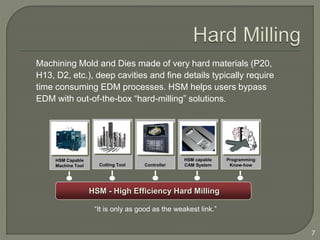

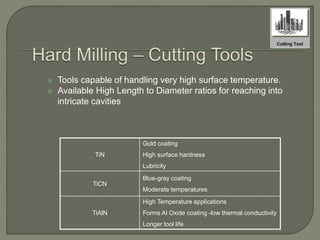

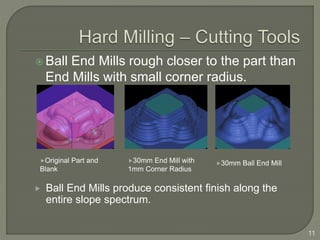

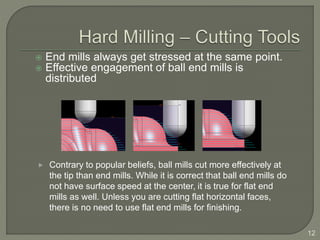

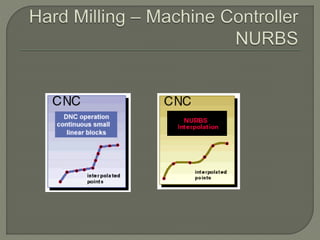

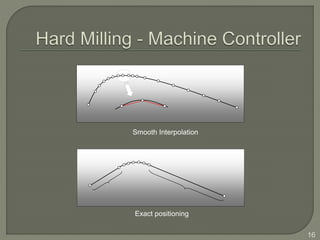

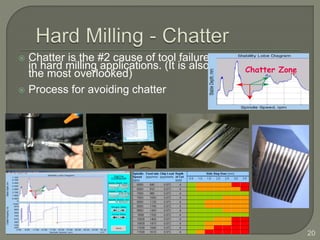

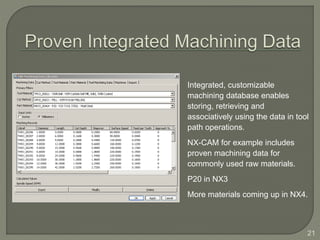

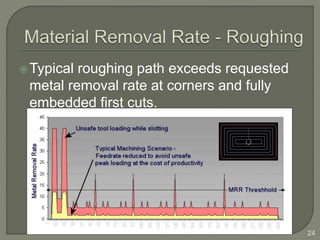

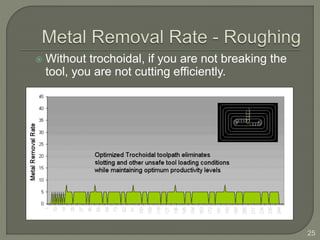

The document outlines the principles, benefits, and challenges of high-speed machining (HSM), particularly in hard milling applications. HSM is characterized by high tool RPM, small depths of cut, and high feed rates, allowing for improved productivity and quality finishes while reducing the need for traditional EDM processes. It emphasizes the importance of components and programming knowledge necessary for effective HSM, including machine capabilities, tool selection, and chatter management.