This document discusses various rotor control techniques for induction motors, including:

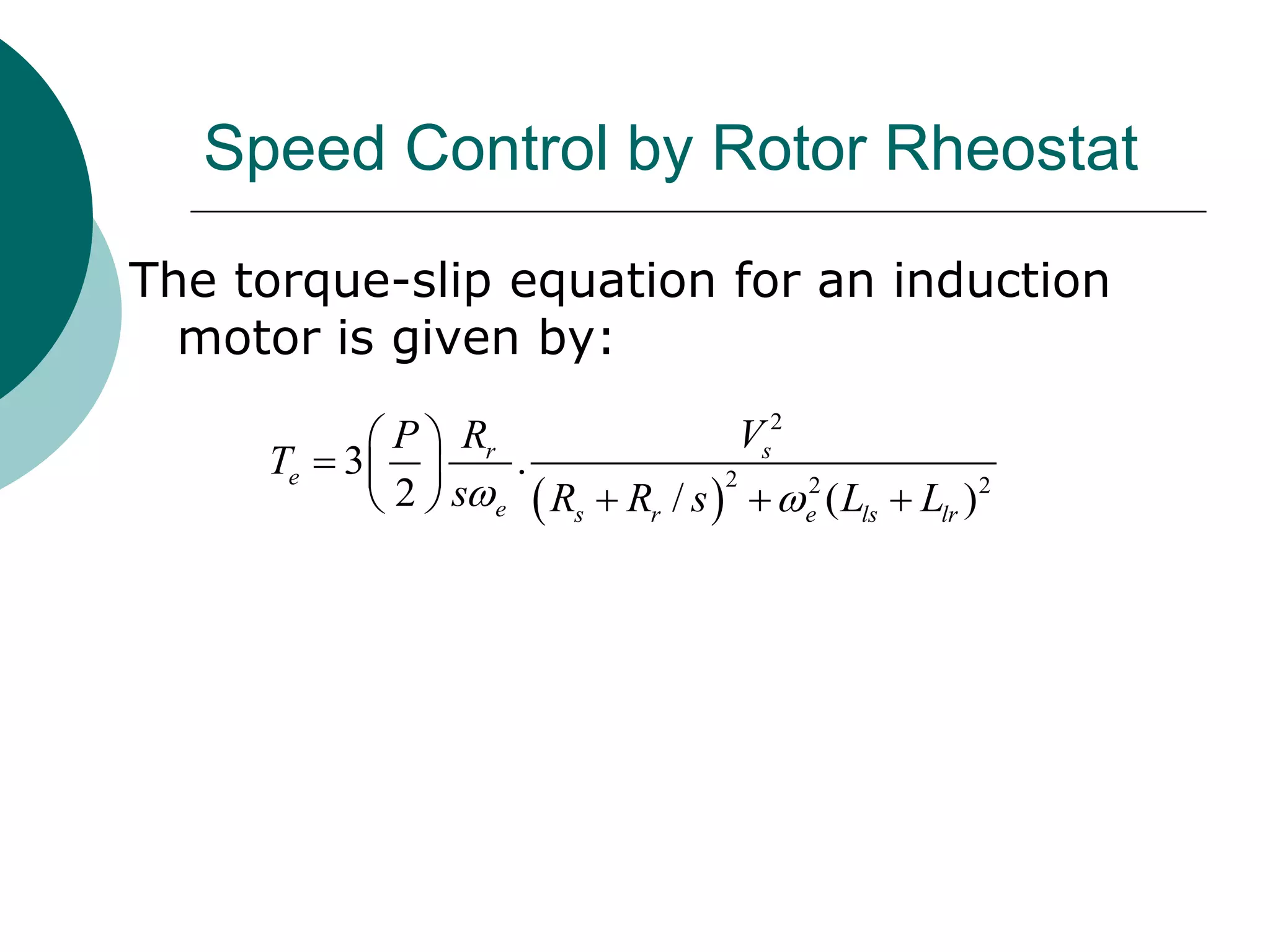

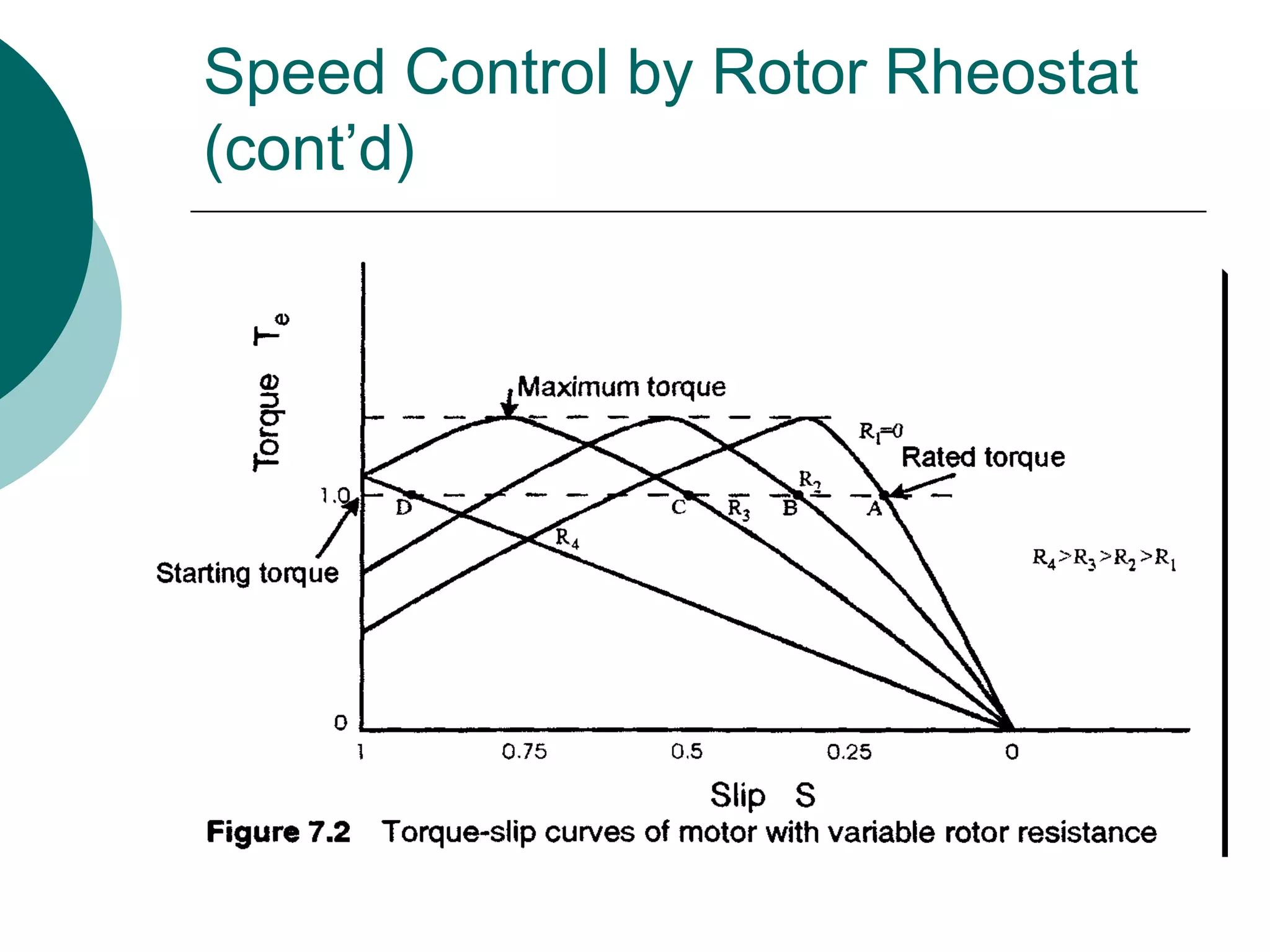

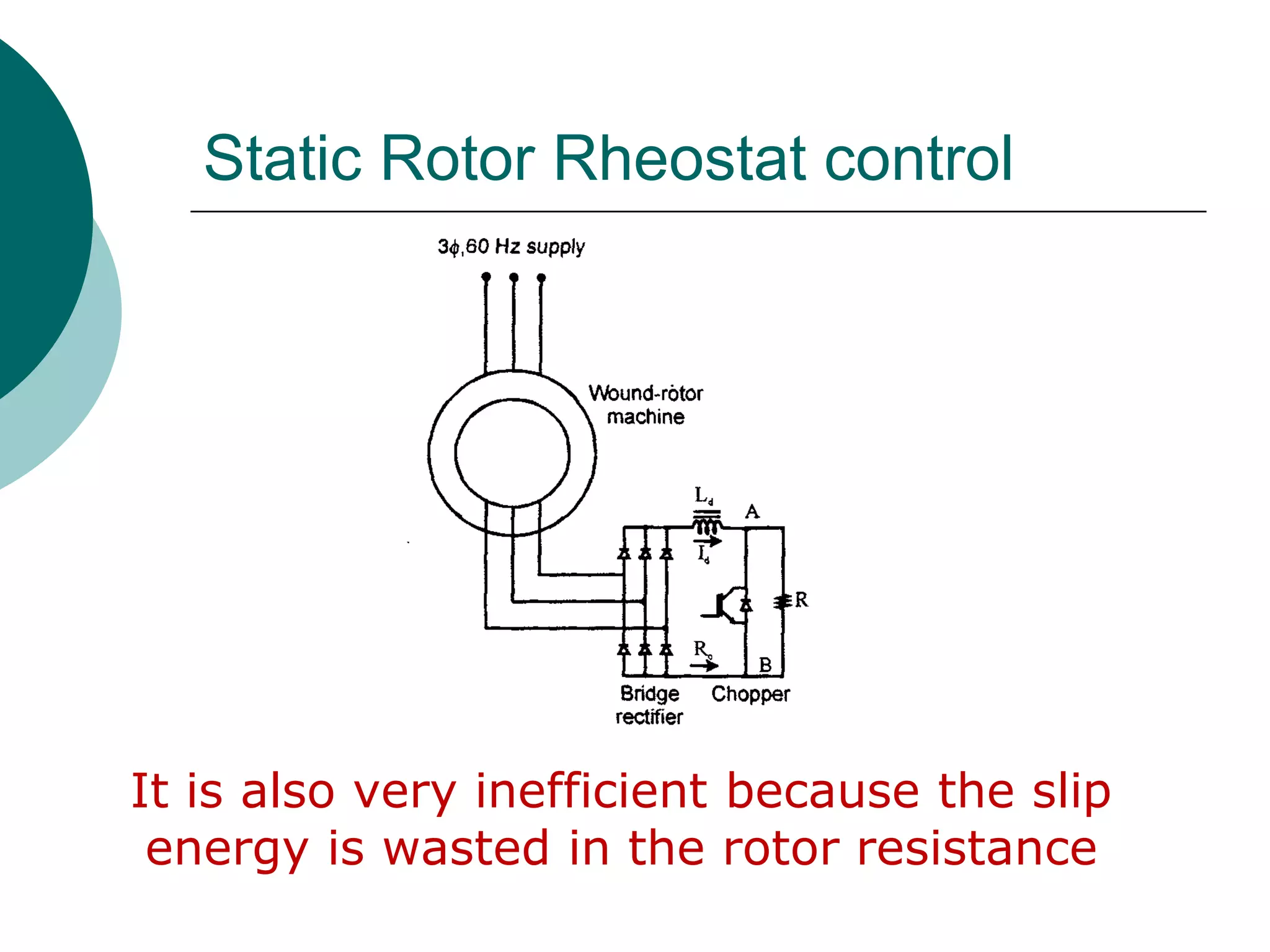

1) Static rotor resistance control, which is simple but inefficient as slip power is wasted in rotor resistance.

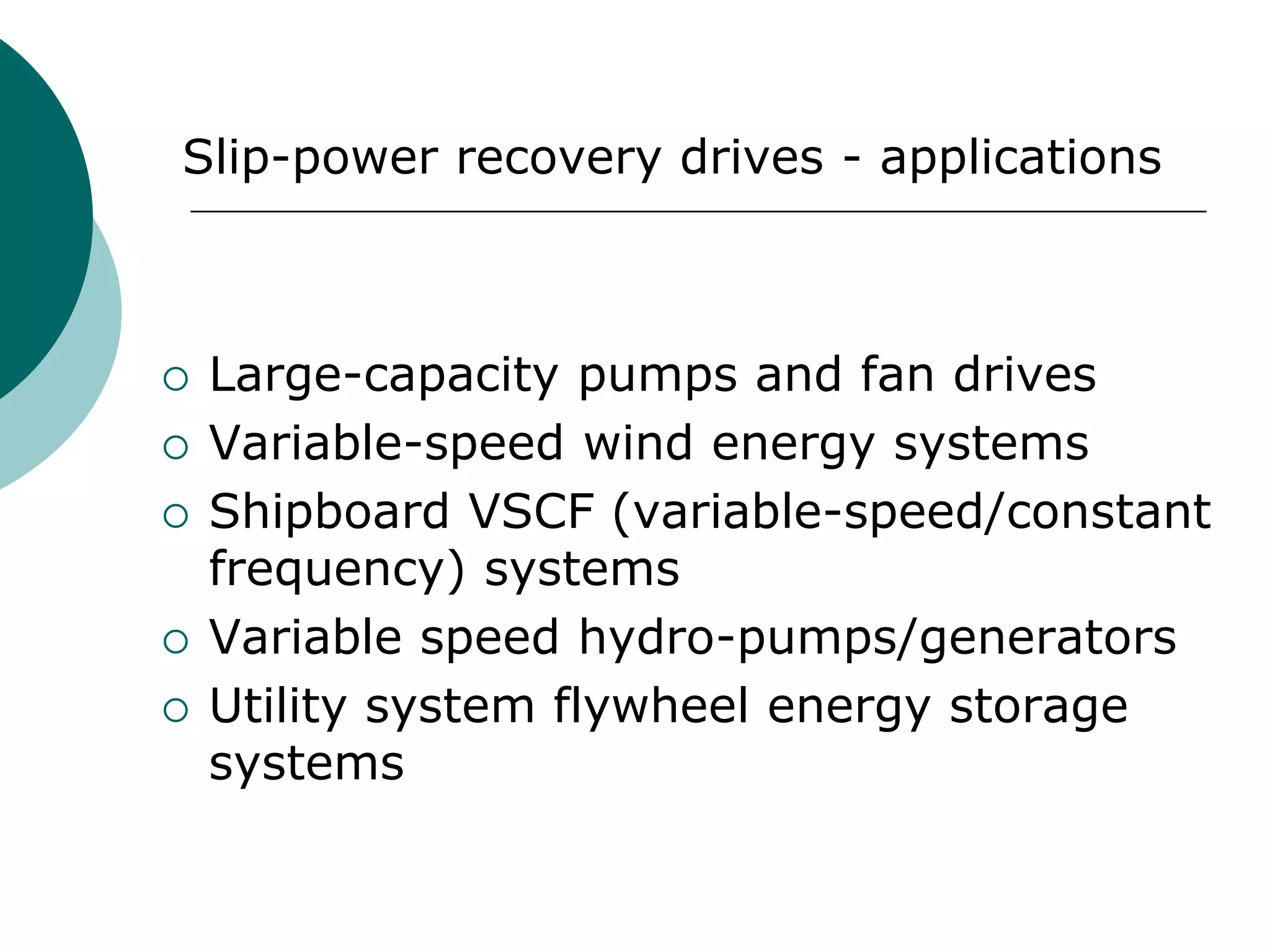

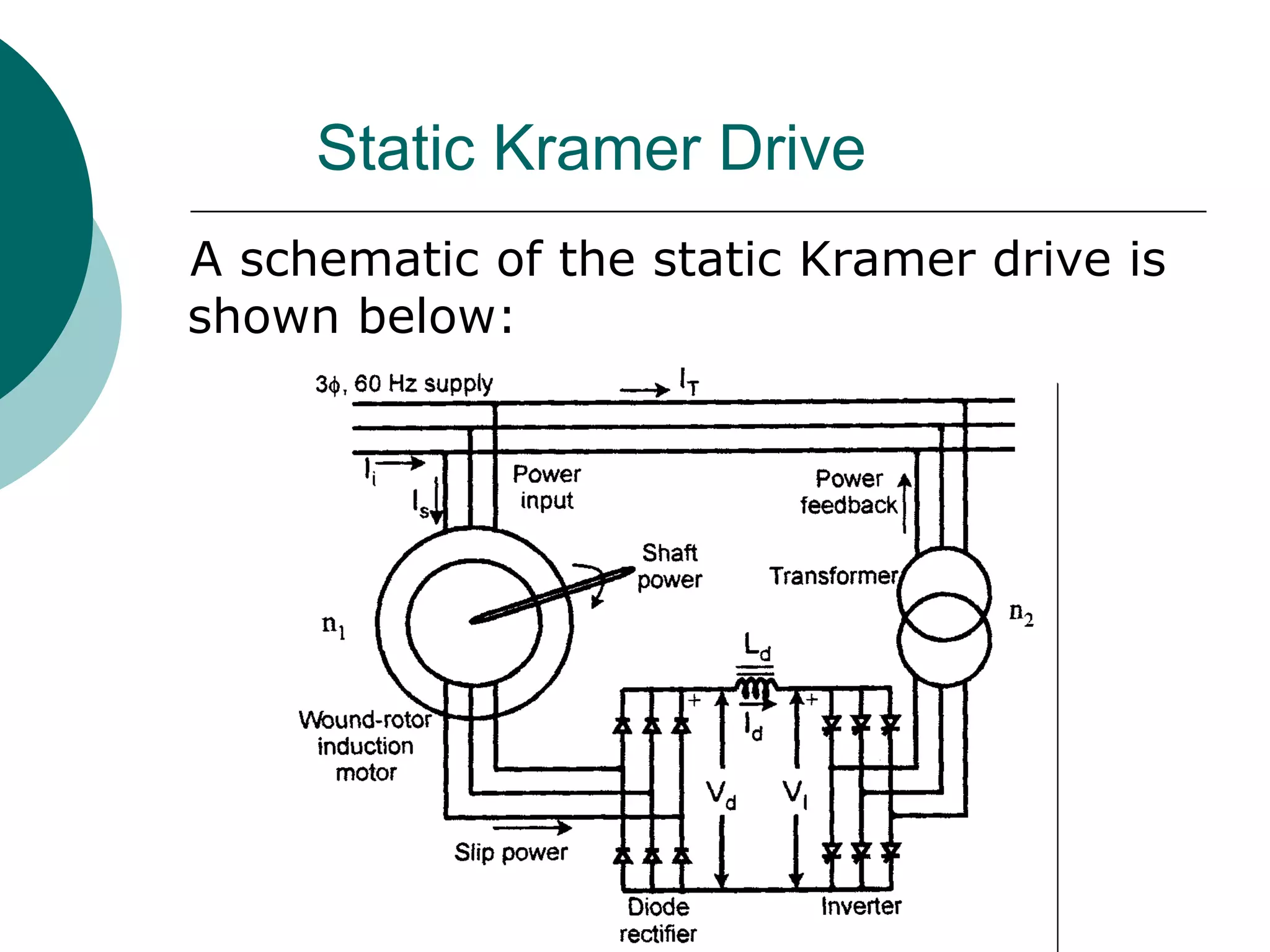

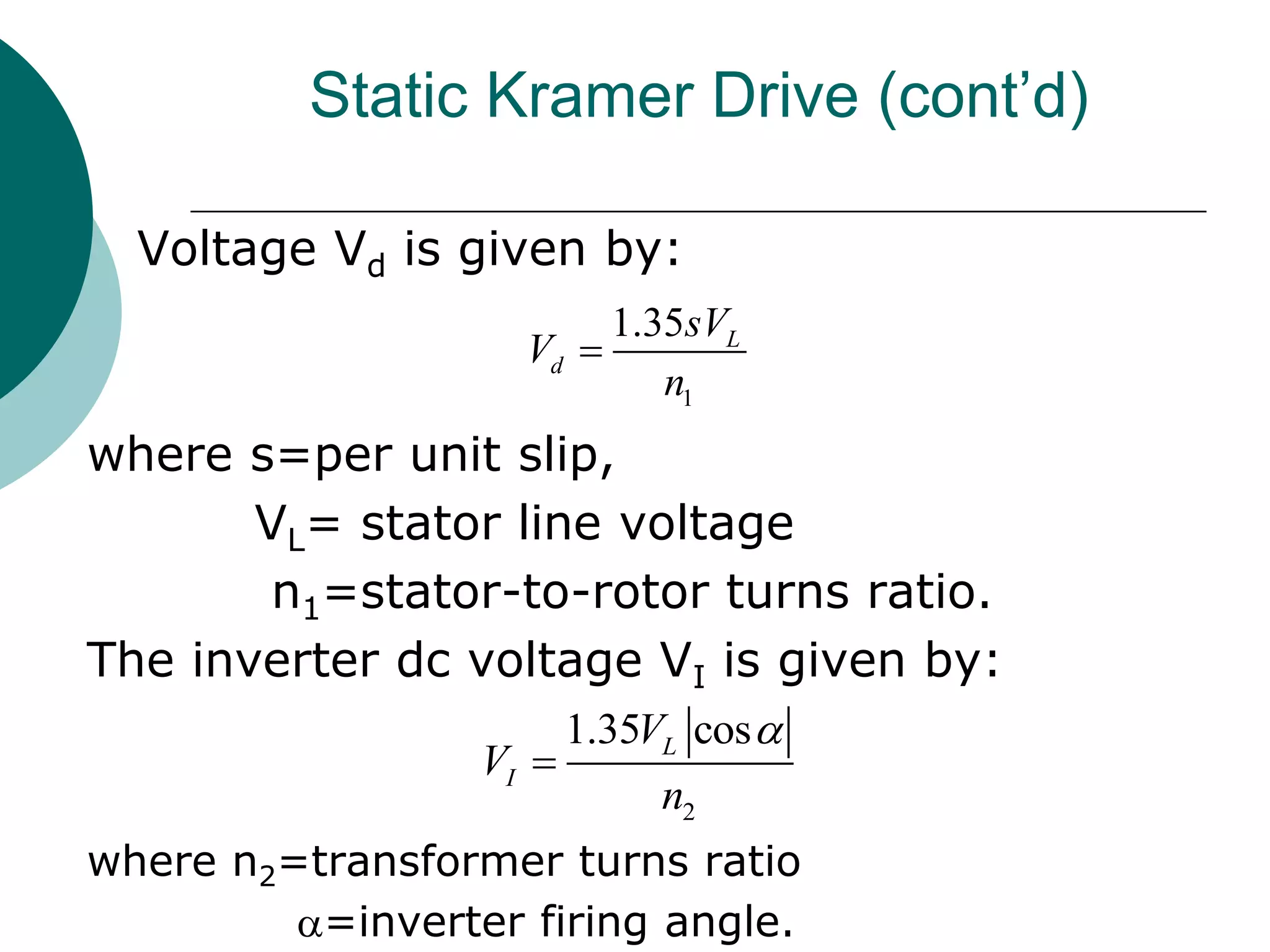

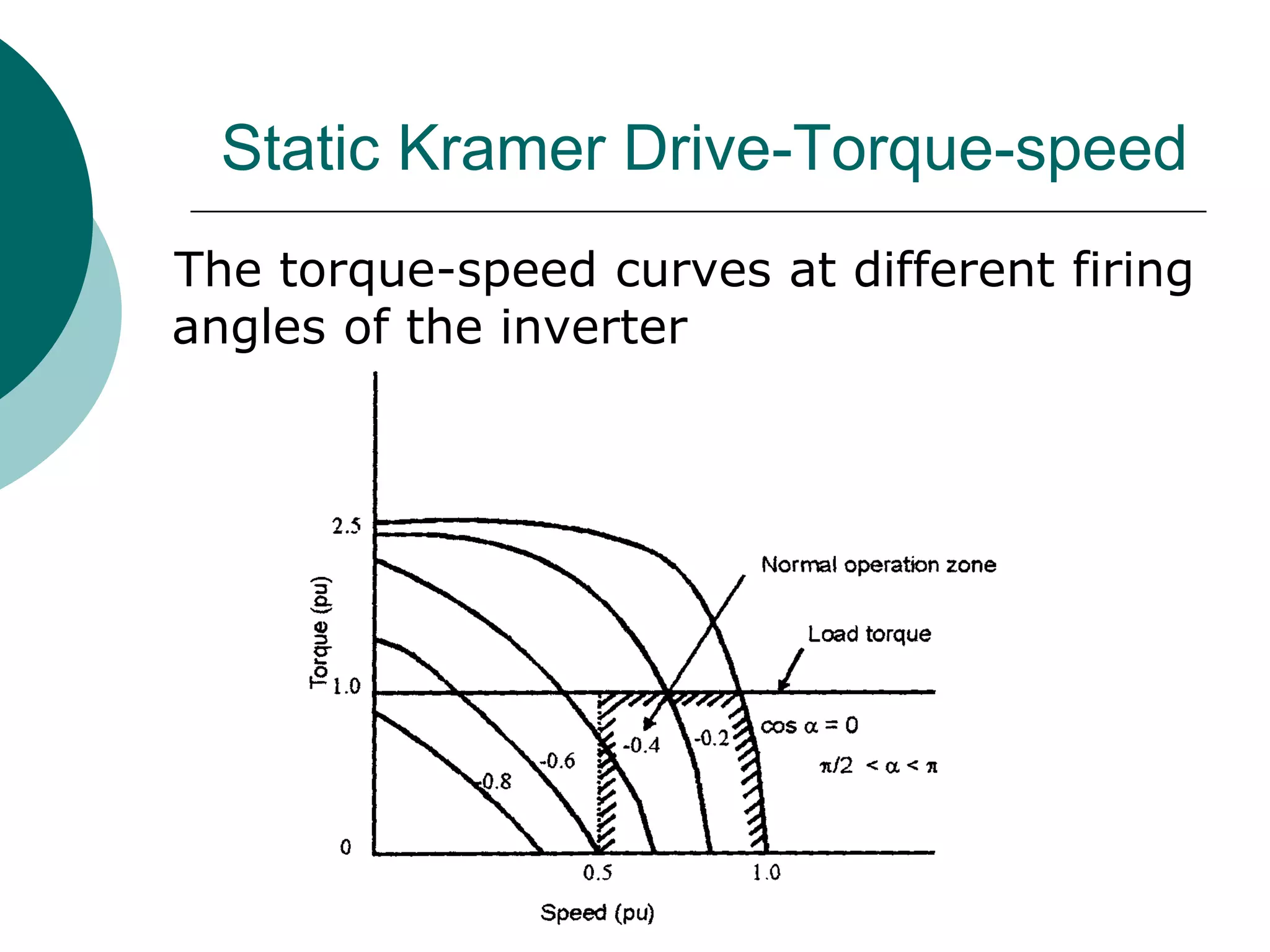

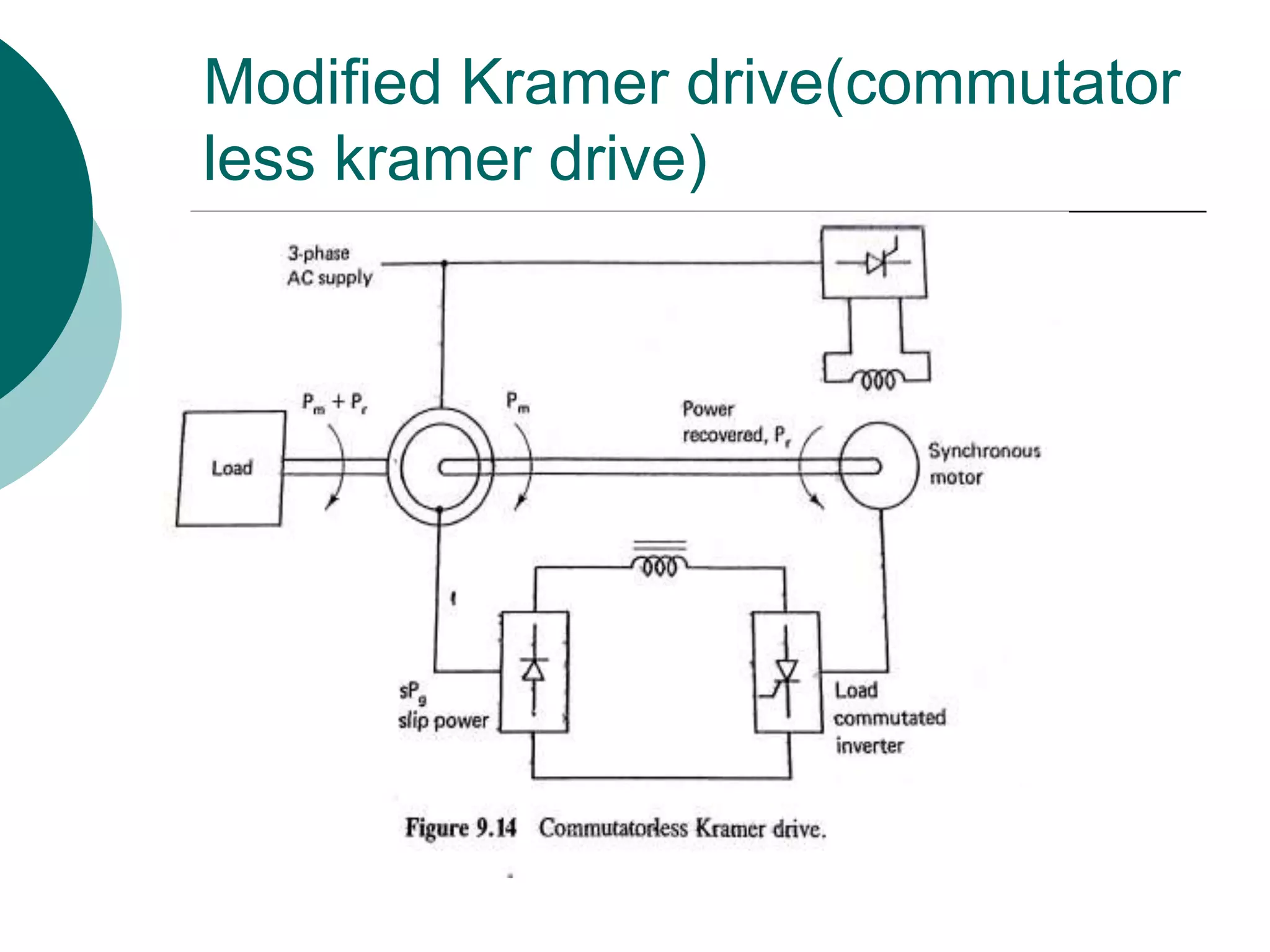

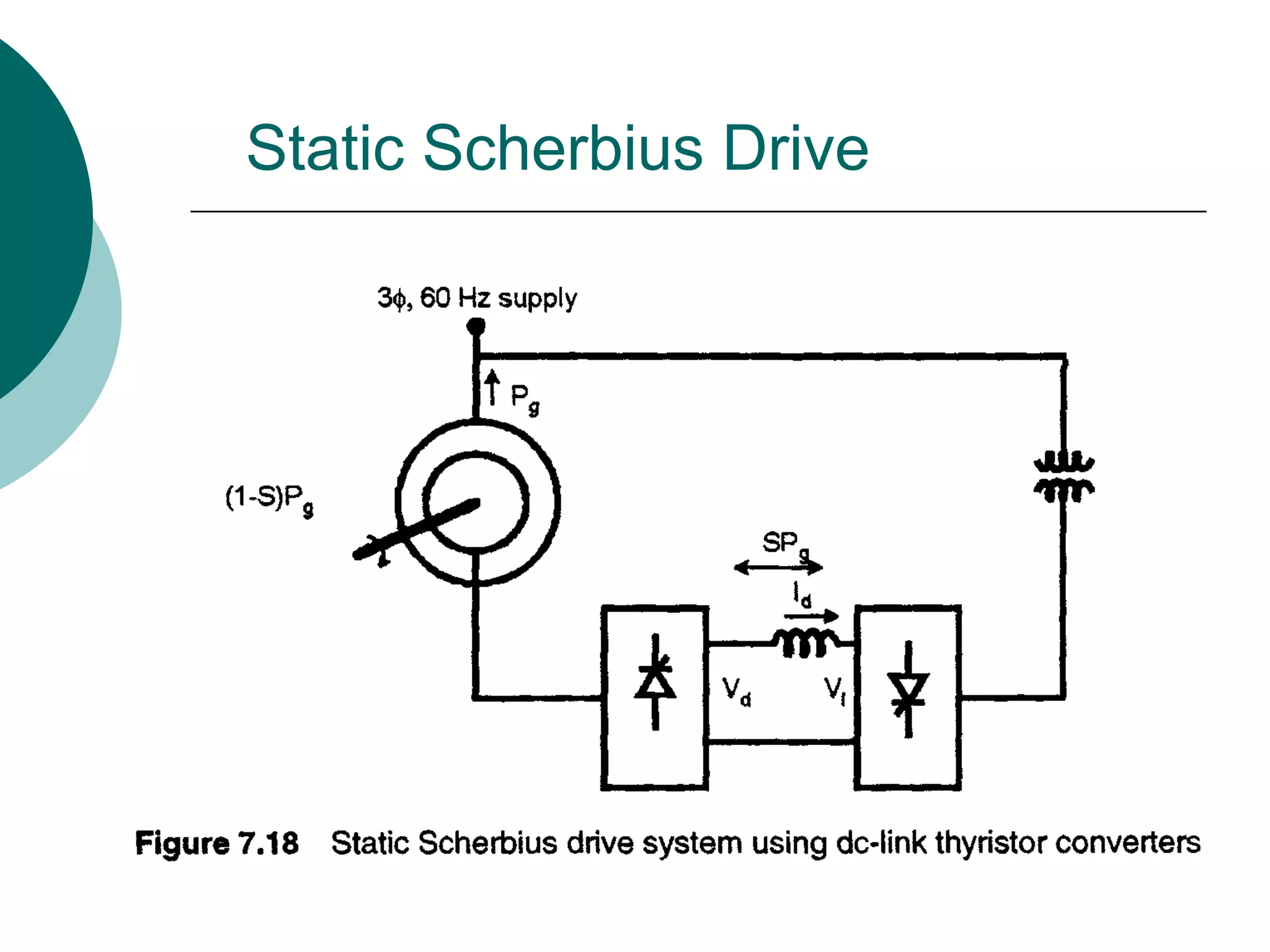

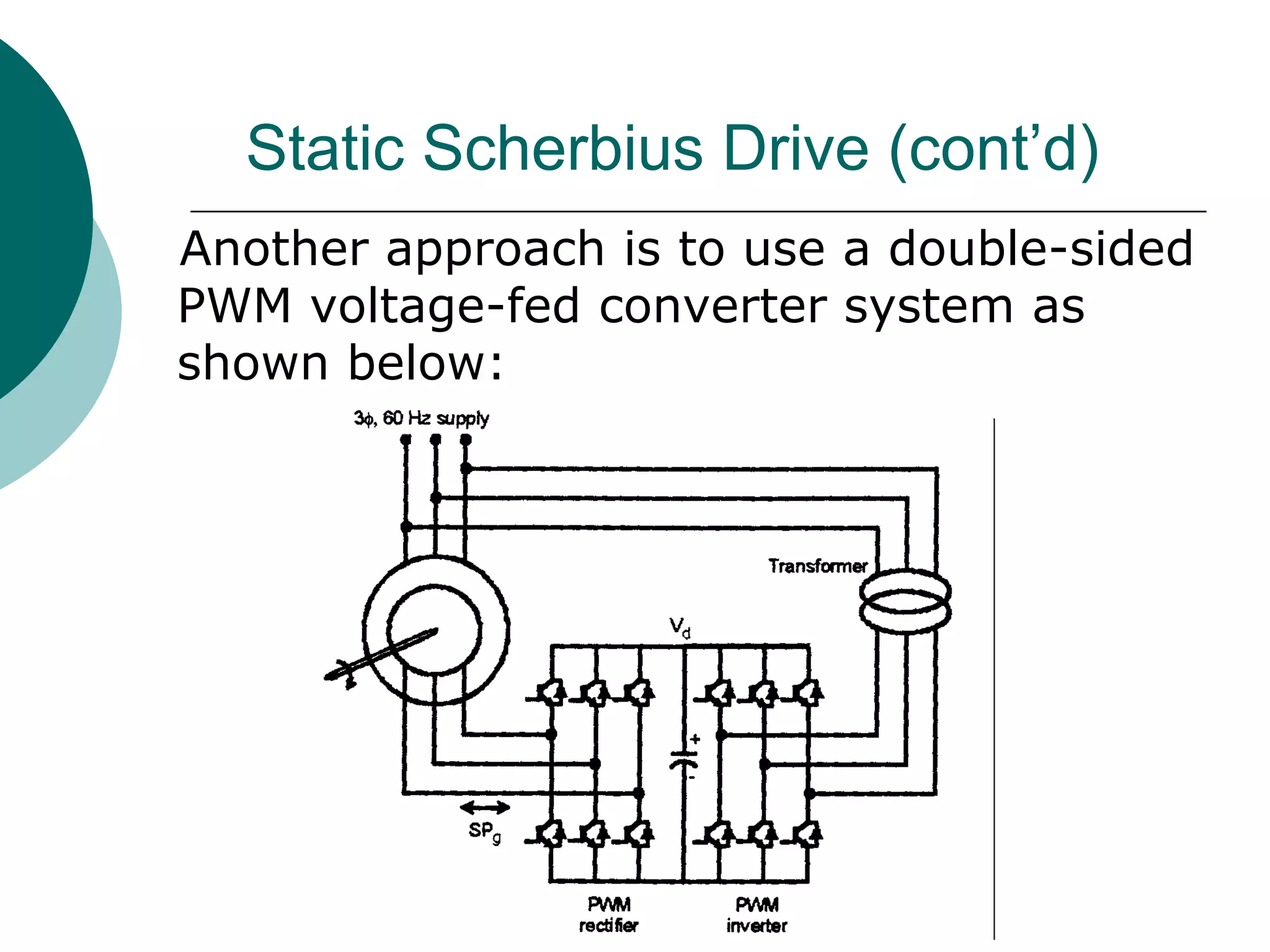

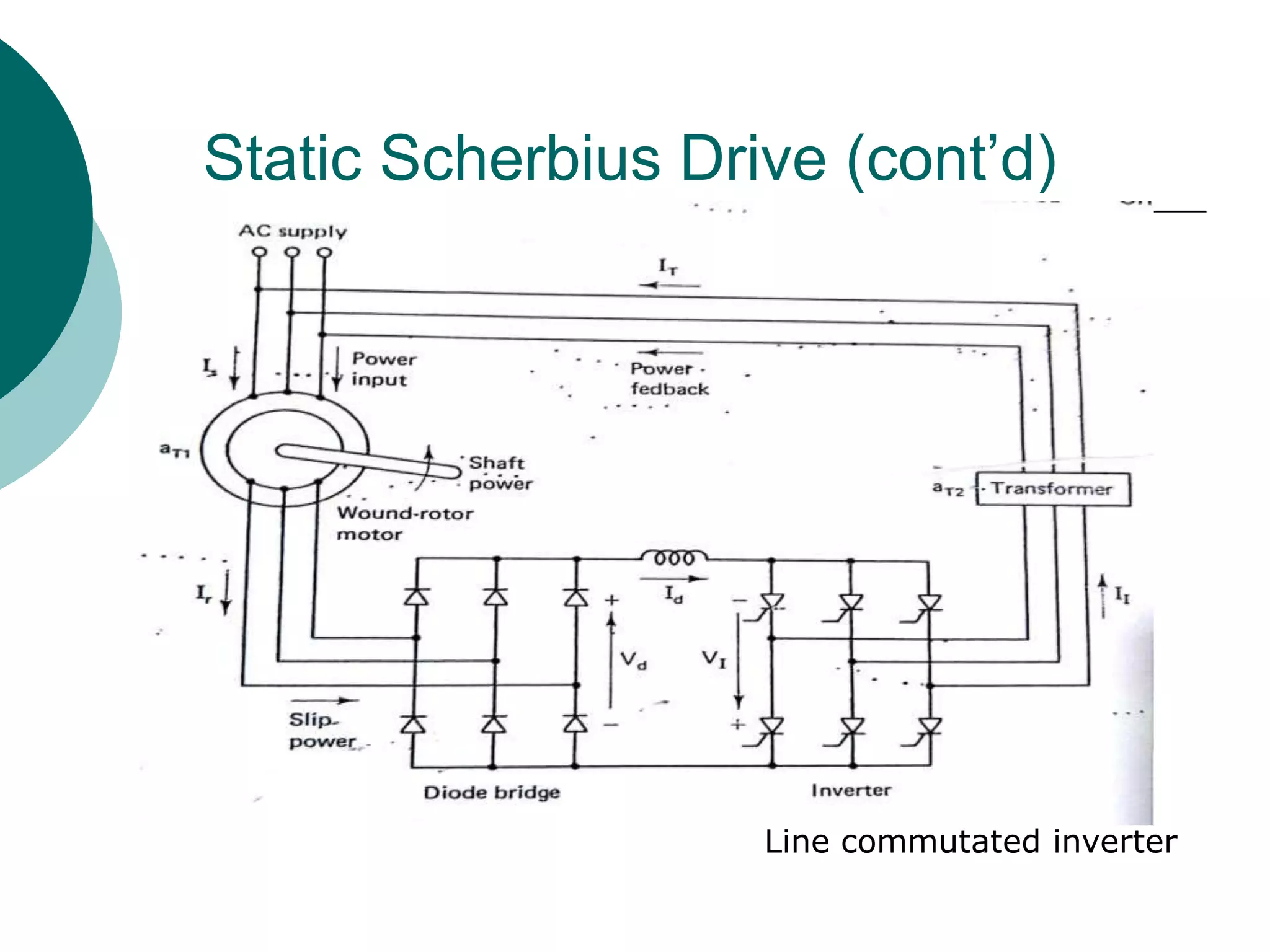

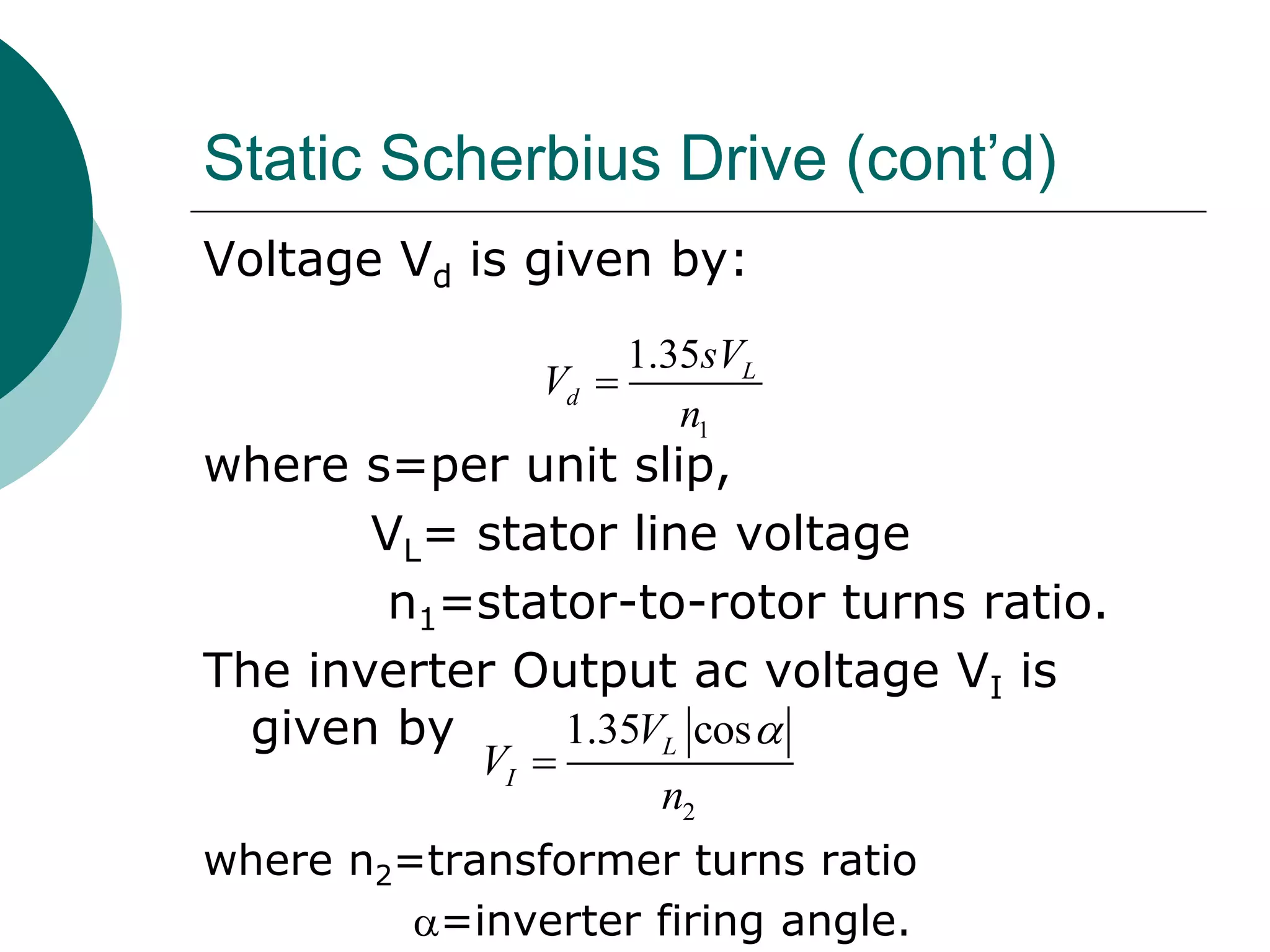

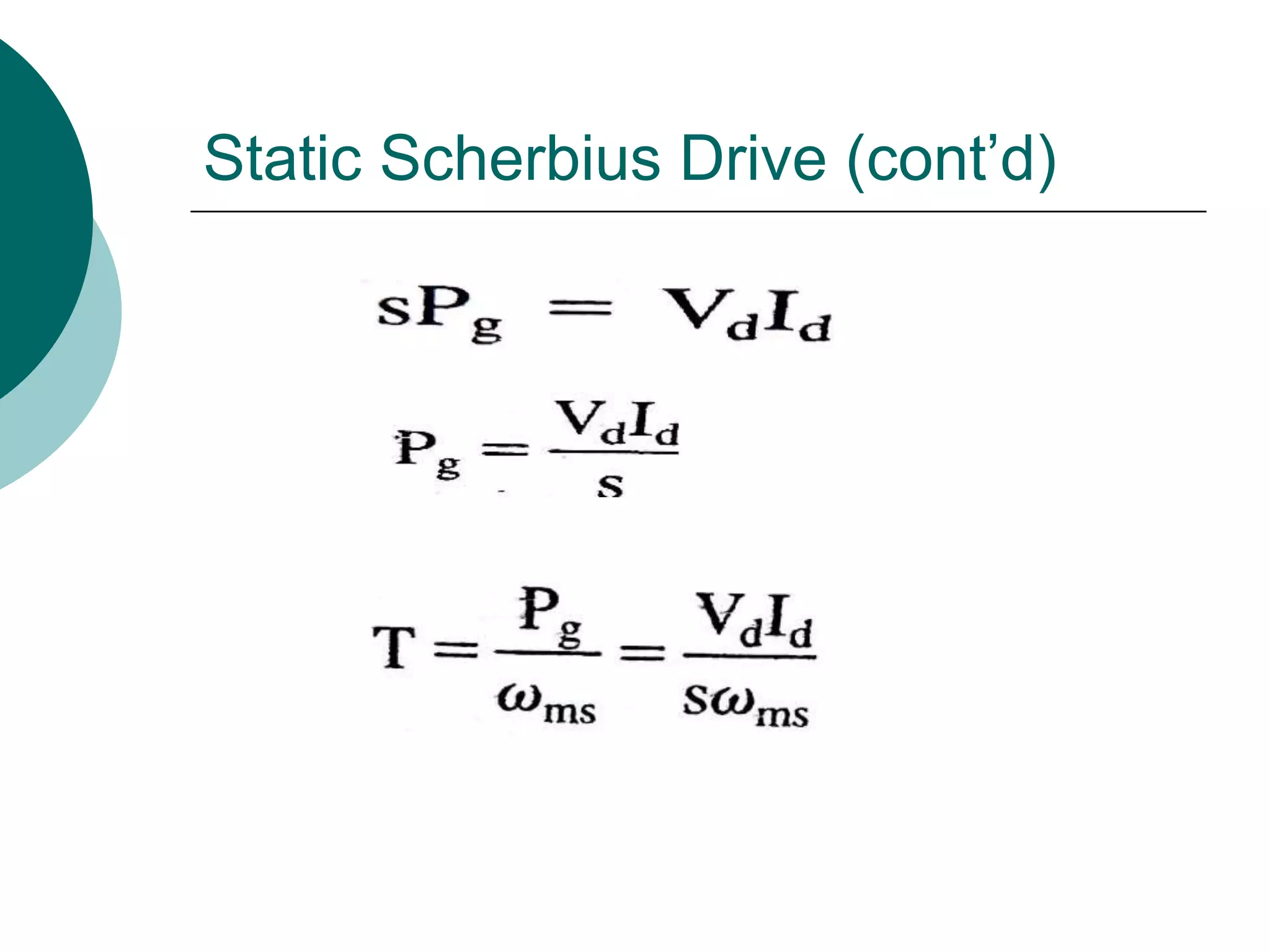

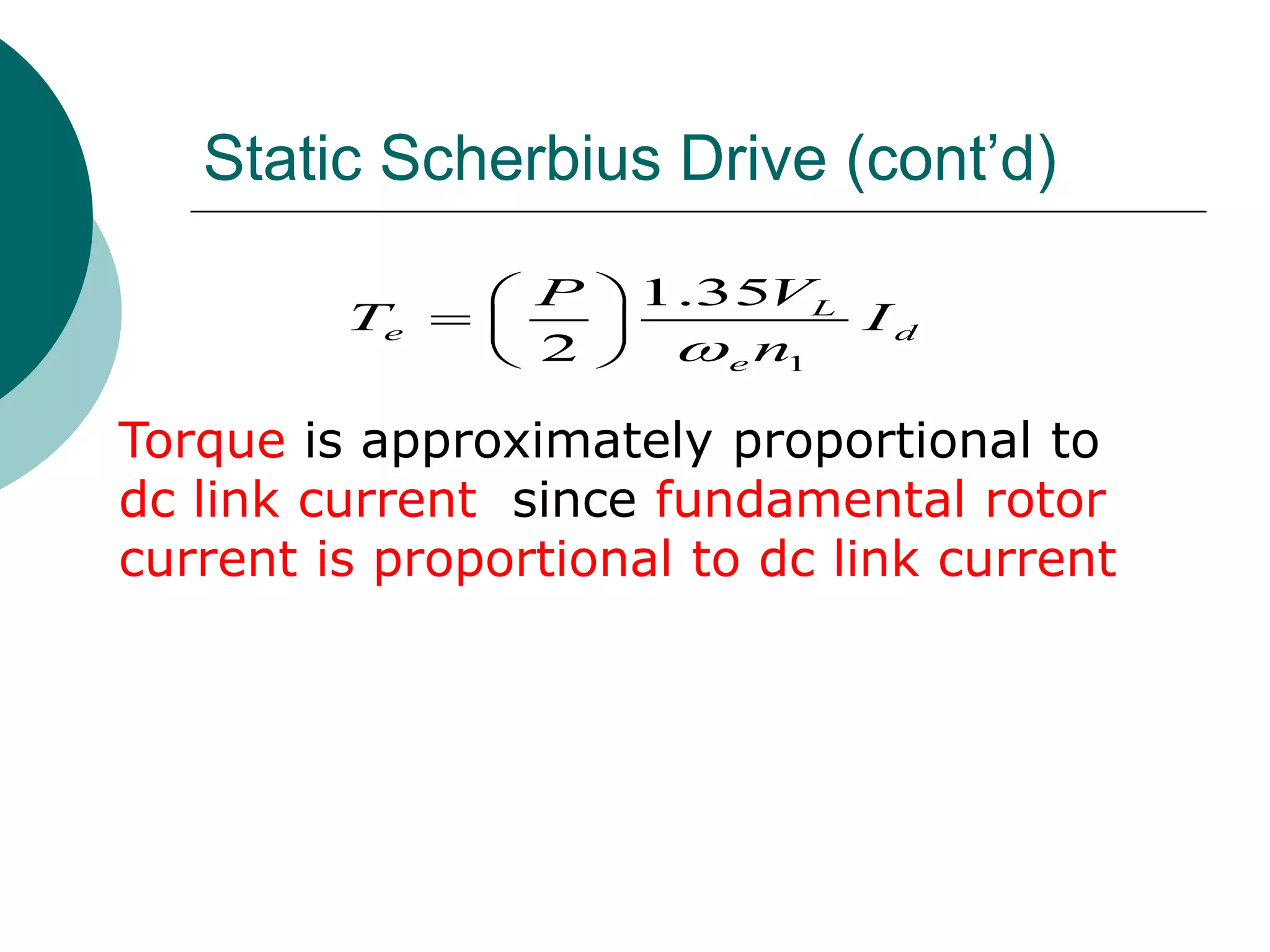

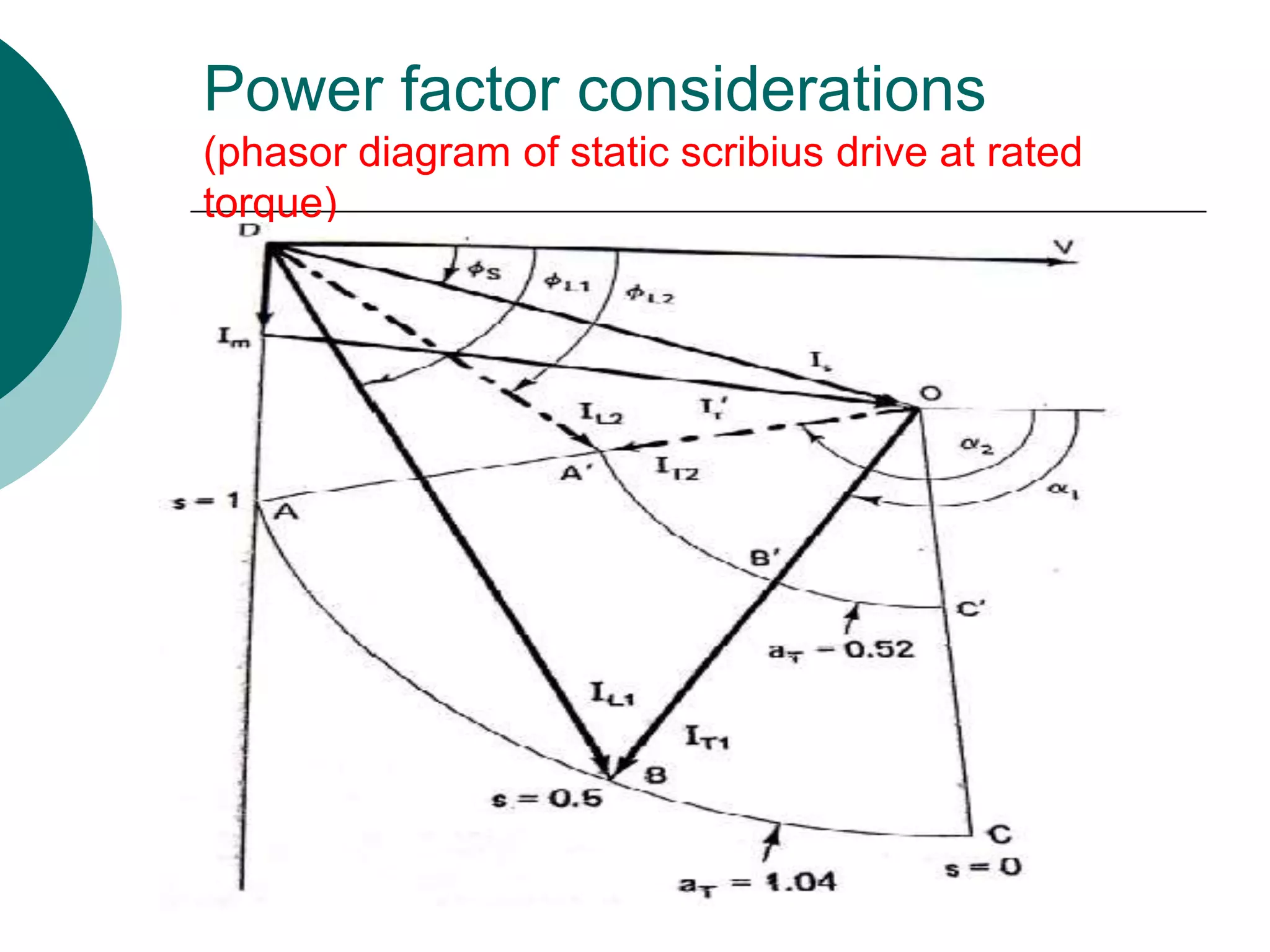

2) Slip power recovery schemes like static Kramer and Scherbius drives that convert slip power to AC line power to improve efficiency.

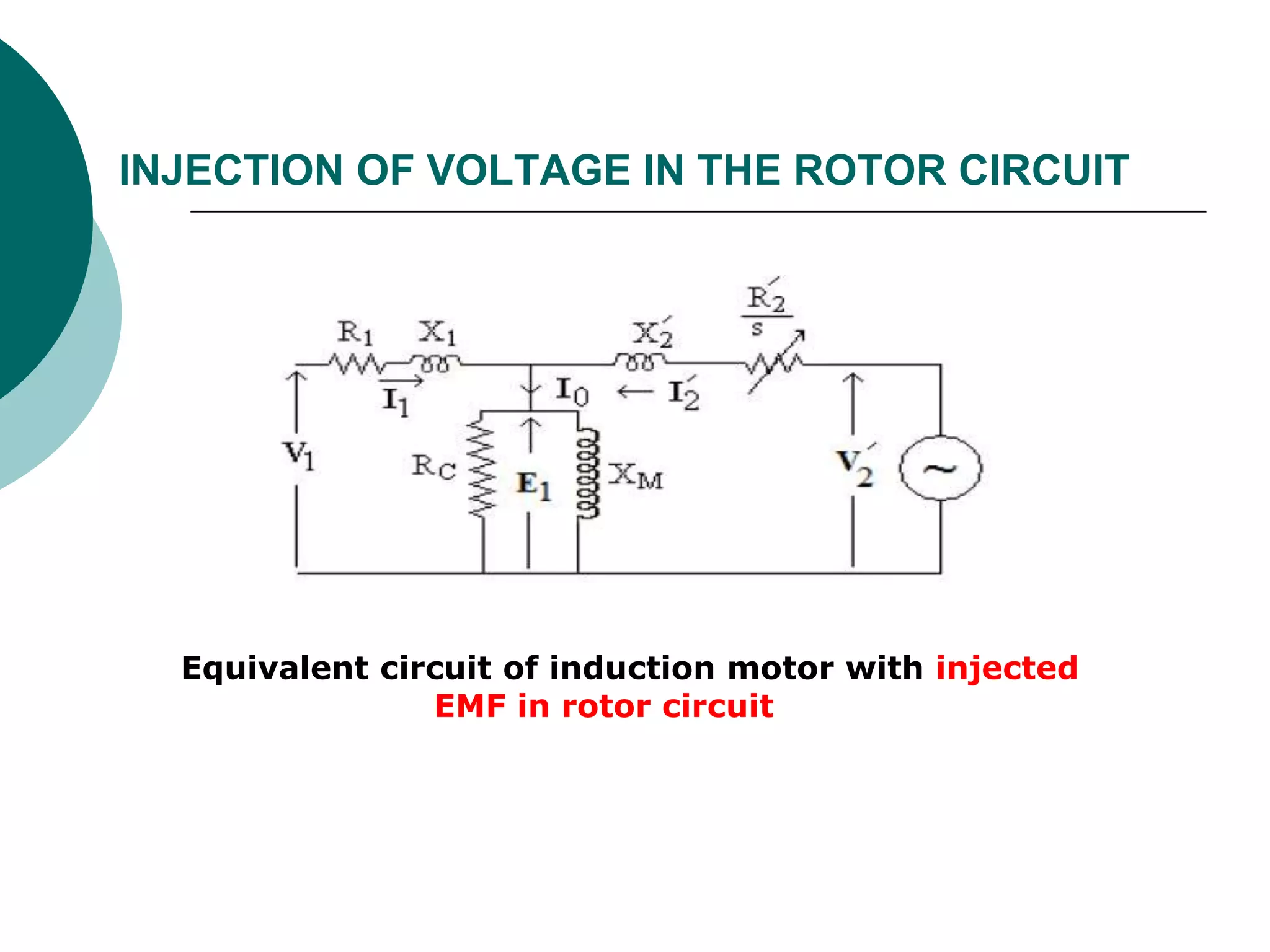

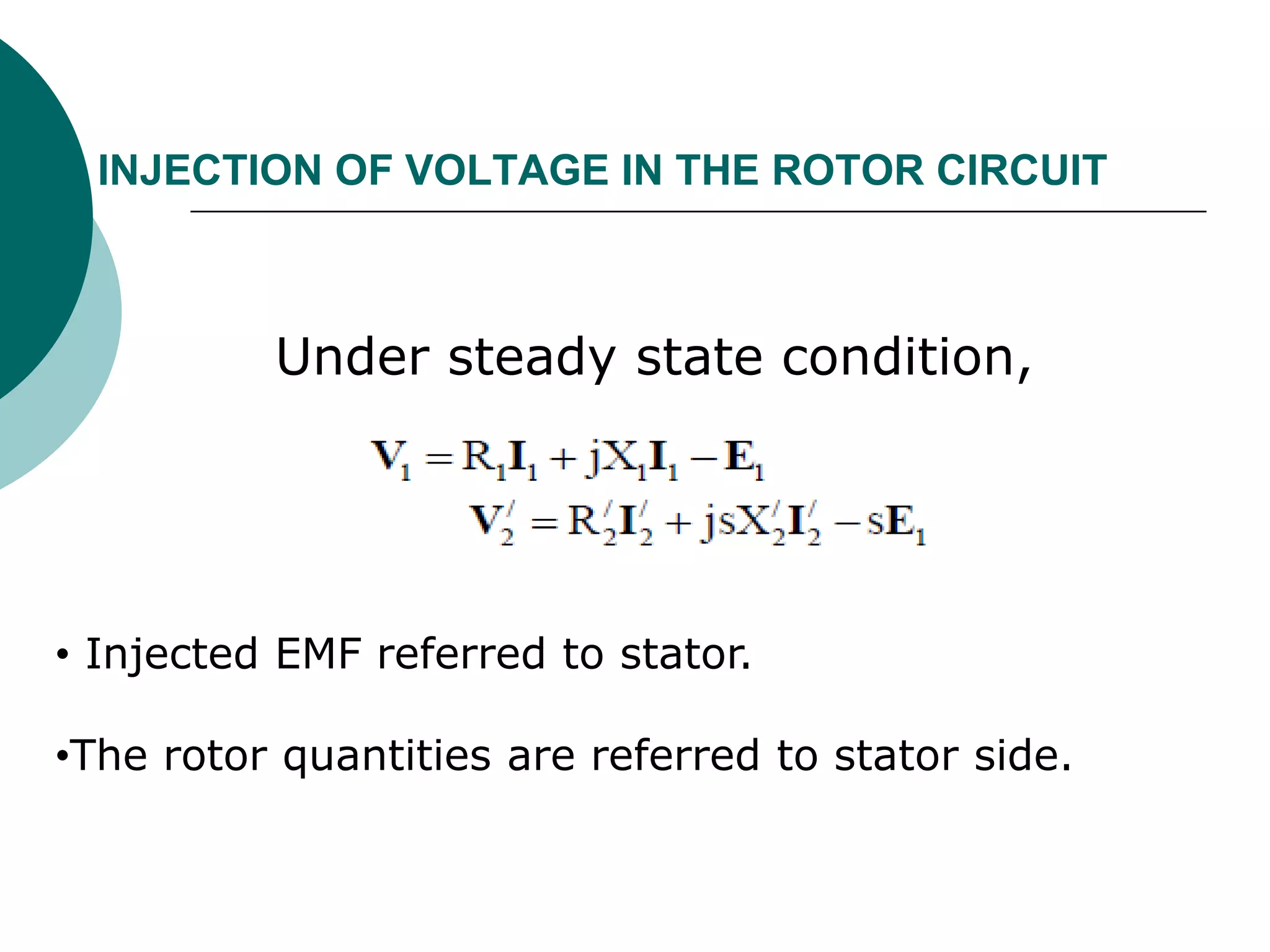

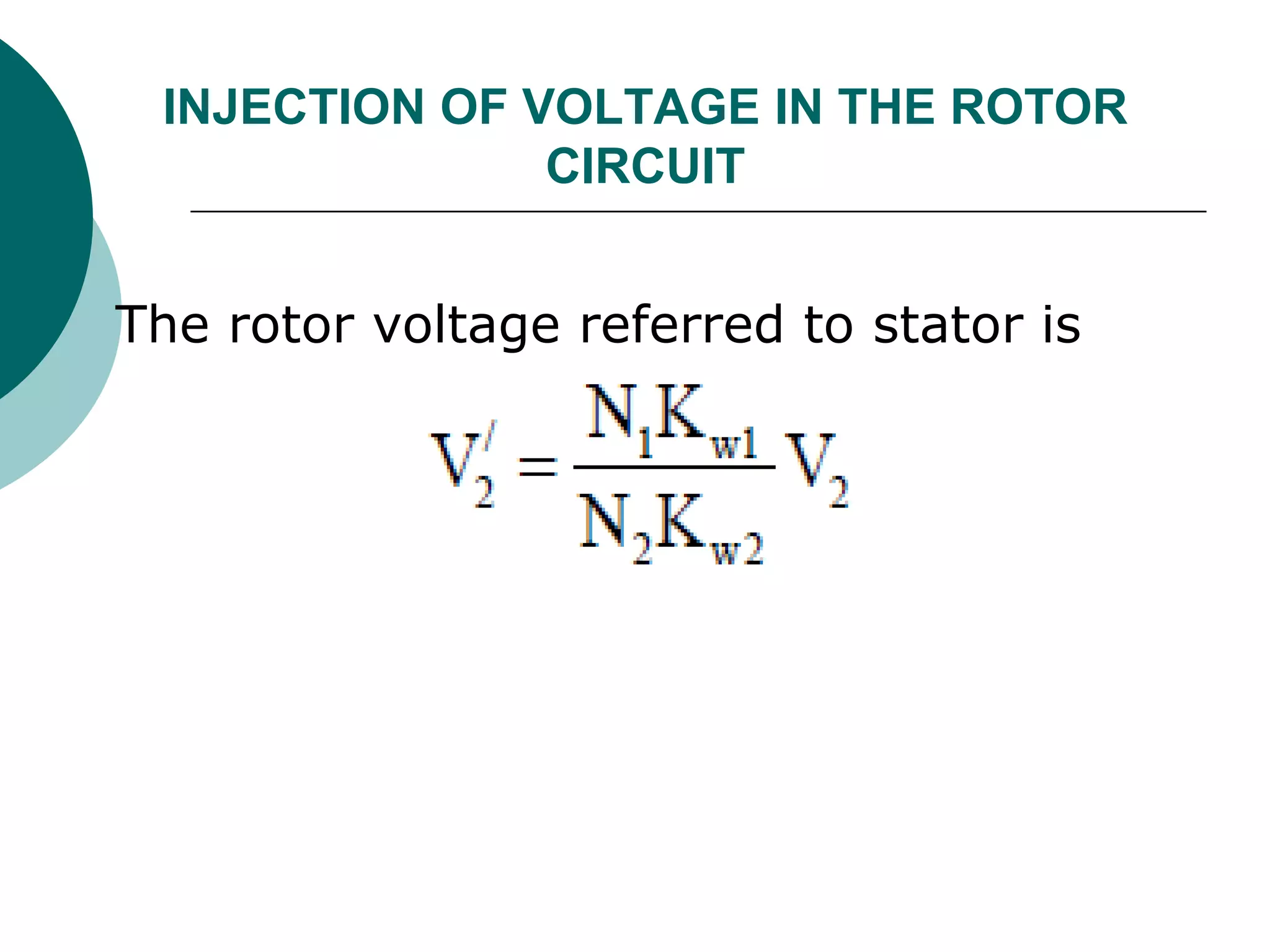

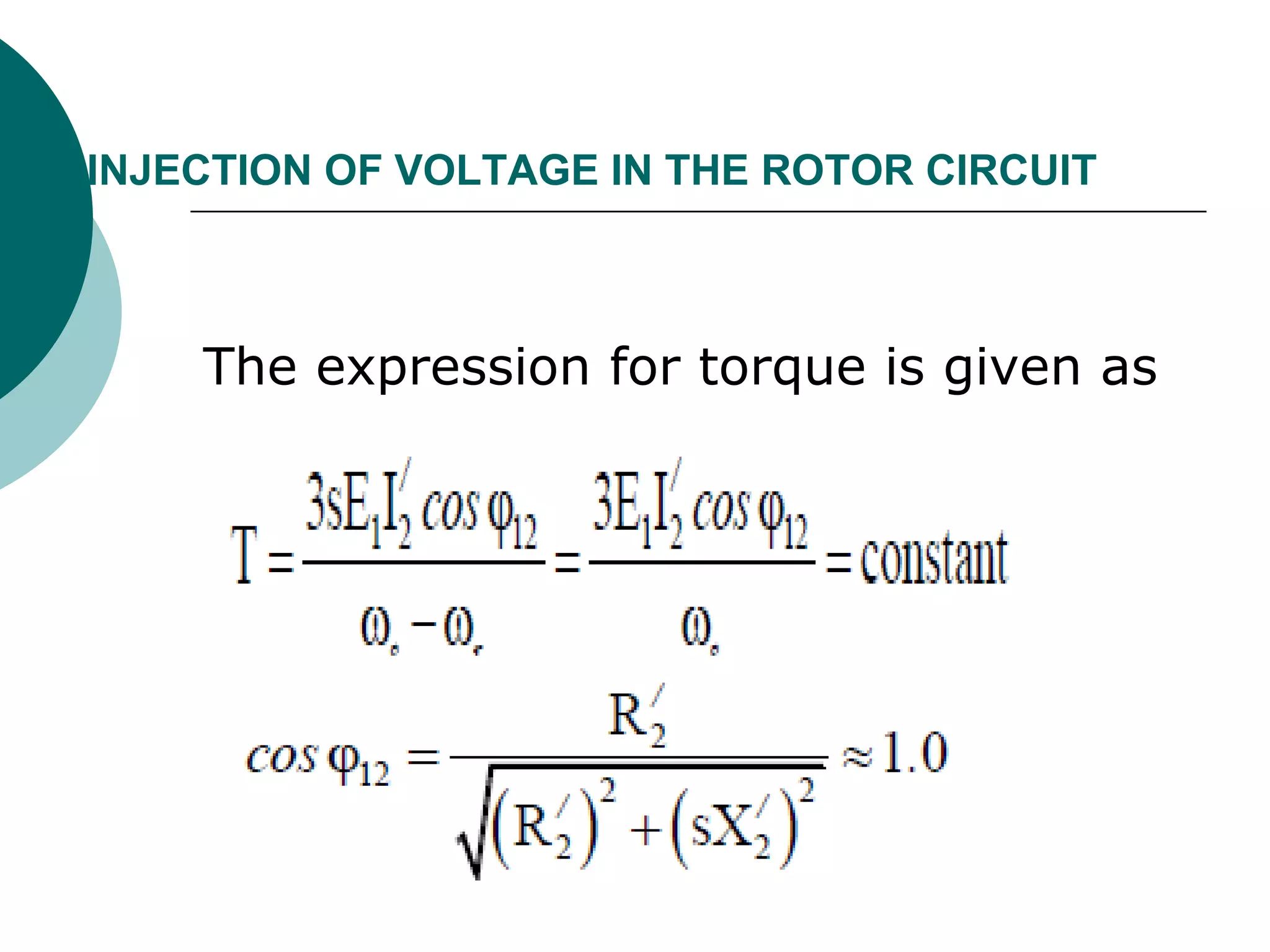

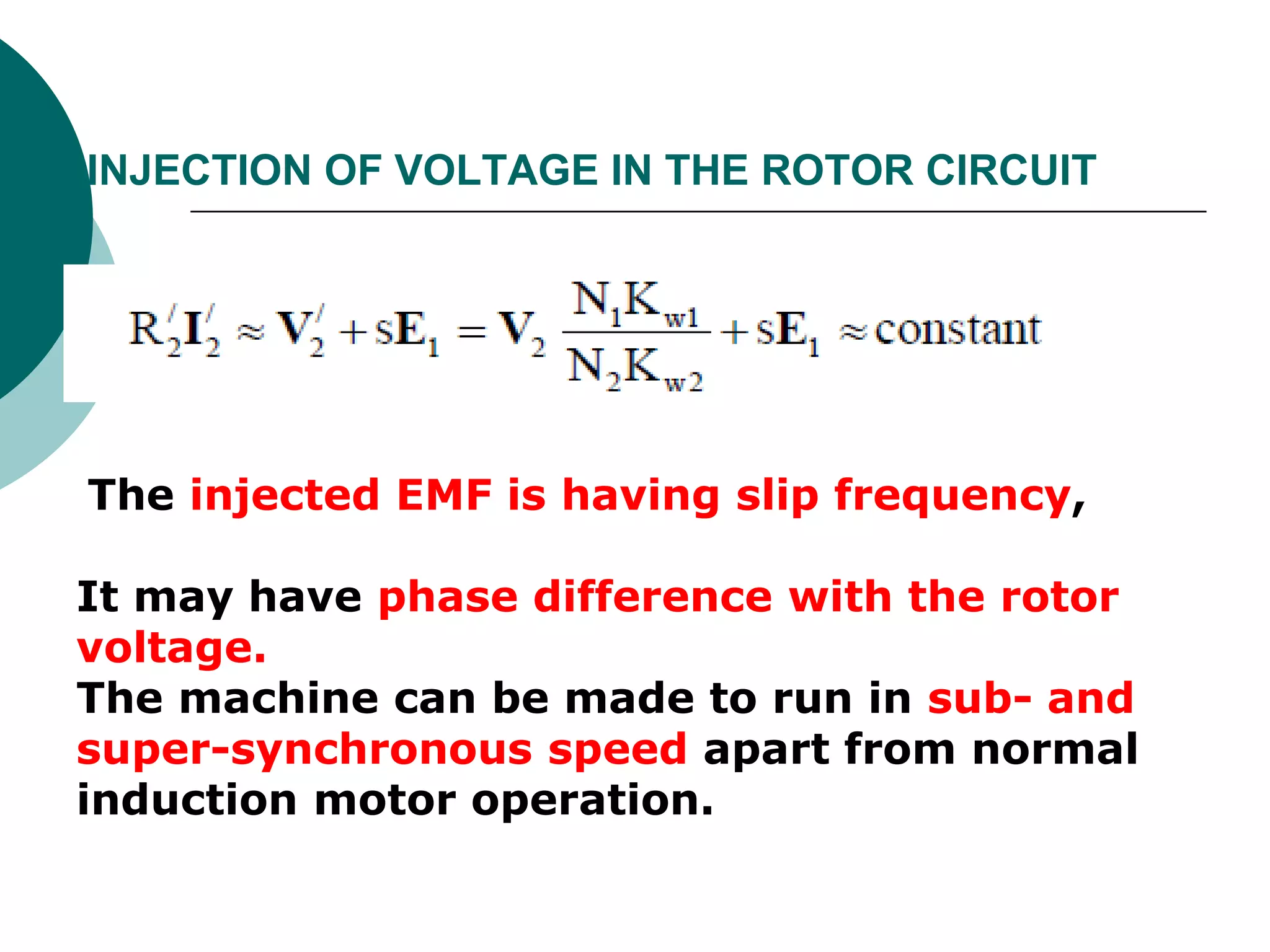

3) Injection of voltage in the rotor circuit using a Schrage motor to produce an EMF that is injected at slip frequency to control speed.

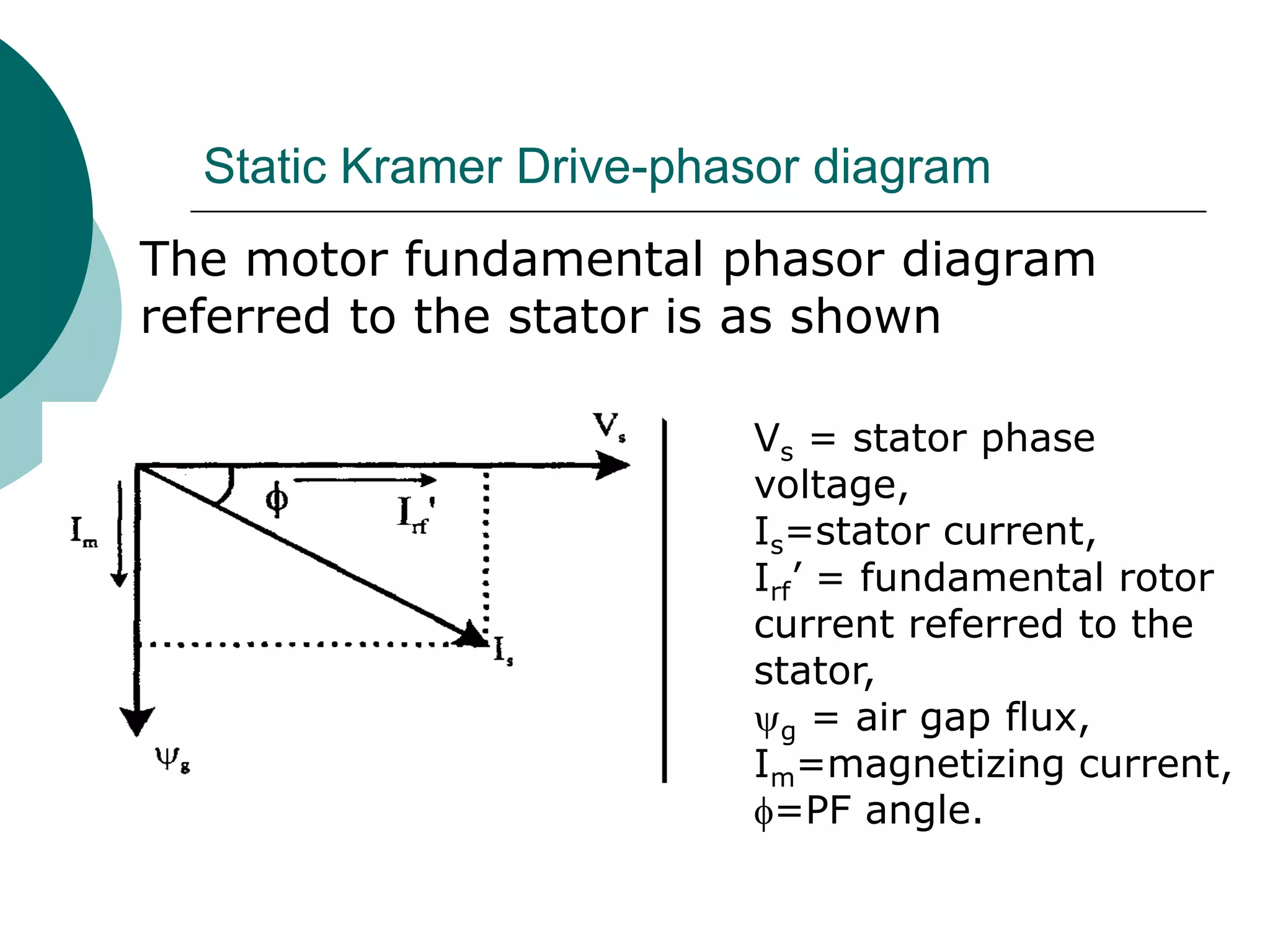

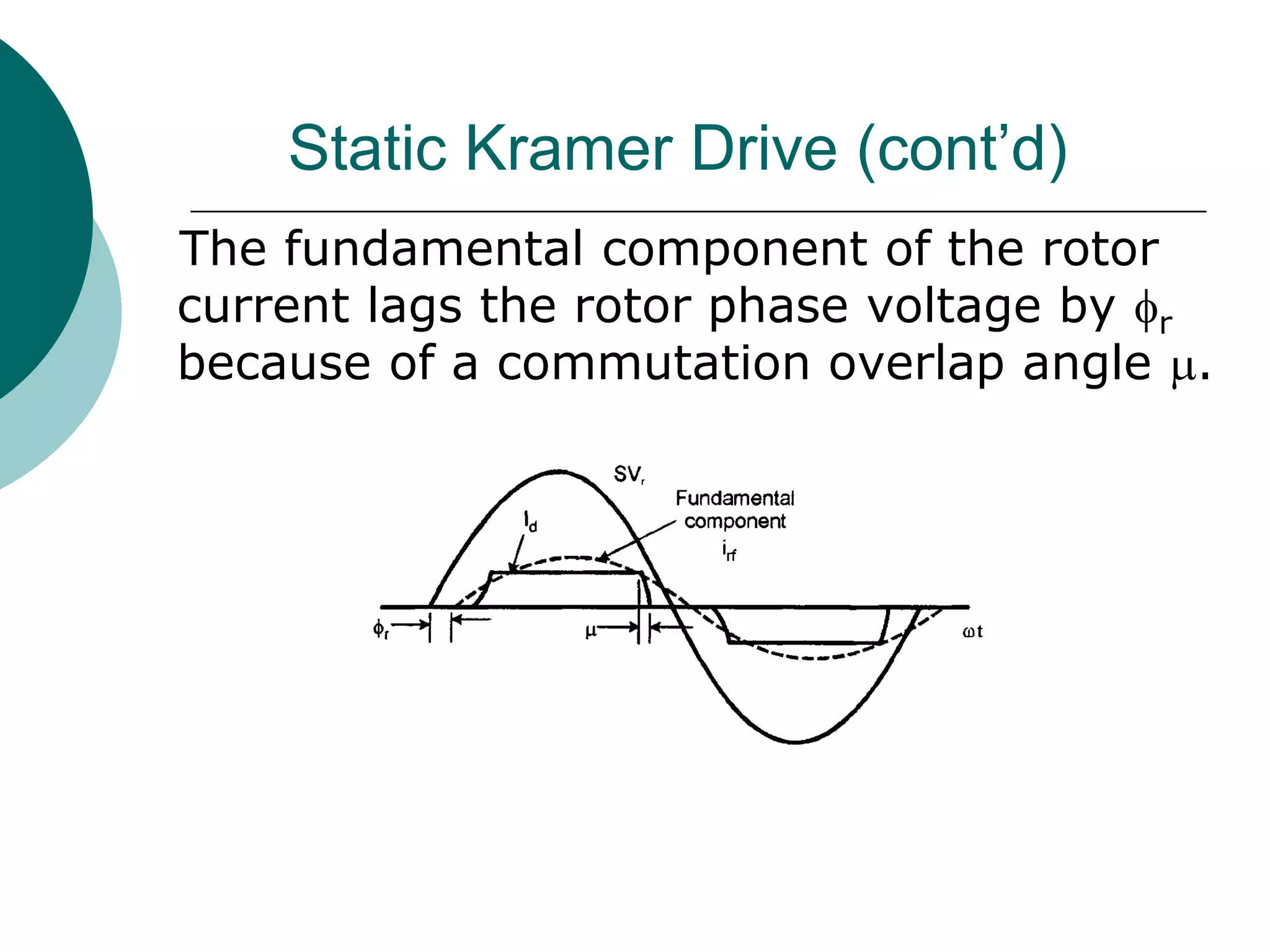

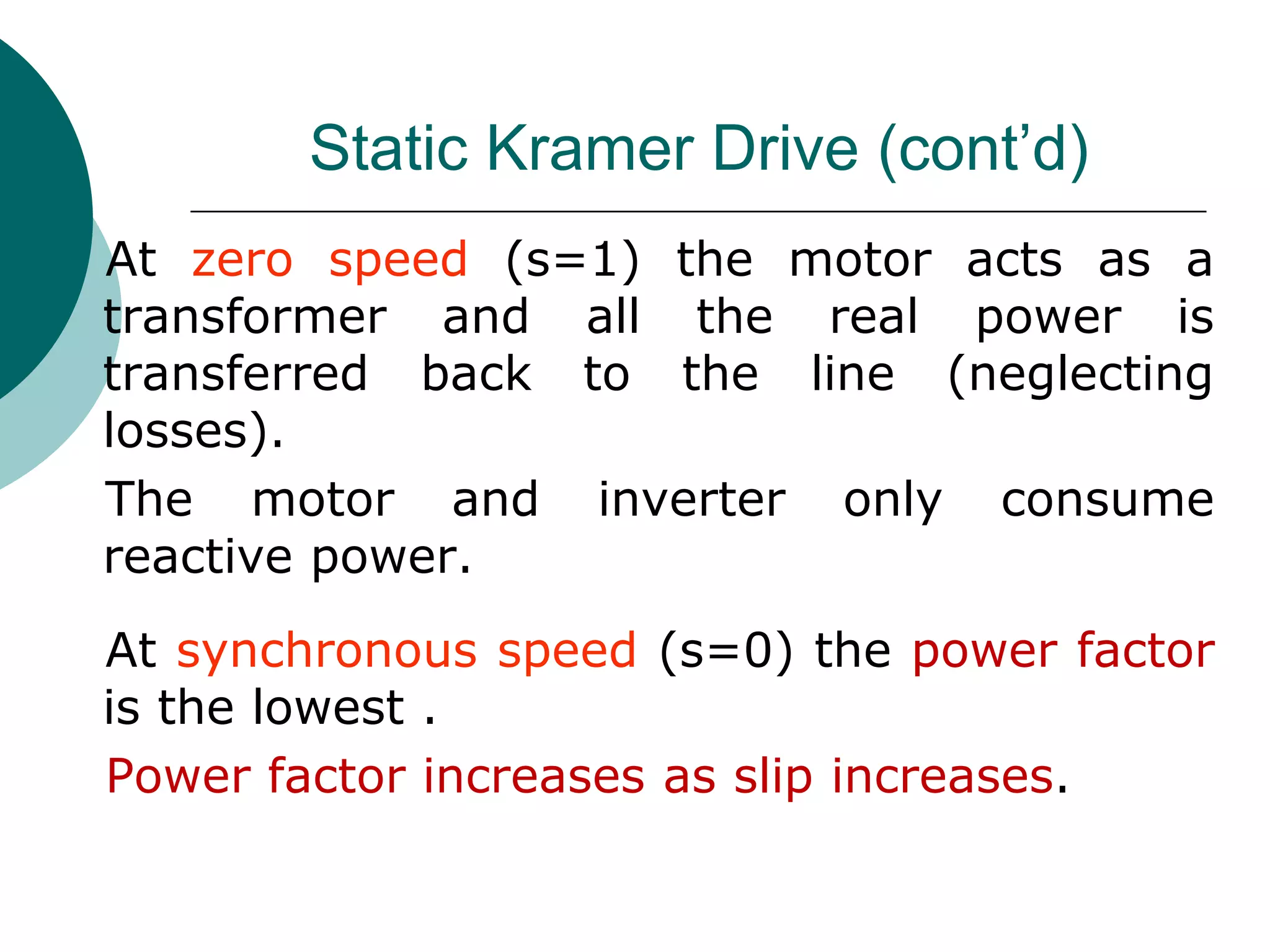

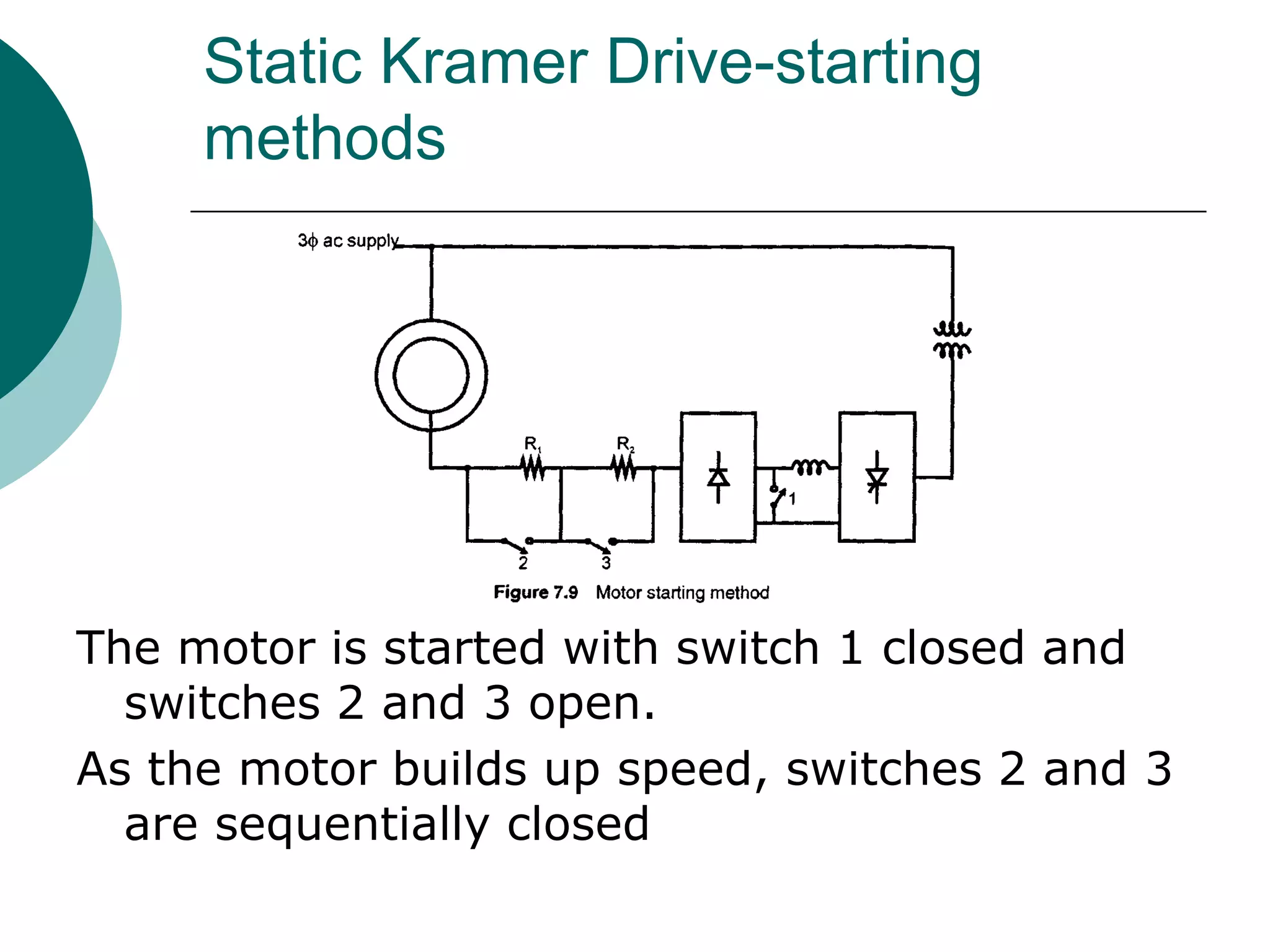

The document provides details on operating principles, equivalent circuits, torque expressions, and power factor considerations for different rotor control induction motor drives.