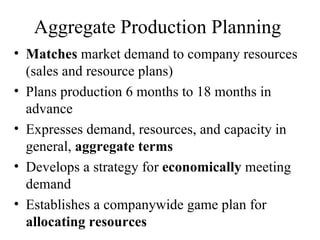

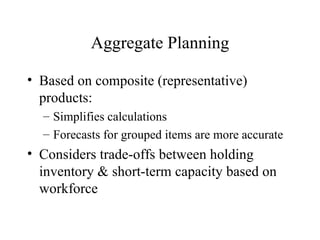

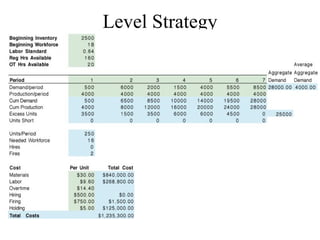

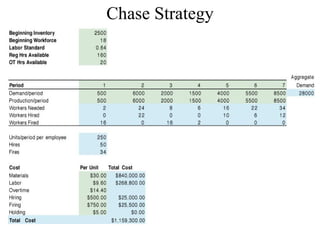

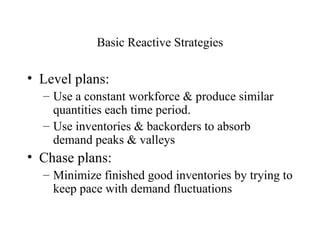

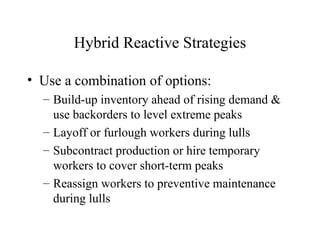

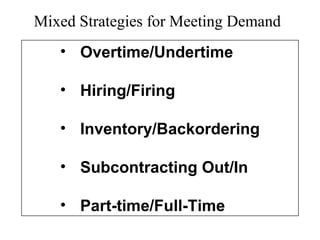

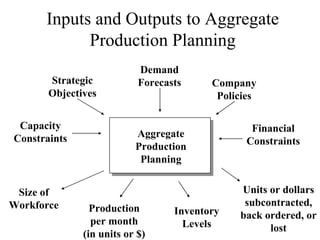

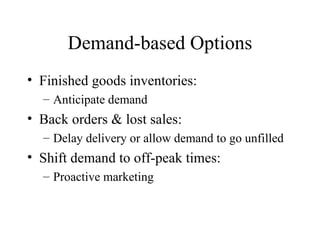

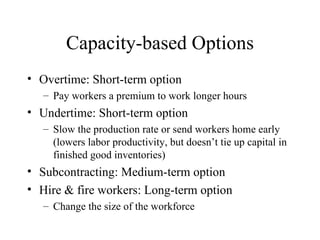

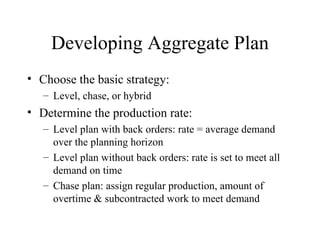

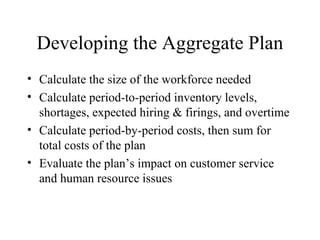

Aggregate planning is intermediate-range production and capacity planning that covers 6 to 18 months. It matches market demand to company resources by developing a strategy to economically meet demand through establishing production rates and workforce levels. Aggregate planning uses composite products to simplify calculations and considers trade-offs between inventory levels and short-term capacity. It can take proactive or reactive approaches to coordinate marketing and production plans.