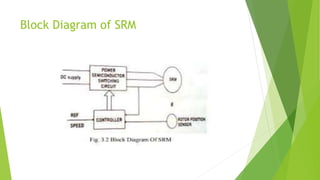

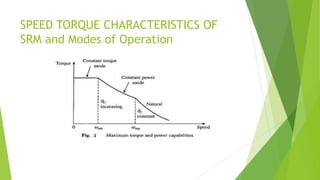

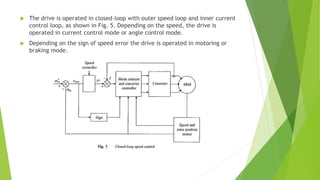

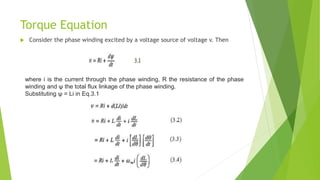

The switched reluctance motor (SRM) operates on the principle of variable reluctance, producing torque when its stator and rotor poles are configured so the magnetic reluctance is minimized. It consists of a silicon steel stator with inward projecting poles and a rotor position sensor. The SRM can operate in three modes: constant torque mode below a base speed, constant power mode above base speed using angle control, and torque proportional to speed squared at maximum speeds like a DC series motor. Torque production is based on current flow in the stator creating flux linkage, with the highest torque occurring when stator and rotor poles are aligned.