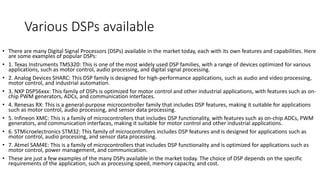

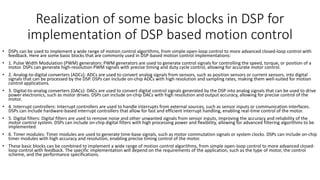

Digital Signal Processors (DSPs) are integral in motion control systems for real-time motor and mechanical system control, offering fast computation, precise control, and flexible programming. Various DSPs, such as those from Texas Instruments and Analog Devices, cater to motor control and industrial applications, featuring capabilities like PWM generation and ADCs. The implementation of basic motion control blocks, including PWM generators and digital filters, enhances the performance and reliability of these systems.