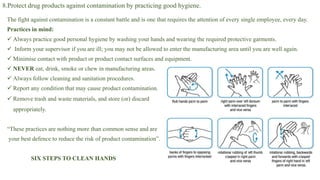

CGMP (Current Good Manufacturing Practices) ensures that medicinal products are consistently produced and controlled to quality standards required for their intended use. QA plays an important role in CGMP by verifying equipment qualifications, approving manufacturing documents, and verifying processes like cleaning validation, data integrity, sampling, and analytical reports. Maintaining CGMP requires following written procedures, accurately recording work, validating processes, developing facilities and equipment properly, maintaining quality control through practices like hygiene, and designing quality into manufacturing processes and product life cycles.