The document discusses four priority sequencing rules - first come first served, shortest processing time, earliest due date, and critical ratio. It provides examples and calculations to demonstrate how to determine the optimal job sequence using each rule. The goal of the rules is to minimize completion time and lateness while maximizing facility utilization and throughput.

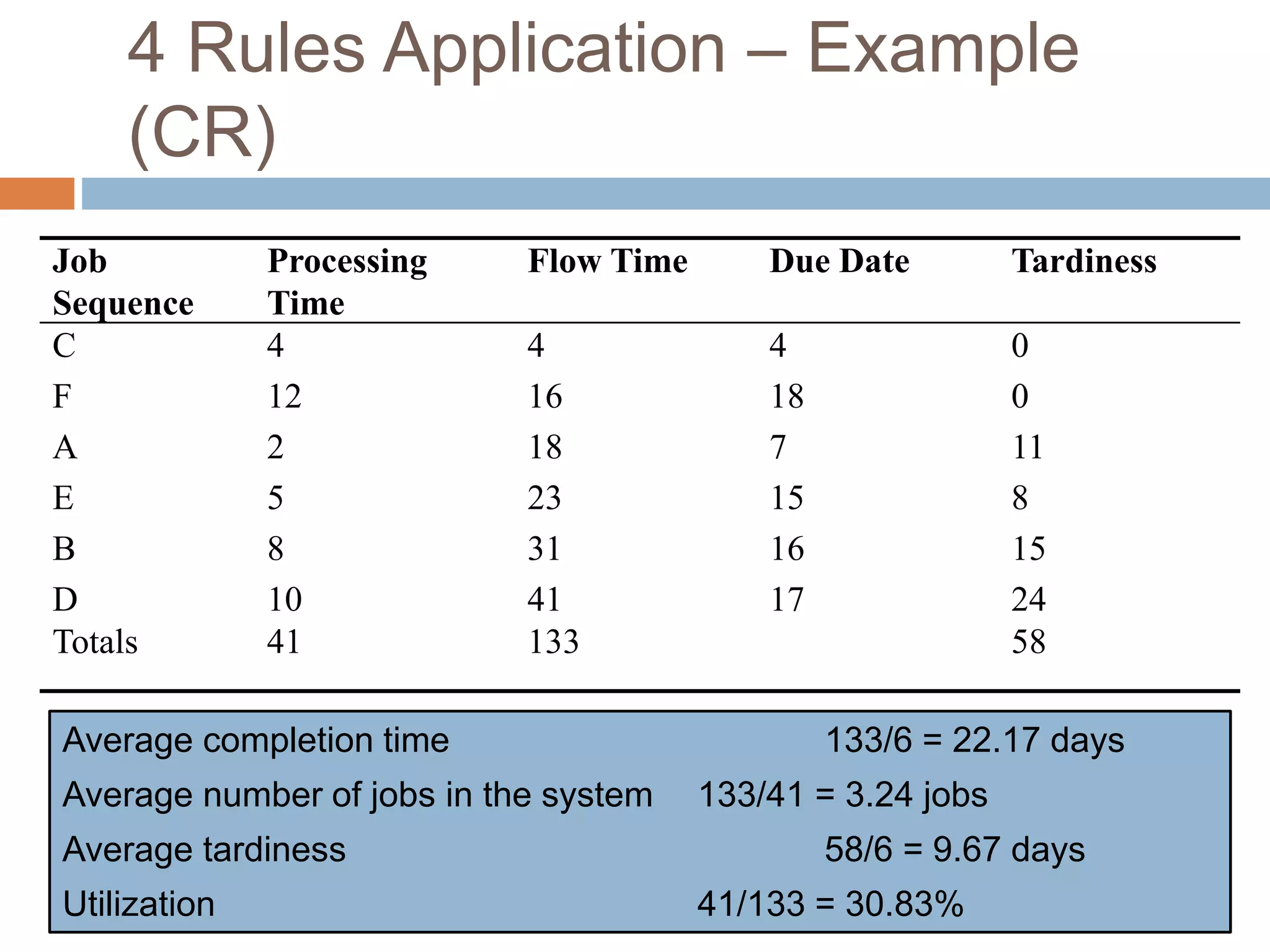

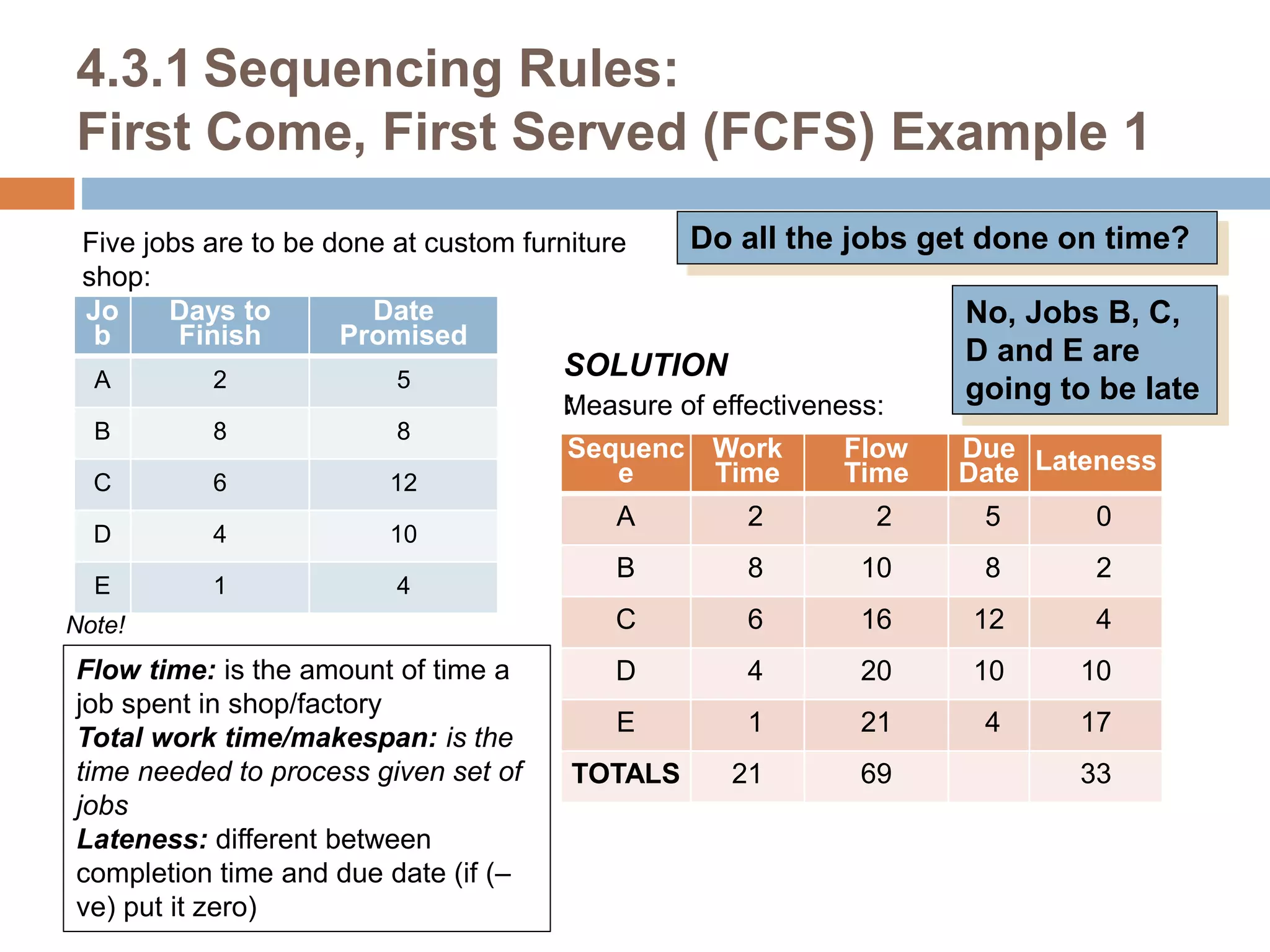

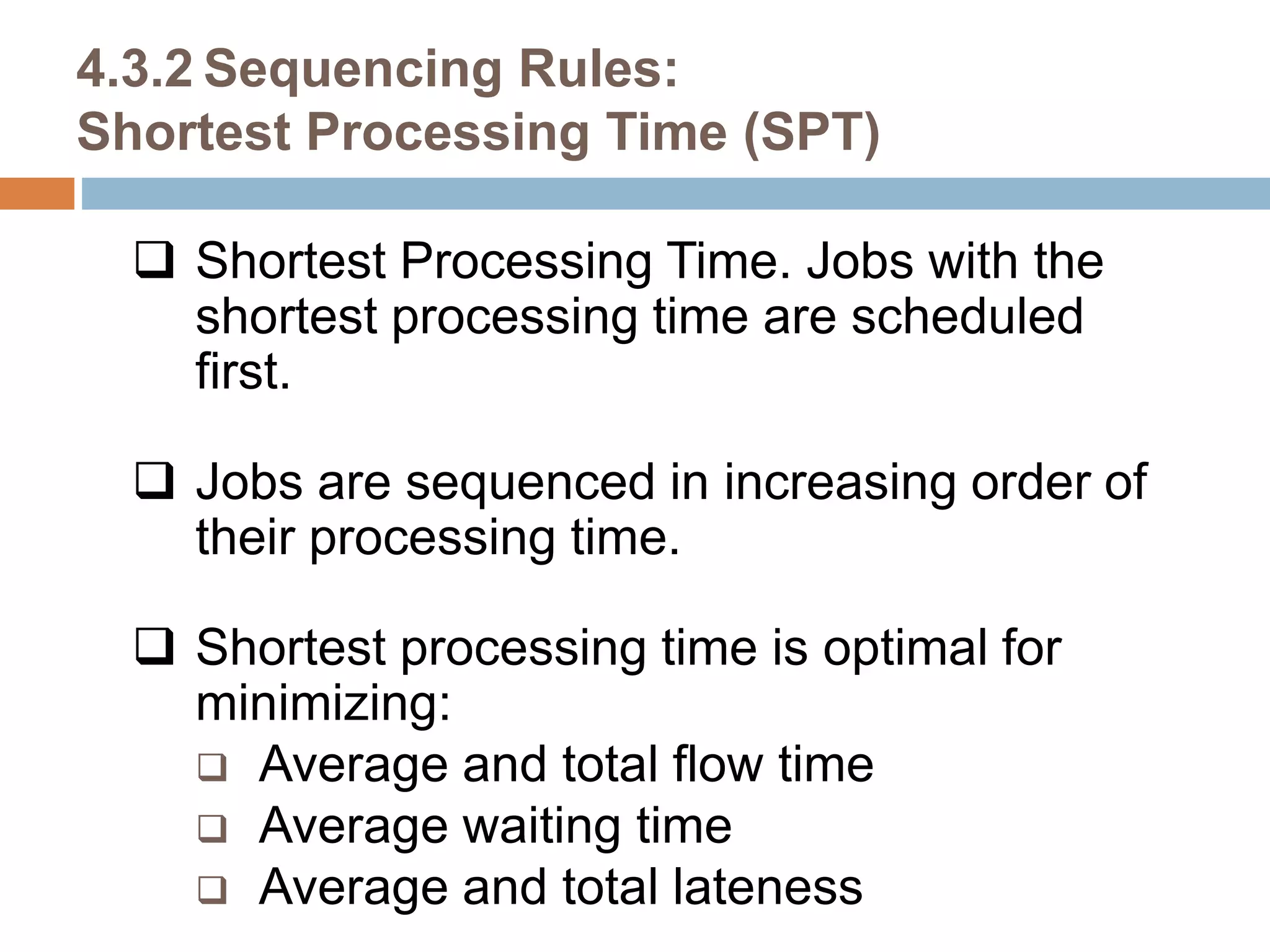

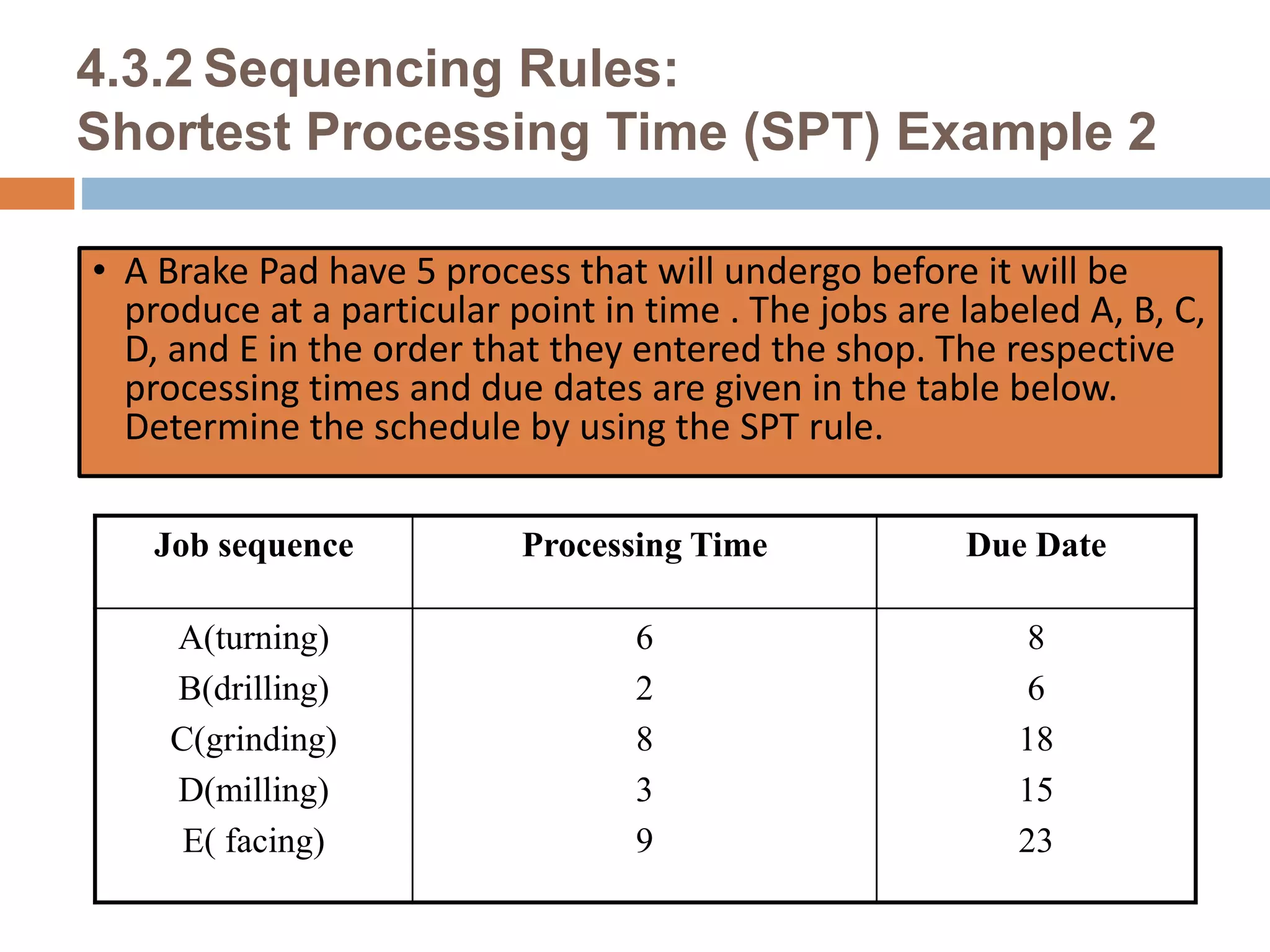

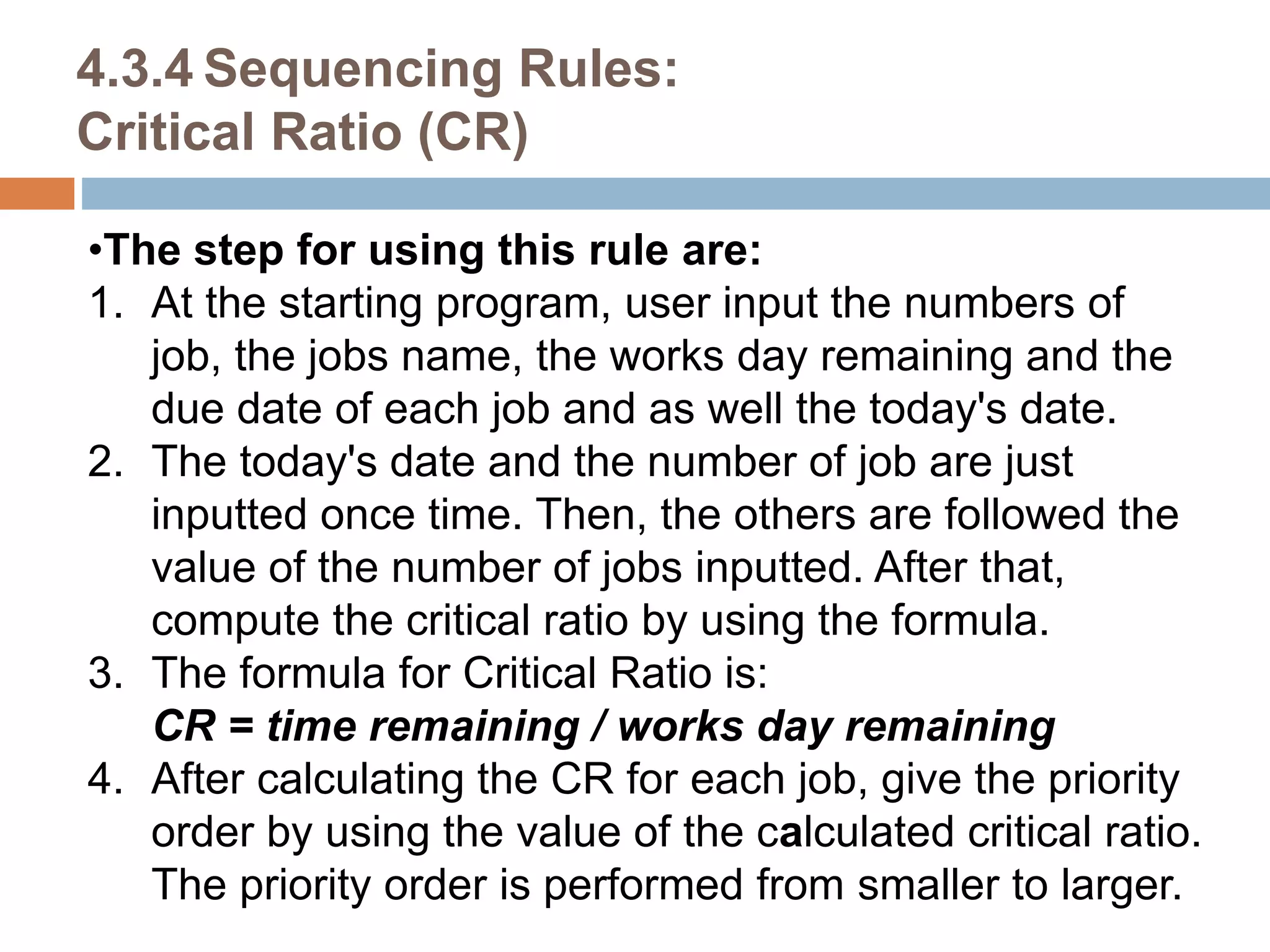

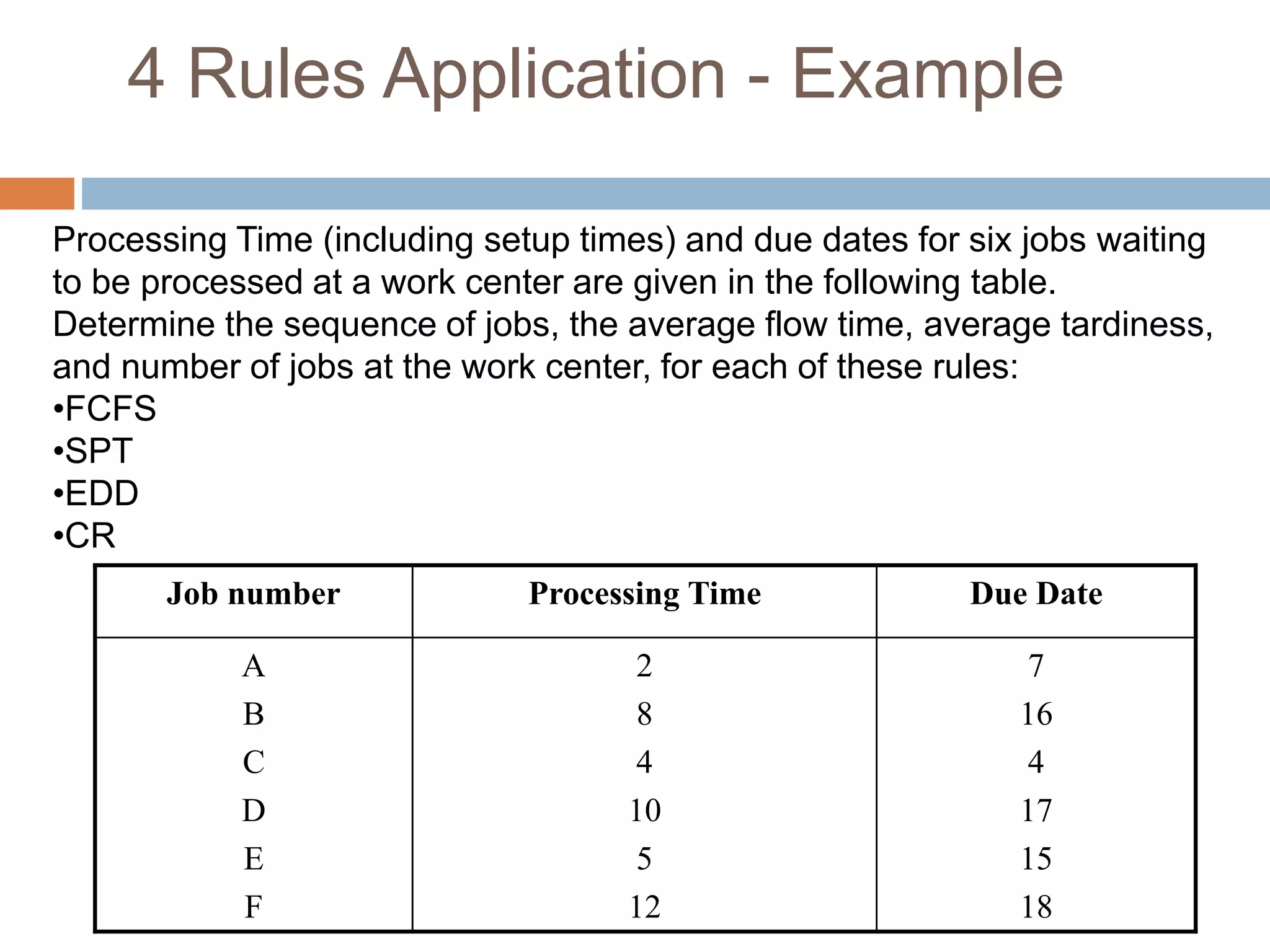

![4 Rules Application – Example

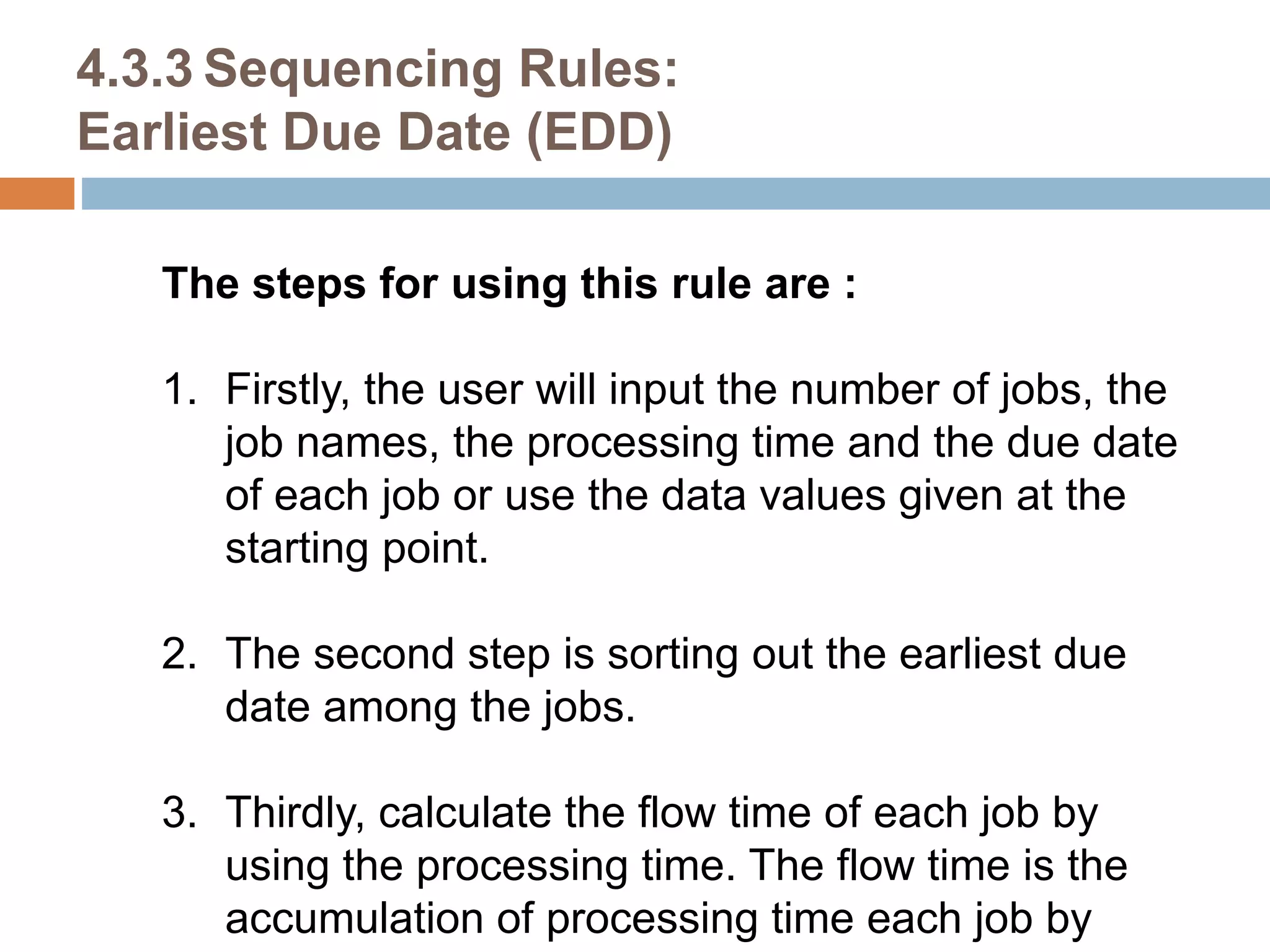

(CR)

Job Sequence Processing Time Due Date Critical Ratio

Calculation

A

B

C

D

E

F

2

8

-

10

5

12

7

16

-

17

15

18

(7-4) / 2 = 1.5

(16-4) / 8 = 1.5

-

(17-4) / 10 = 1.3

(15-4) / 5 = 2.2

(18-4) / 12 = 1.17 (Lowest)

At t=4, day 4 [C completed],

•Job F is the second job to complete base on the

lowest critical ratio.](https://image.slidesharecdn.com/fr-processscheduling-sequencing-rules-230224043756-7386d1ad/75/scheduling-sequencing-rules-pptx-33-2048.jpg)

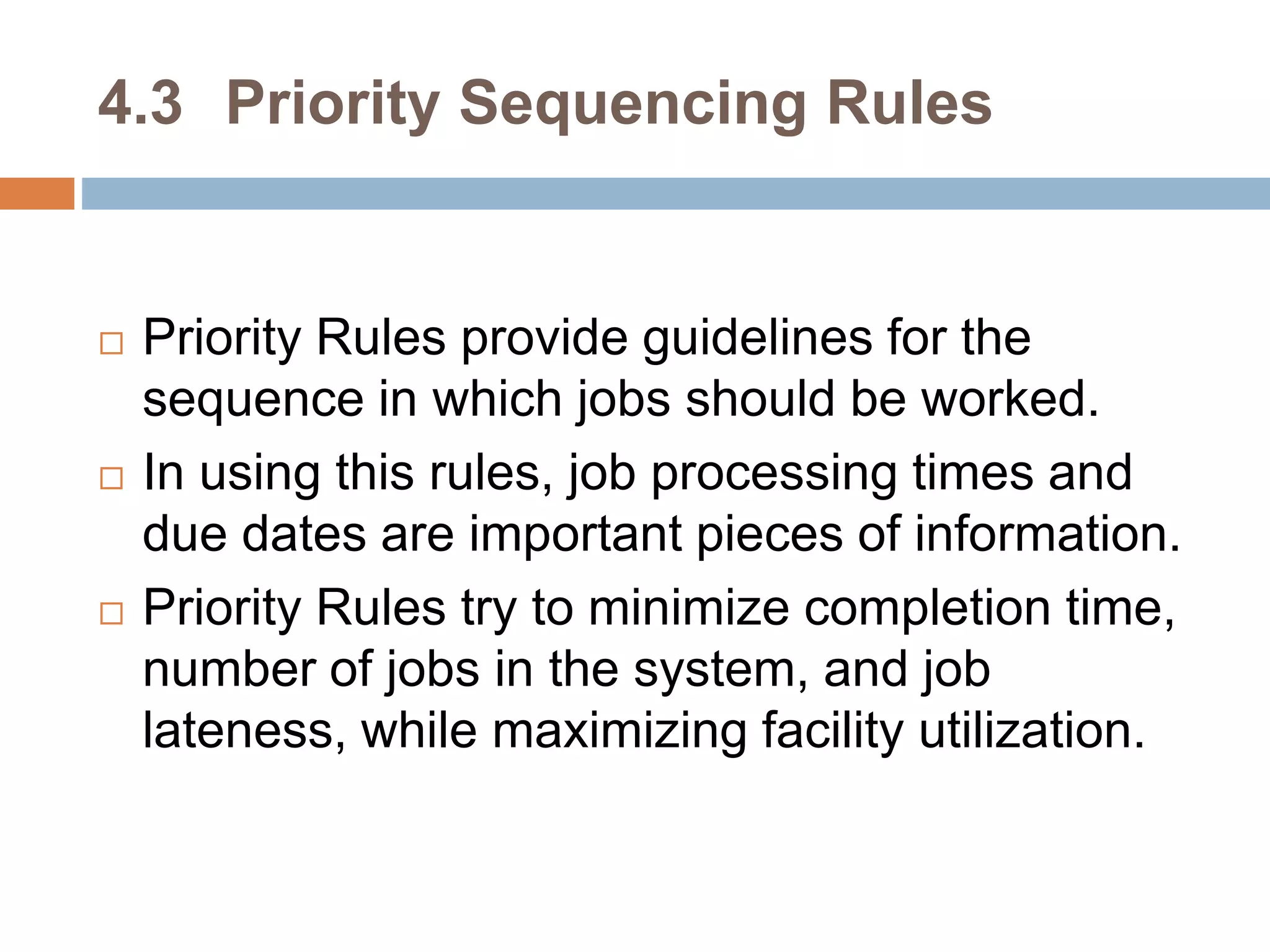

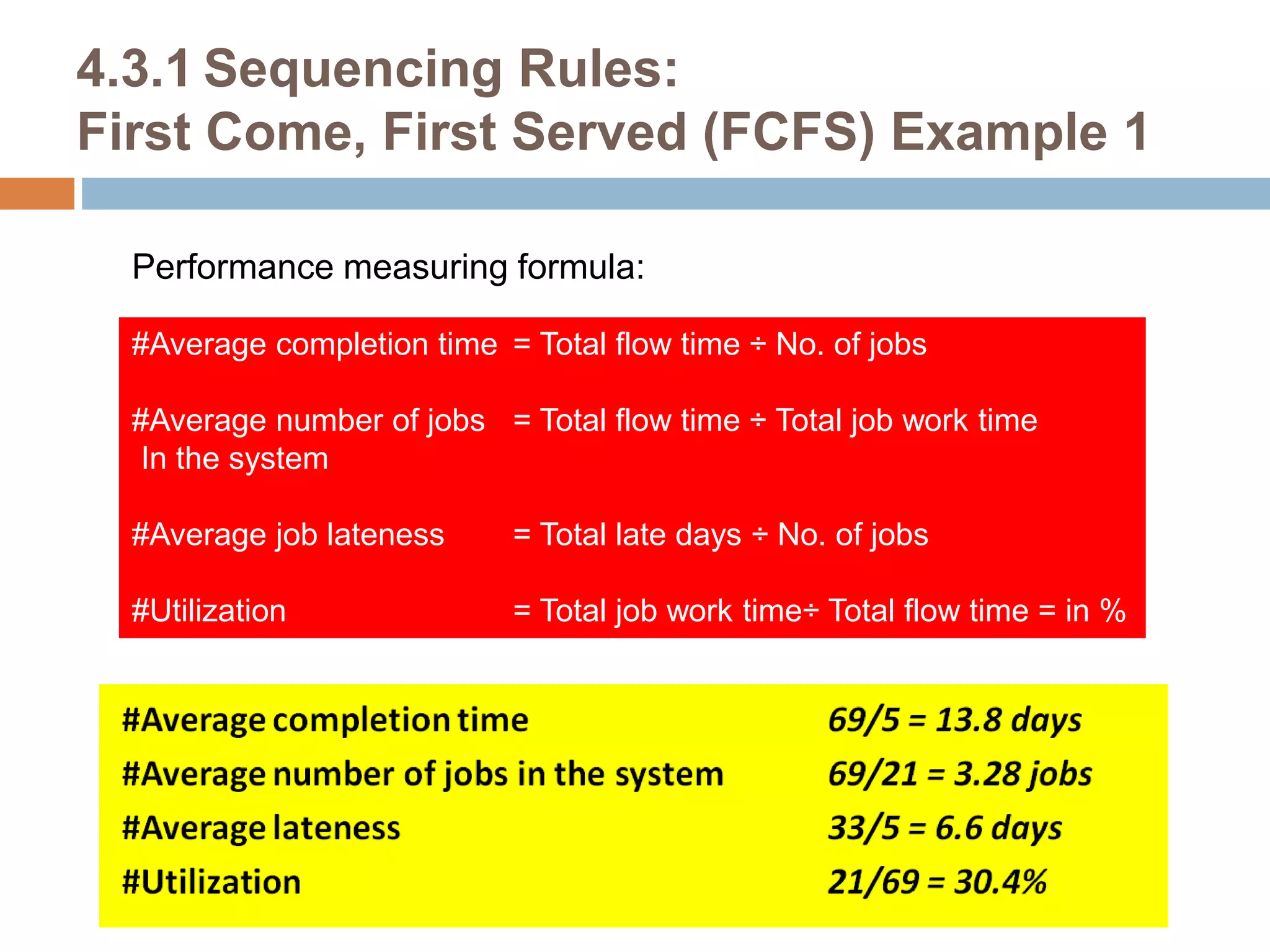

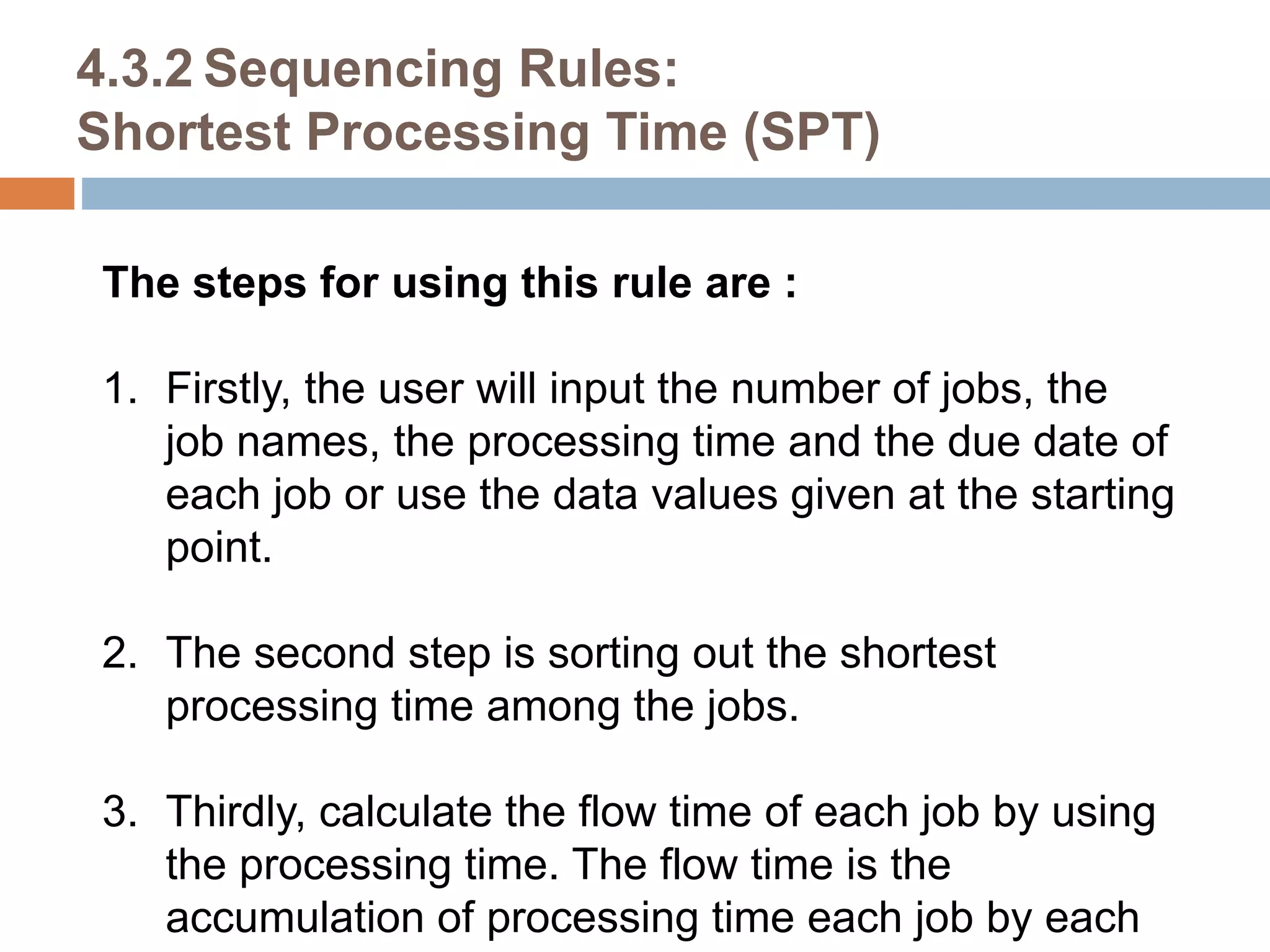

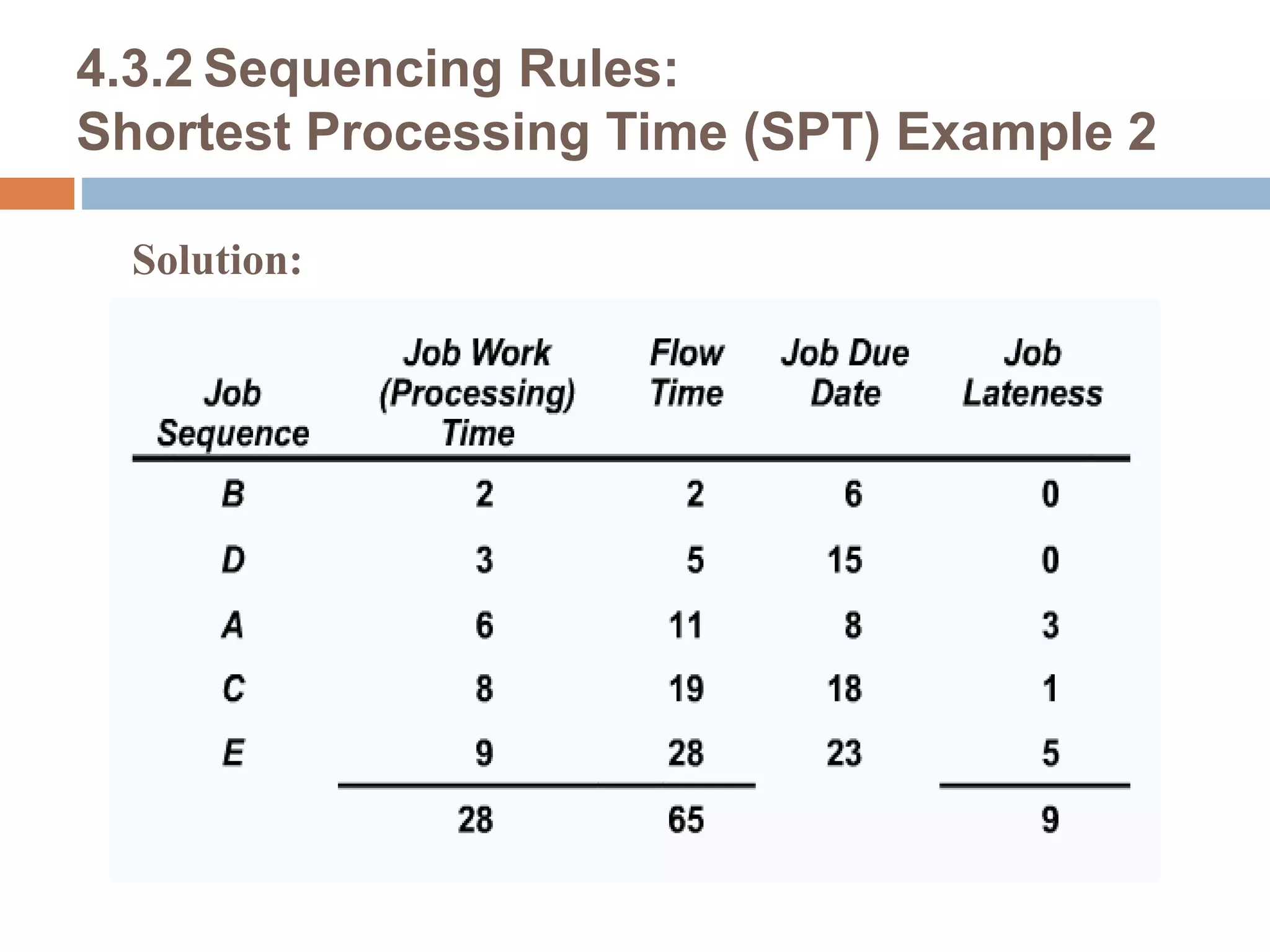

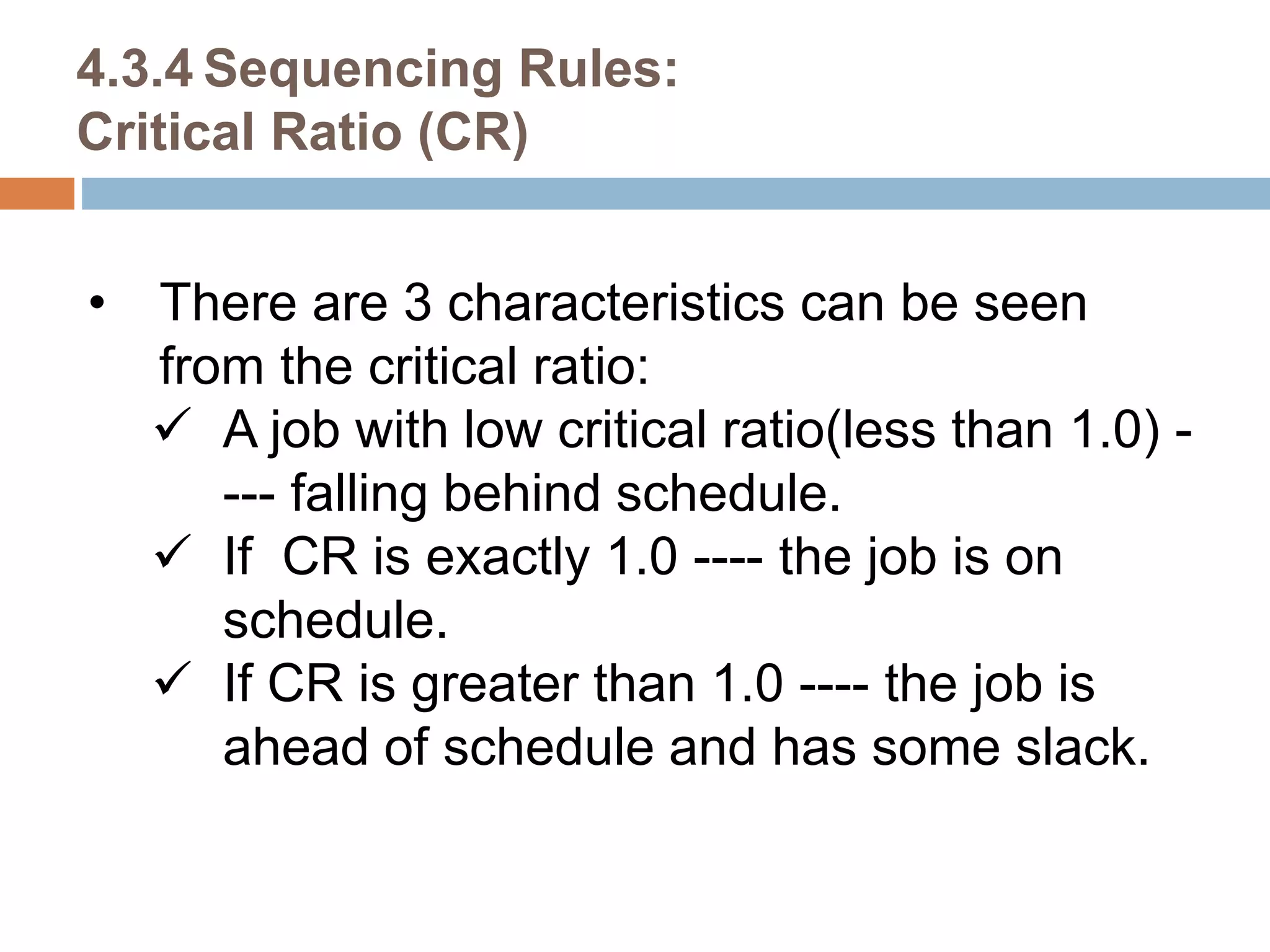

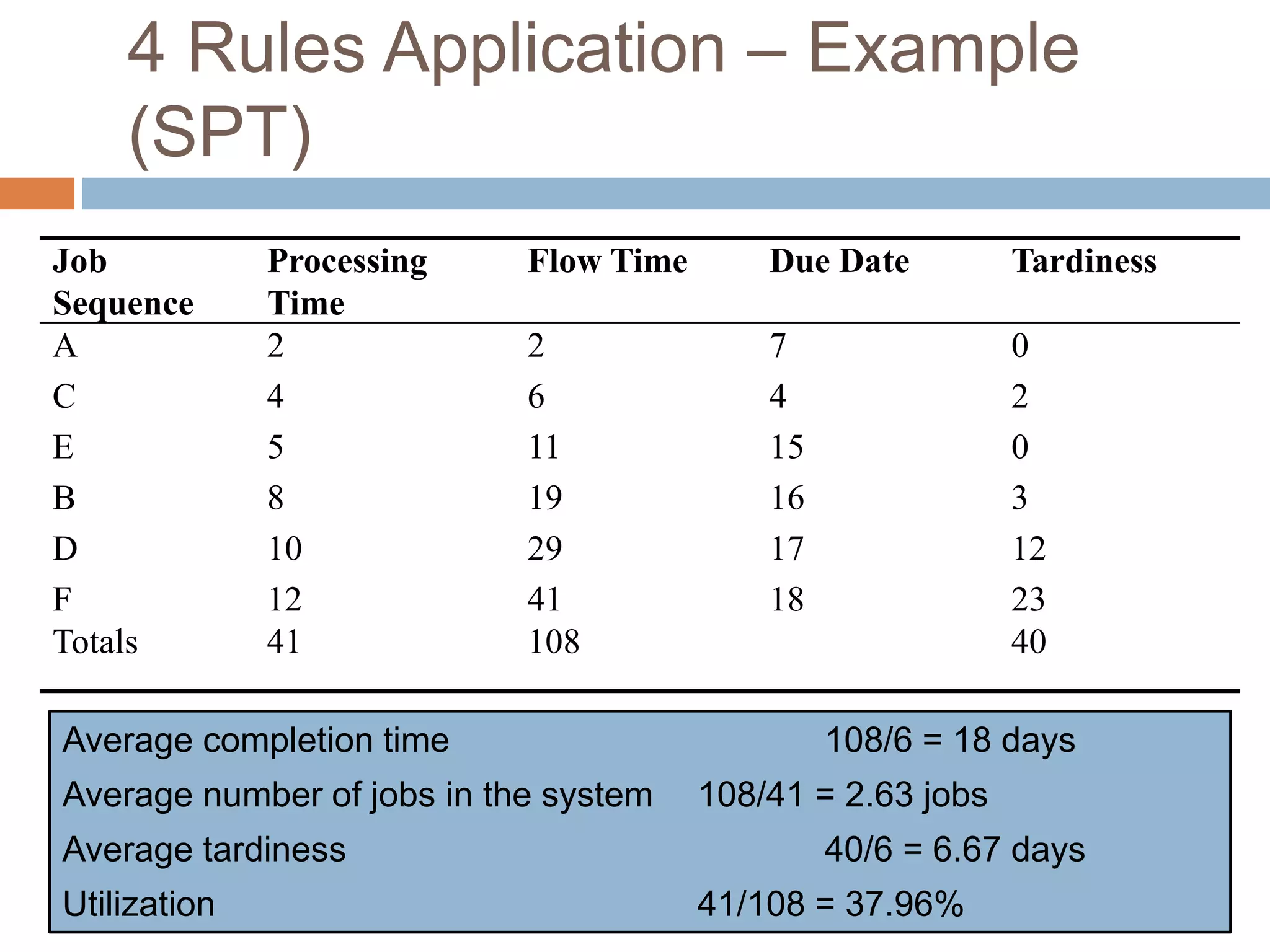

![4 Rules Application – Example

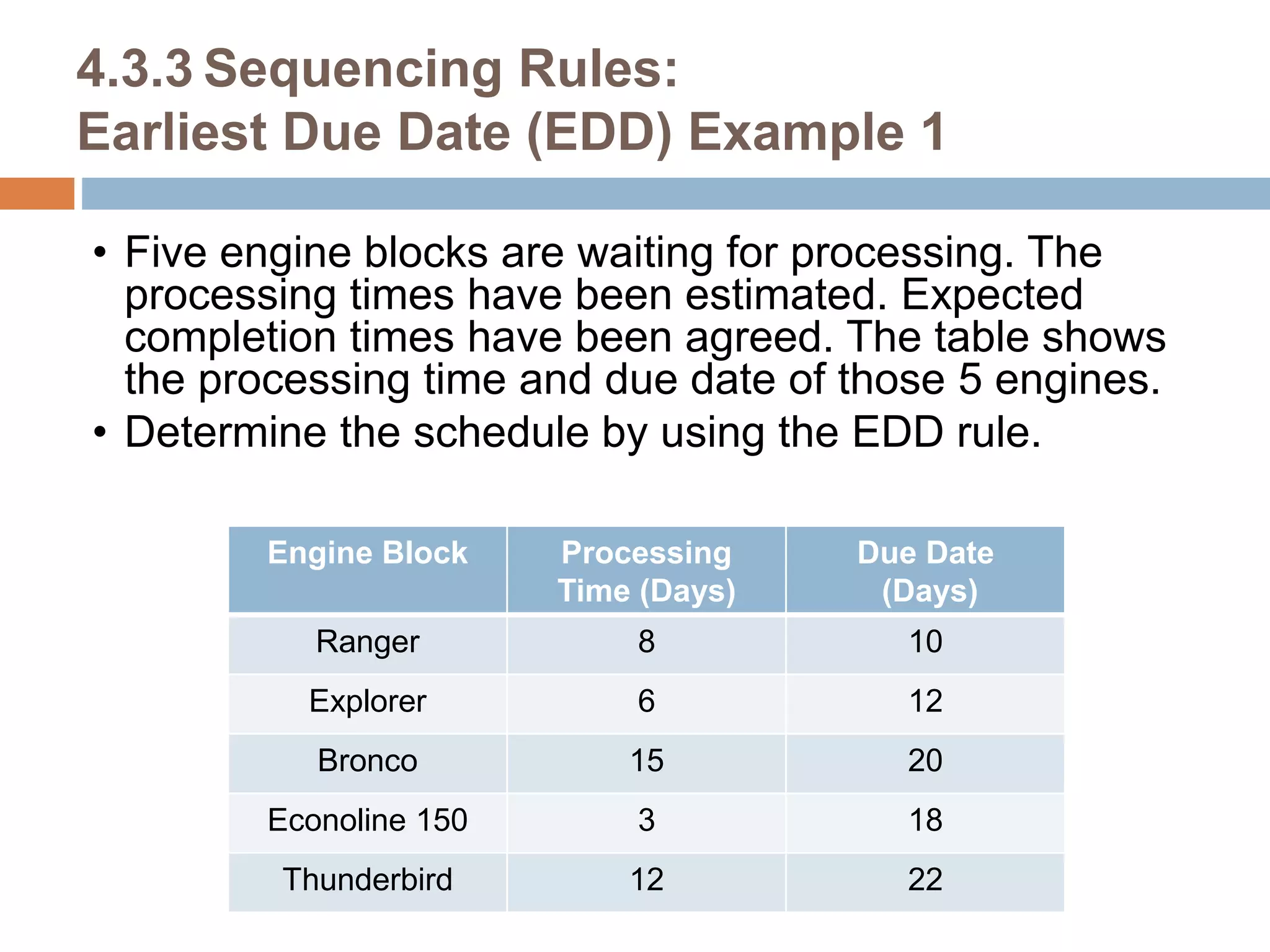

(CR)

Job Sequence Processing Time Due Date Critical Ratio

Calculation

A

B

C

D

E

F

2

8

-

10

5

-

7

16

-

17

15

-

(7-16) / 2 = -4.5 (Lowest)

(16-16) / 8 = 0

-

(17-16) / 10 = 0.1

(15-16) / 5 = -0.2

-

At t=16, day 16 [C and F completed],

•Job A is the third job to complete base on the

lowest critical ratio.](https://image.slidesharecdn.com/fr-processscheduling-sequencing-rules-230224043756-7386d1ad/75/scheduling-sequencing-rules-pptx-34-2048.jpg)

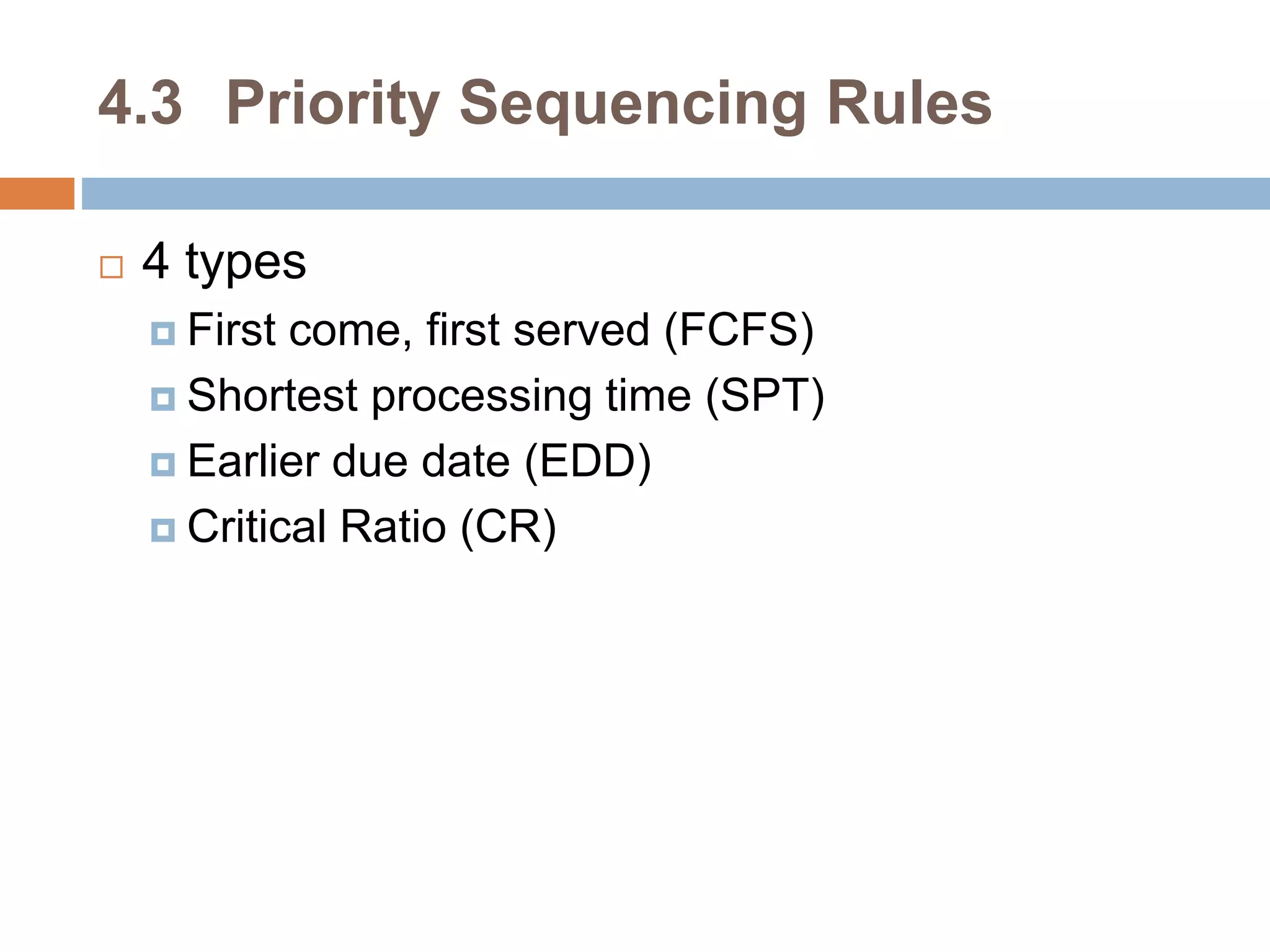

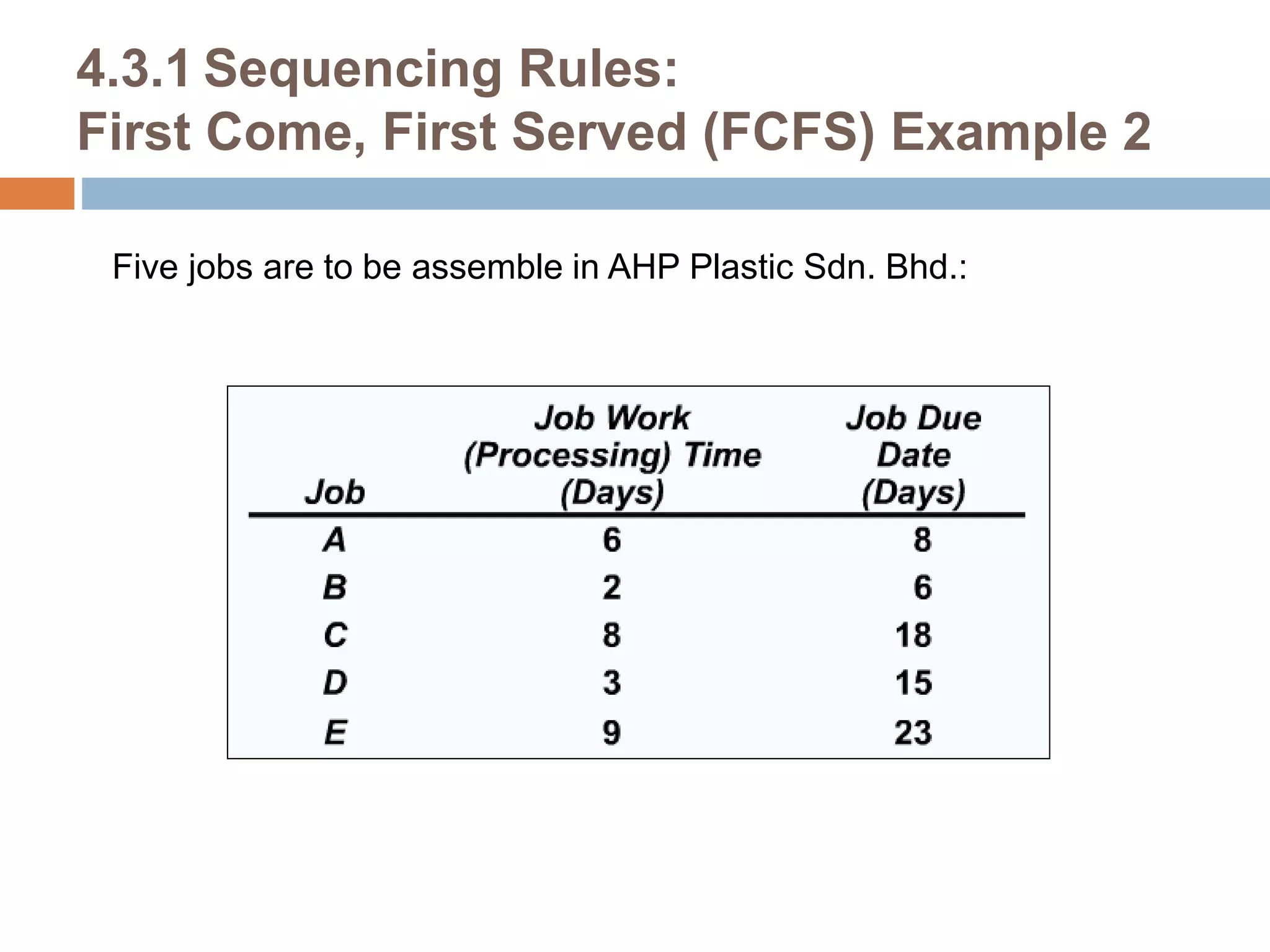

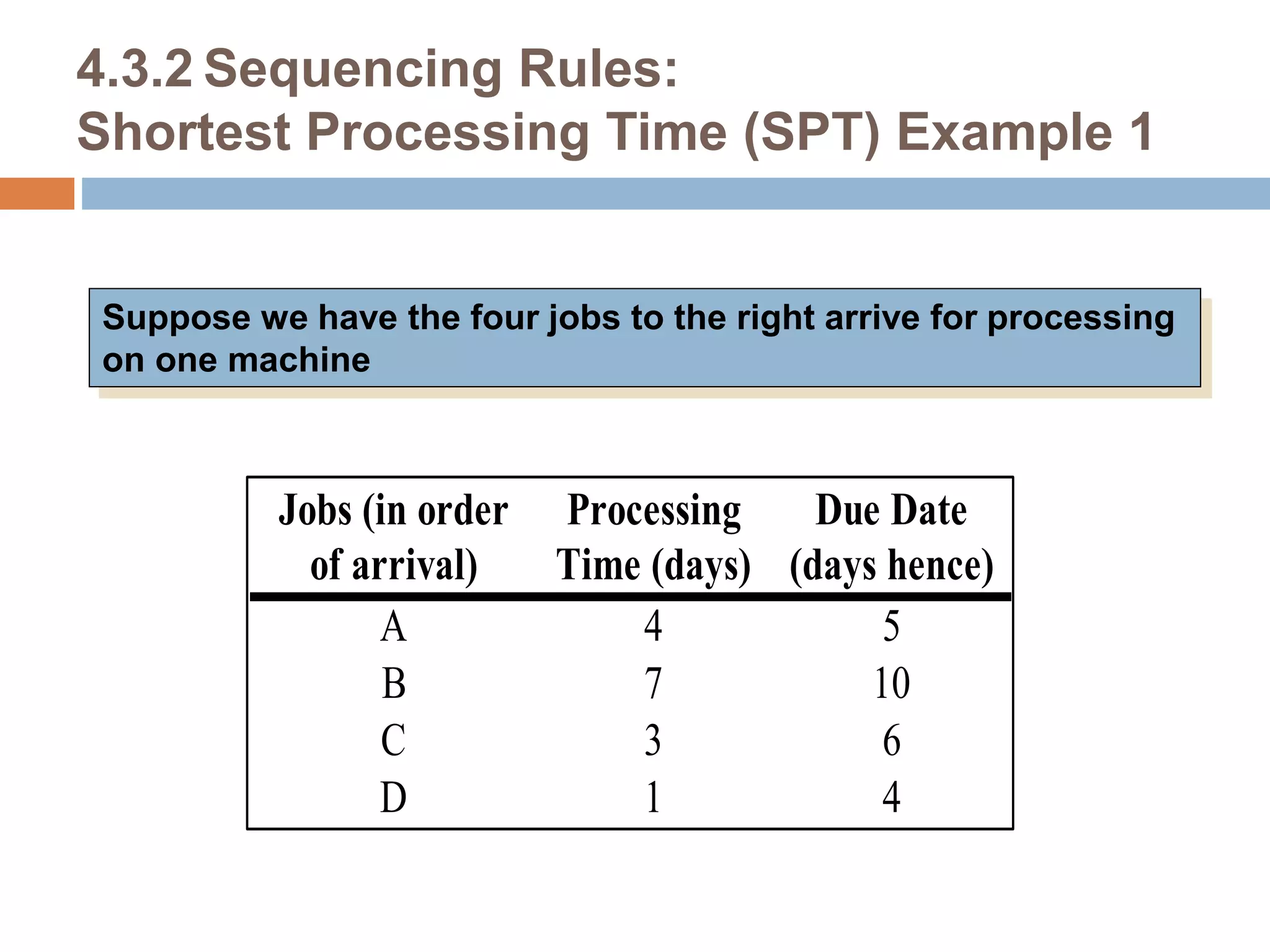

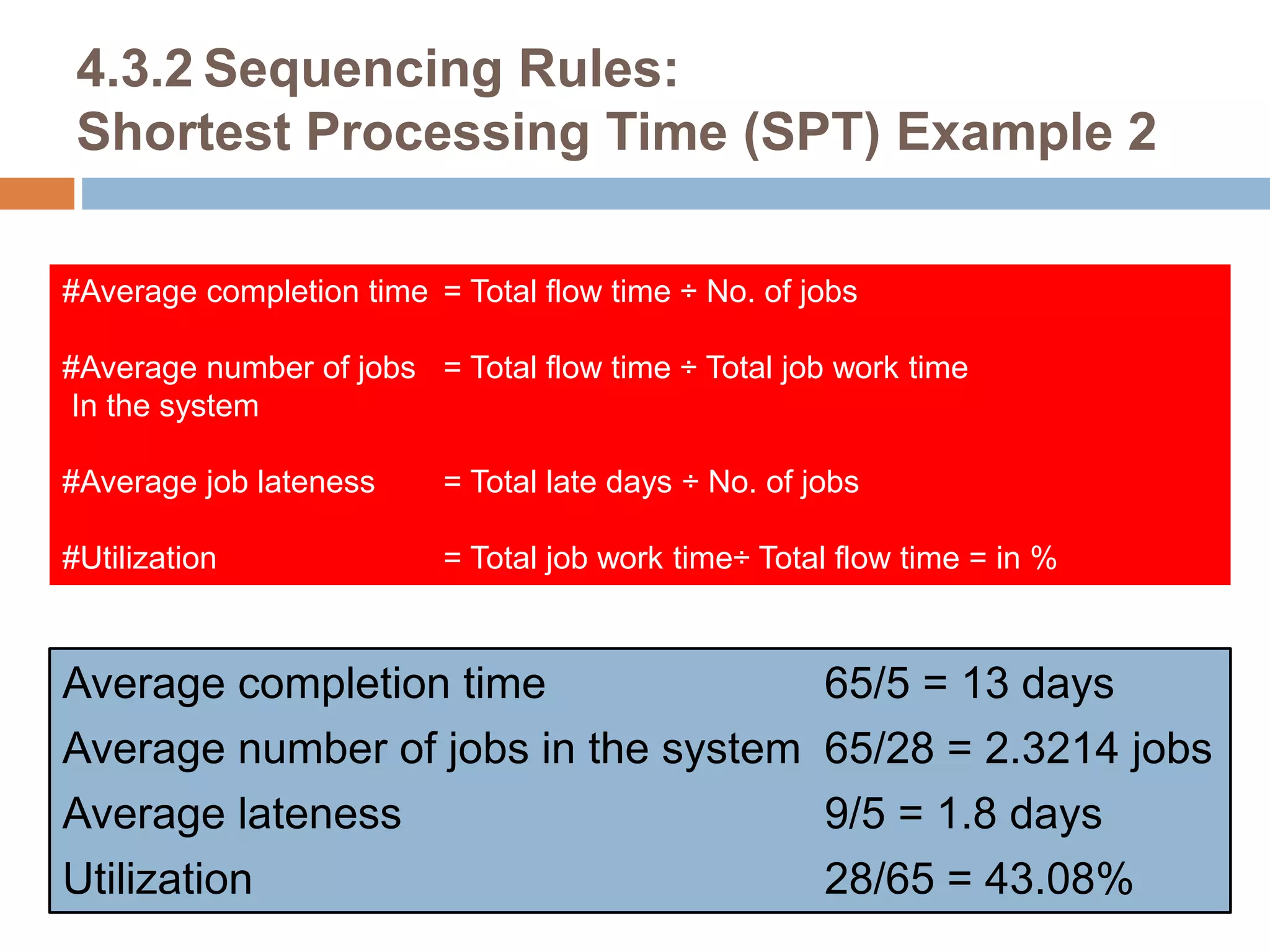

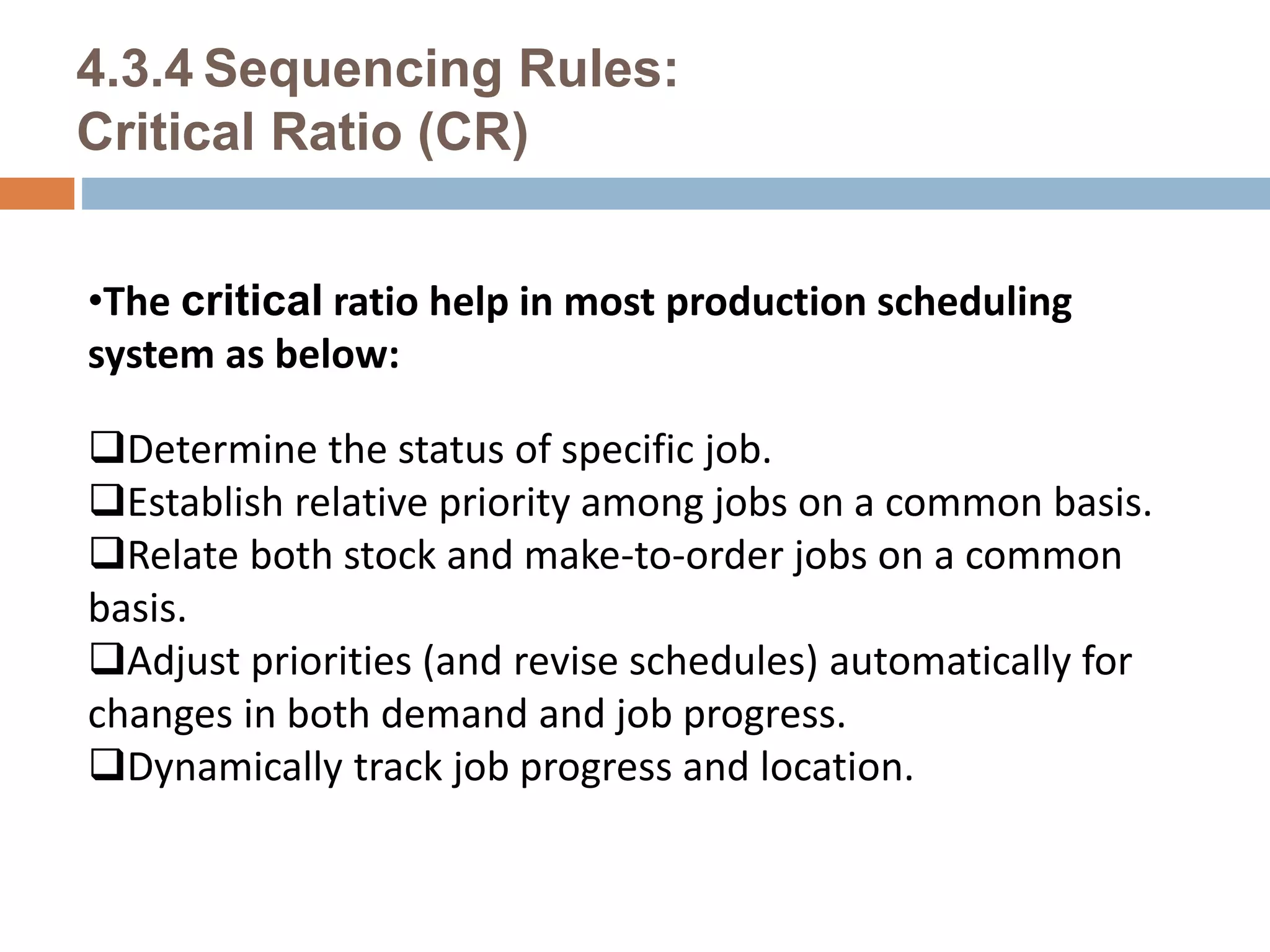

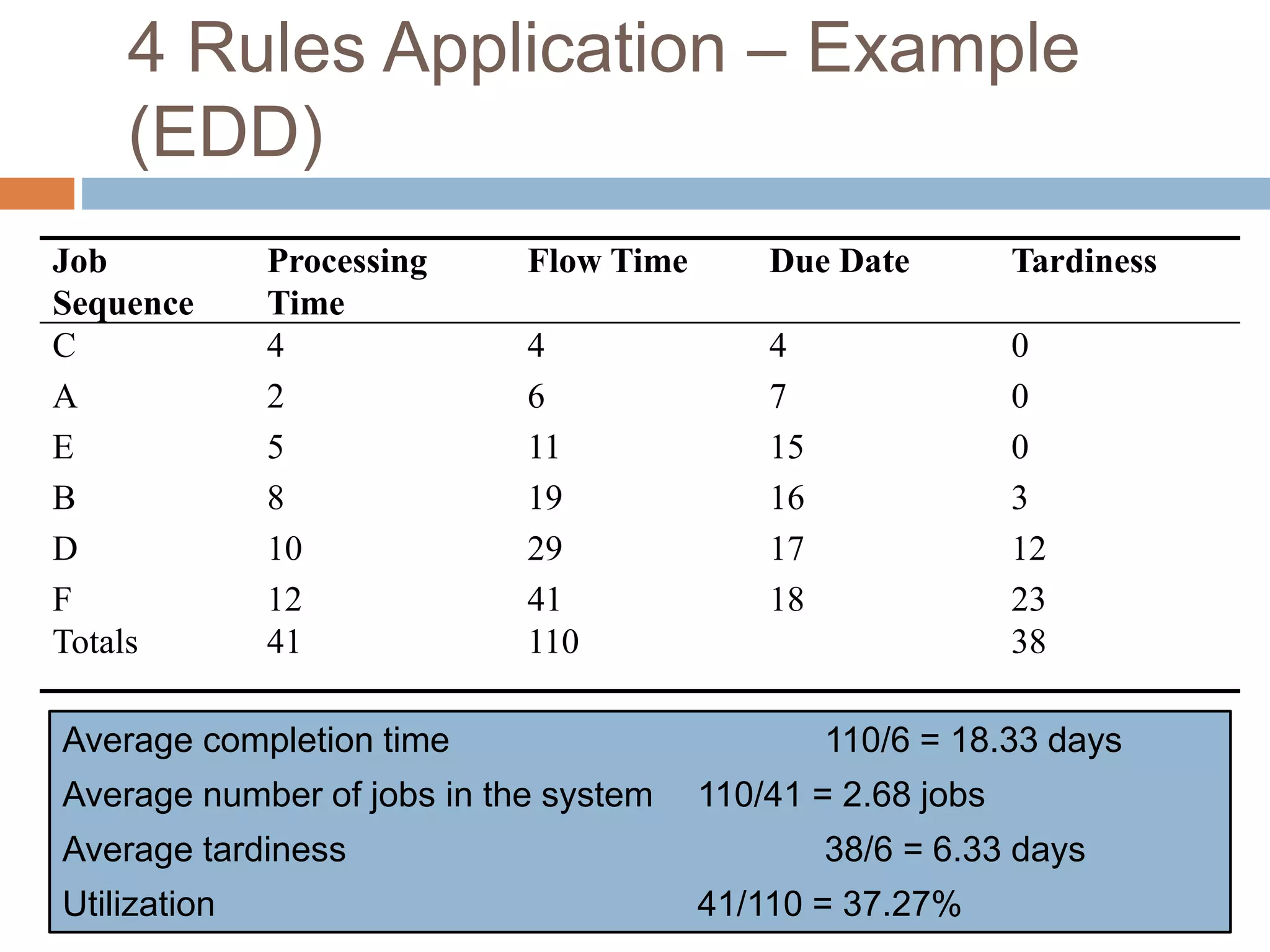

![4 Rules Application – Example

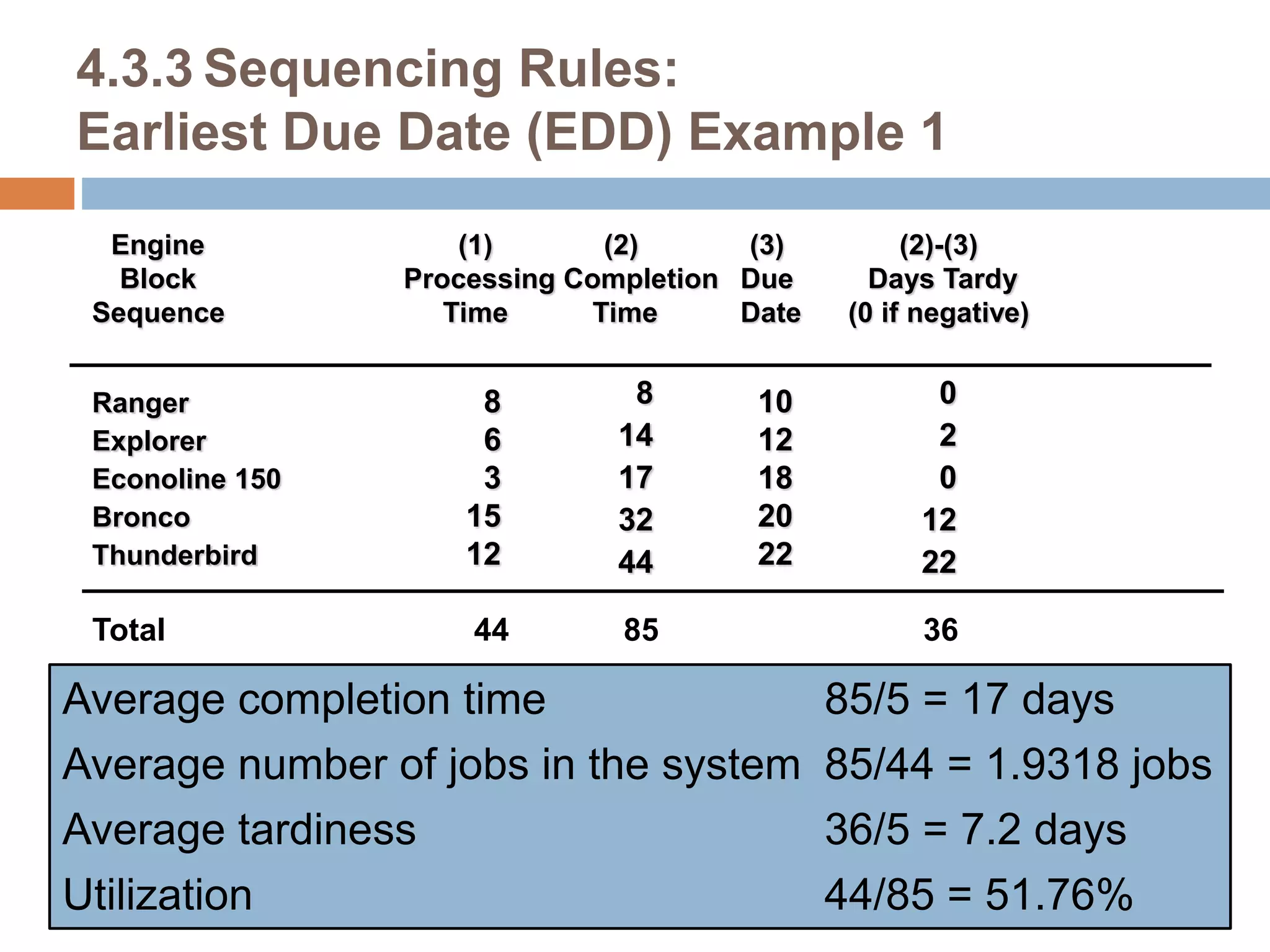

(CR)

Job Sequence Processing Time Due Date Critical Ratio Calculation

A

B

C

D

E

F

-

8

-

10

5

-

-

16

-

17

15

-

-

(16-18) / 8 = -0.25

-

(17-18) / 10 = -0.10

(15-18) / 5 = -0.60 (Lowest)

-

At t=18, day 18 [C, F and A completed],

•Job E is the fourth job to complete base on the

lowest critical ratio.](https://image.slidesharecdn.com/fr-processscheduling-sequencing-rules-230224043756-7386d1ad/75/scheduling-sequencing-rules-pptx-35-2048.jpg)

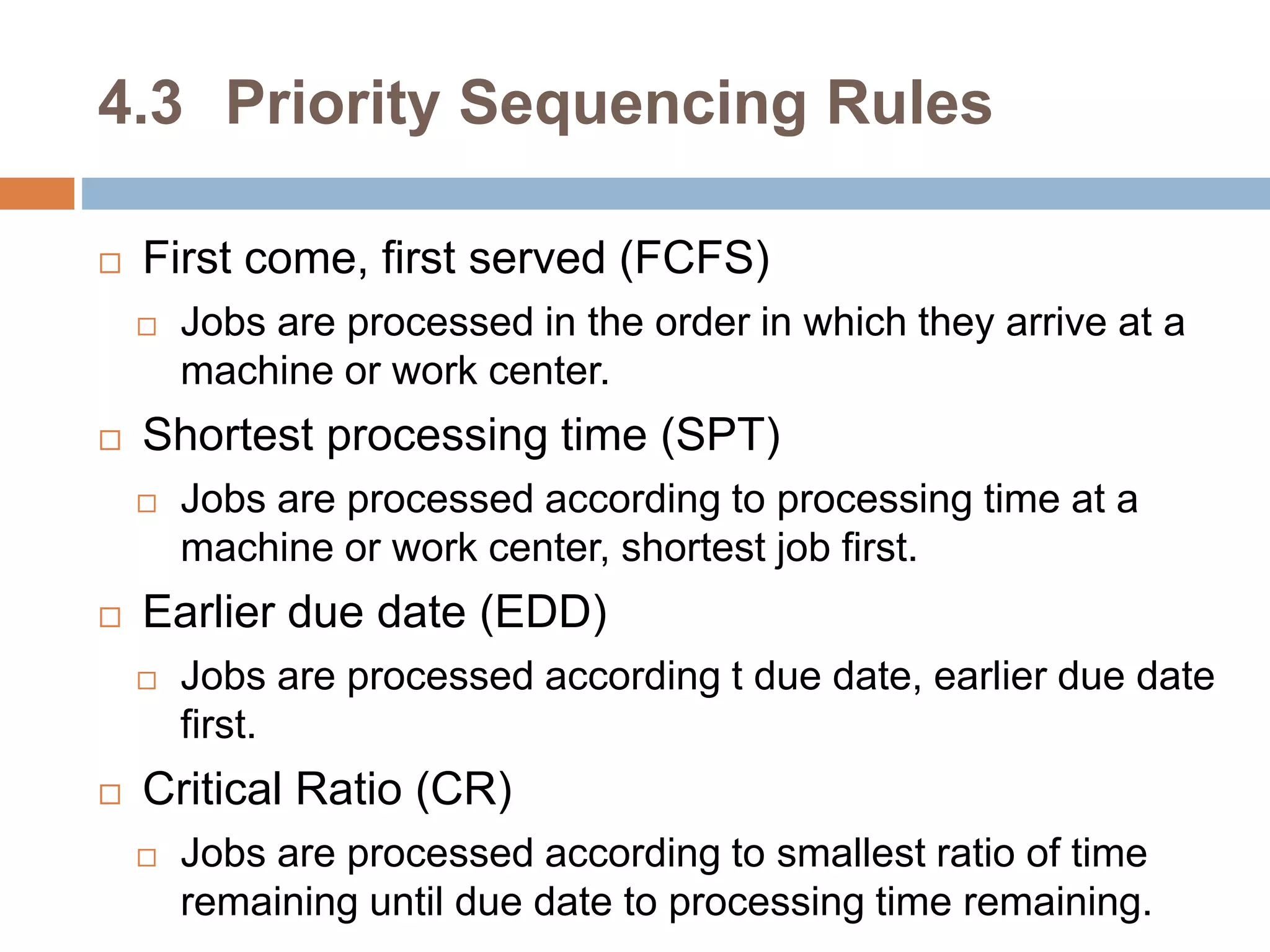

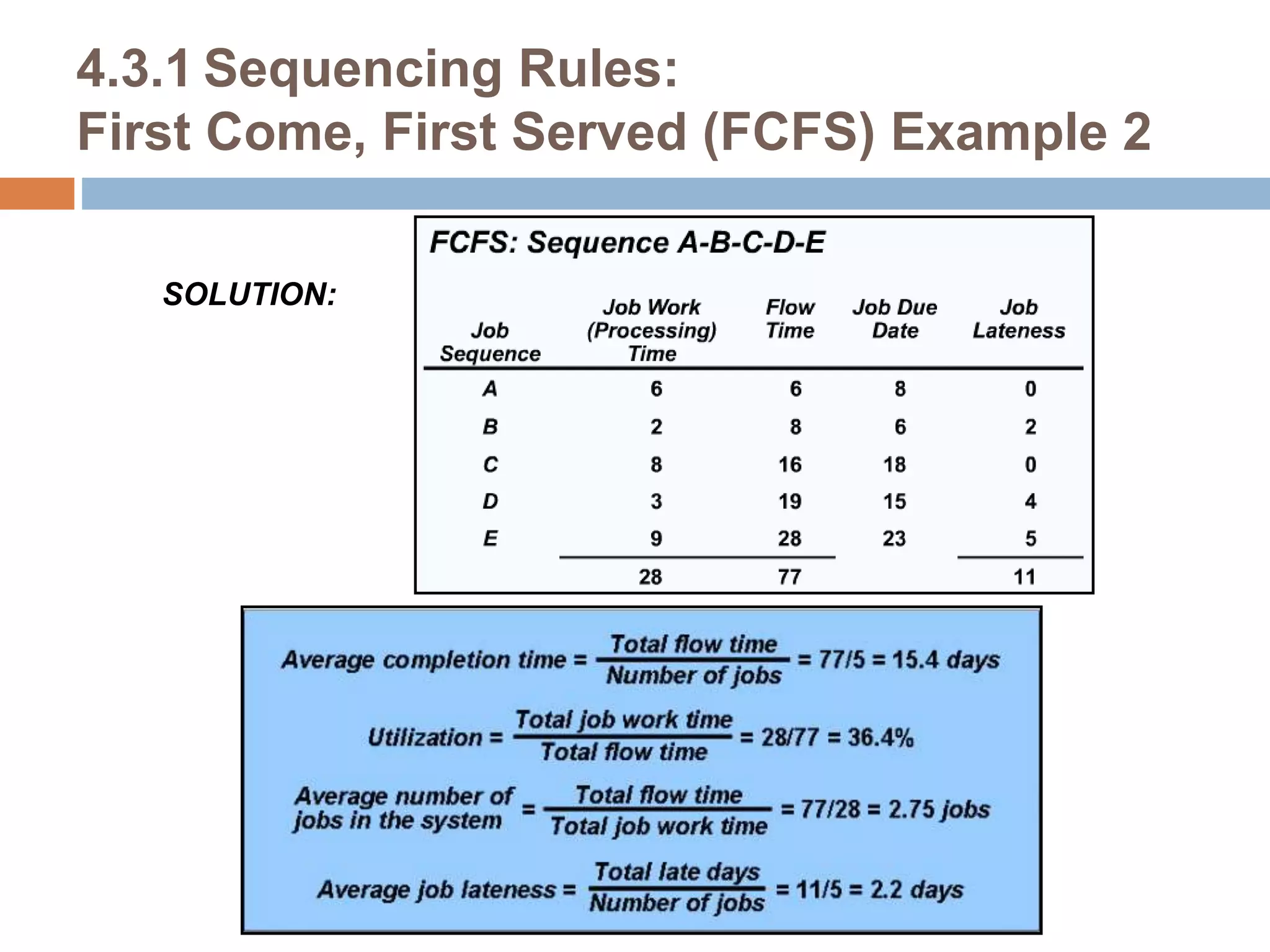

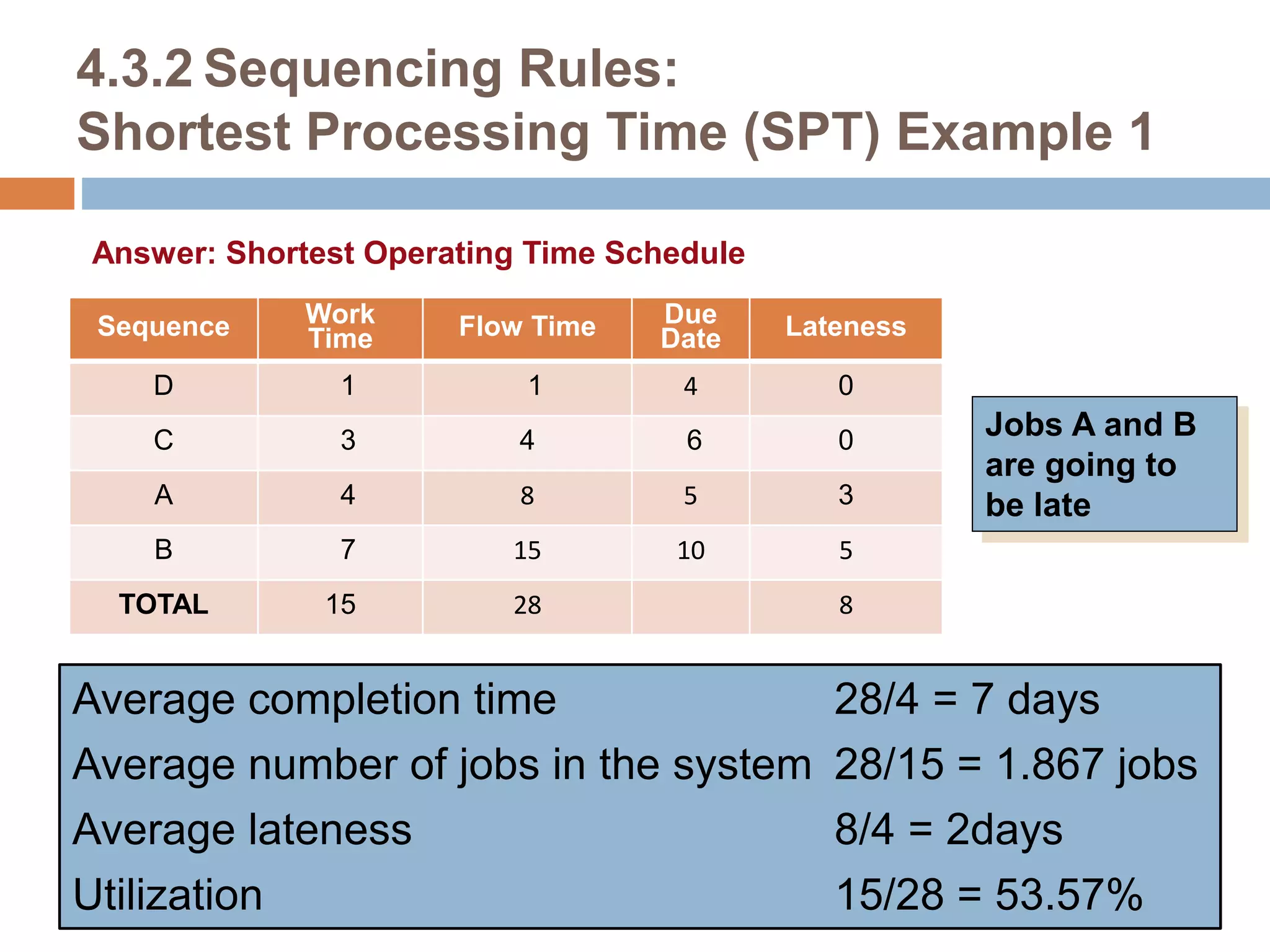

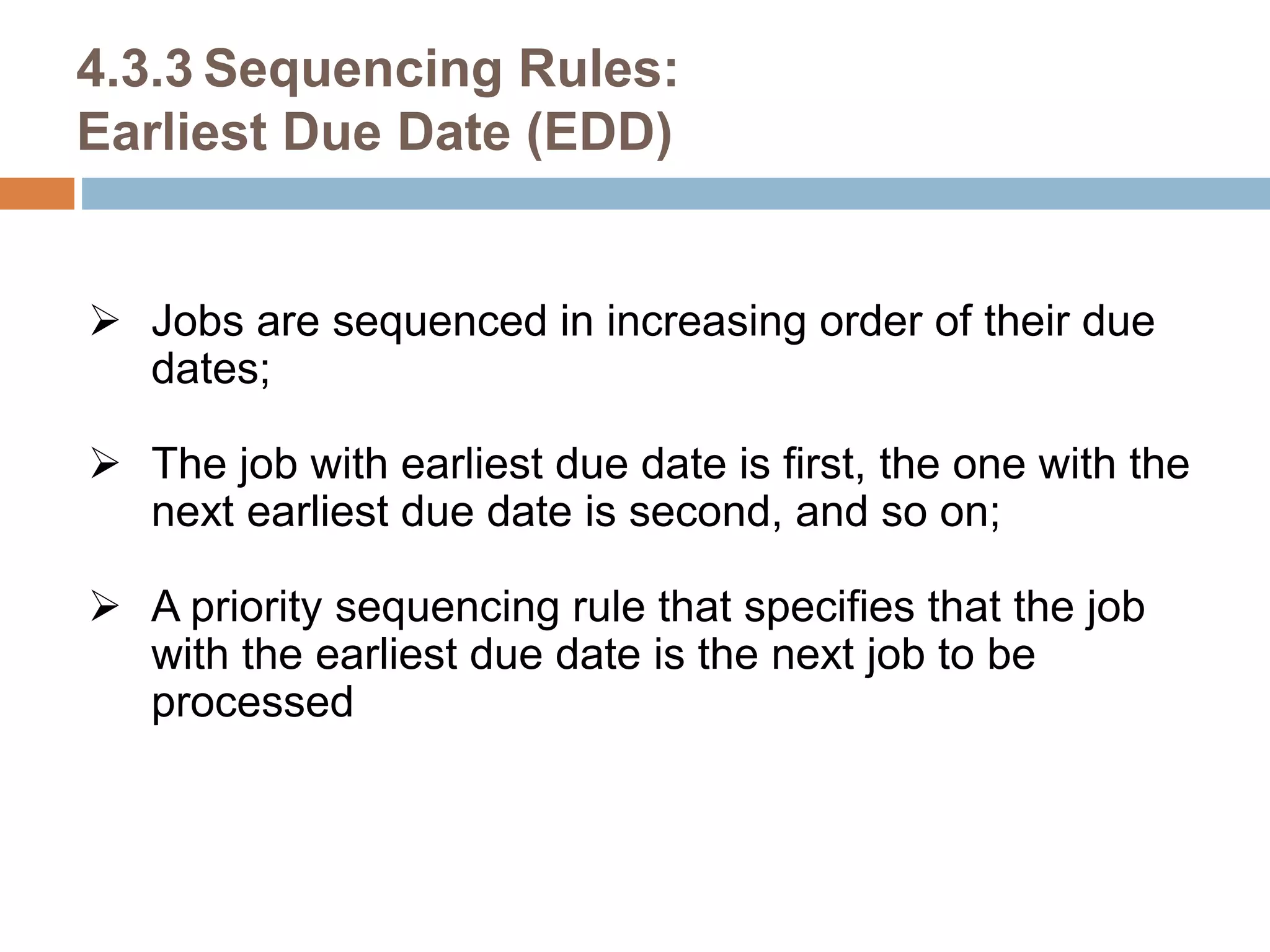

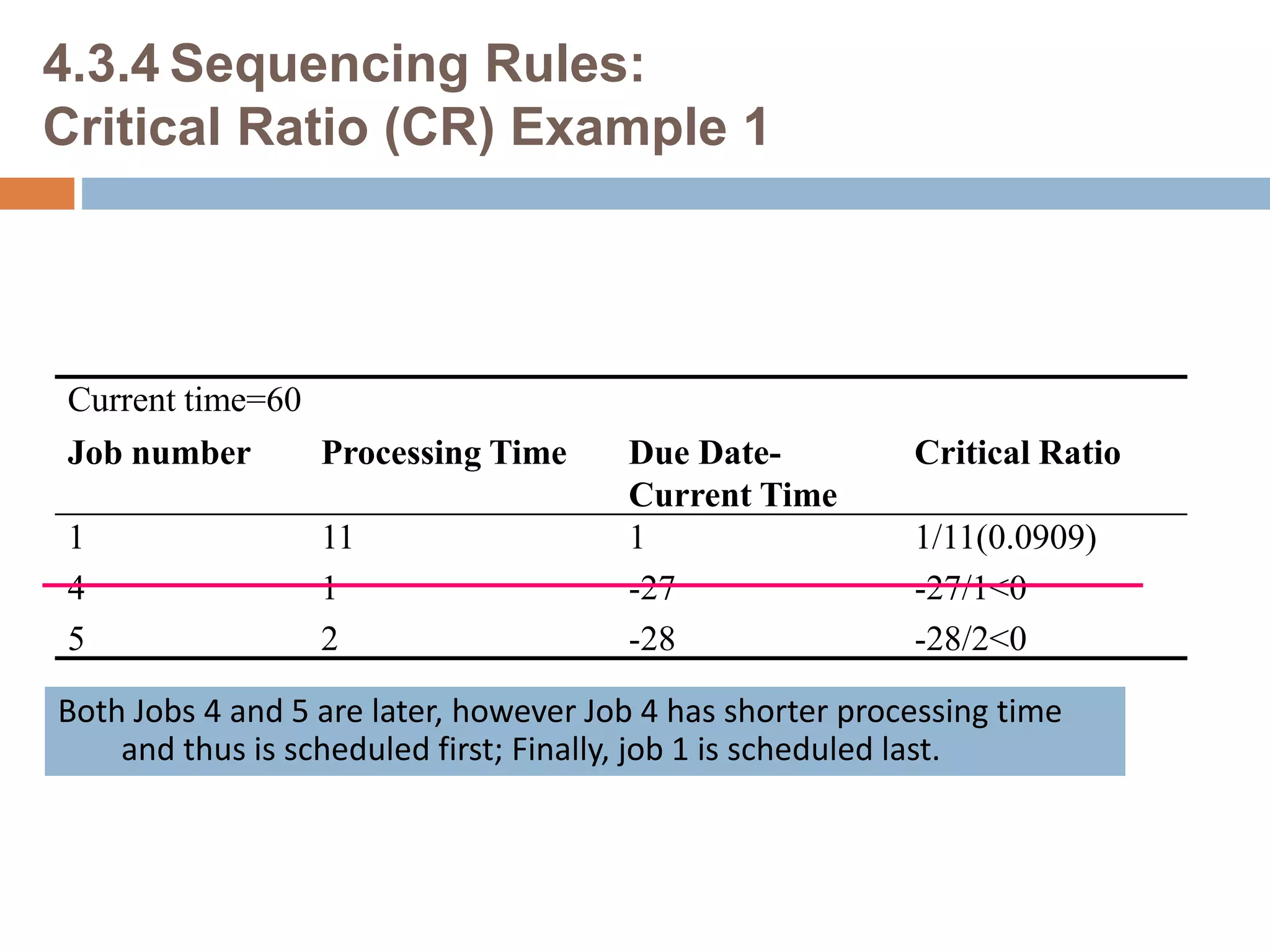

![4 Rules Application – Example

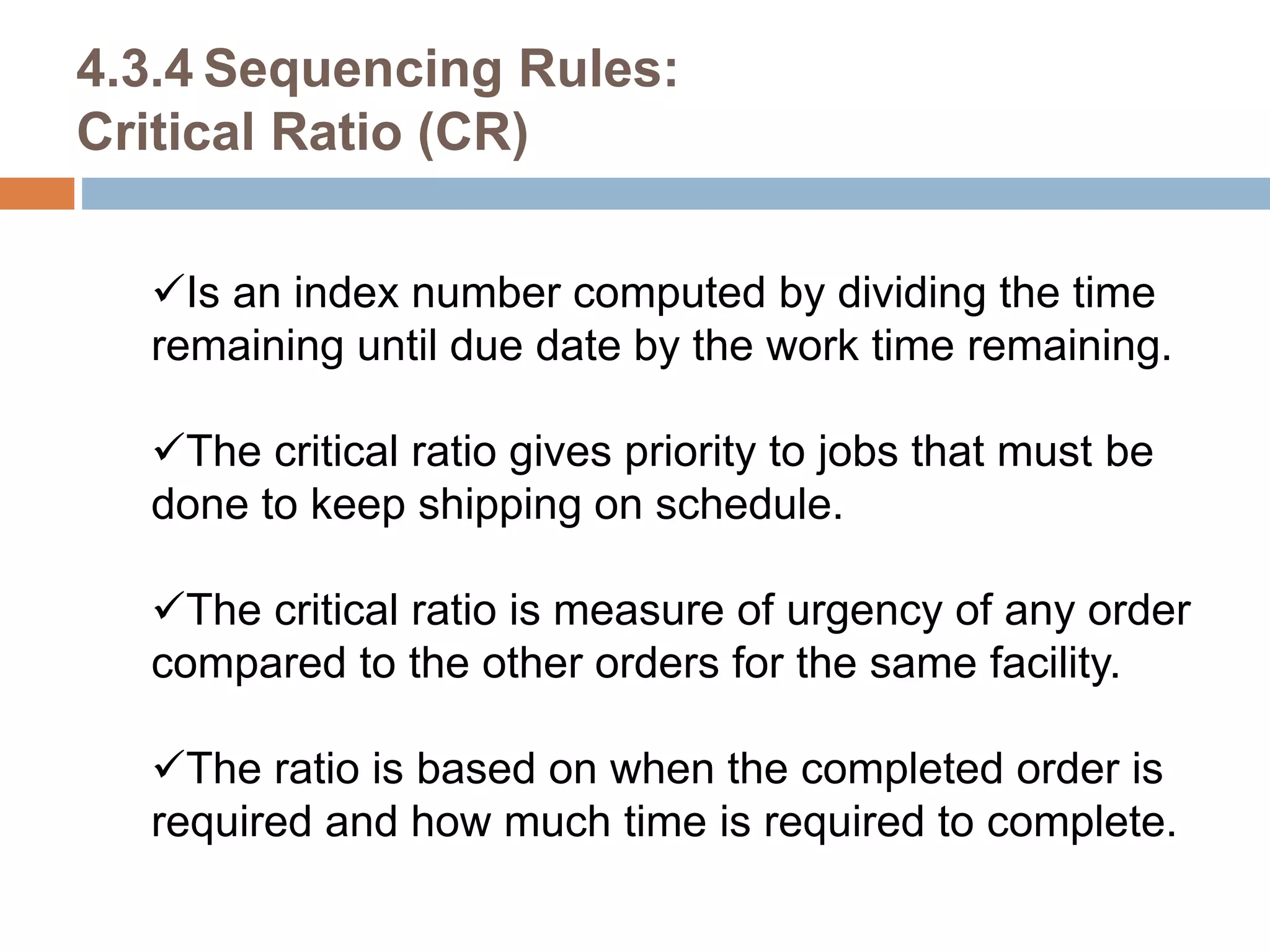

(CR)

Job Sequence Processing Time Due Date Critical Ratio Calculation

A

B

C

D

E

F

-

8

-

10

-

-

-

16

-

17

-

-

-

(16-23) / 8 = -0.875 (Lowest)

-

(17-23) / 10 = -0.60

-

-

At t=23, day 23 [C, F, A and E completed],

•Job B is the fifth job to complete base on the lowest

critical ratio and follow by Job D in last.](https://image.slidesharecdn.com/fr-processscheduling-sequencing-rules-230224043756-7386d1ad/75/scheduling-sequencing-rules-pptx-36-2048.jpg)