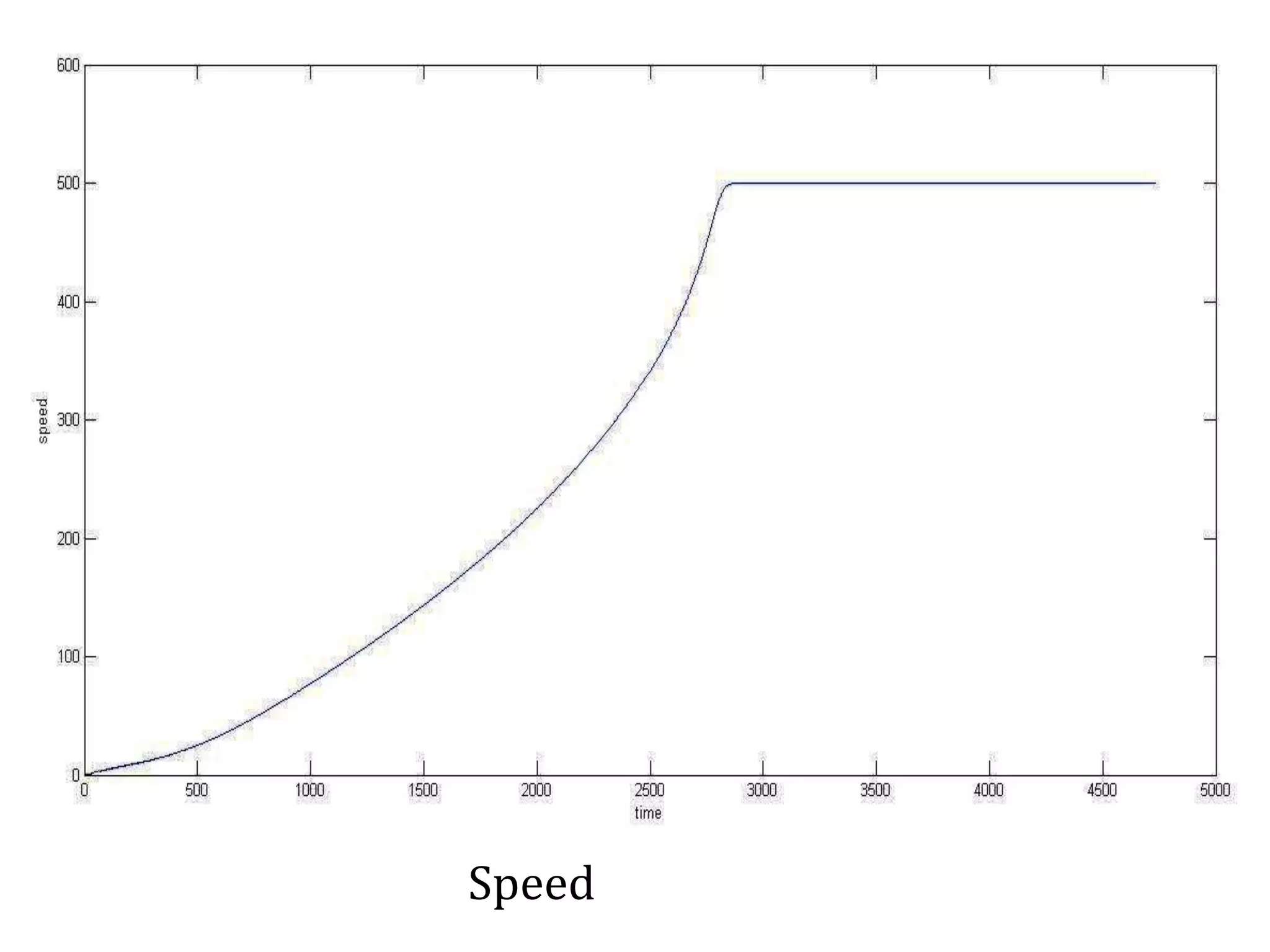

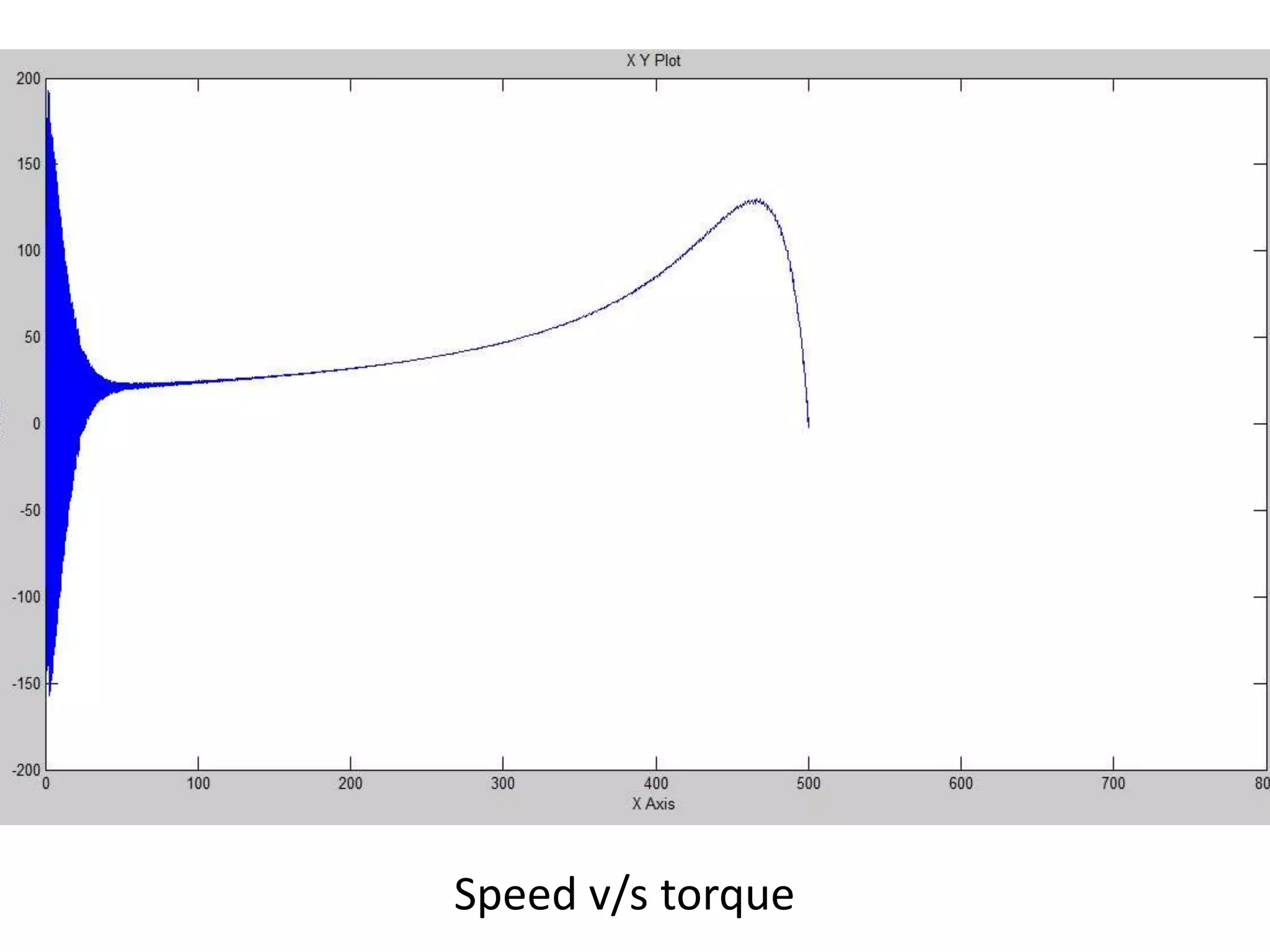

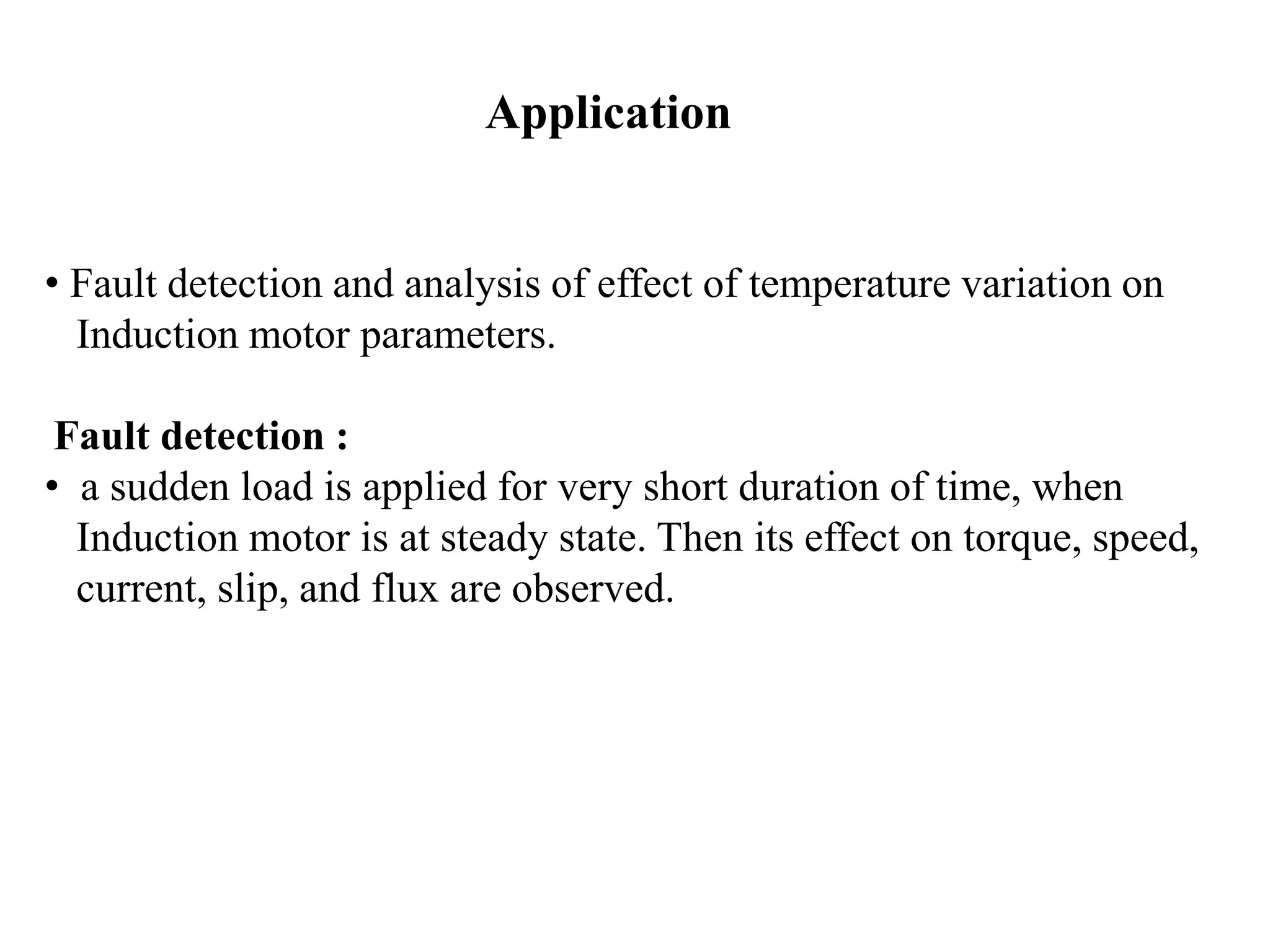

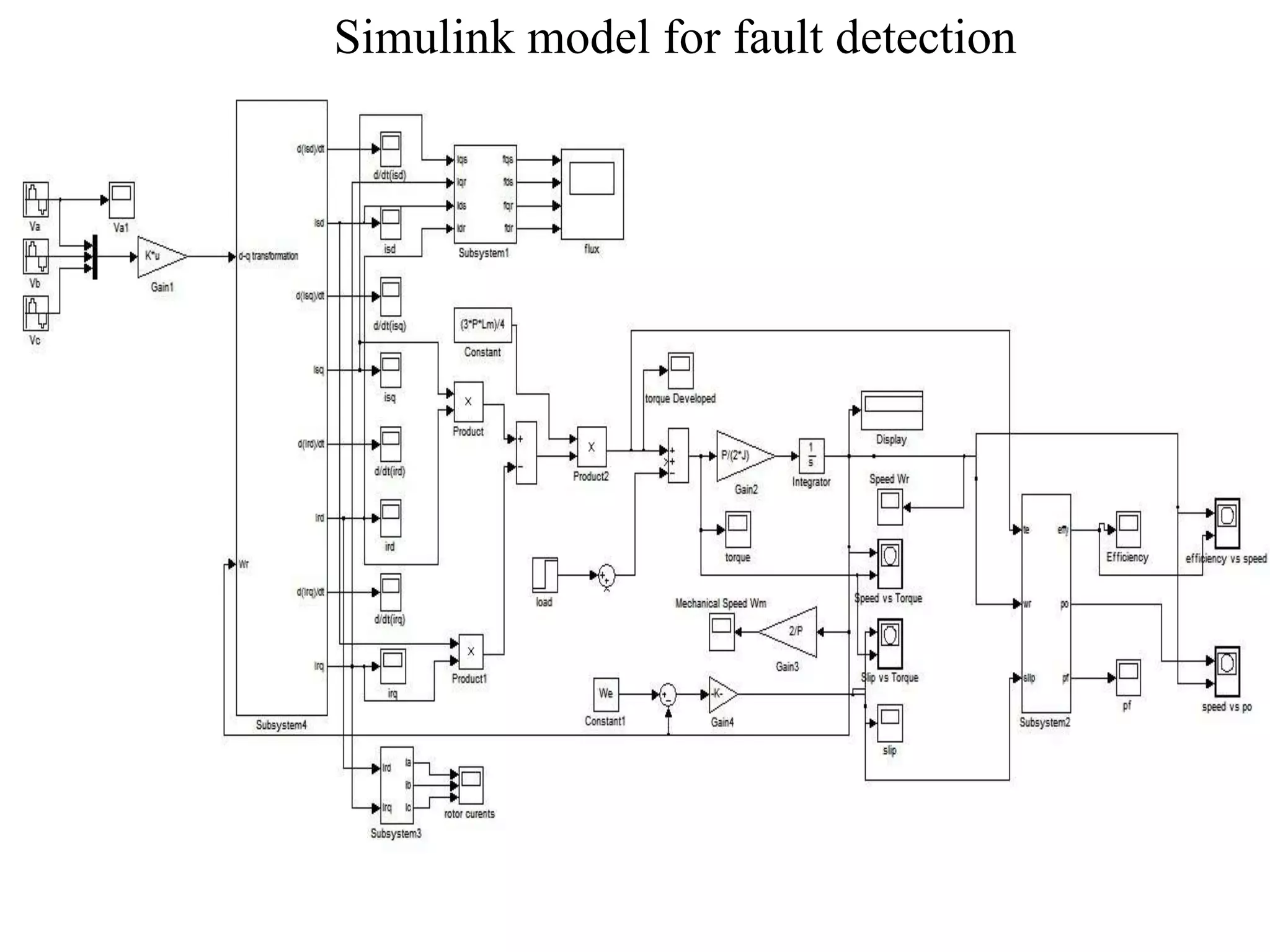

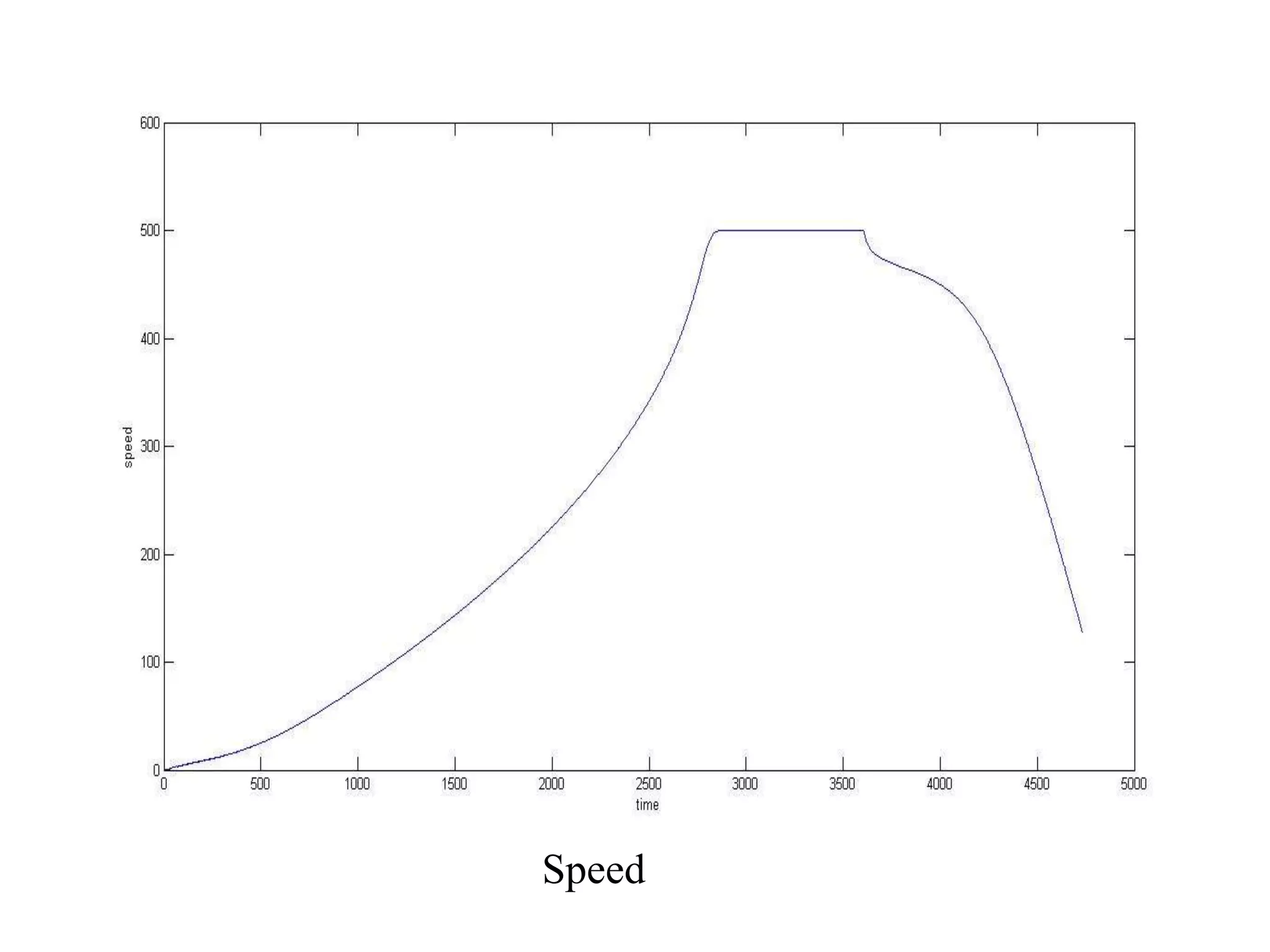

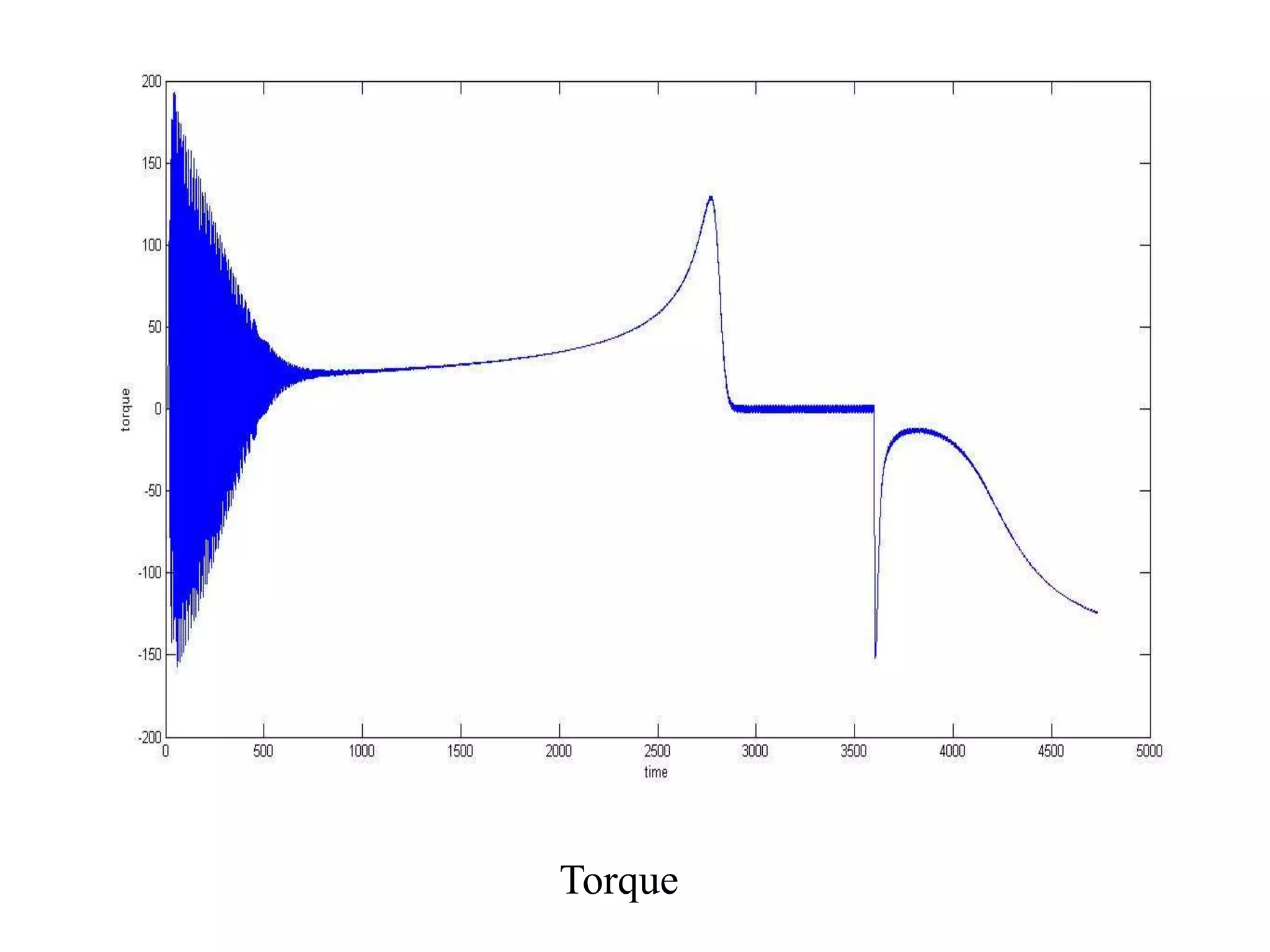

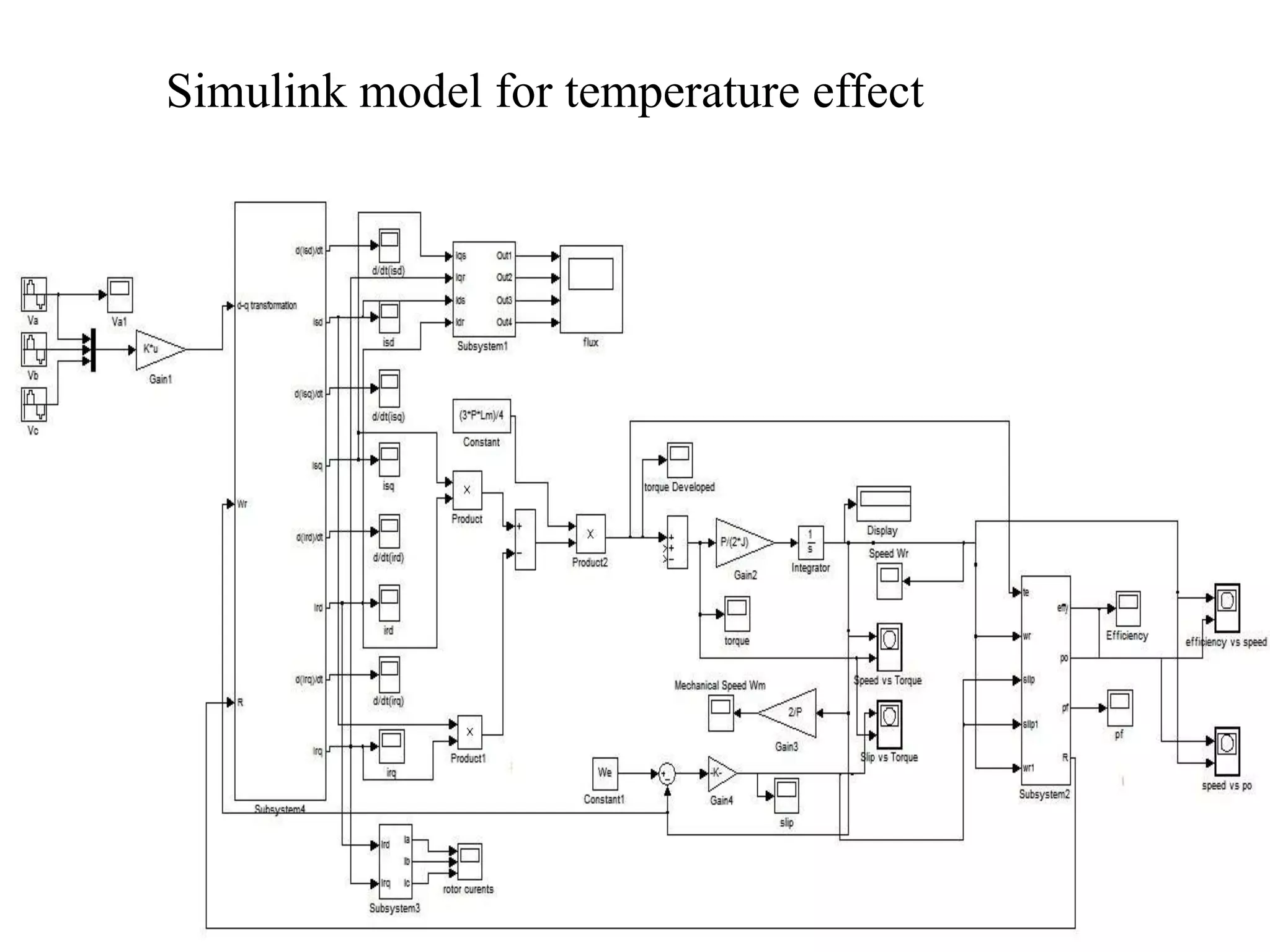

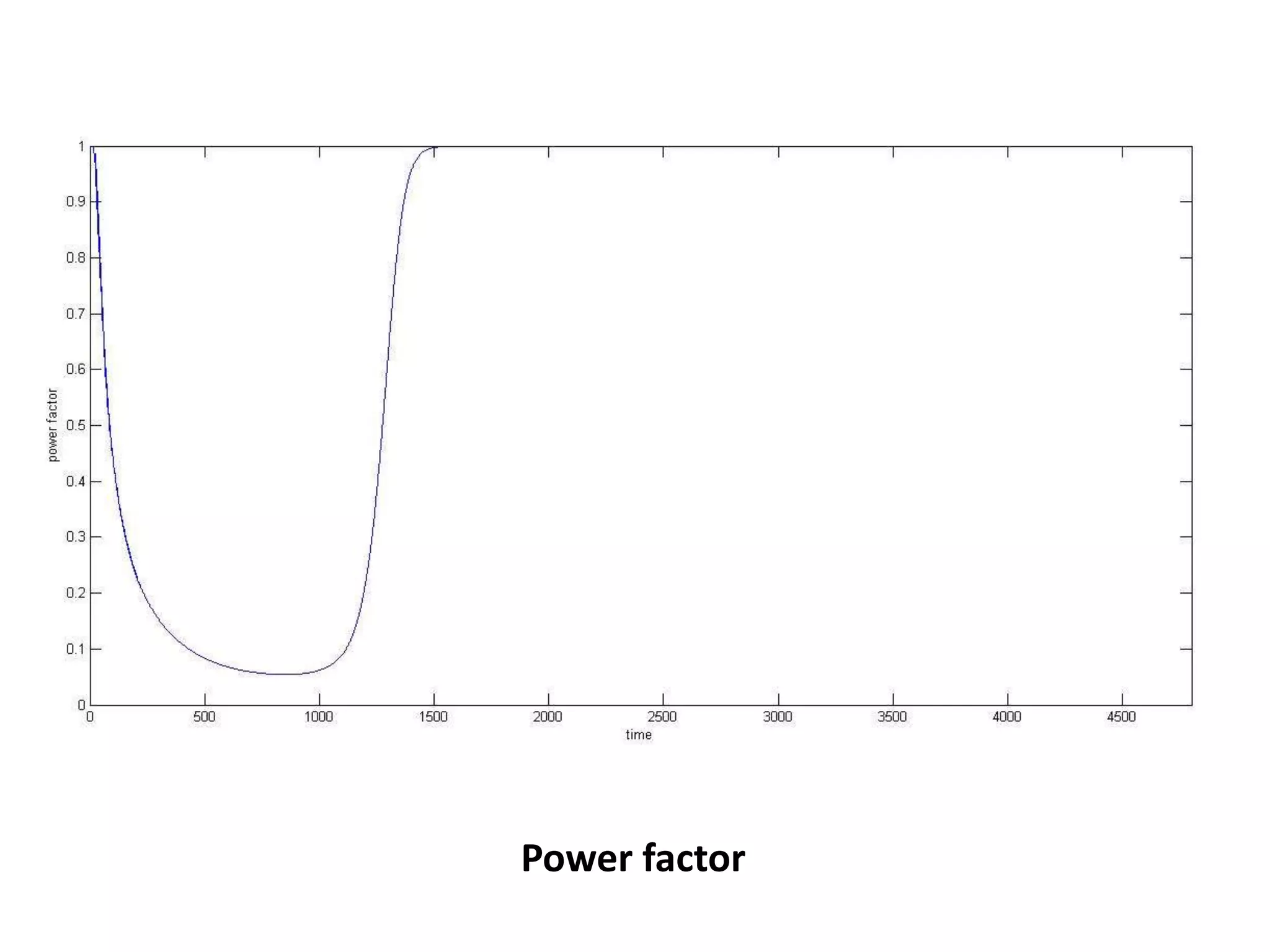

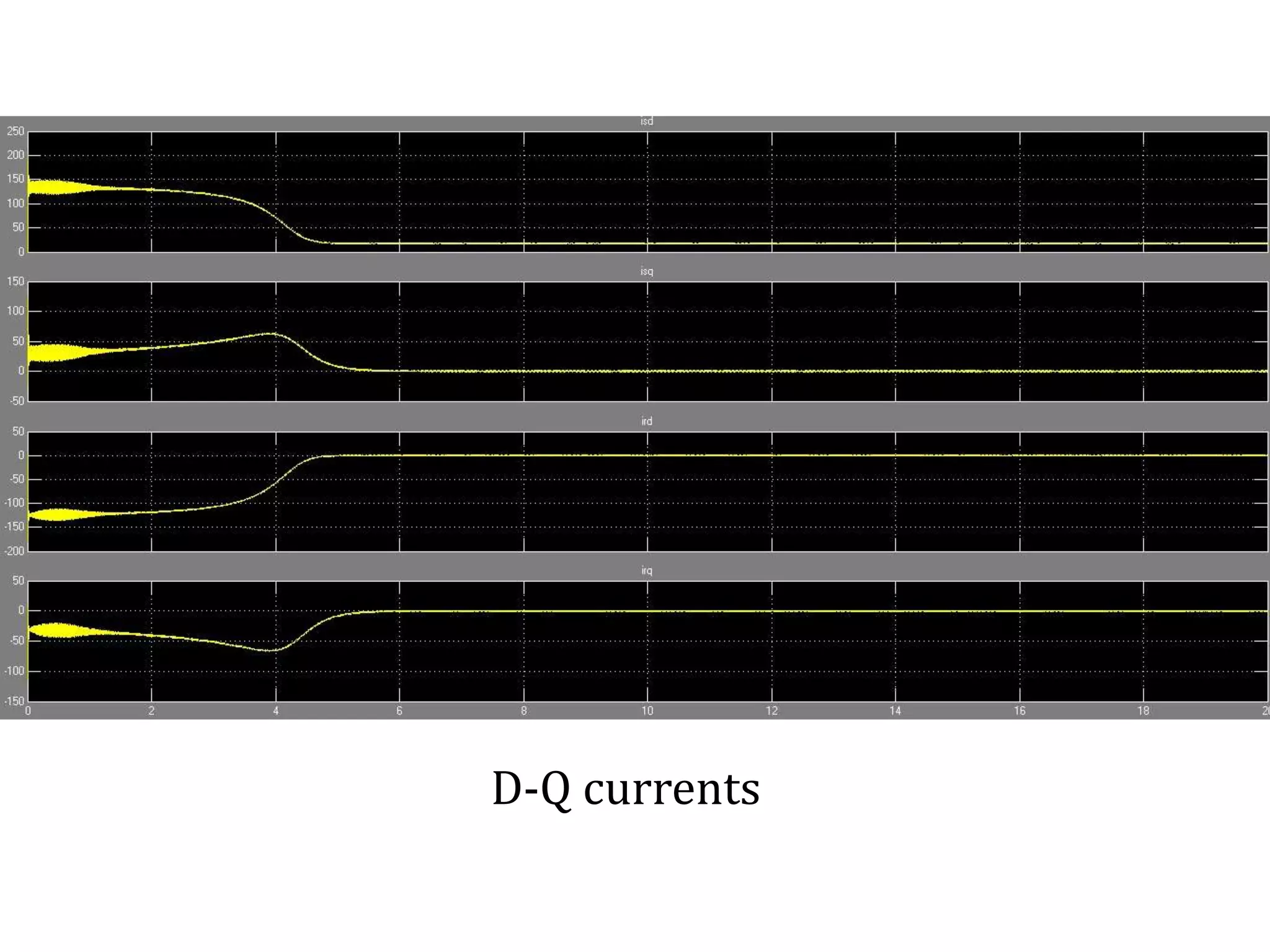

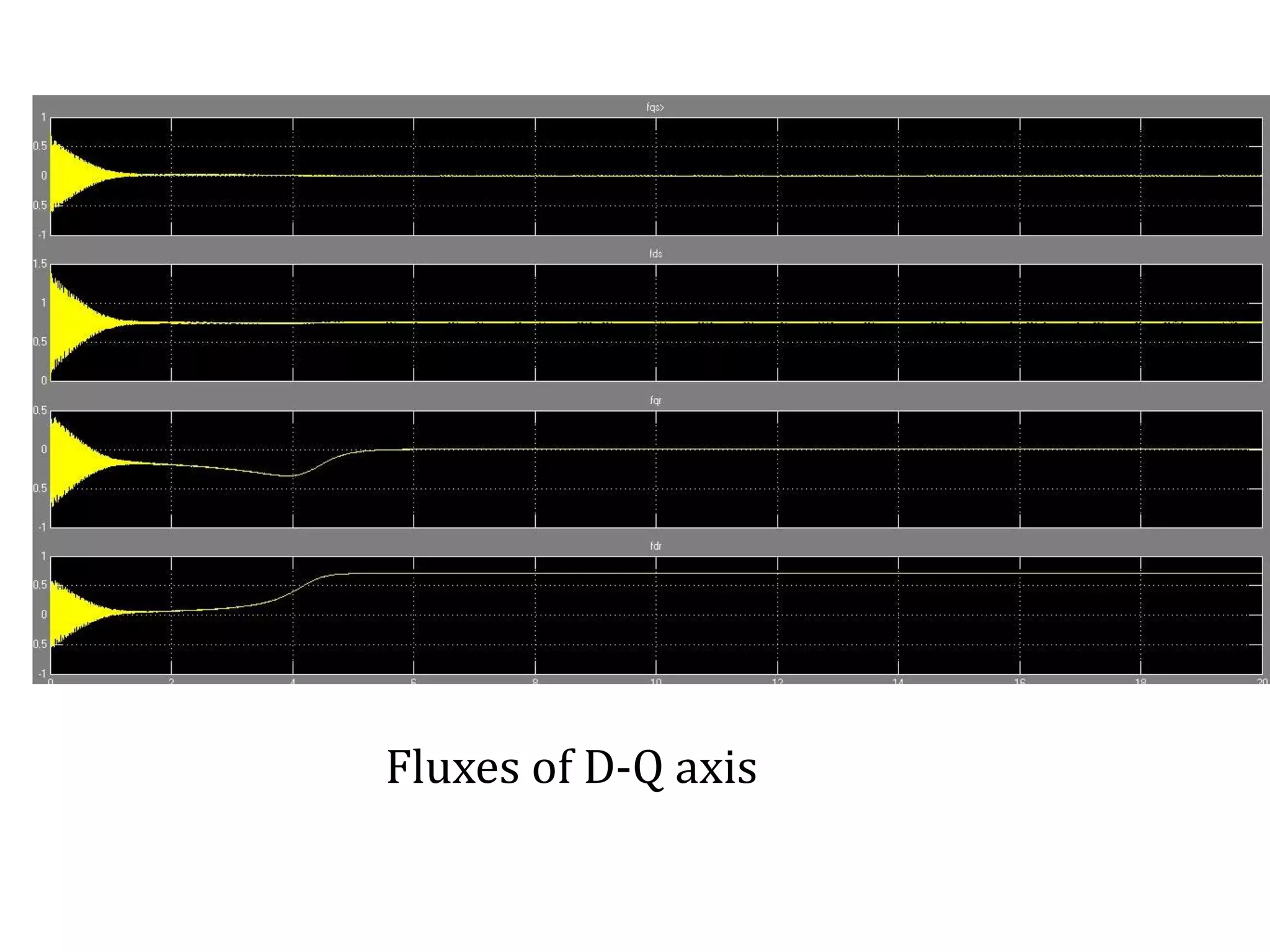

The document presents a project on induction motor modeling and applications, focusing on objectives, methodology, simulation results, and conclusions regarding the influence of temperature on motor parameters. Key findings include the development of equations for torque, rotor speed, and the impact of heating on efficiency and power factor, achieved through simulink modeling. Future work aims to enhance control algorithms for automatic speed adjustment and hardware implementation.

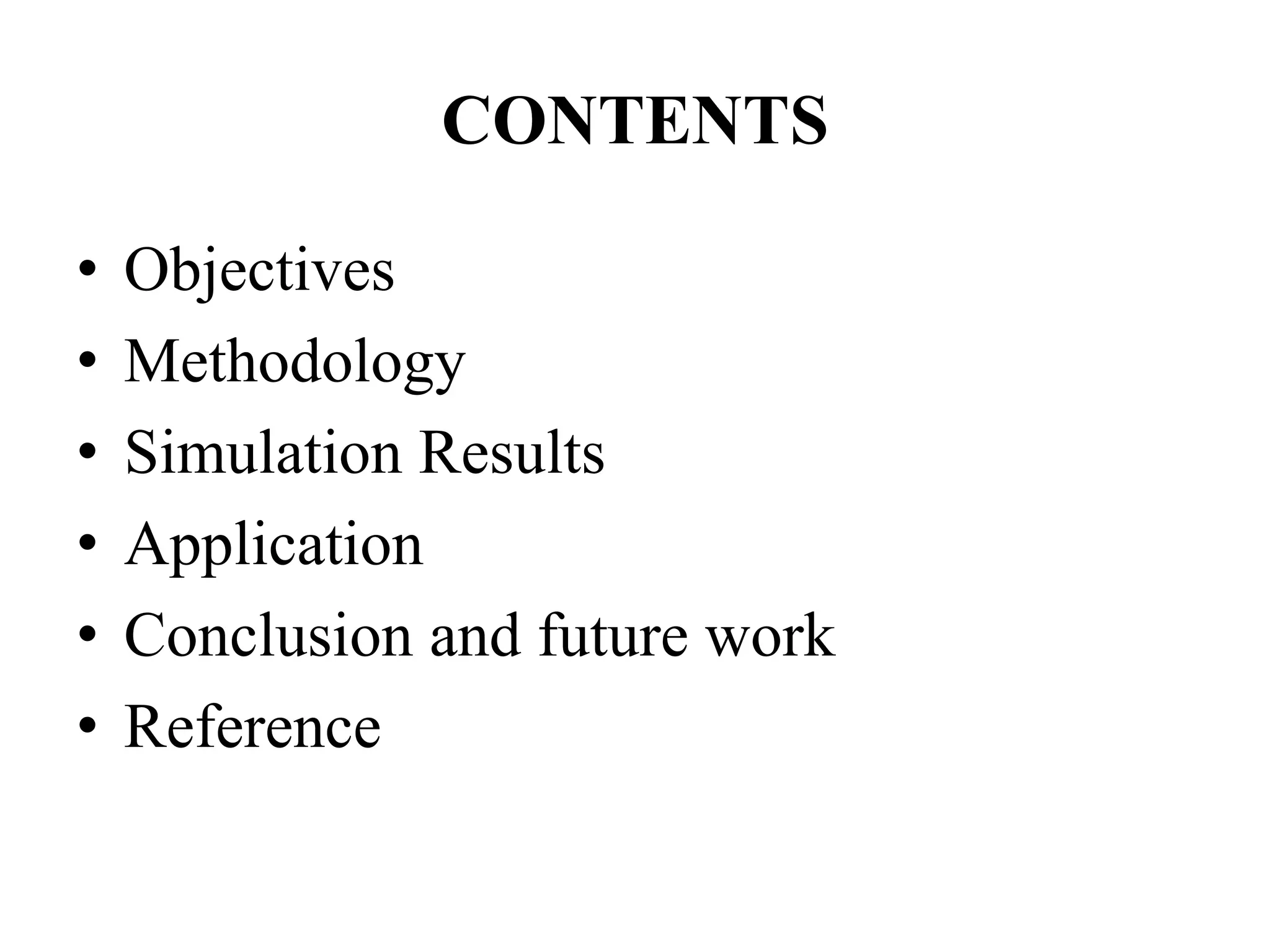

![Voltage equations

Flux equations

Where,

Synchronous Speed , or Speed of RMF

Rotor Speed

s

r

[ ] [ ]

[ ] [ ]

sdq s sdq sr rdq

rdq r rdq sr sdq

L i M i

L i M i

[ ]

[ ] [ ]

[ ]

[ ] [ ]

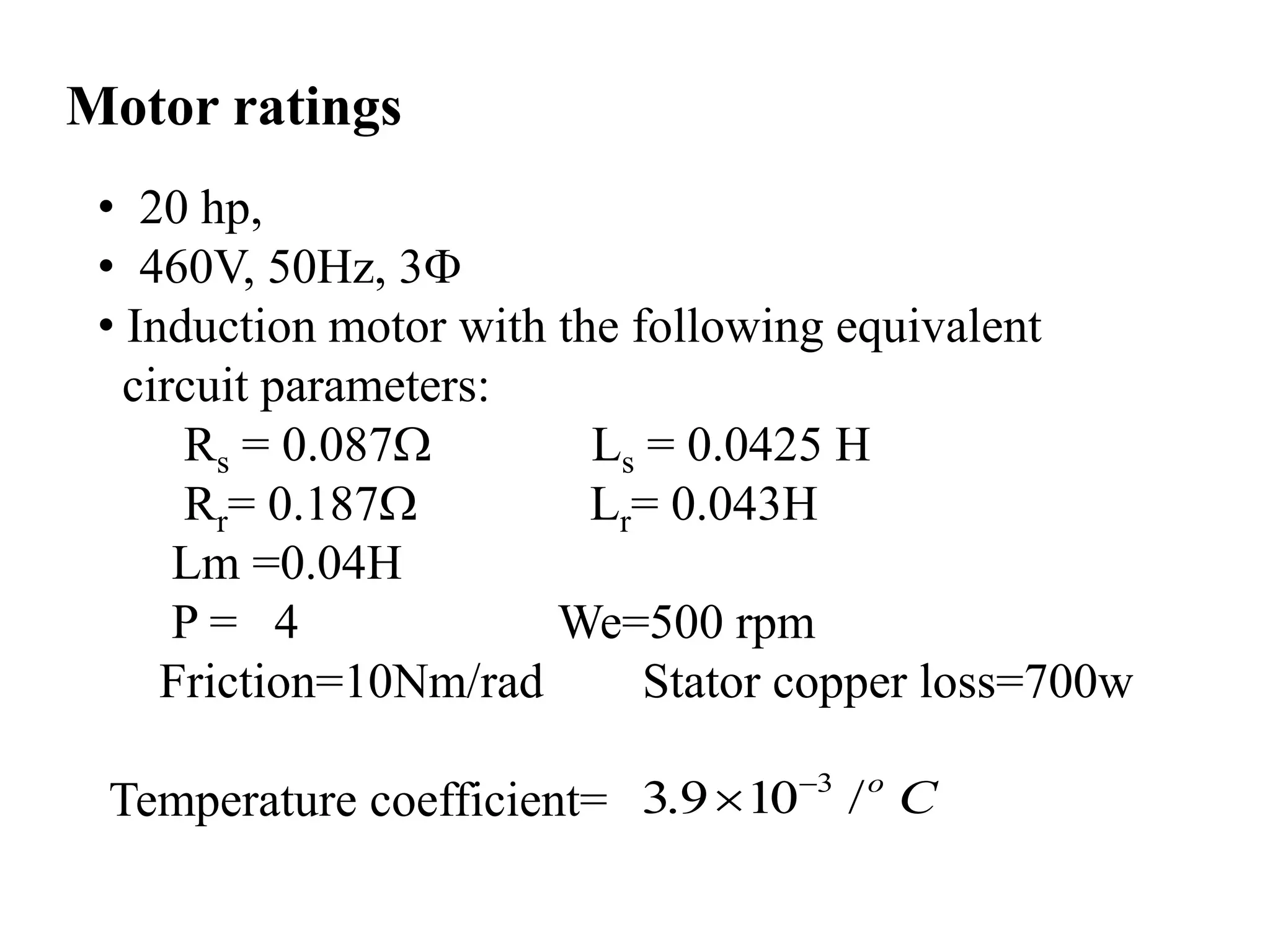

sabc

sabc s sabc

rabc

rabc r rabc

d

V R i

dt

d

V R i

dt

Basic Voltage Equations

( )

( )

sd

sd s sd s sq

sq

sq s sq s sd

rq

rd r rd s r rq

rq

rq r rq s r rd

d

V R i

dt

d

V R i

dt

d

V R i

dt

d

V R i

dt

](https://image.slidesharecdn.com/inductionmotormodellingandapplications-161130095101/75/Induction-motor-modelling-and-applications-8-2048.jpg)

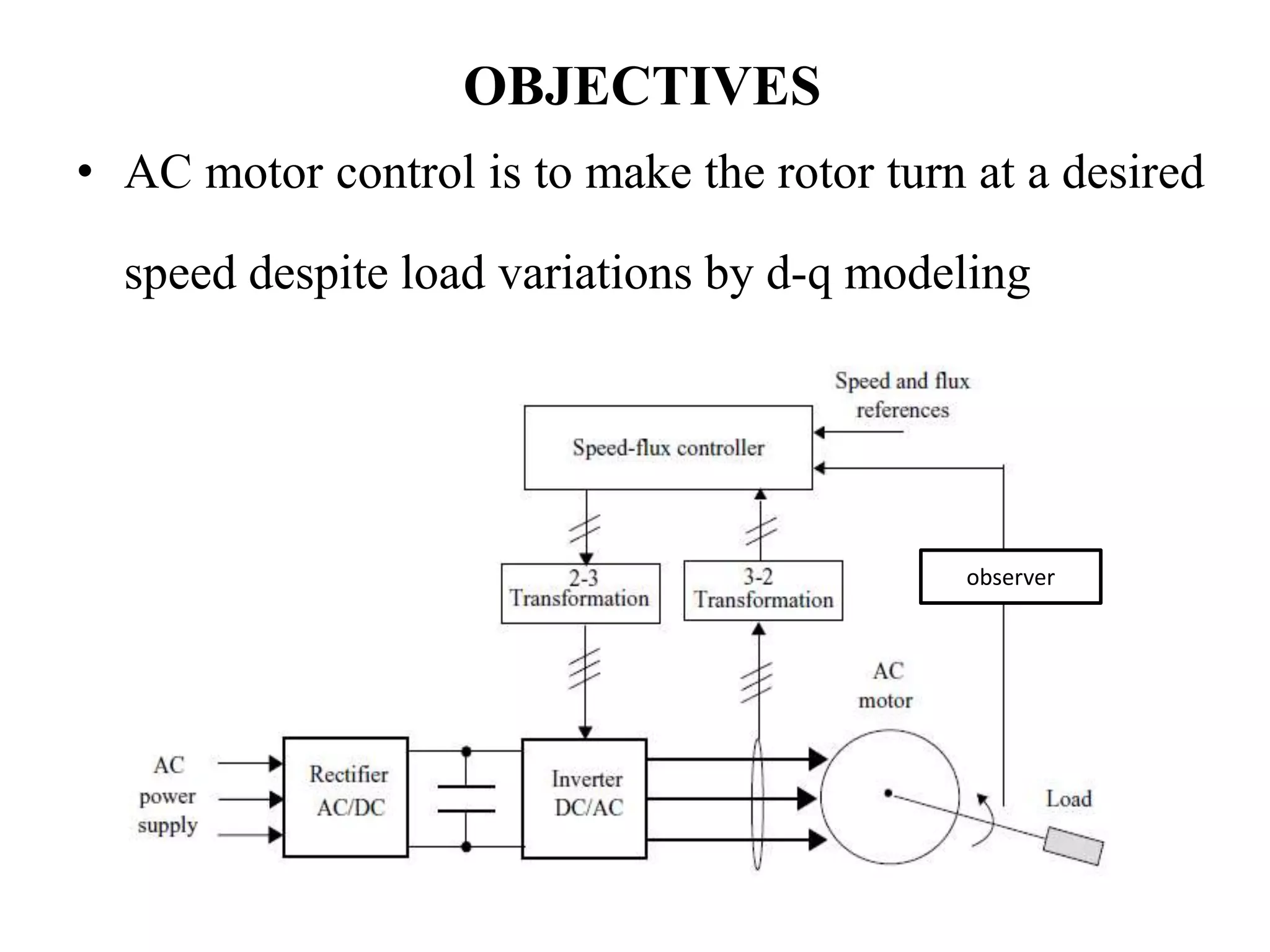

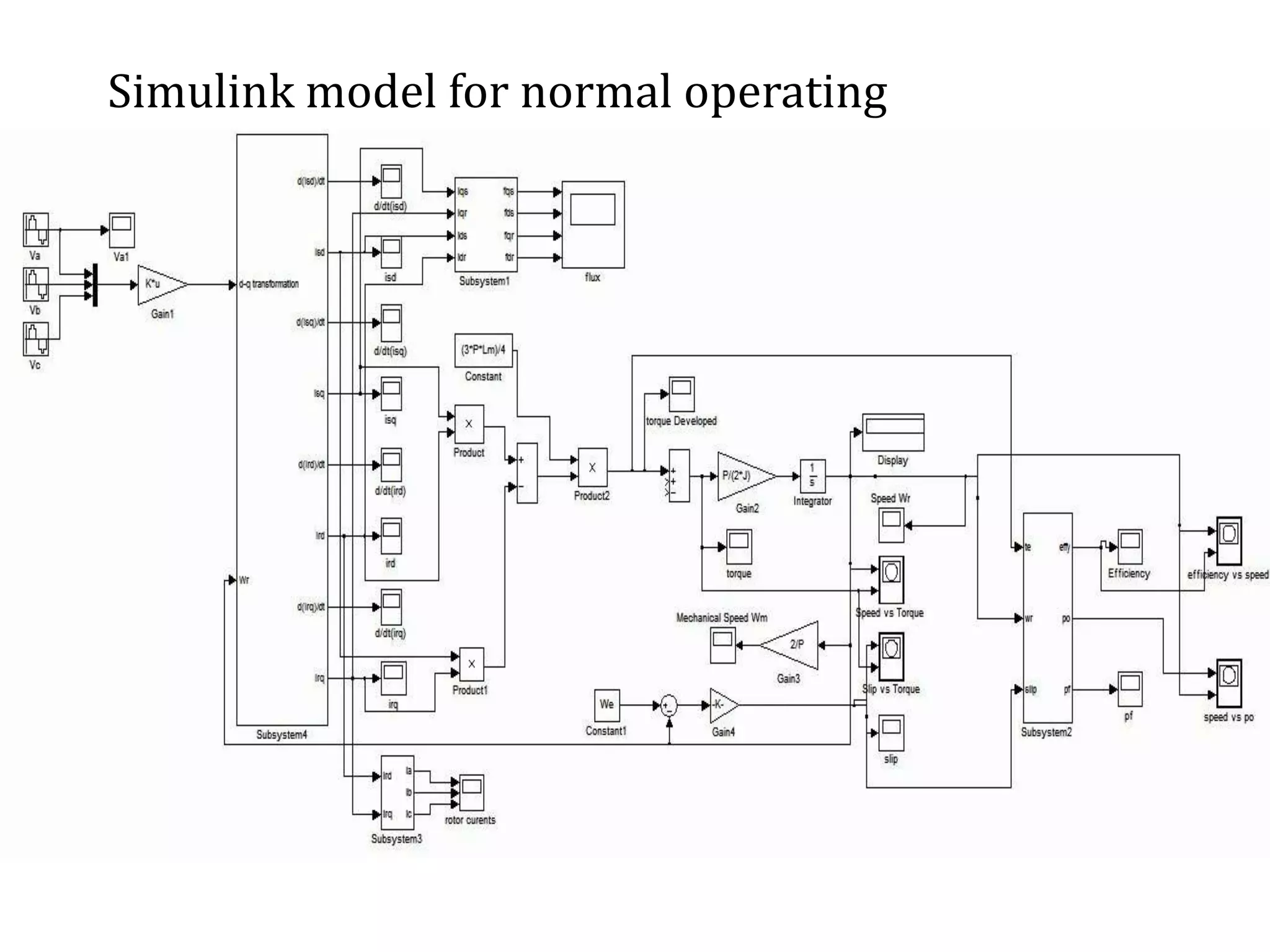

![1

[ ]

[ ]

( )

[ ]

( )

sd sd rd s sd s

sr s sq sr rq

s s s s

sq sq s sq rqsr s

s sd sr rd

s s s s

rd rd sr sd s rr

rd r rq sr sq

r r r r

rq rq r rq sqsr s r

r r r

di V di R i

M L i M i

dt L L dt L L

di V R i diM

L i M i

dt L L L dt L

di V M diR

i L i M i

dt L L L dt L

di V R i diM

dt L L L dt L

[ ]r rd sr sd

r

L i M i

Final equations](https://image.slidesharecdn.com/inductionmotormodellingandapplications-161130095101/75/Induction-motor-modelling-and-applications-9-2048.jpg)

![REFERENCES

[1]Norman S Nise, “Control Systems Engineering”, Wiley Student Edition, 5th Edition, 2009

[2] Joseph J Distefano III and other, “Feedback and Control Systems”, Schaum’s Outlines,

TMH, 2ndEdition, 2007

[3] Ashfaq Hussain, “Electrical Machines”, Dhanpat Rai Publications

[4] Katsuhiko Ogata, “Modern Control Engineering”, PHI,5th Edition, 2010

[5] Fouad Giri “AC electric motors control”: advanced design techniques and applications ,

John Wiley & Sons, Ltd. 2013

[6] Chee-Mun ong , “Dynamic simulation of electric machinary”,using matlab/simulink

[7] Krstic M, Kanellakopoulos I, and Kokotovic P (1995) “Nonlinear and Adaptive Control

Design”. John Wiley & Sons. Leonard W (2001) “Control of Electrical Drives”. Springer,

New York.

[8] Novotnak RT, Chiasson J, and Bodson M (1999) High performance mtion control of an

induction motor with magnetic saturation, IEEE Transactions on Control Systems

Technology, 7, 315–327.

[9] Astolfi A, Karagiannis D, and Ortega R (2007) “Nonlinear and Adaptive Control with

Applications”. Springer. Besanc¸on G (2007) “Nonlinear Observers and Applications”.

Springer

[10] Khalil HK and Strangas EG (1996) Robust speed control of induction motors using

position and current measurement. IEEE Transactions on Automatic Control, 41, 1216–

1220.

[11] Dorf & Bishop- Pearson education, “Modern control systems”, 11th Edition 2008.](https://image.slidesharecdn.com/inductionmotormodellingandapplications-161130095101/75/Induction-motor-modelling-and-applications-30-2048.jpg)