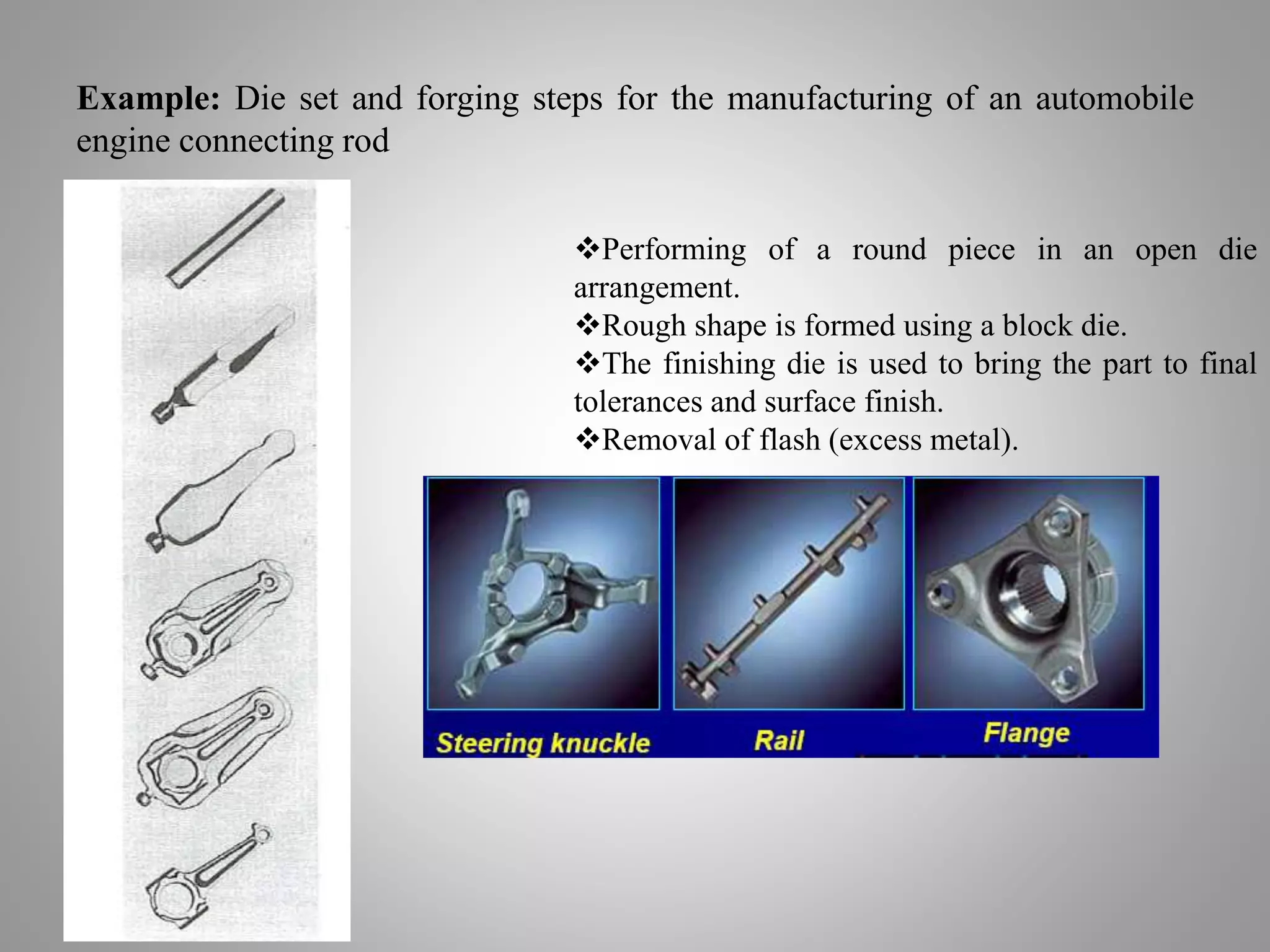

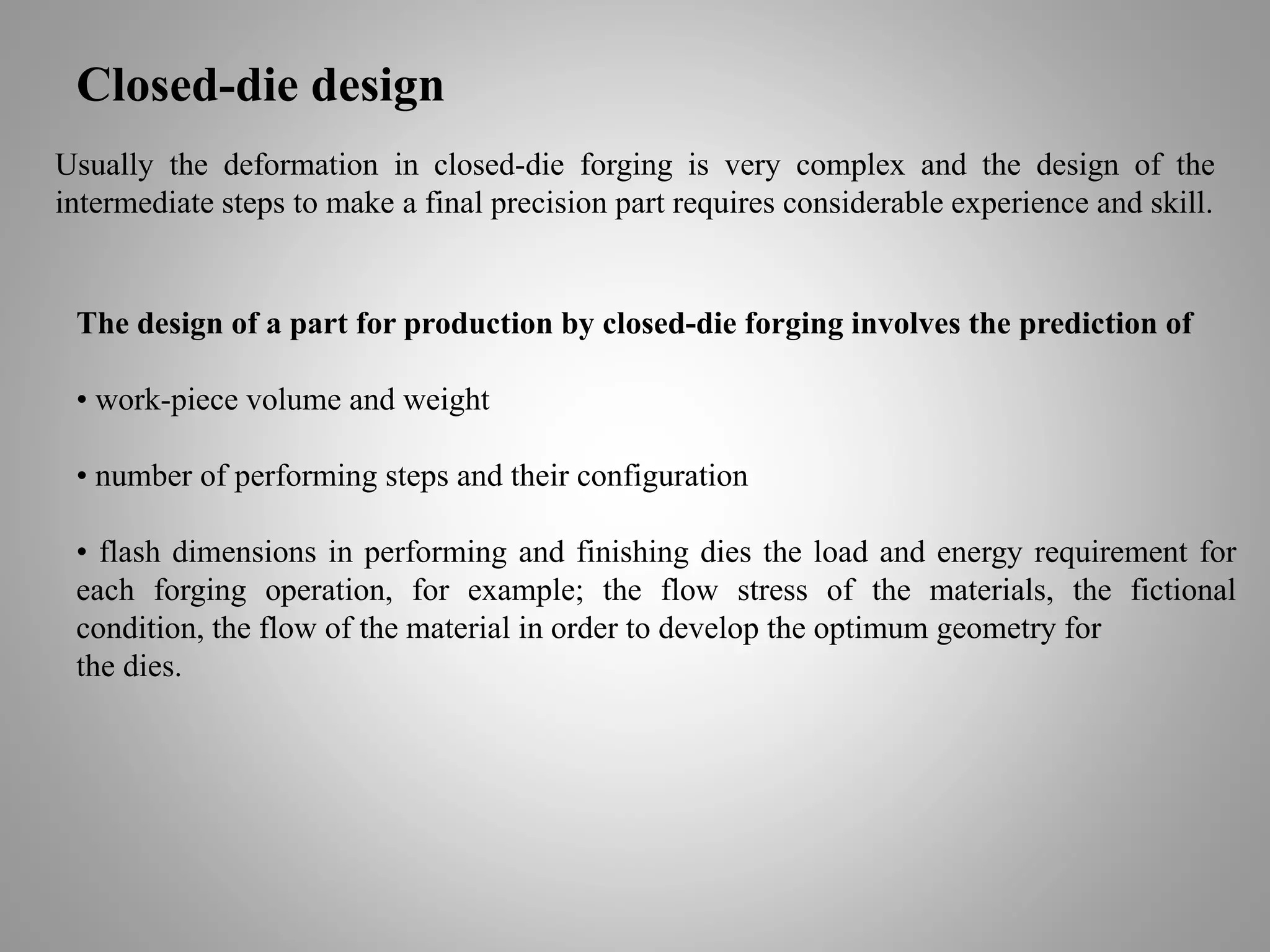

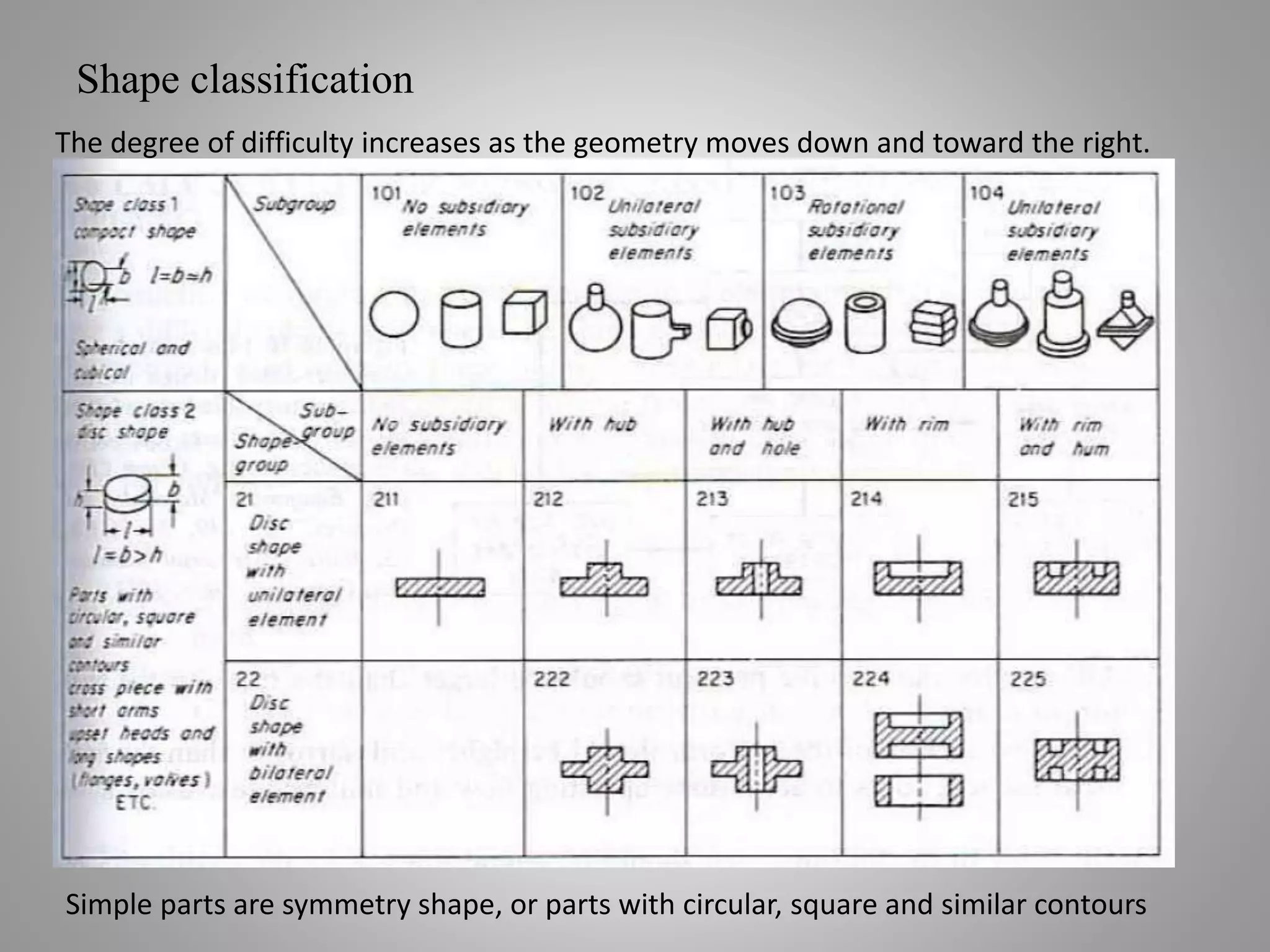

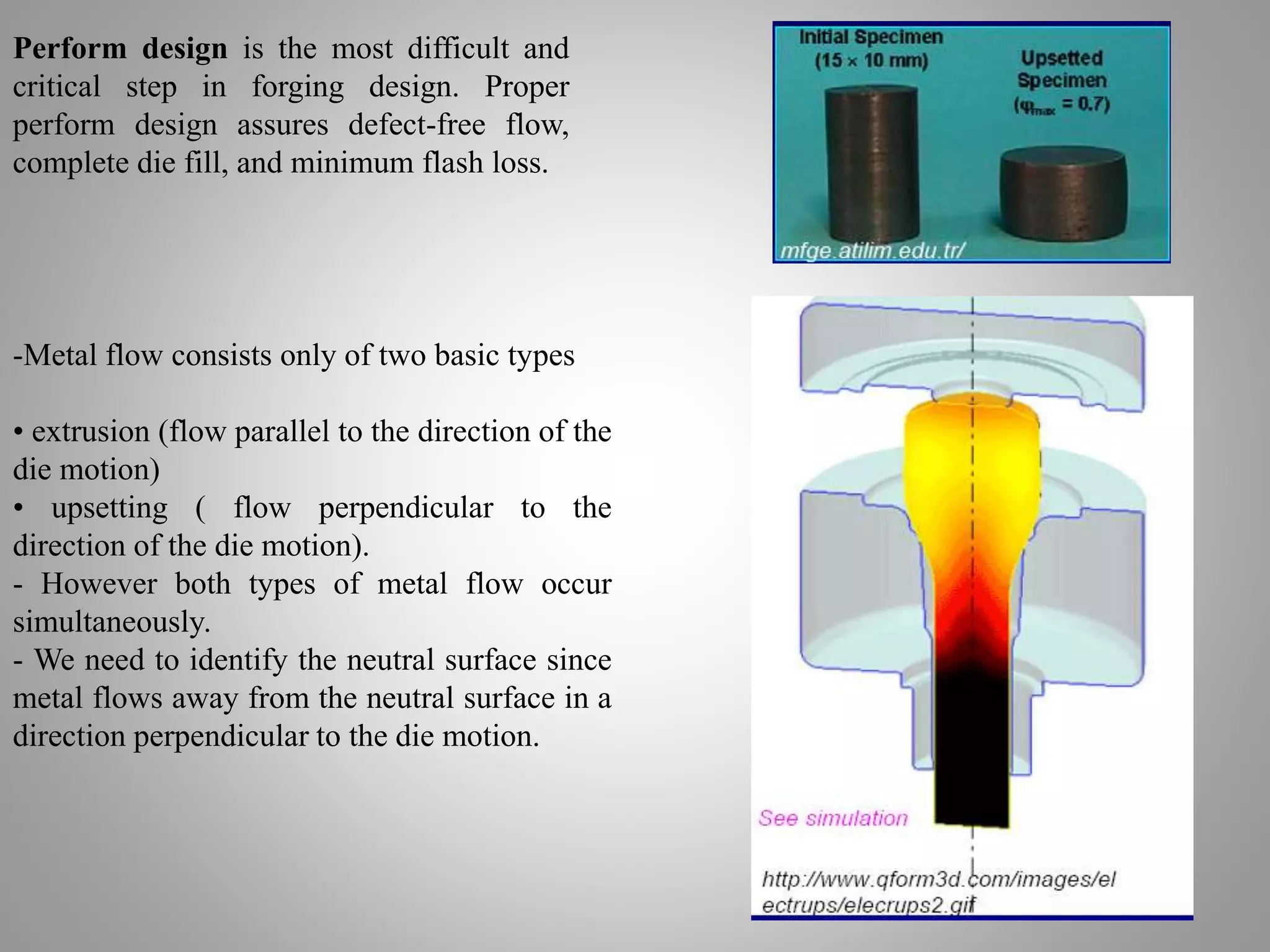

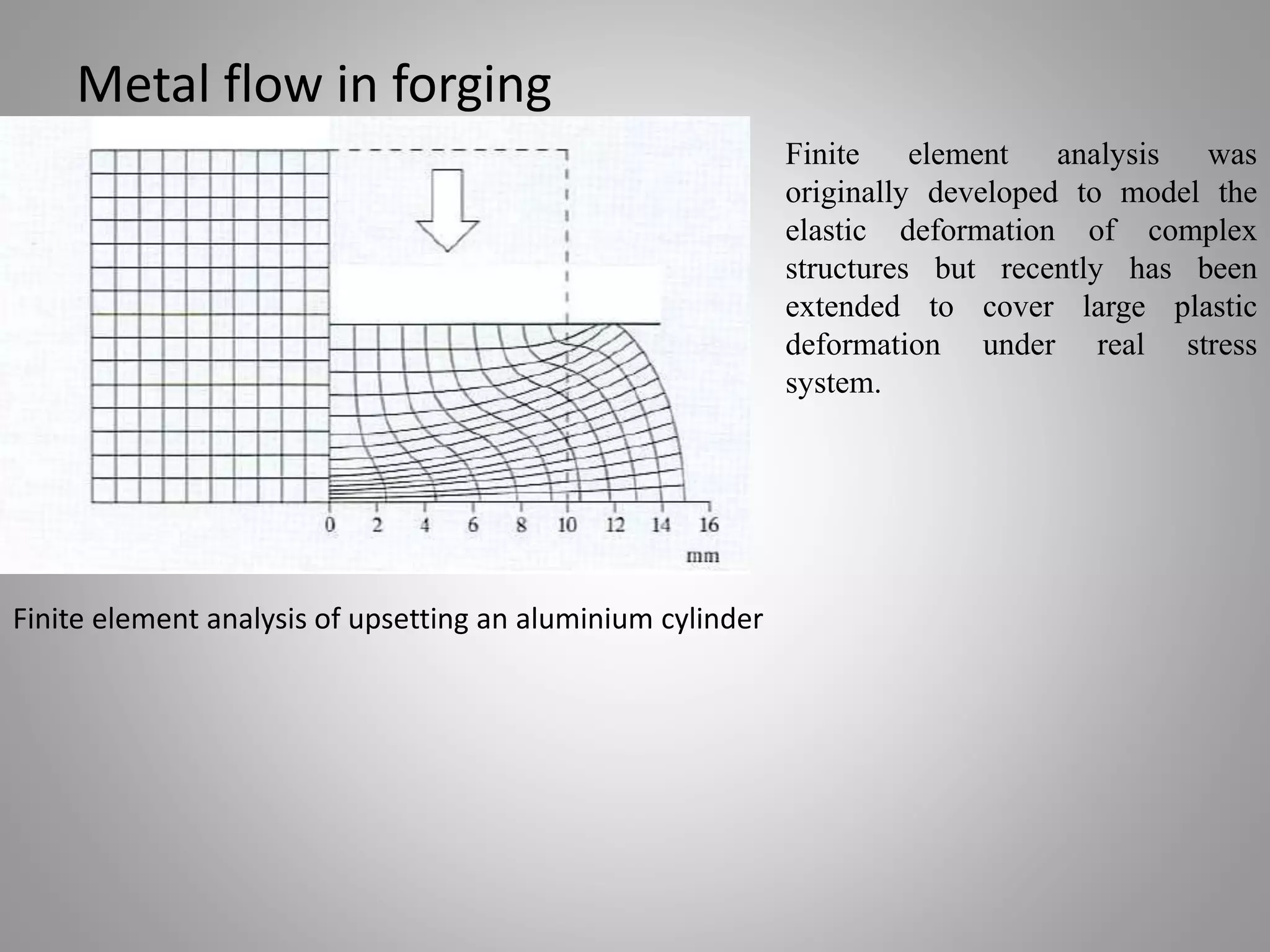

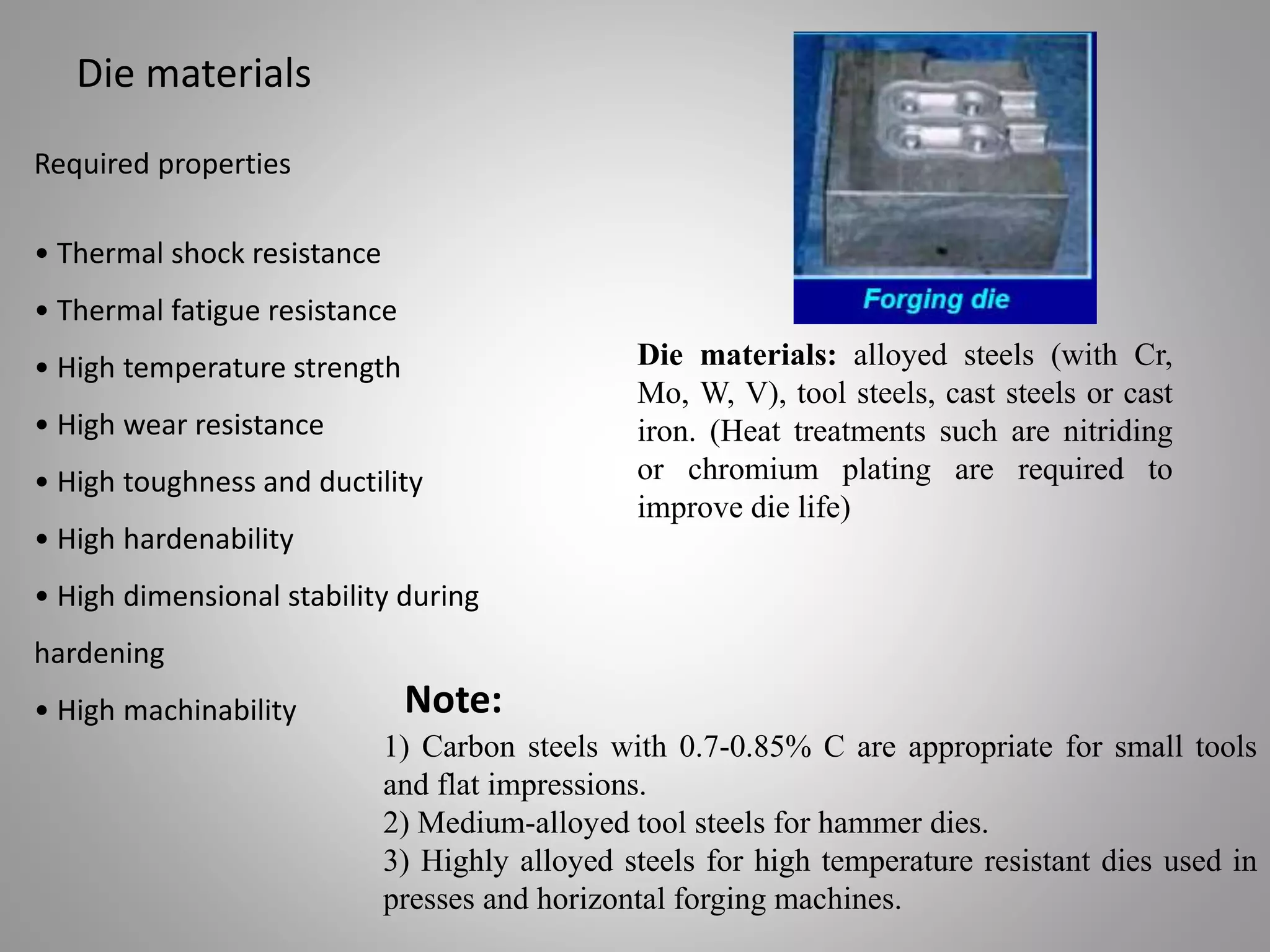

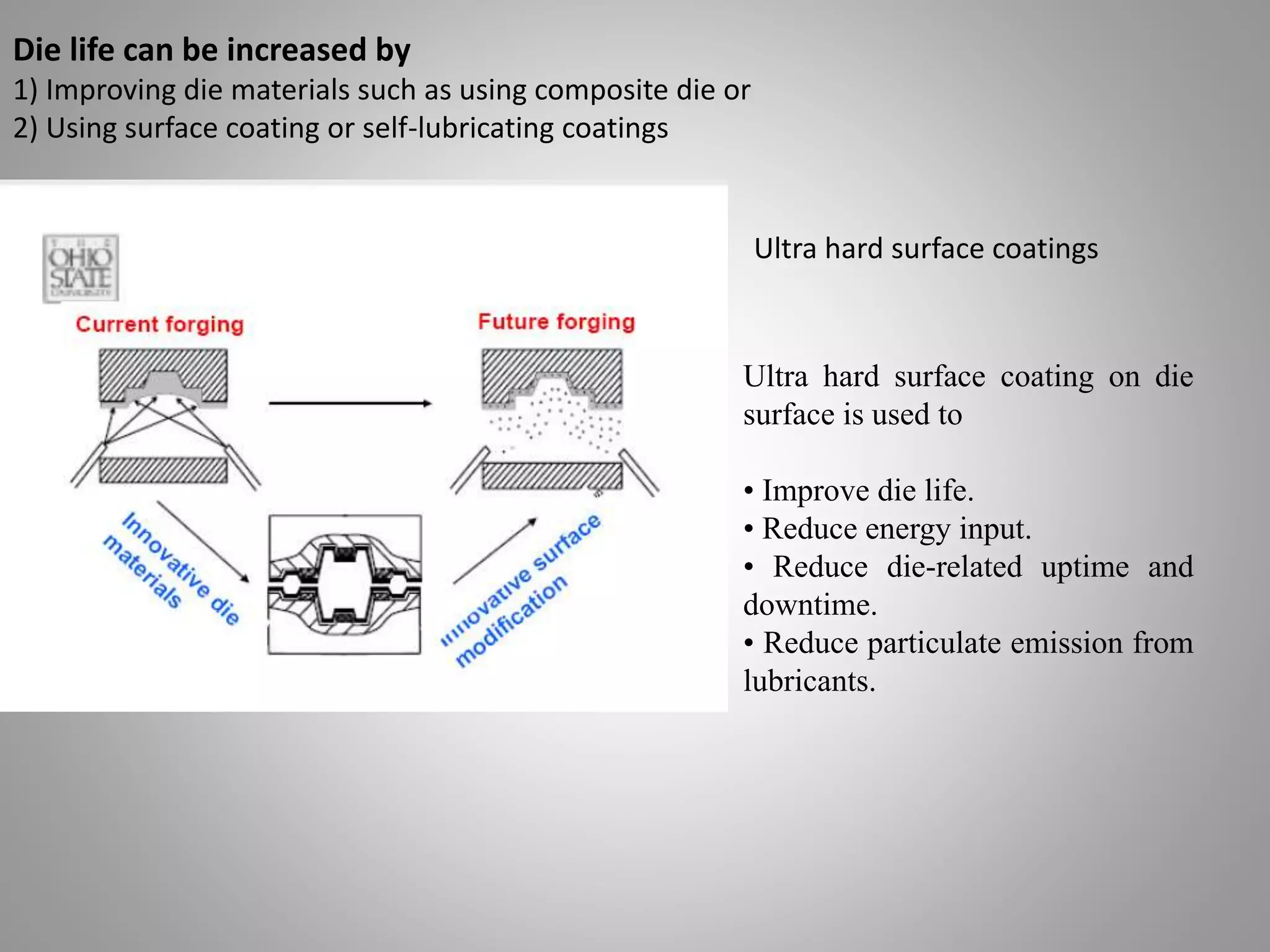

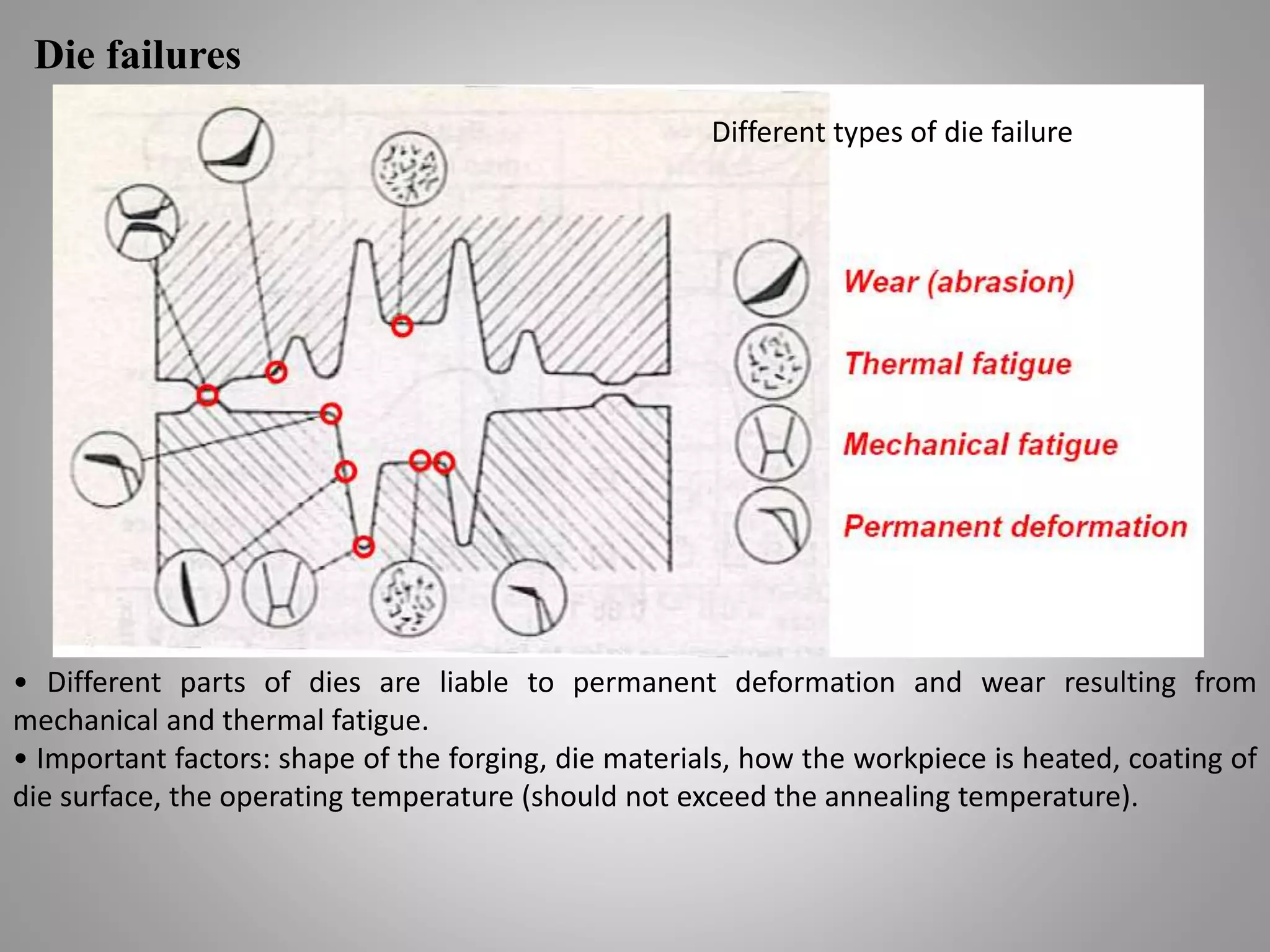

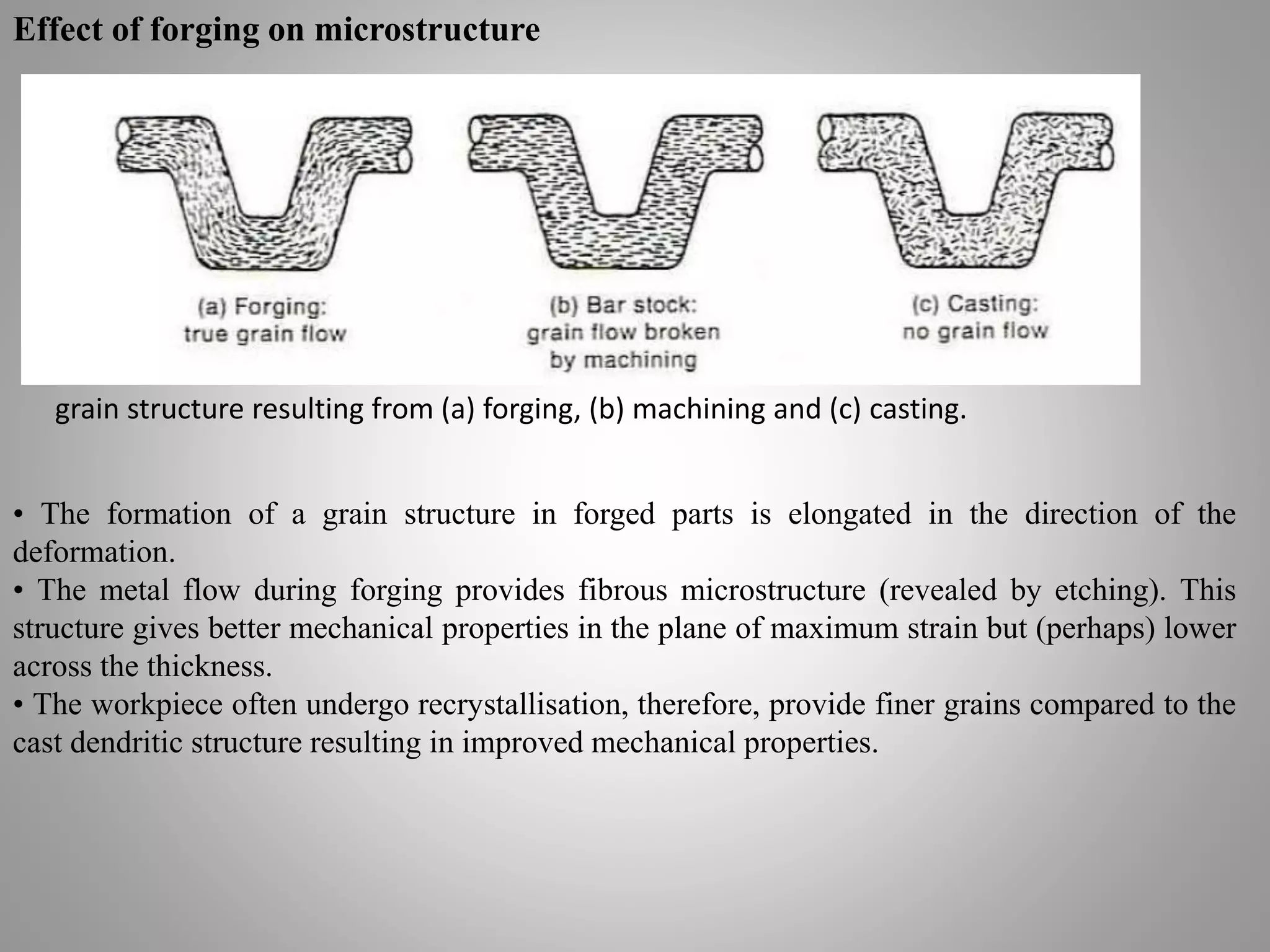

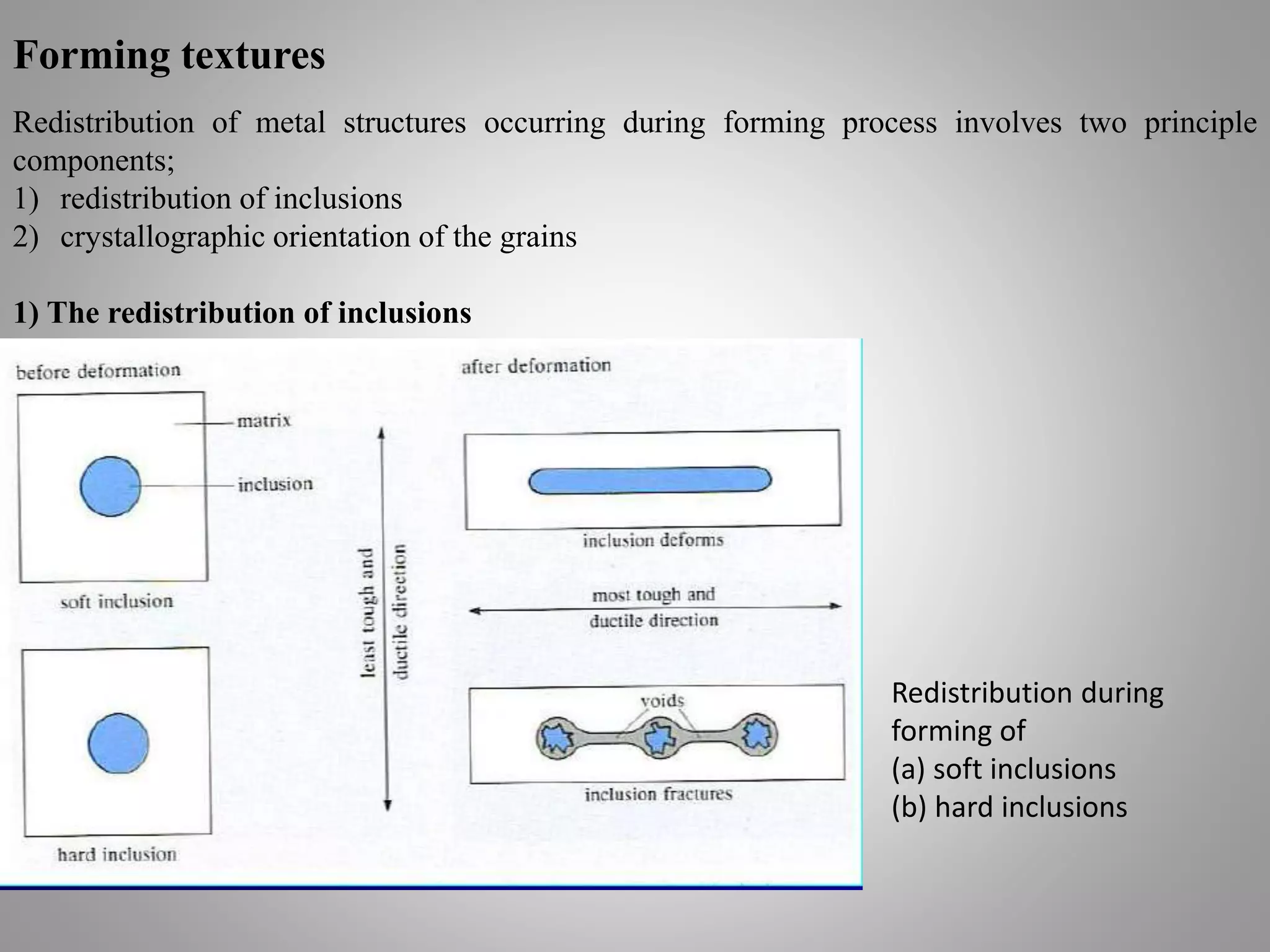

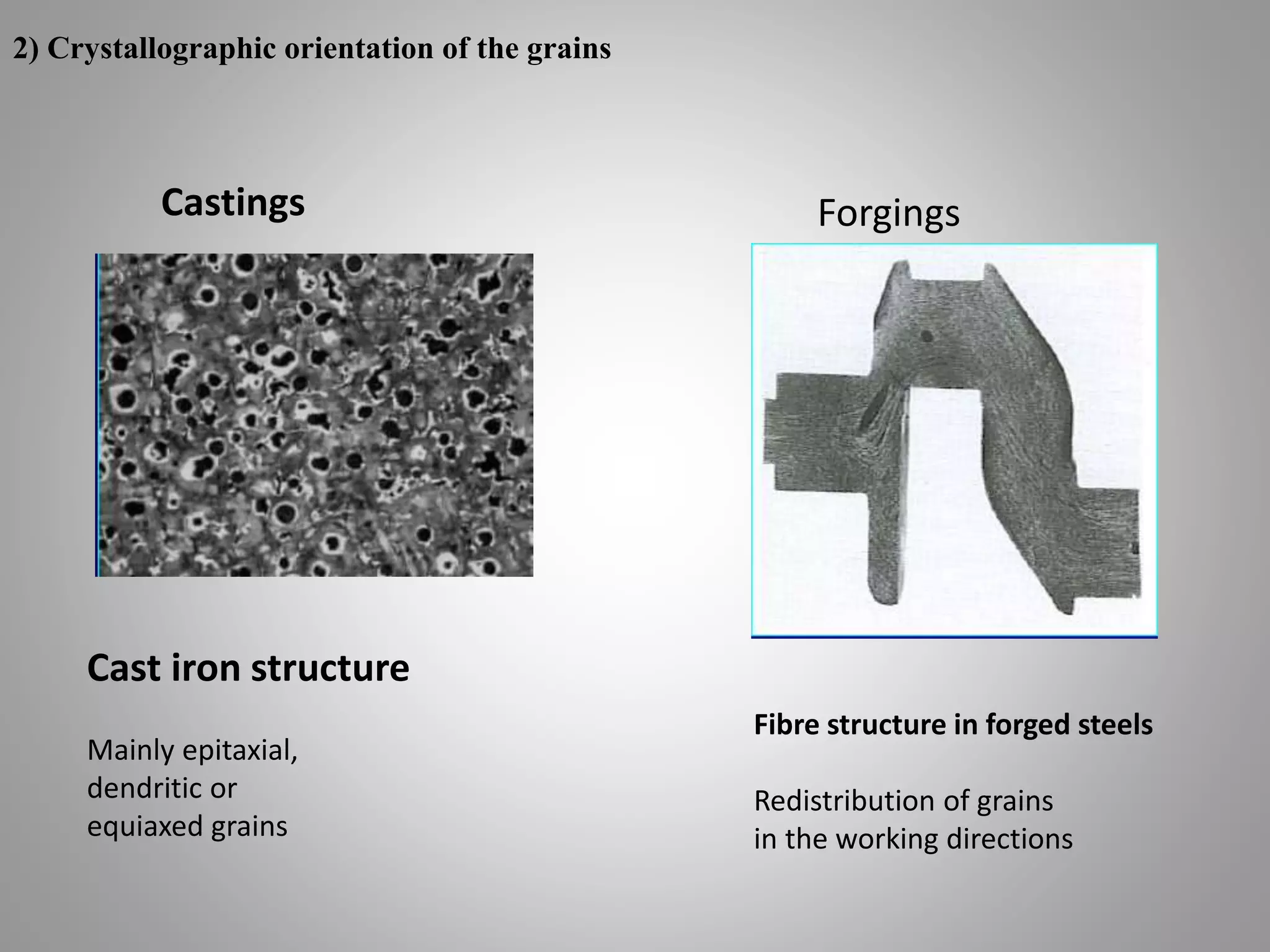

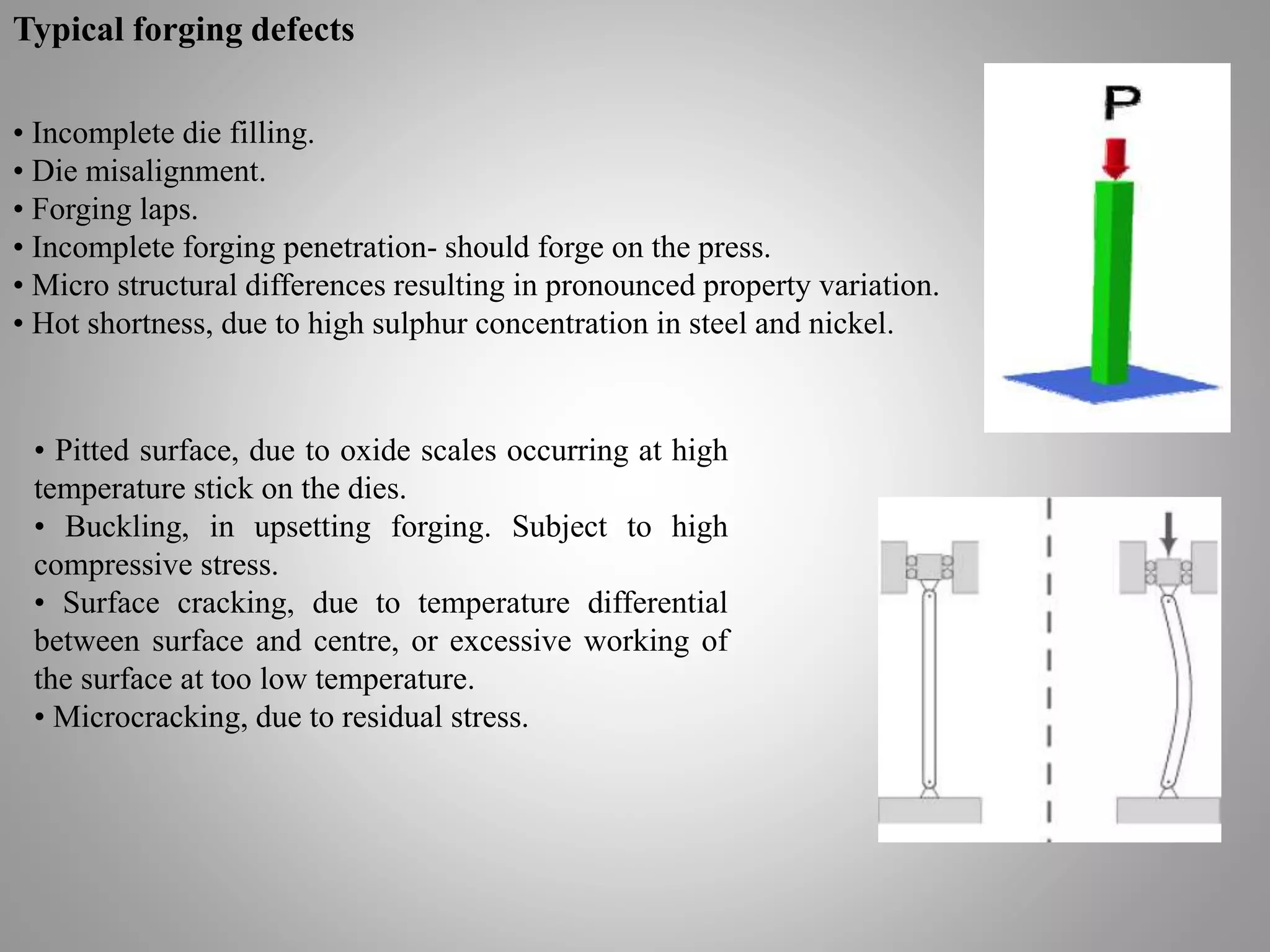

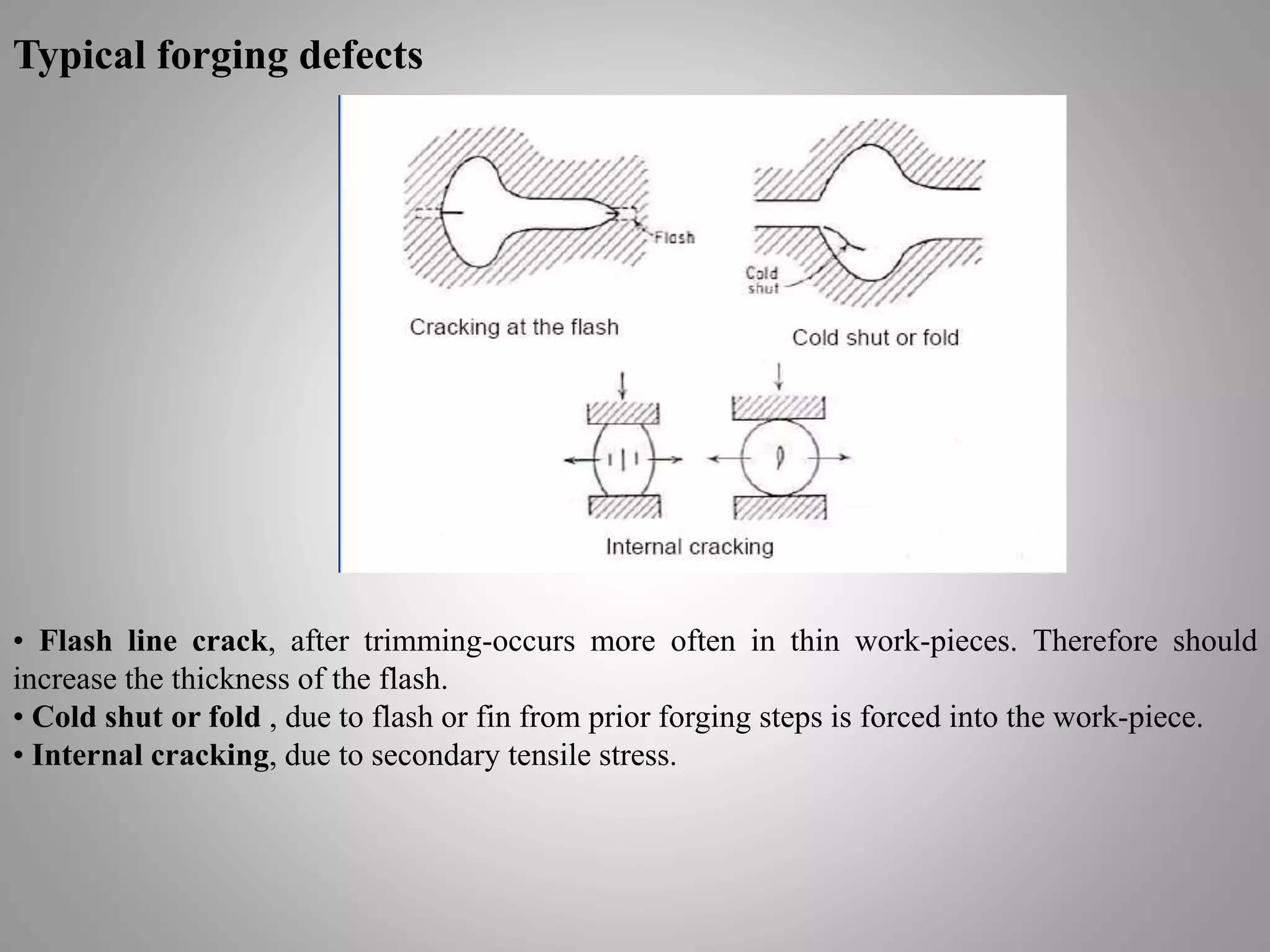

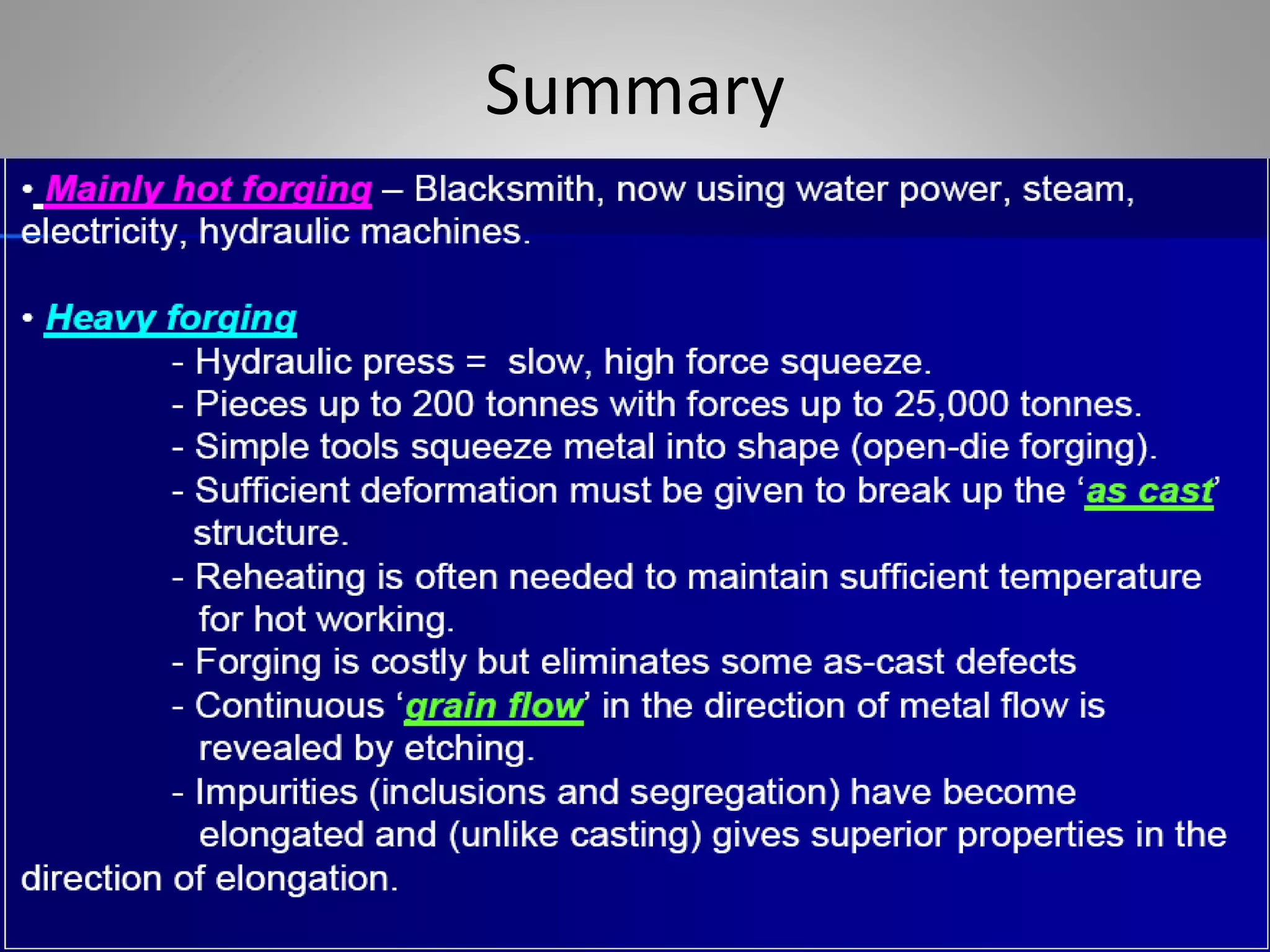

Forging processes involve shaping metals by applying compressive forces. There are four main types: hammer/drop forging uses gravity impacts, press forging uses hydraulic or mechanical presses, and open-die and closed-die forging differ in whether dies fully contain the metal. Forging increases strength by working the metal and altering its microstructure. Proper die and process design are needed to control metal flow, fill dies completely, and minimize flash and defects. Die materials must withstand thermal and mechanical stresses, while coatings can extend die life.