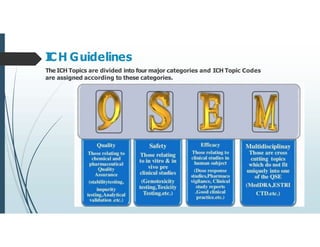

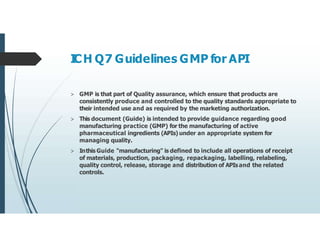

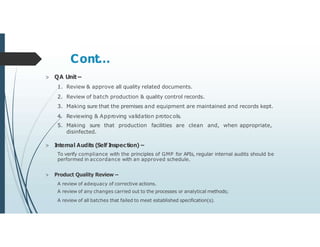

The document provides an overview of the ICH Q7 guidelines focused on Good Manufacturing Practice (GMP) for active pharmaceutical ingredients (APIs), emphasizing the importance of quality assurance and control in drug manufacturing. It outlines the responsibilities of personnel, facility requirements, production processes, and documentation necessary to ensure high-quality and effective medicines. Adhering to these guidelines is essential for regulatory compliance and improving manufacturing efficiency.