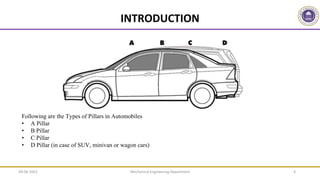

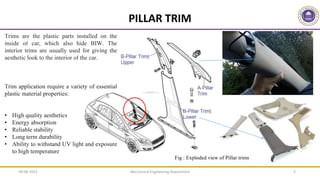

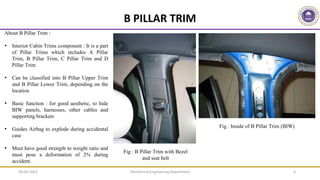

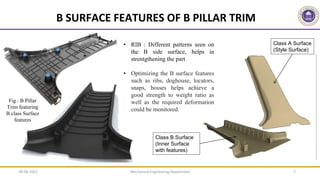

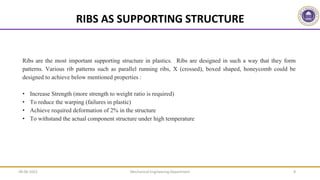

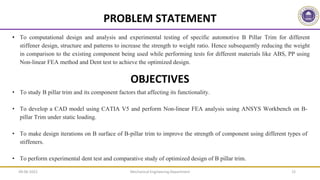

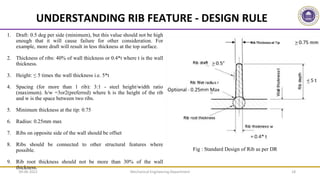

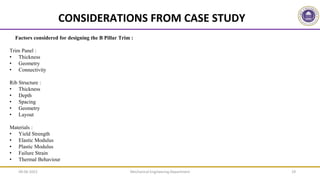

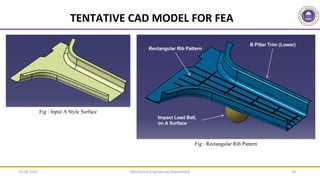

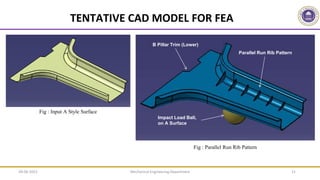

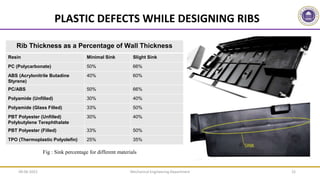

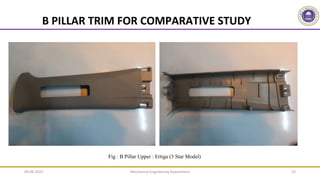

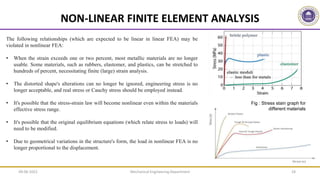

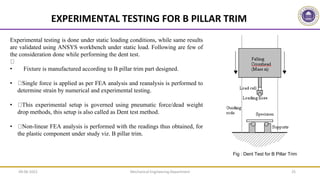

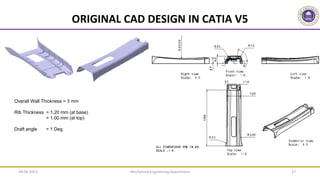

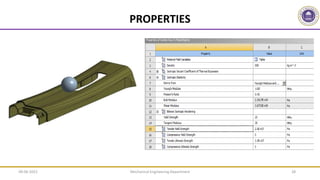

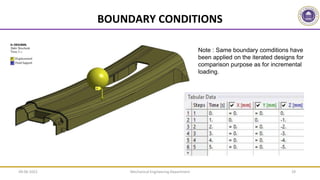

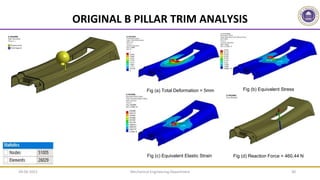

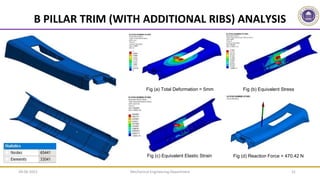

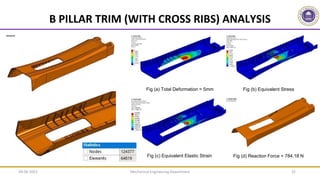

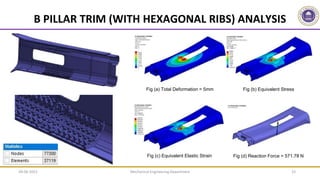

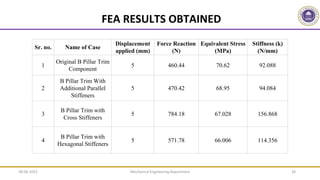

The document discusses the design and optimization of a B pillar trim component for automobiles using nonlinear finite element analysis (FEA) and dent testing. It provides background on pillar trims and B pillar trims specifically. The objectives are to computationally design and experimentally test different B pillar trim designs with varying stiffener patterns and materials to improve strength-to-weight ratio. The methodology involves CAD modeling, nonlinear FEA, design iteration, 3D printing fabrication, and dent testing validation. Progress includes understanding rib features, initial CAD modeling, material selection, and reverse engineering of an existing design.

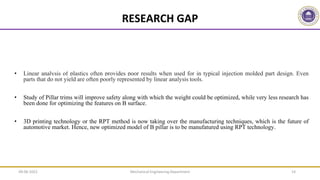

![REFERENCES

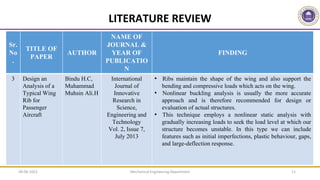

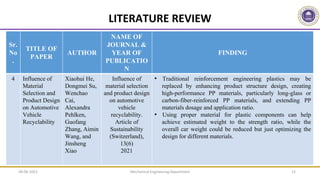

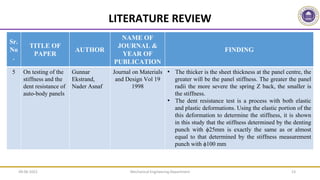

[1] Xiaohui He, Dongmei Su, Wenchao Cai, Alexandra Pehlken, Guofang Zhang, Aimin Wang, and Jinsheng Xiao (2021).

Influence of material selection and product design on automotive vehicle recyclability. Article of Sustainability (Switzerland),

13(6).

[2] P, C. T., Dinesh Kumar, S., S, H. K., & Harti, J. I. (2021). FMVSS Head Crash Target Point Bp2 FEA Simulation Using B

Pillar Trim, IRE Journals.

[3] Zhang, M., Zhu, Z., Zeng, Y., Liu, J., & Hu, Z. (2020). Analytical Method for Evaluating the Impact Response of Stiffeners

in a Ship Side Shell Subjected to Bulbous Bow Collision. Mathematical Problems in Engineering, 2020.

[4] Sabah, F., Wahid, A., Kartouni, A., Chakir, H., & ELghorba, M. (2019). Failure analysis of acrylonitrile butadiene styrene

(ABS) materials and damage modeling by fracture. International Journal of Performability Engineering, 15(9), 2285–2293.

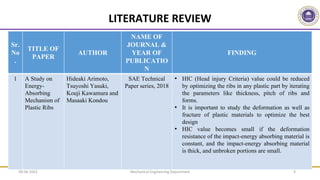

[5] Hideaki Arimoto, Tsuyoshi Yasuki, Kouji Kawamura and Masaaki Kondou (2018). A Study on Energy-Absorbing

Mechanism of Plastic Ribs, SAE Technical paper series.

Mechanical Engineering Department 36

09-06-2022](https://image.slidesharecdn.com/projectppt2-230108174114-beda7d3b/85/Project_PPT2-pptx-36-320.jpg)

![REFERENCES

[6] Arimoto, H., Yasuki, T., Kawamura, K., & Kondou, M. (2018). A Study on Energy-Absorbing Mechanism of Plastic Rib.

SAE International.

[7] Chen, D., Lu, G., He, L., Li, W., & Yuan, J. (2015). Warpage of injection-molded automotive B pillar trim fabricated with

ramie fiber-reinforced polypropylene composites. Journal of Reinforced Plastics and Composites, 34(14), 1144–1152.

[8] Ahmad Rosli Abdul Manaf, Mohd Zairulnizam Mohd Zawawi and Nik Zuraida Imran Adly (2014). Thin walled part

warping overcoming by honeycomb ribs design. Advanced Materials Research, 903, 181–186.

[9] Kim, D. Y., Kim, Y., & Kim, H. Y. (2014). Material modelling considering the pressure dependence and the volume change

for plastics with applications to the interior parts of a vehicle. Proceedings of the Institution of Mechanical Engineers, Part D:

Journal of Automobile Engineering, 228(5), 535–548.

[10] Bindu H.C1, Muhammad Muhsin Ali.H (2013). DESIGN AND ANALYSIS OF A TYPICAL WING RIB FOR

PASSENGER AIRCRAFT. International Journal of Innovative Research in Science, Engineering and Technology (Vol. 2).

Mechanical Engineering Department 37

09-06-2022](https://image.slidesharecdn.com/projectppt2-230108174114-beda7d3b/85/Project_PPT2-pptx-37-320.jpg)

![REFERENCES

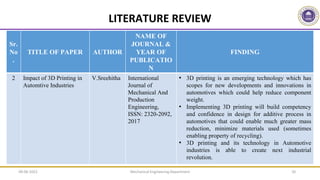

[11] V.Shreehita, (2017). Impact of 3D Printing in Automtive Industries. International Journal of Mechanical And Production

Engineering, ISSN: 2320-2092, Volume- 5, Issue-2.

[12] Balaji Thiyagarajan, P. (2008). Non-linear finite element analysis and optimization for light weight design of an automotive

seat backrest, Tiger-prints.

[13] Santiago, J. (2005). Comparing Material Impact Strength of Three High Impact Plastic Resins Used In Automotive Grille

Using Nonlinear Finite Element Analysis Tools.

[14] Deng, N., & Chen, Z. (1998). A new nonlinear ABS-type algorithm and its efficiency analysis. Optimization Methods and

Software, 10(1), 71–85.

[15] Ekstrand, G., & Asnafi, N. (1998). On testing of the stiffness and the dent resistance of autobody panels. In Materials and

Design (Vol. 19).

Mechanical Engineering Department 38

09-06-2022](https://image.slidesharecdn.com/projectppt2-230108174114-beda7d3b/85/Project_PPT2-pptx-38-320.jpg)