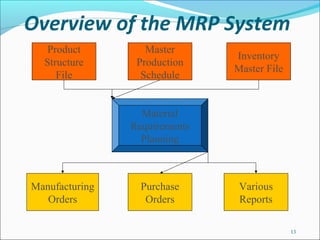

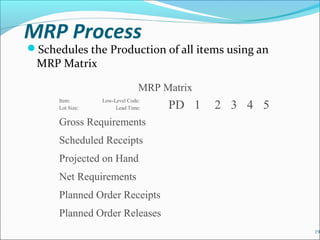

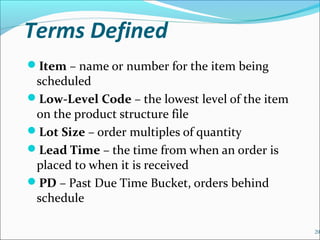

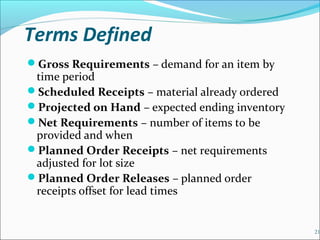

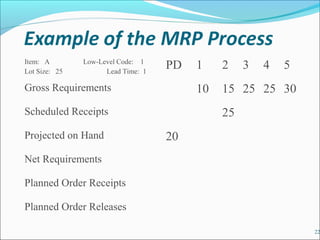

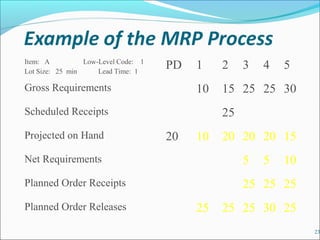

MRP (Material Requirements Planning) is a computerized inventory control and production planning system that determines what materials and components are needed for production and when, based on orders and forecasts. It schedules the production of all items using an MRP matrix to track inventory levels and help manage other aspects of business like purchasing, production, and shipping. The system inputs include a product structure file, master production schedule, and inventory master file. The outputs are manufacturing orders, purchasing orders, and various reports.