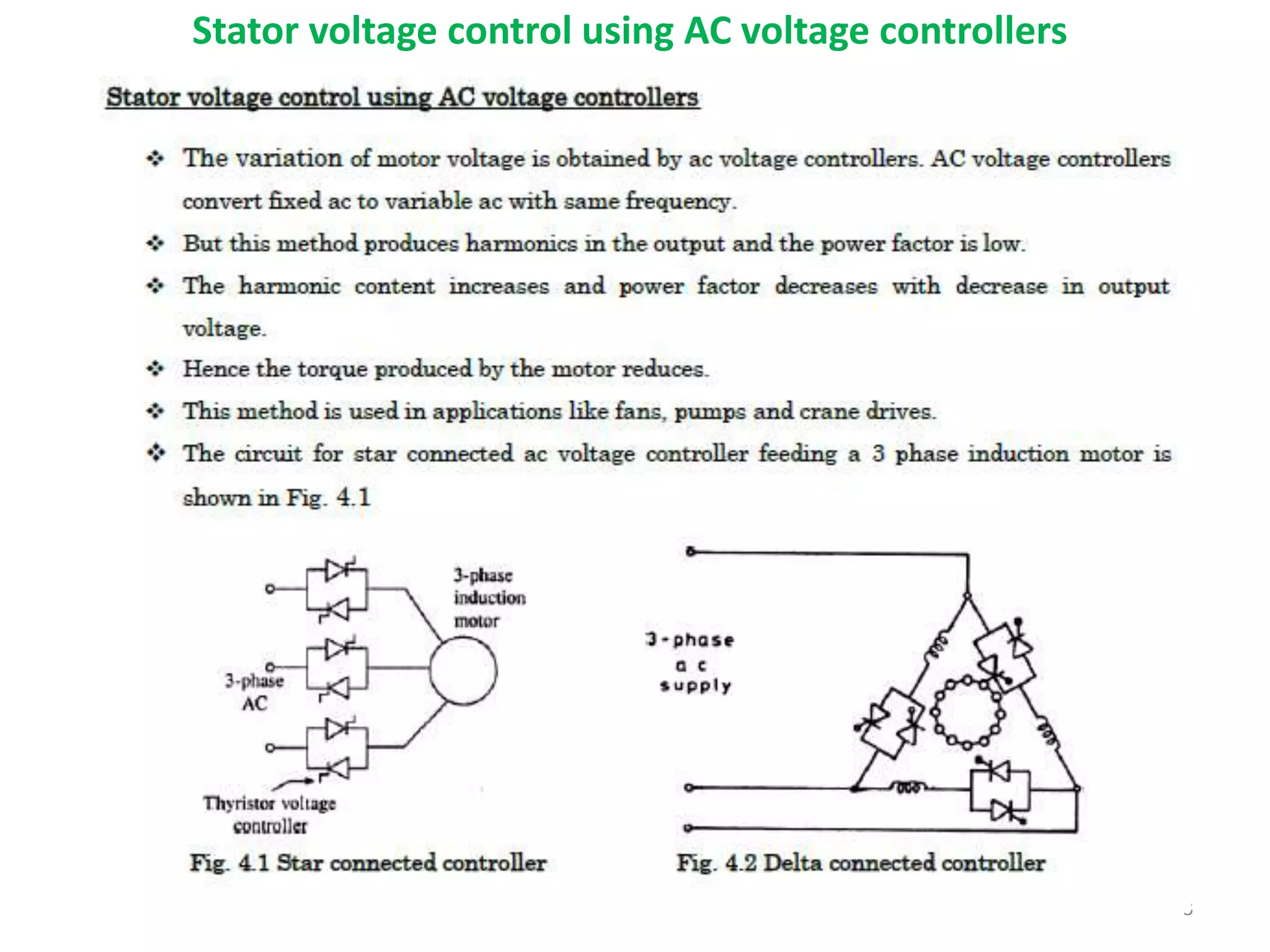

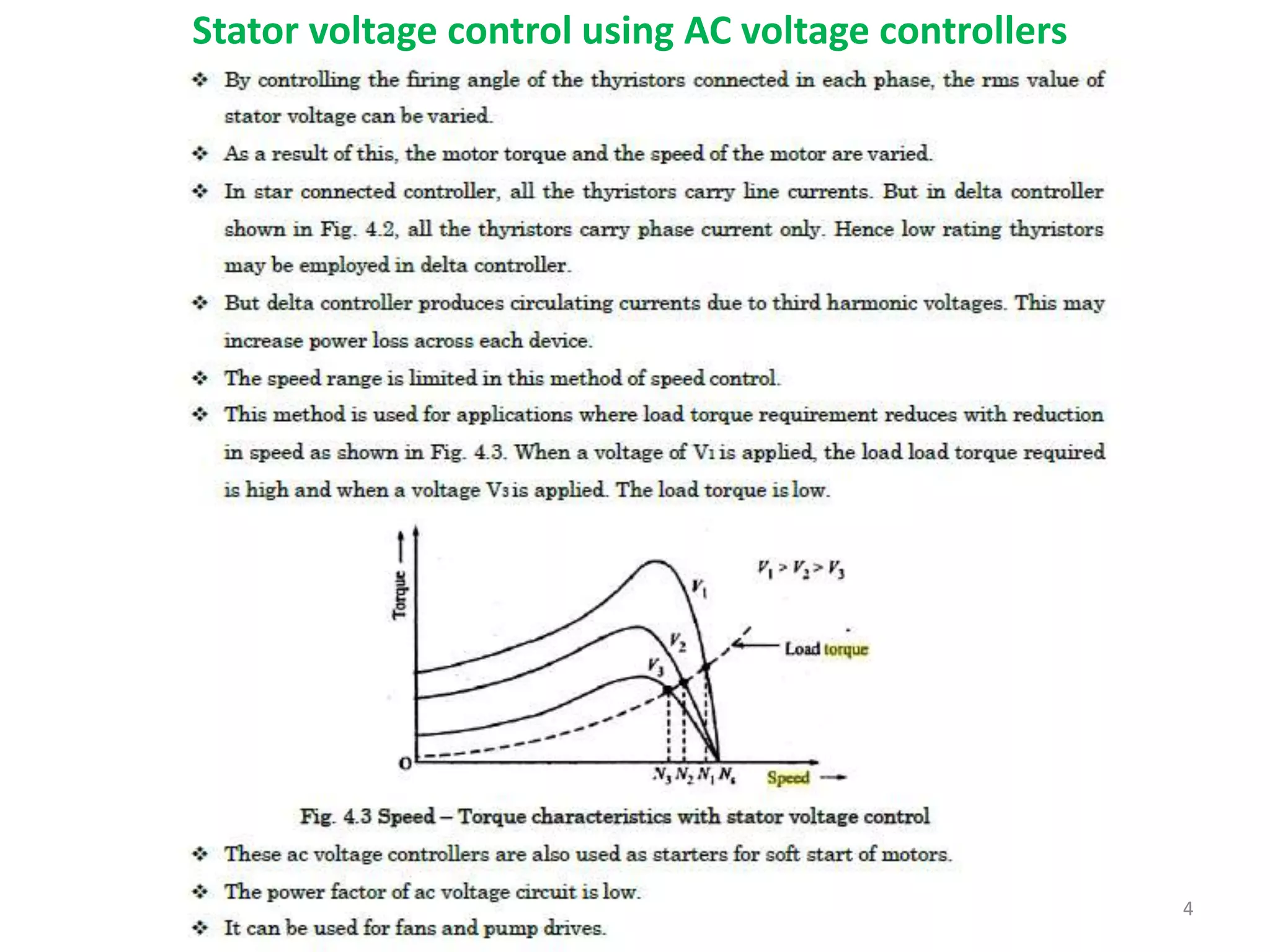

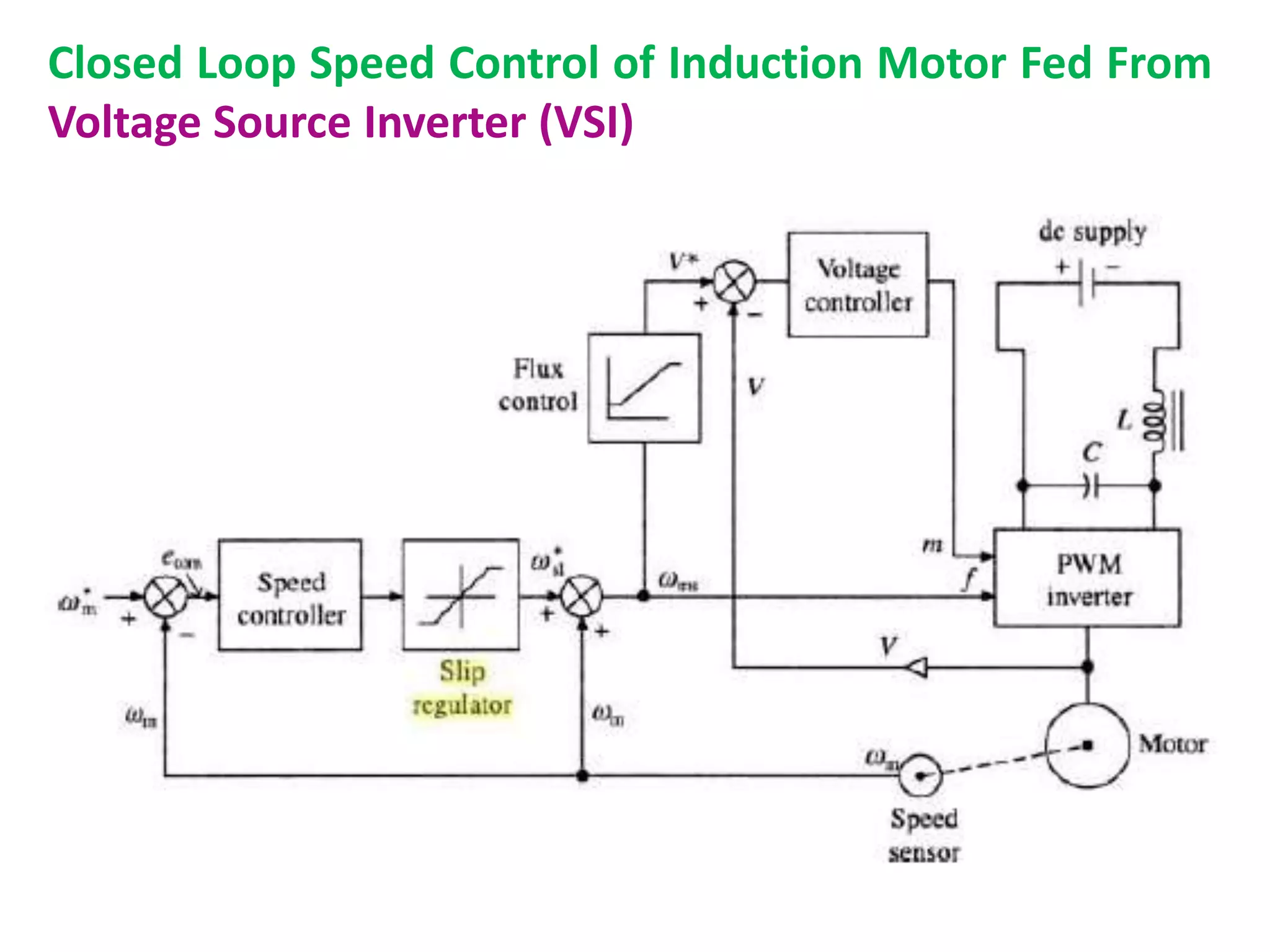

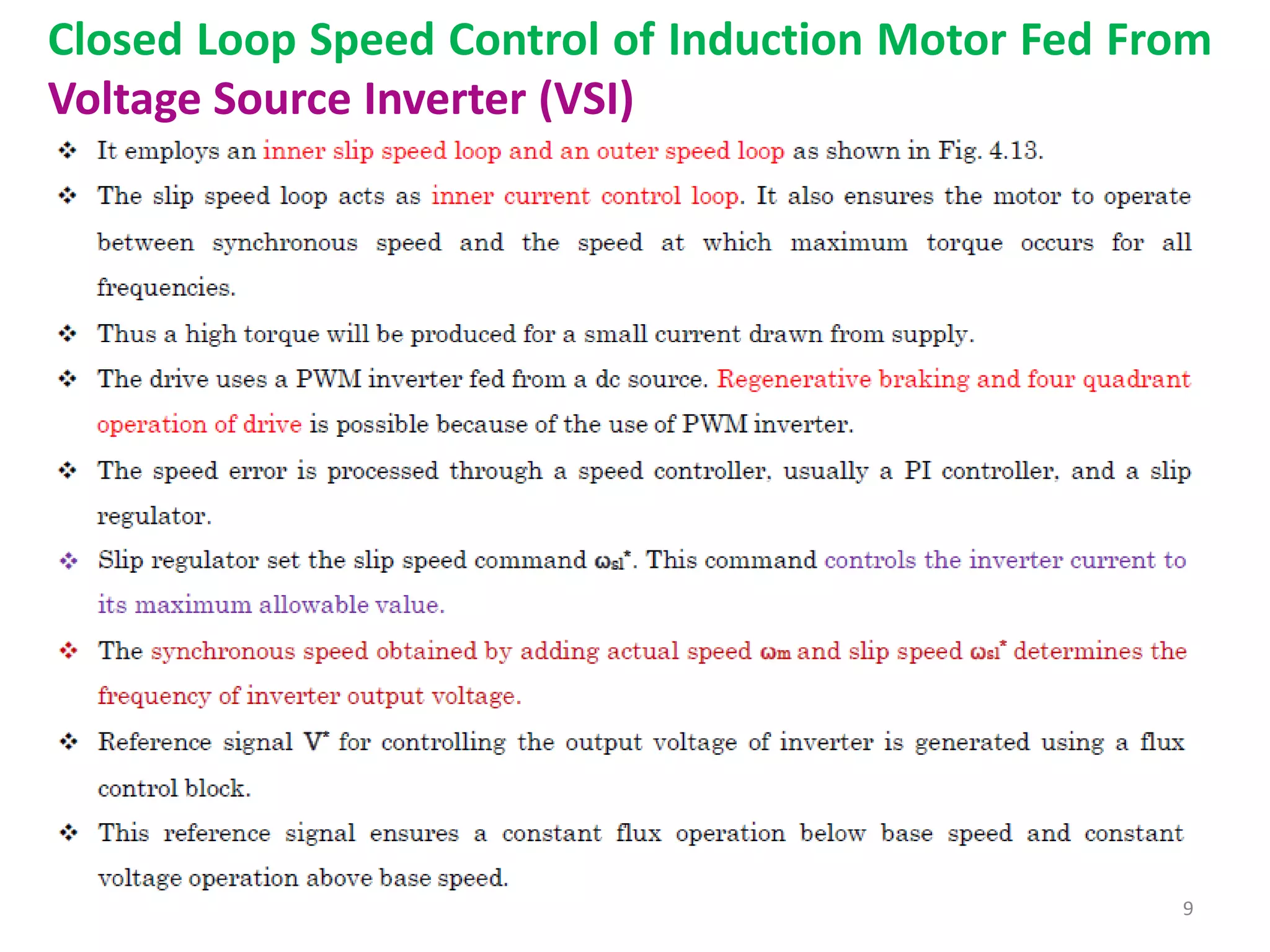

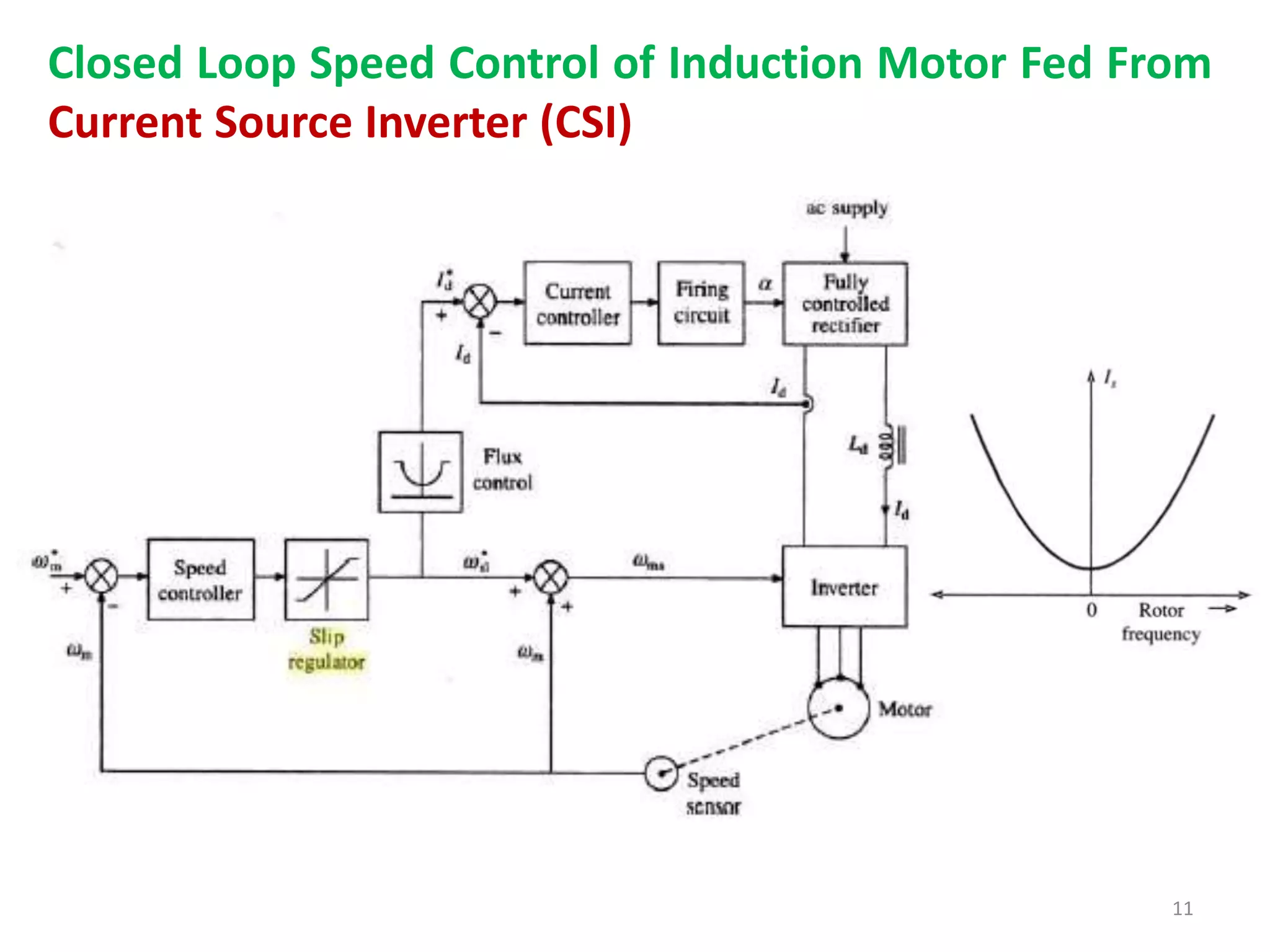

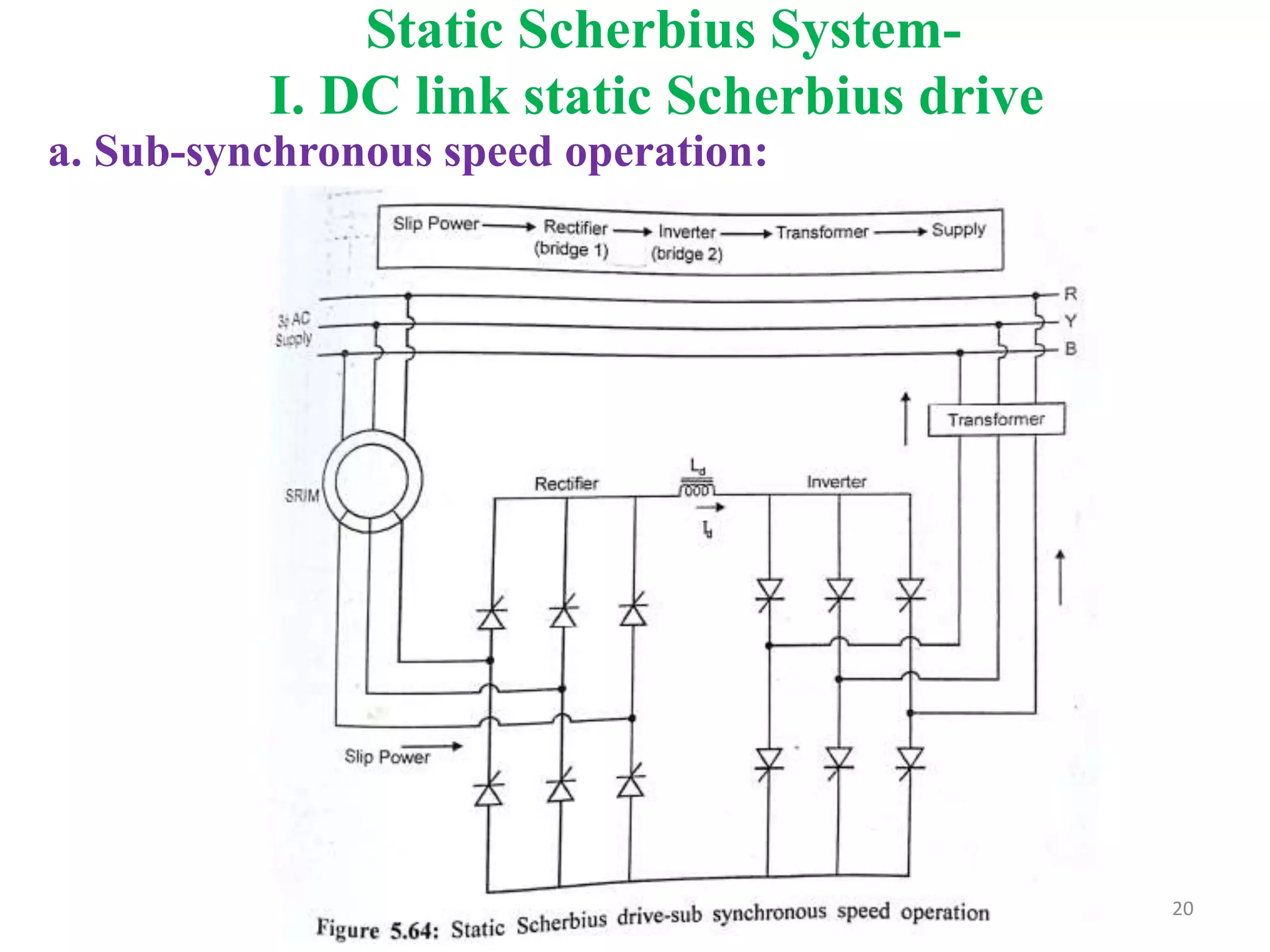

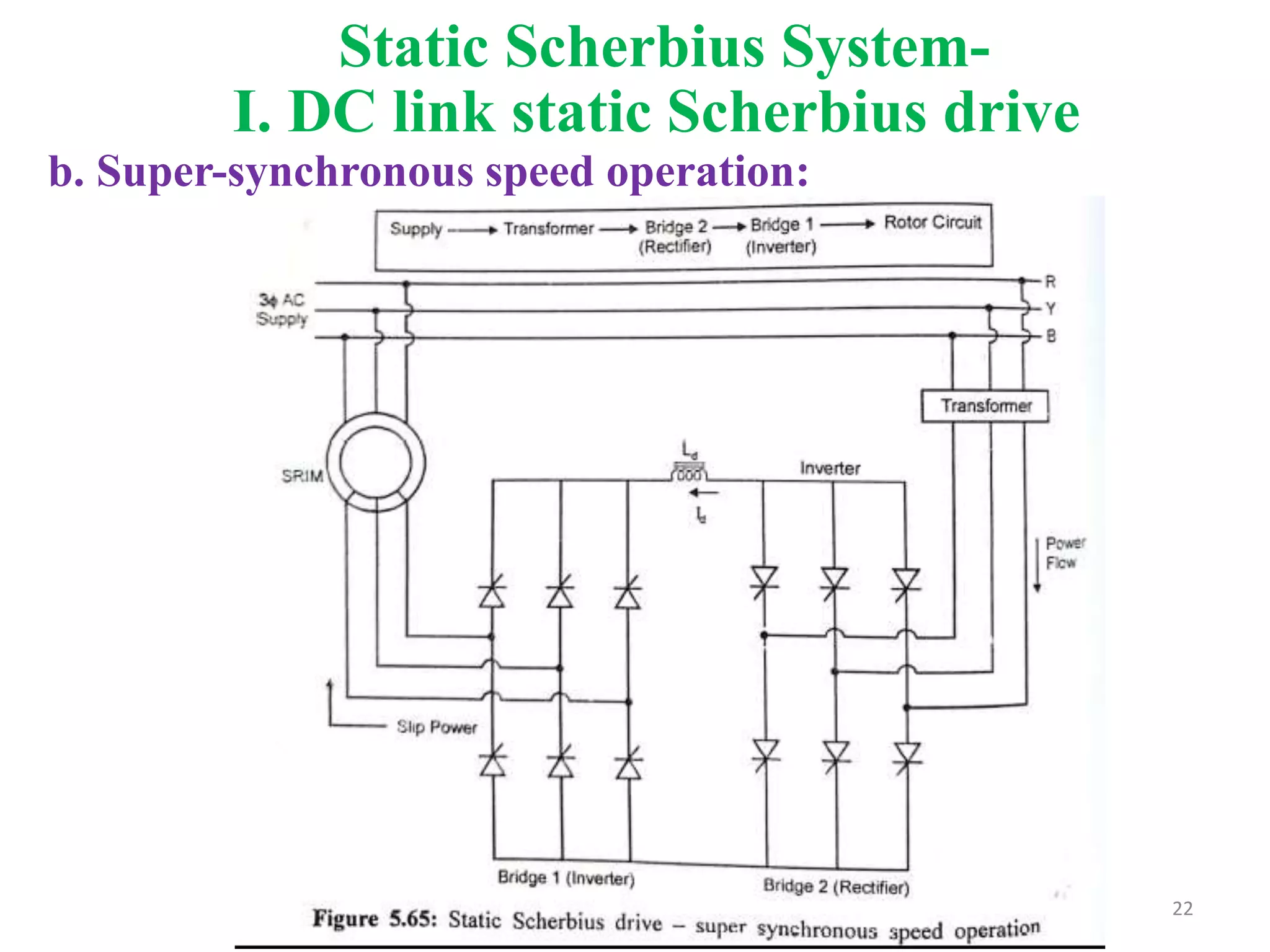

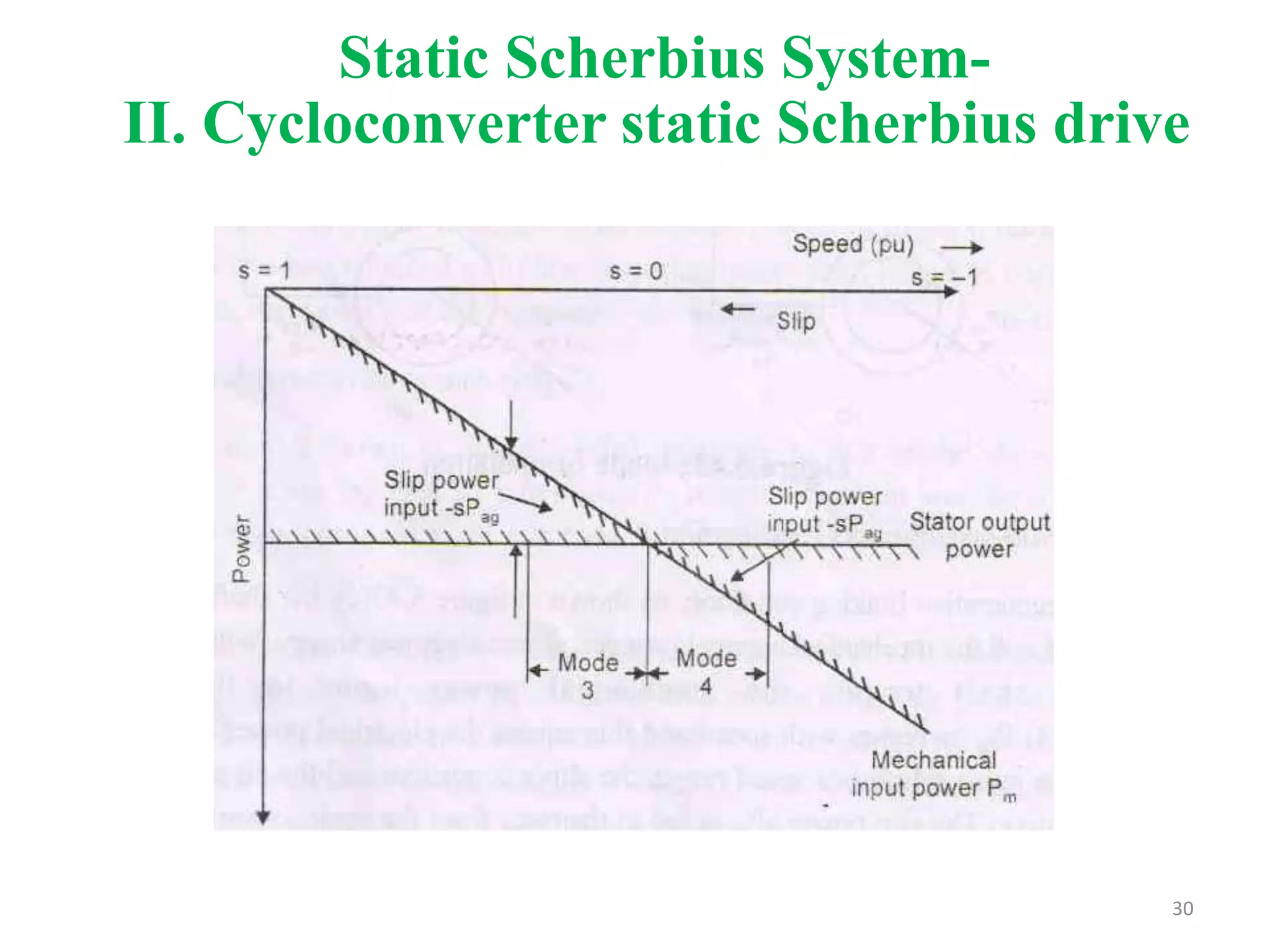

This document discusses various speed control methods for induction motor drives, including closed loop control schemes. It covers stator voltage control using AC controllers, stator frequency/field weakening control, and V/F control. Methods for closed loop speed control of induction motors powered by voltage source inverters and current source inverters are also examined. The document then focuses on slip power recovery schemes, describing the Kramer and Scherbius systems. Static implementations of these schemes are detailed, including static Kramer drives, DC link static Scherbius drives, and cycloconverter static Scherbius drives. Vector control of induction motors is also briefly mentioned.