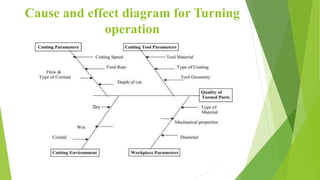

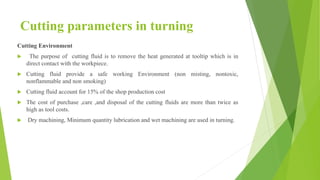

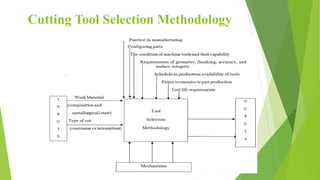

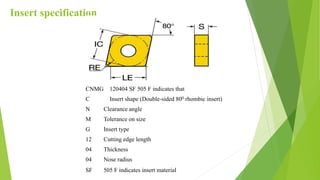

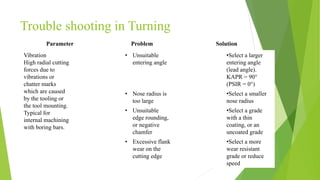

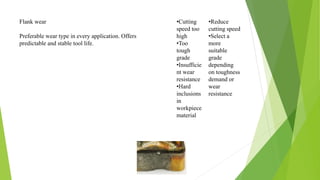

The document provides an overview of turning, a machining process using a single-point cutting tool for material removal, which involves key components like the machine, workpiece, and cutting tool. It discusses hard turning as a beneficial method for finishing products, including its advantages, limitations, and applications across various industries such as automotive and aerospace. Additionally, the document details the selection of cutting tools, the importance of machining conditions, and various parameters affecting the turning process.