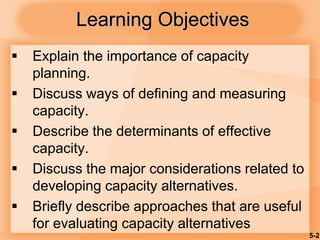

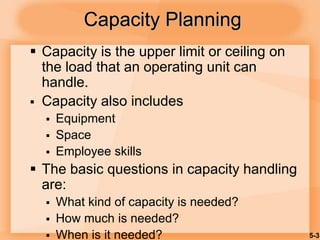

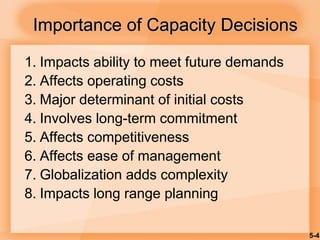

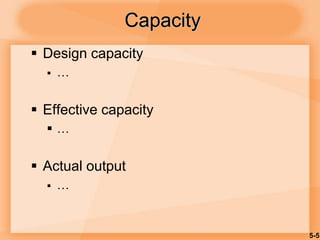

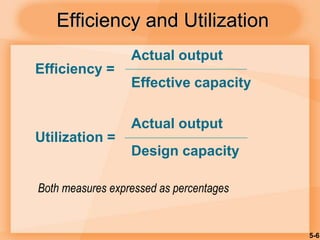

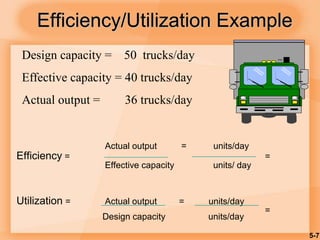

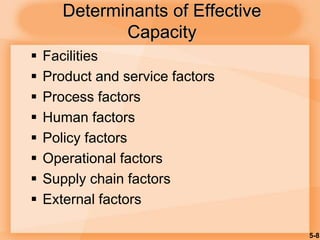

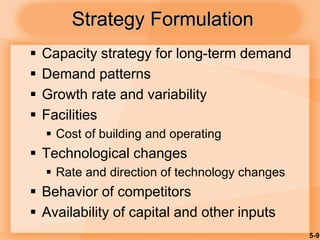

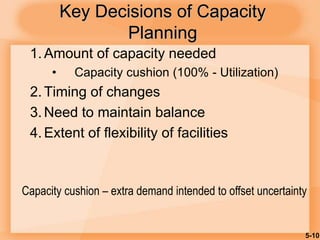

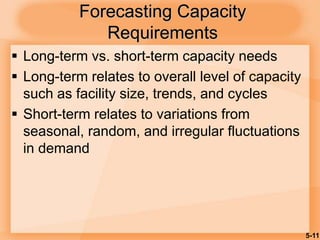

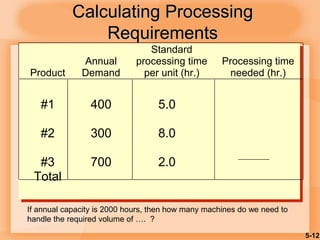

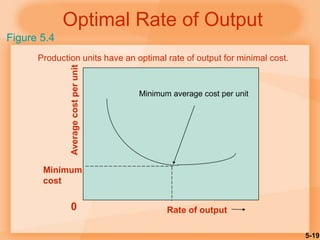

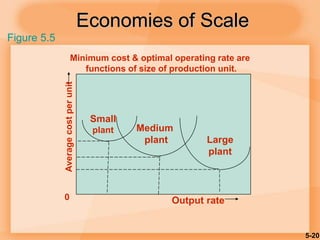

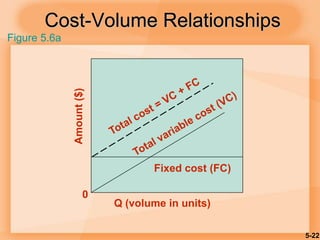

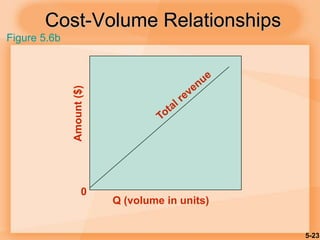

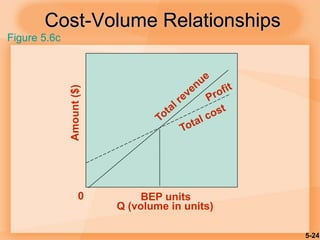

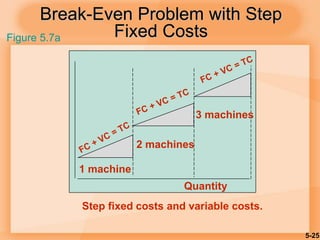

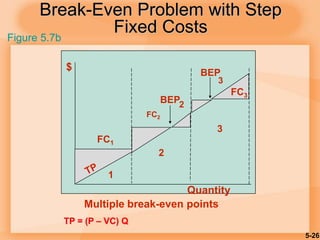

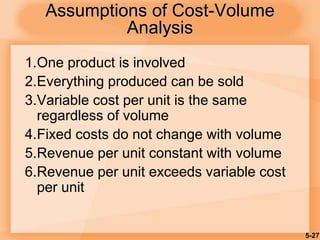

The document discusses capacity planning for products and services. It explains key concepts like capacity, effective capacity, and utilization. It also outlines factors to consider when developing capacity alternatives and approaches for evaluating alternatives, including cost-volume analysis, break-even analysis, financial analysis, and waiting-line analysis. The goal of capacity planning is to determine the appropriate level and timing of capacity to meet future demand in a cost-effective manner.