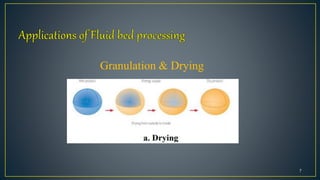

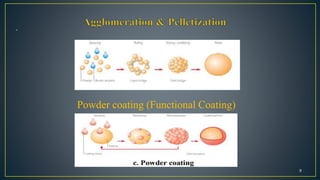

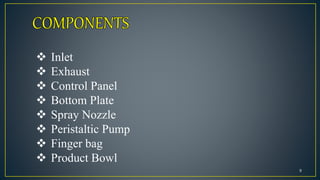

This document provides an overview of fluidized bed processing (FBP). It discusses the principle of fluidization, how FBP works, its components, and applications. FBP uses air to fluidize solid particles, allowing for high rates of heat and mass transfer. This makes it useful for granulation, drying, and coating processes. It has advantages like high drying rates and easy handling but also disadvantages like potential for product loss and requirement of skilled operators. FBP is widely used in pharmaceutical manufacturing for applications like granule drying, tablet coating, and functional powder coating.