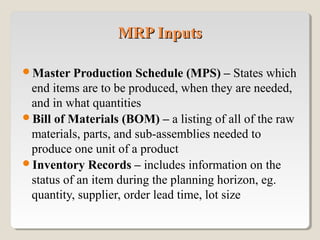

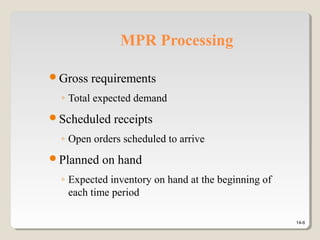

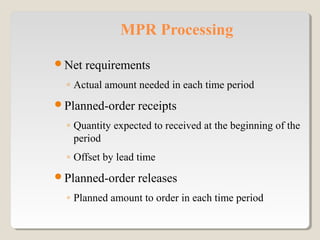

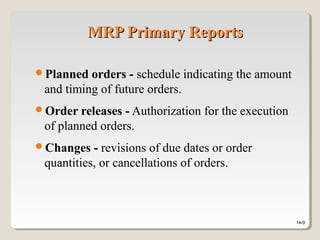

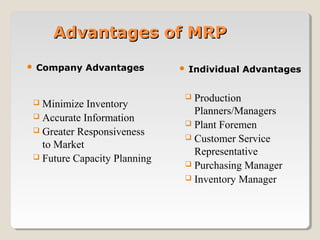

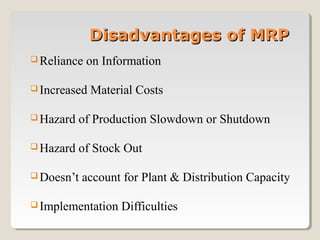

This document provides an overview of material requirements planning (MRP). MRP is a computer-based information system that translates master schedule requirements for end items into time-phased requirements for subassemblies, components, and raw materials. The key inputs to MRP are the master production schedule, bill of materials, and inventory records. MRP processing involves calculating gross requirements, scheduled receipts, projected on hand, net requirements, planned-order receipts, and planned-order releases. The primary outputs of MRP are planned orders, order releases, and changes to due dates or order quantities. MRP provides advantages like minimized inventory, accurate information, and greater responsiveness, but also has disadvantages such as reliance on accurate information