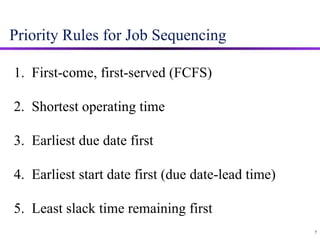

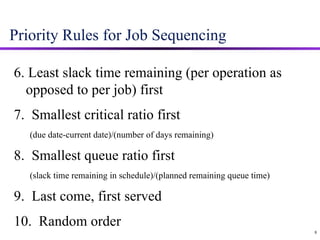

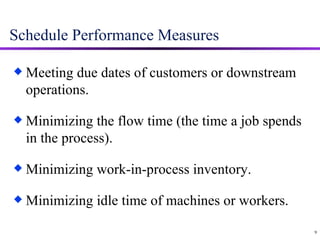

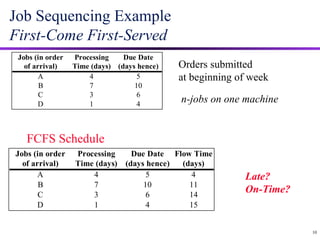

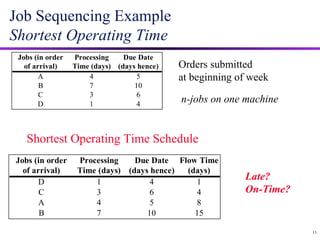

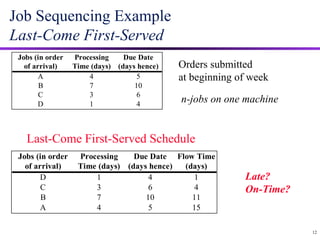

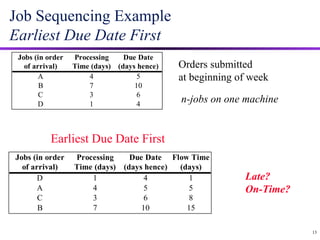

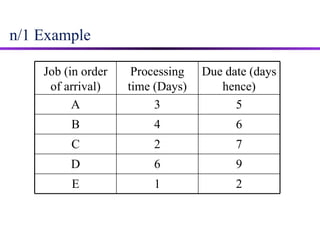

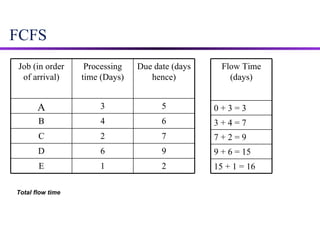

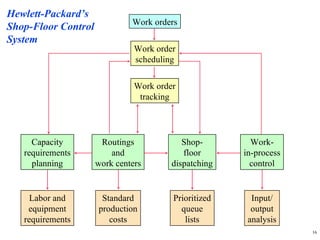

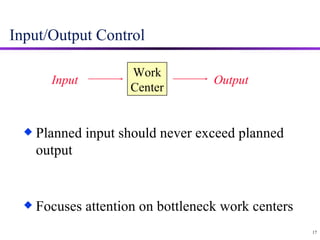

The document discusses production and operations management concepts related to work center scheduling. It defines work centers and describes typical scheduling functions like allocating orders and determining sequence. It then covers priority rules for job sequencing, schedule performance measures, and examples of different sequencing methods. Finally, it discusses shop-floor control functions and principles of work center and job shop scheduling.