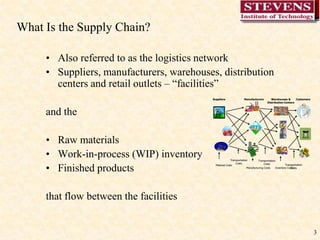

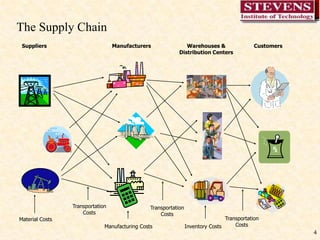

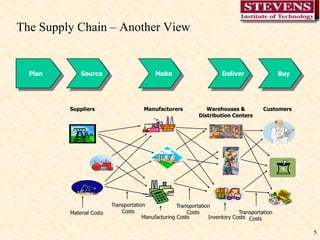

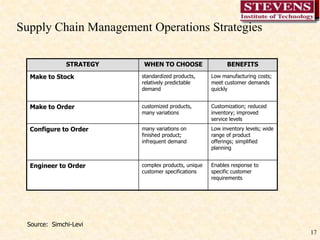

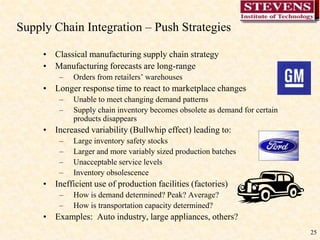

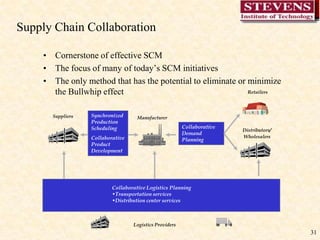

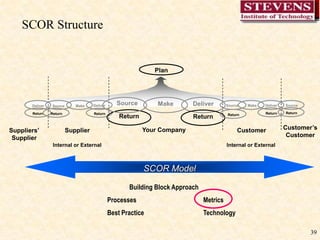

1. A supply chain involves all parties involved in fulfilling a customer request, including suppliers, manufacturers, distributors, and retailers. Materials and products flow between these entities.

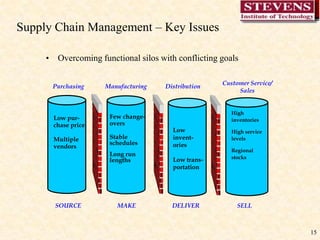

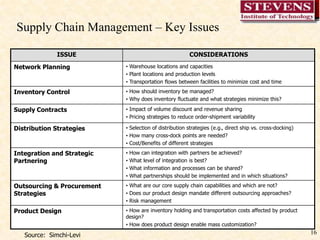

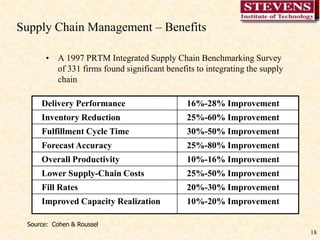

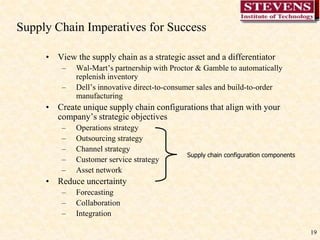

2. Supply chain management (SCM) aims to efficiently integrate these entities so that the right products are delivered to the right place at the right time while minimizing costs.

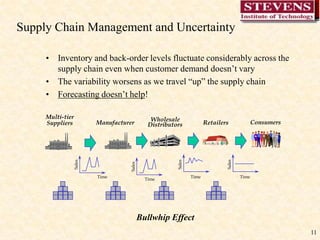

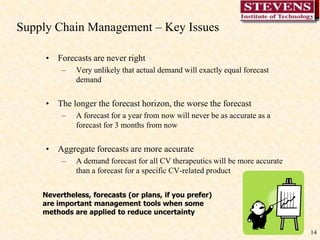

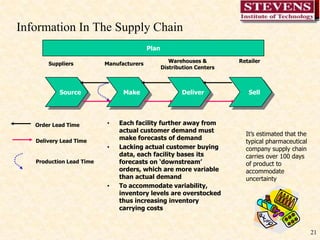

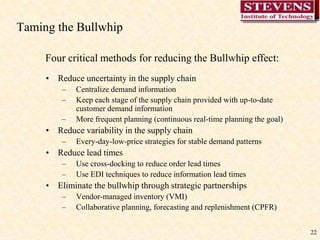

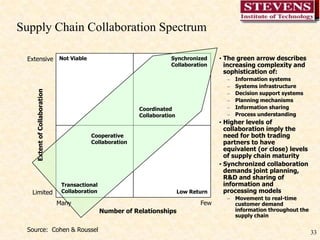

3. Uncertainty is inherent in supply chains and can cause fluctuations in inventory levels and backorders, even if customer demand remains steady. SCM strategies aim to reduce this uncertainty and its negative effects.