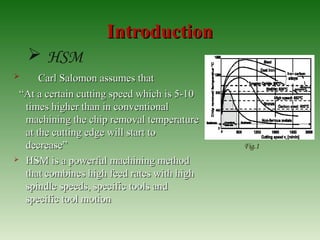

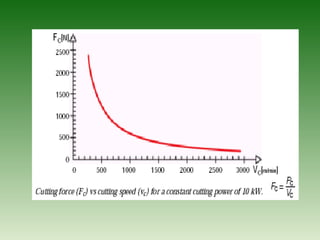

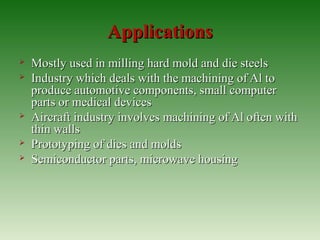

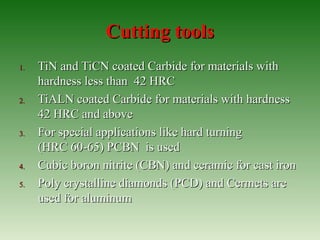

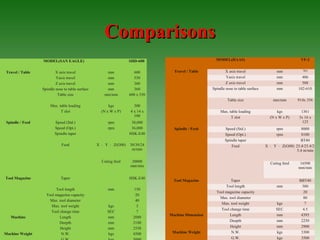

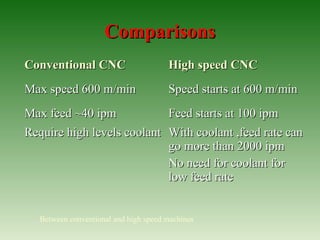

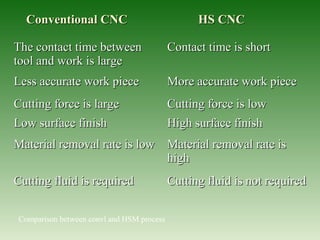

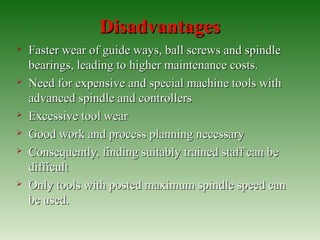

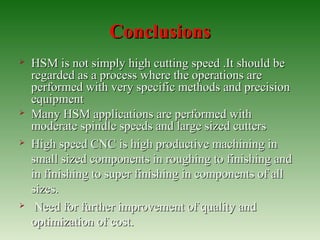

This document provides an overview of high speed CNC machining. It discusses how high speed CNC combines high feed rates and spindle speeds with specialized tools and motions. Key advantages include high material removal rates, improved surface finish and accuracy, and increased productivity. High speed CNC demands high power spindles that can reach speeds over 60,000 RPM along with rapid tool changes and integrated coolant systems. It finds applications in hard metals and high precision industries. While enabling greater efficiencies, high speed CNC also requires more advanced machine tools and trained operators.