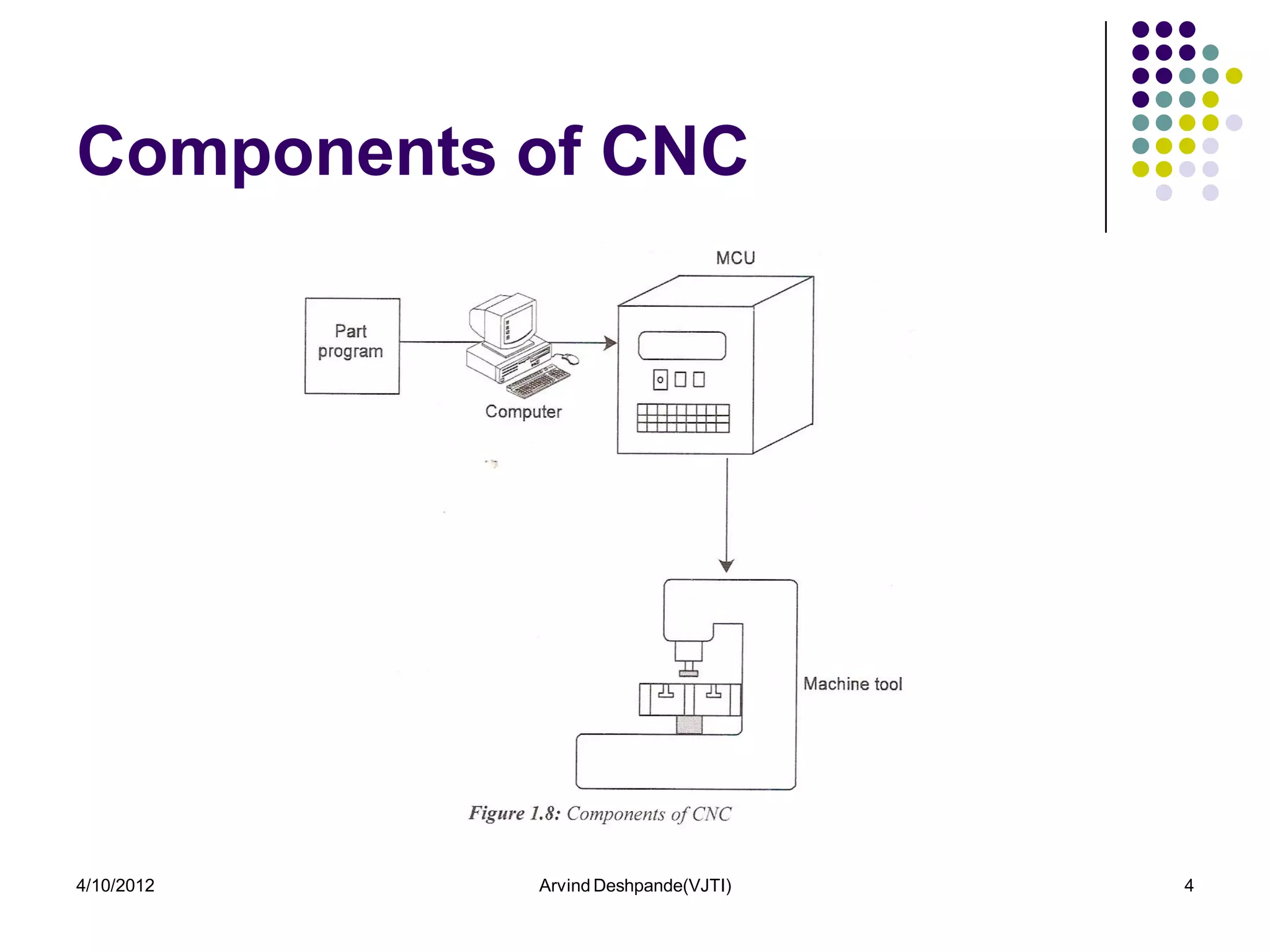

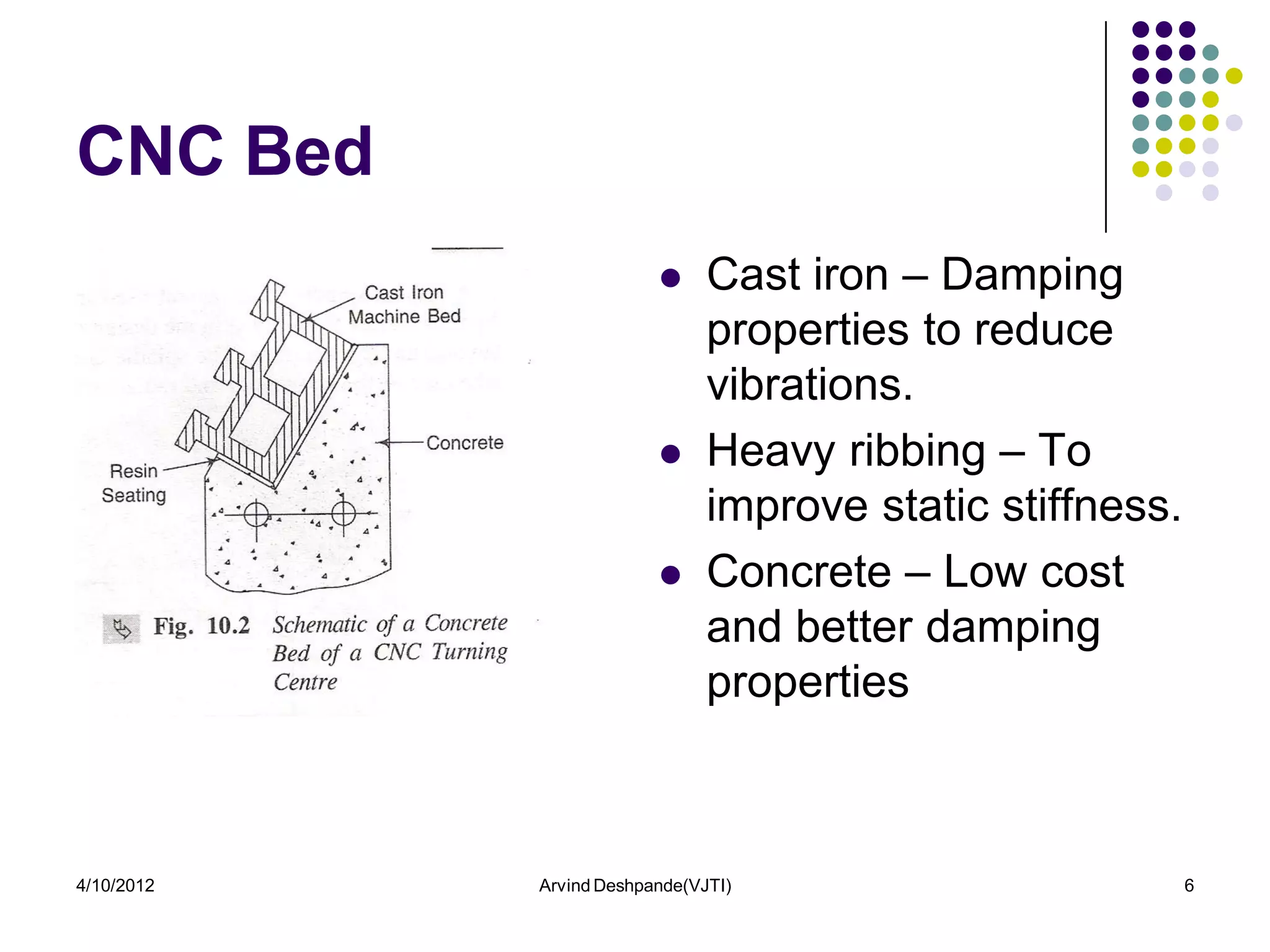

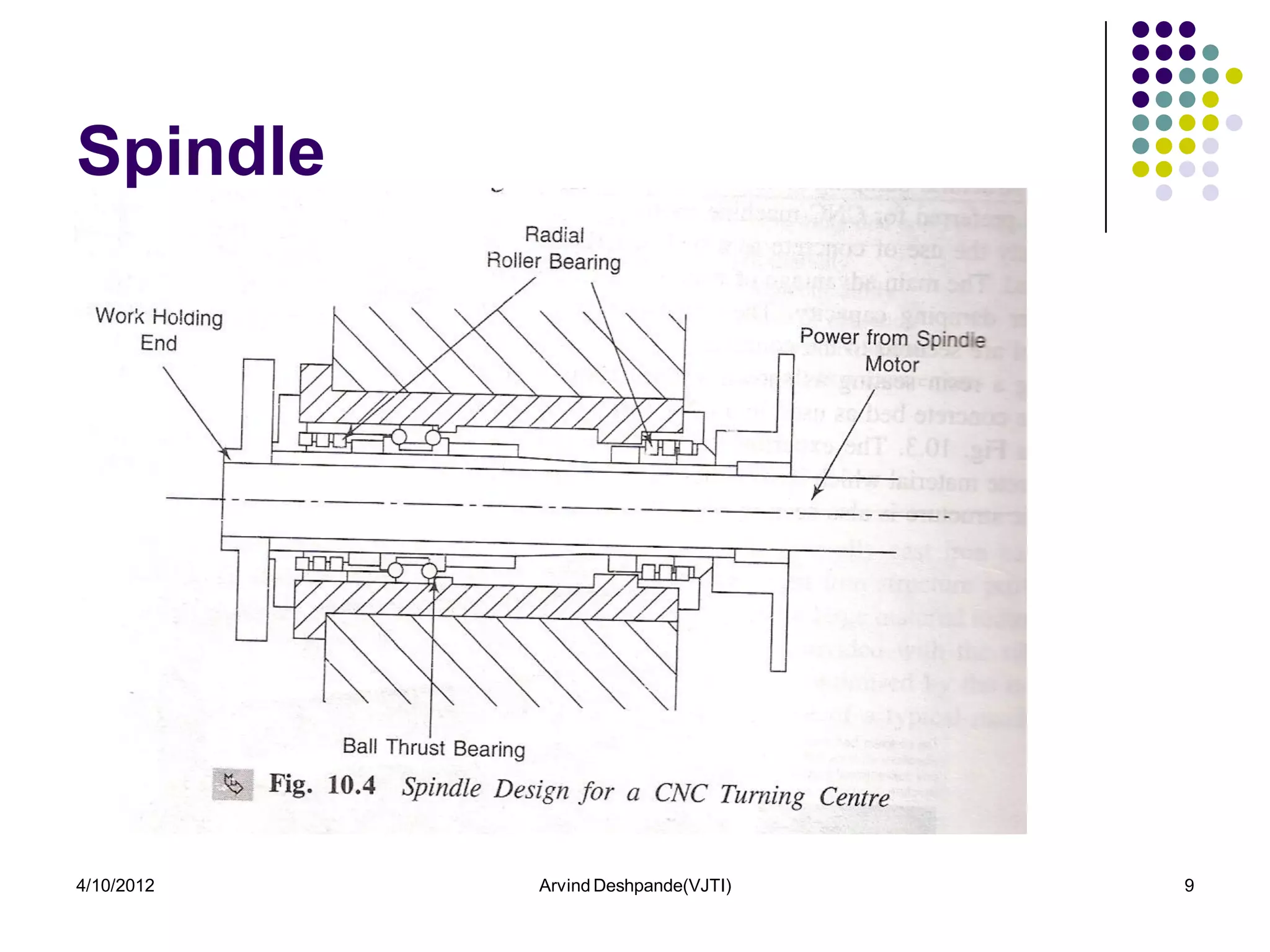

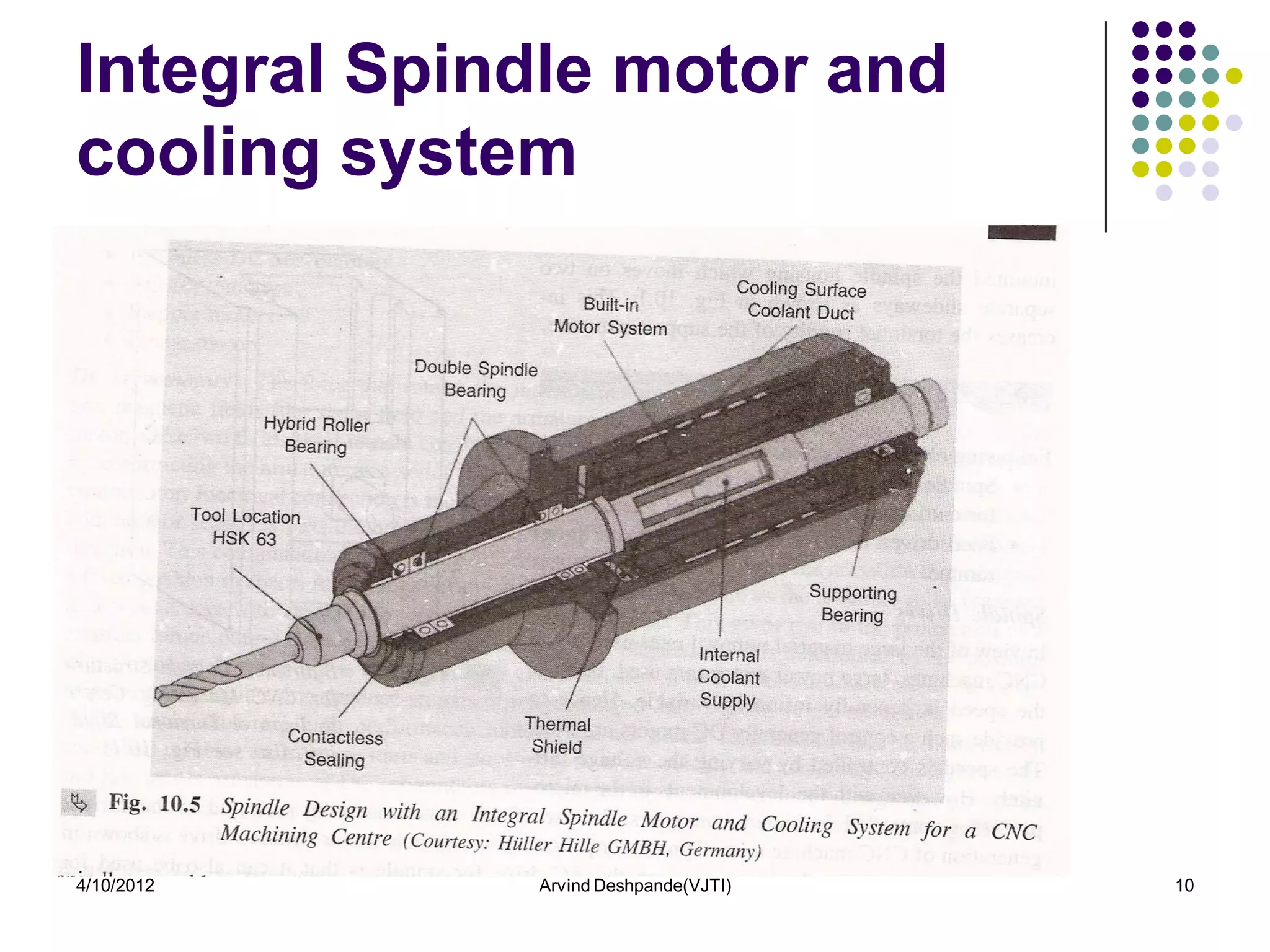

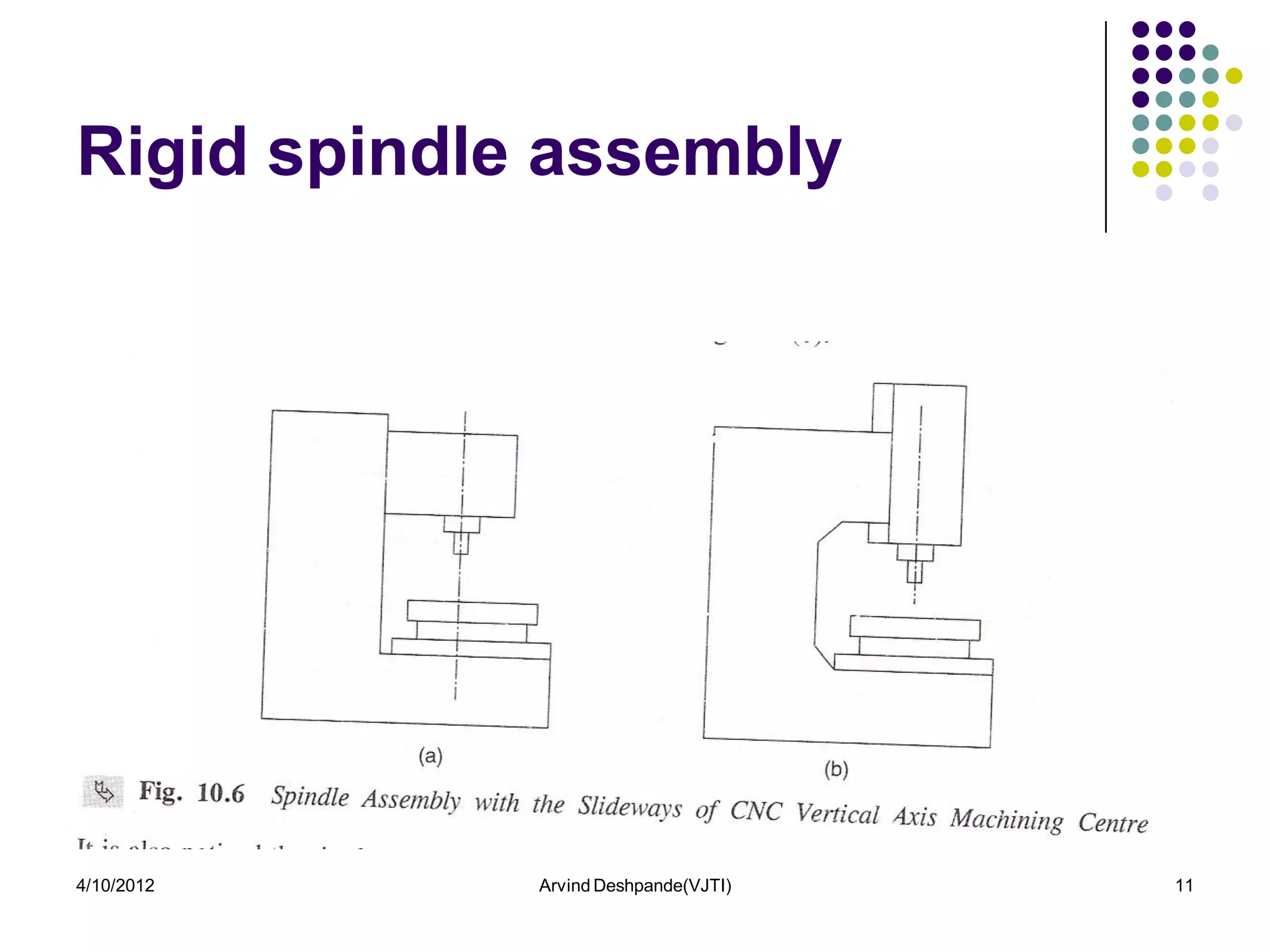

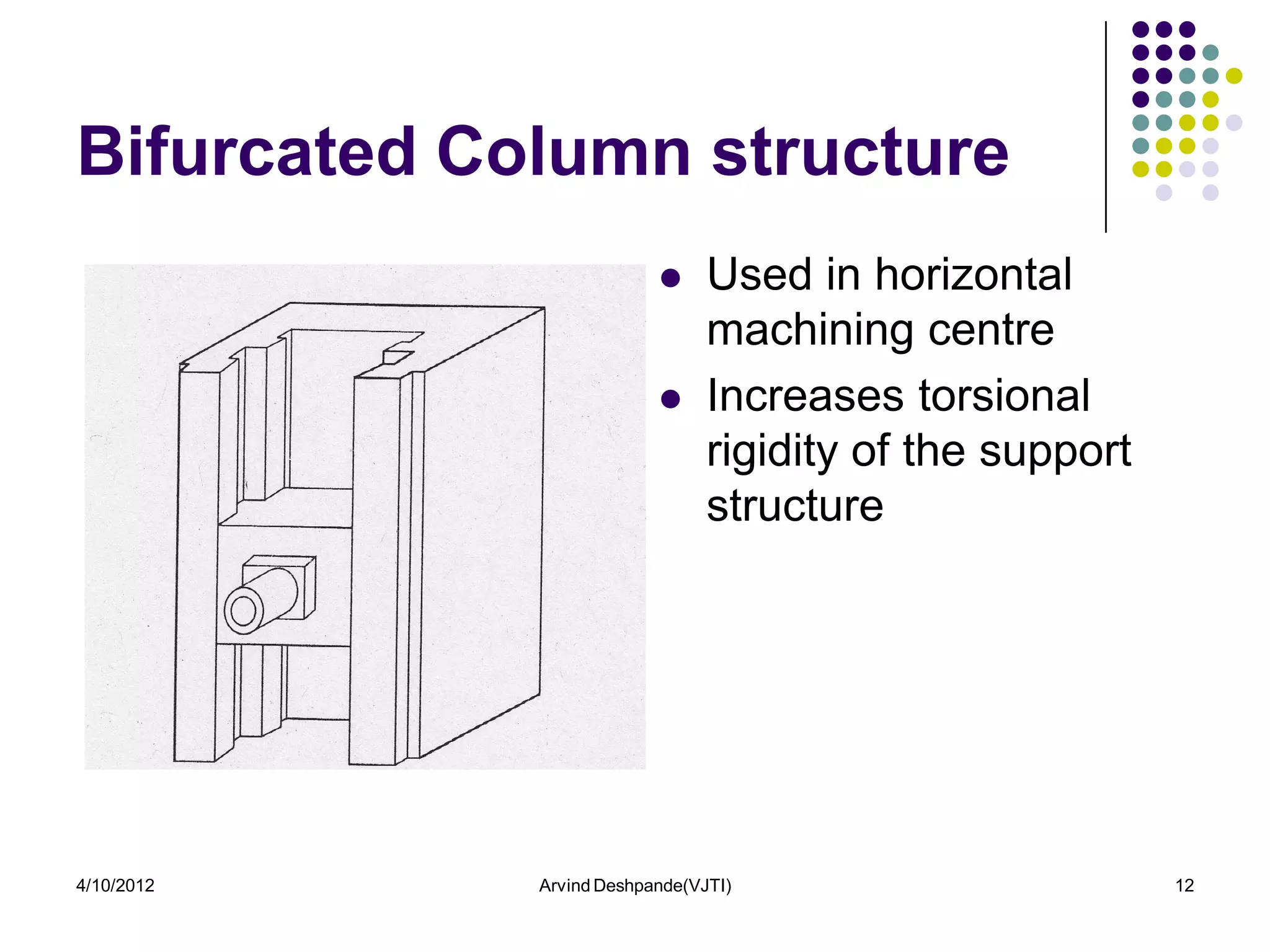

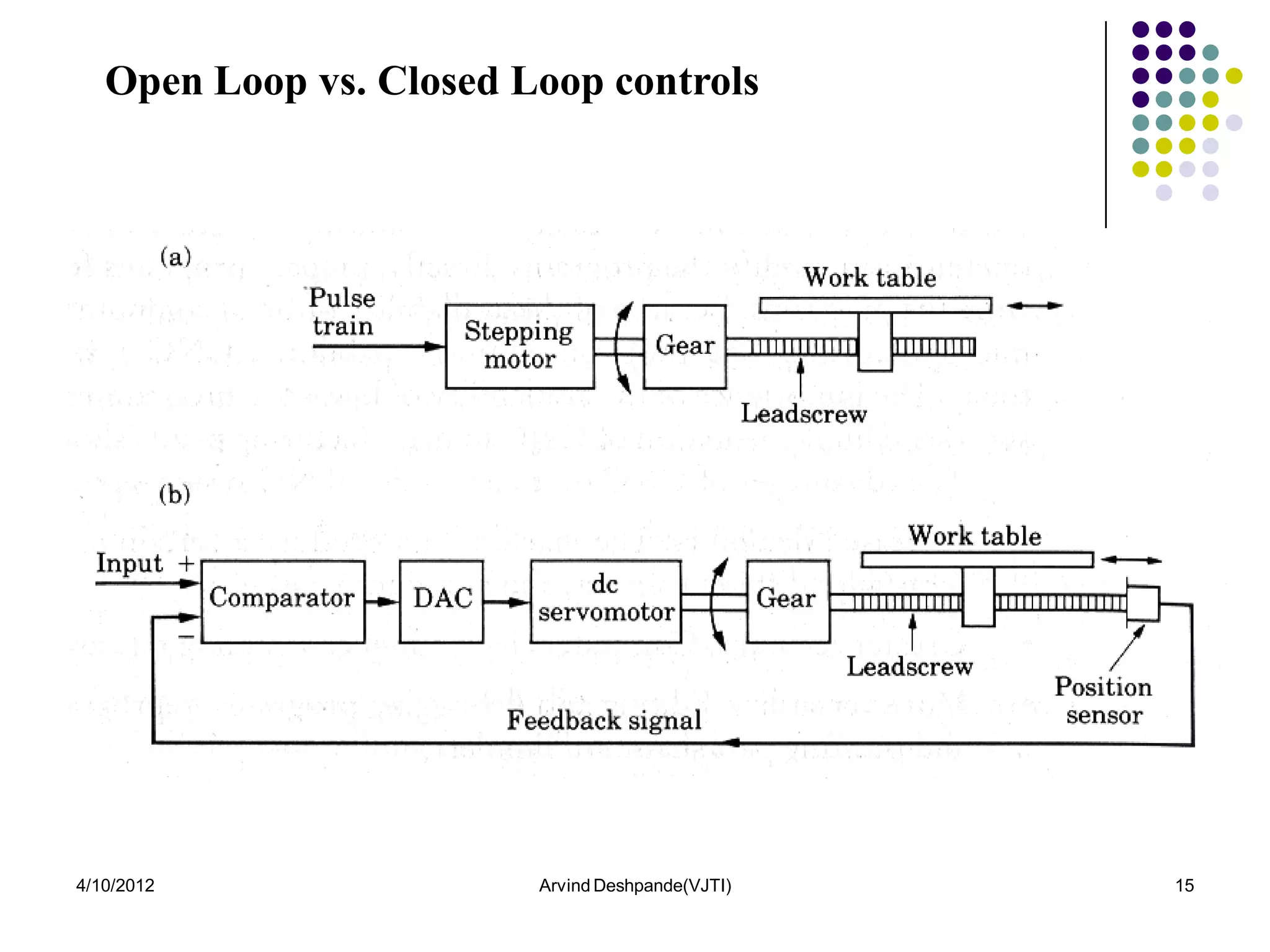

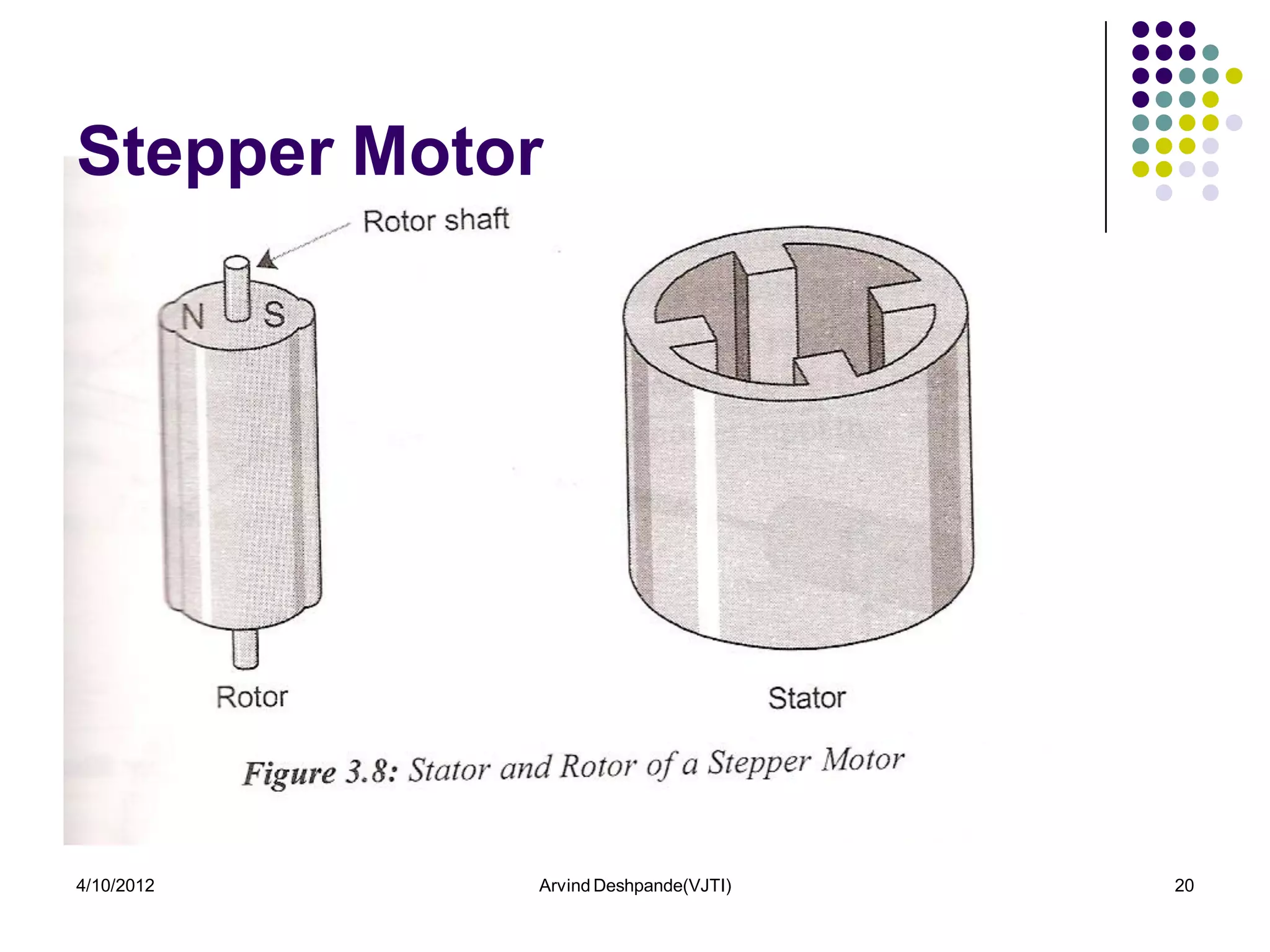

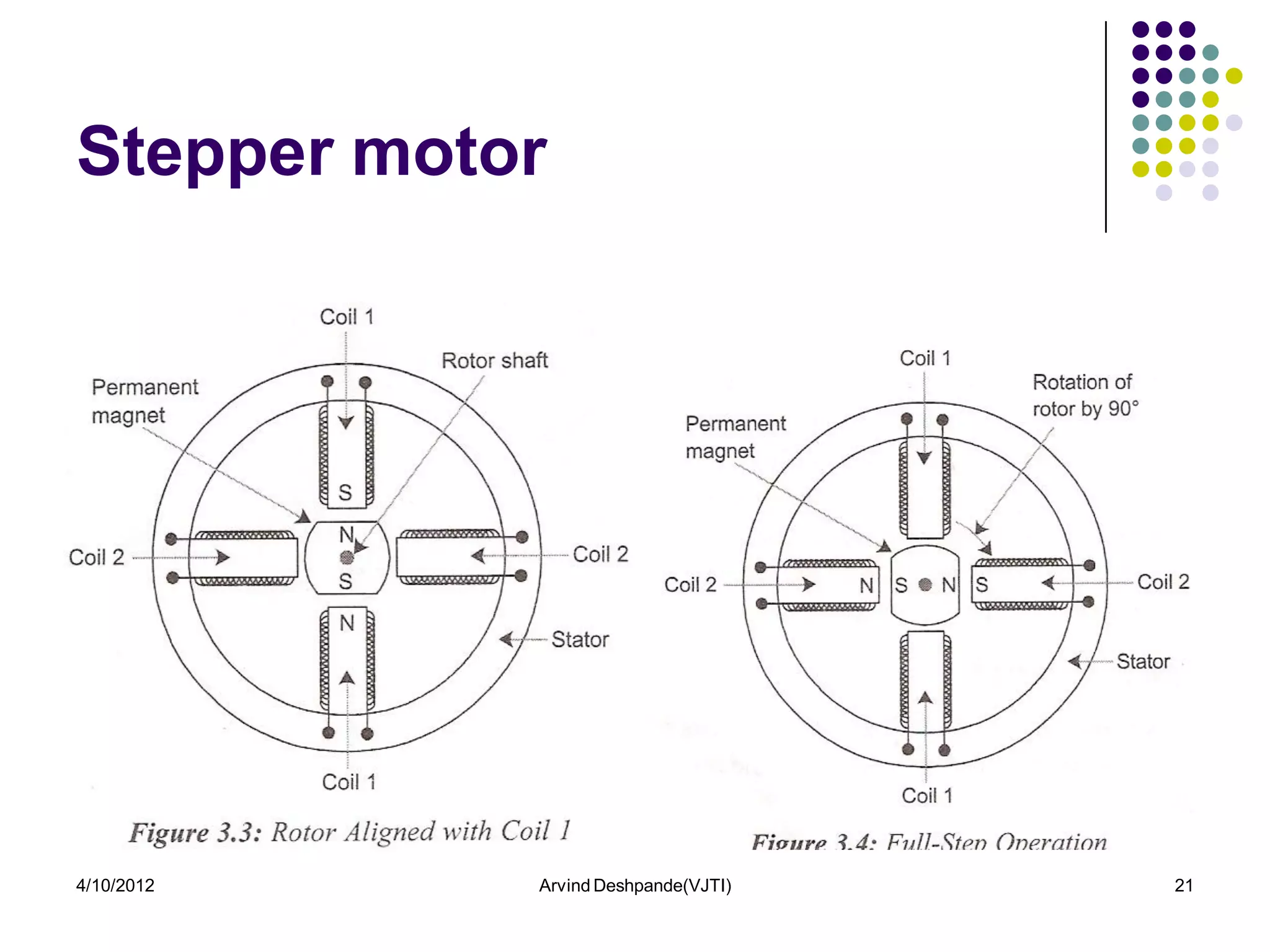

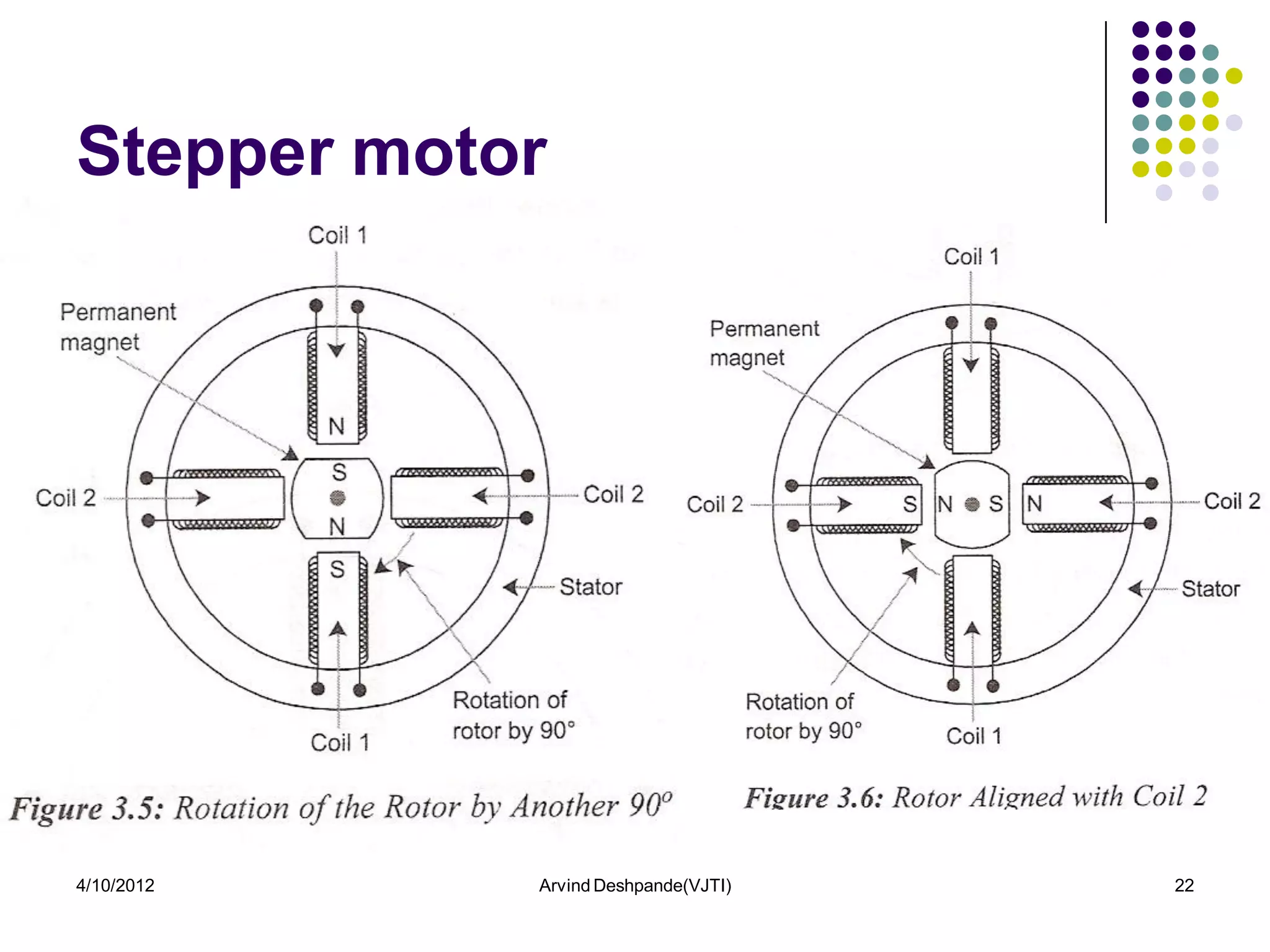

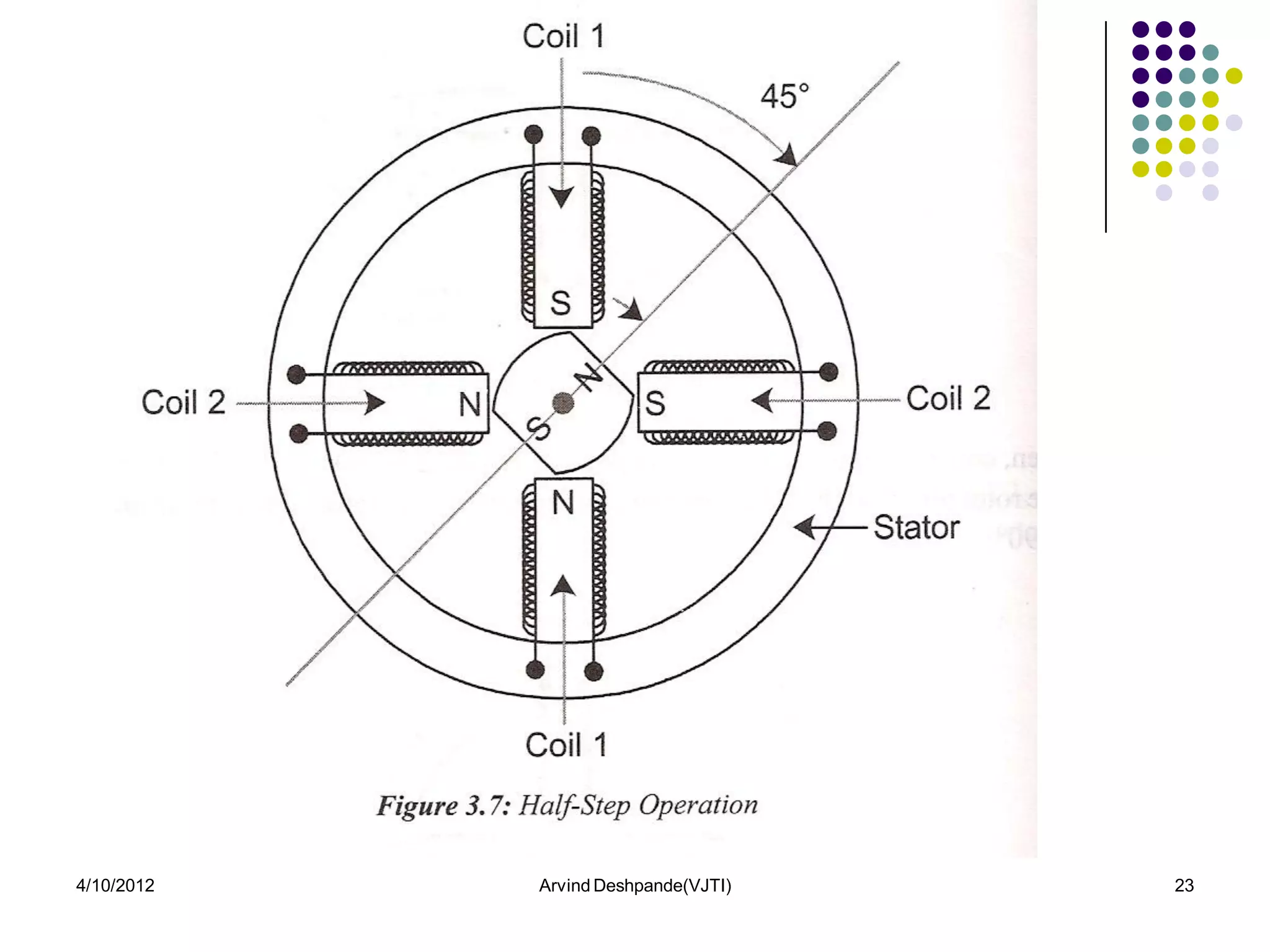

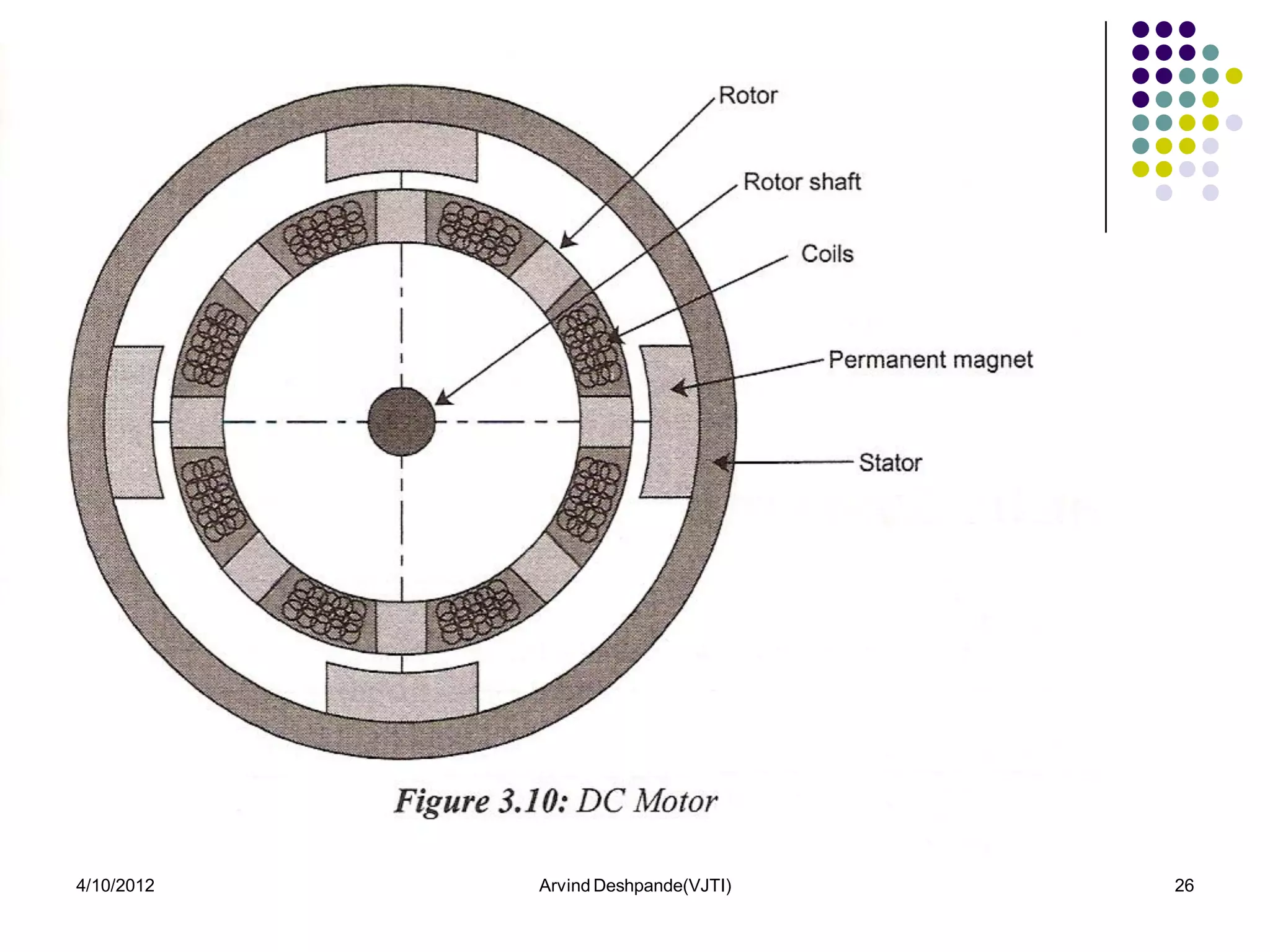

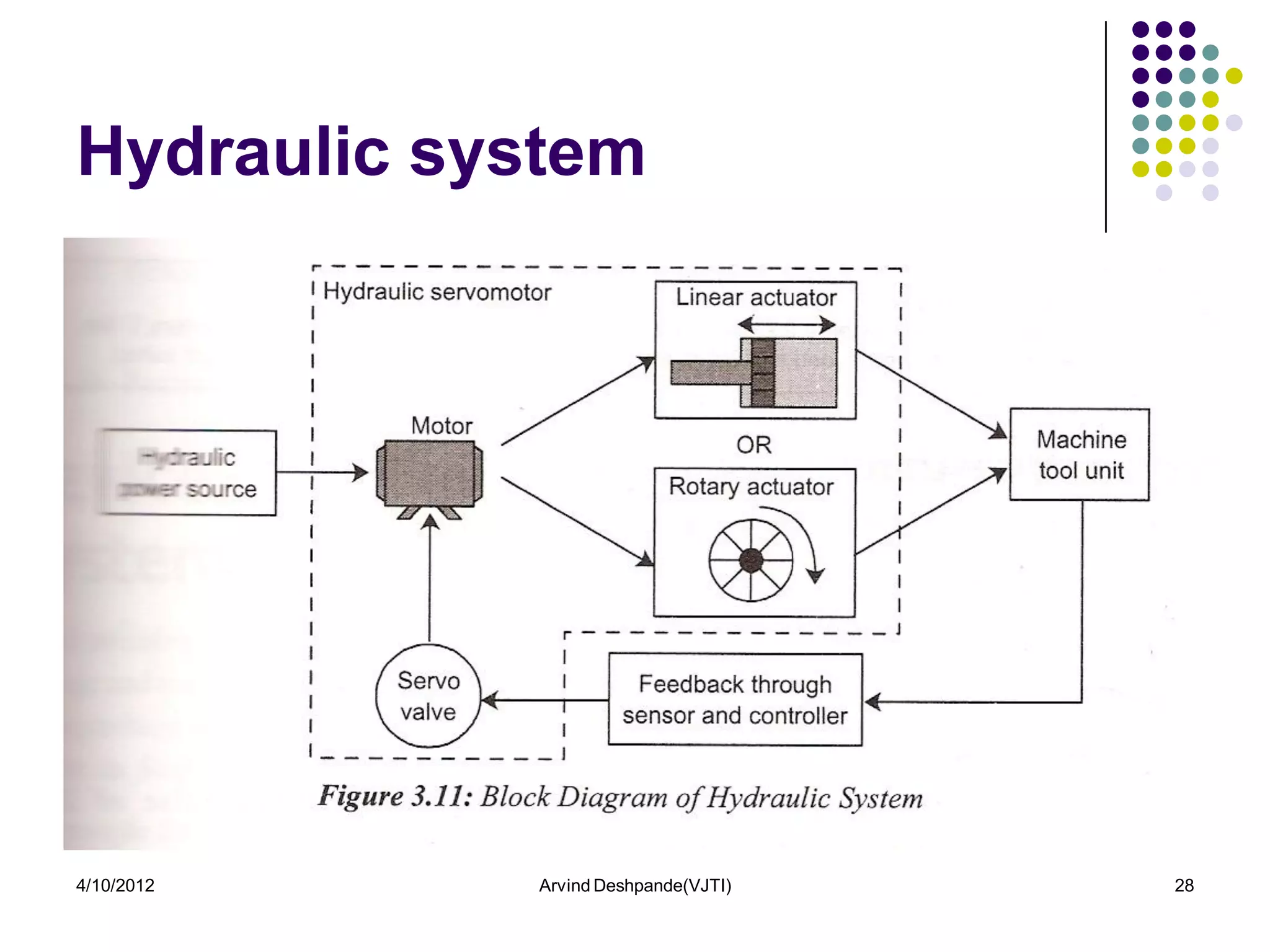

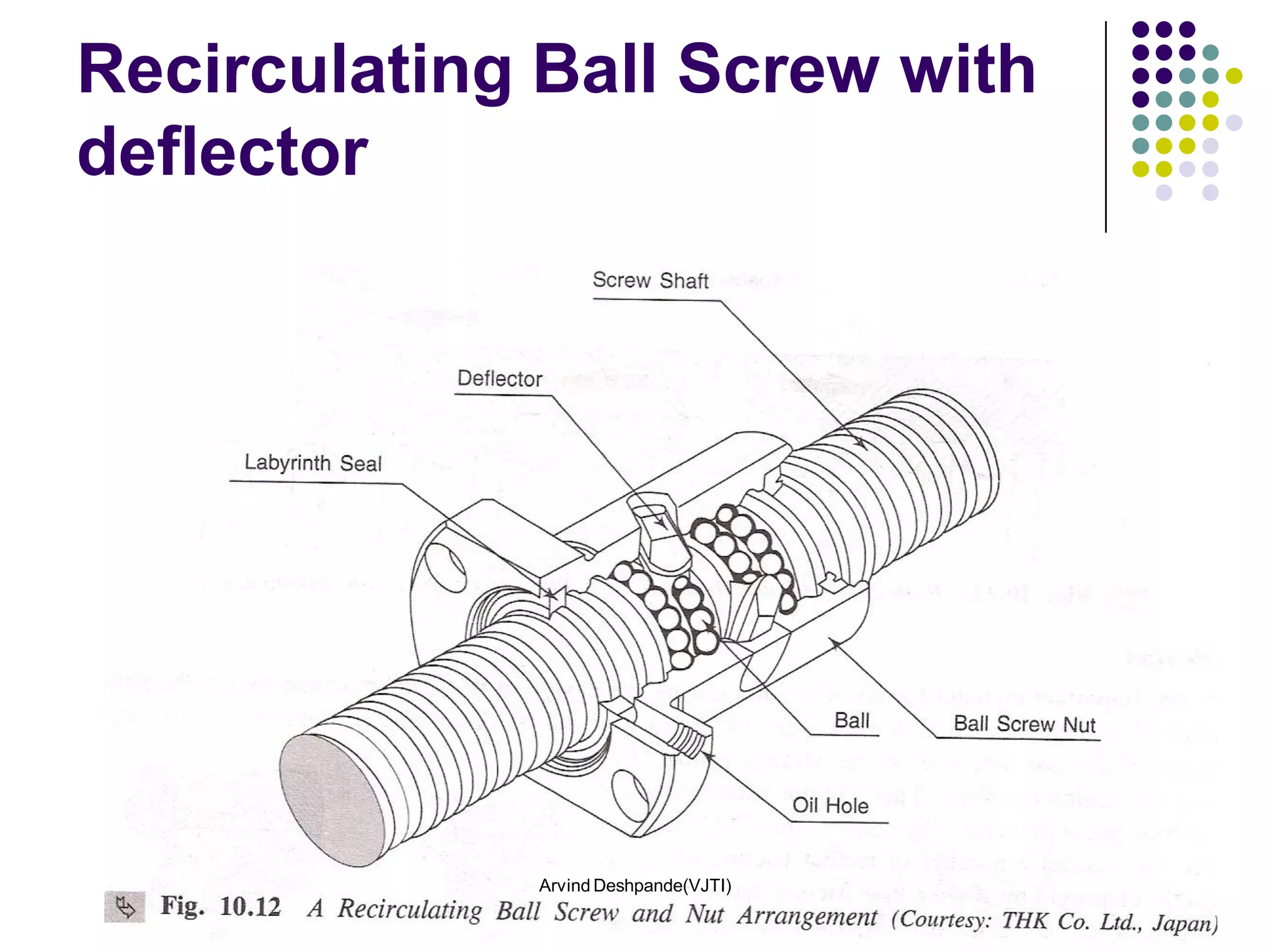

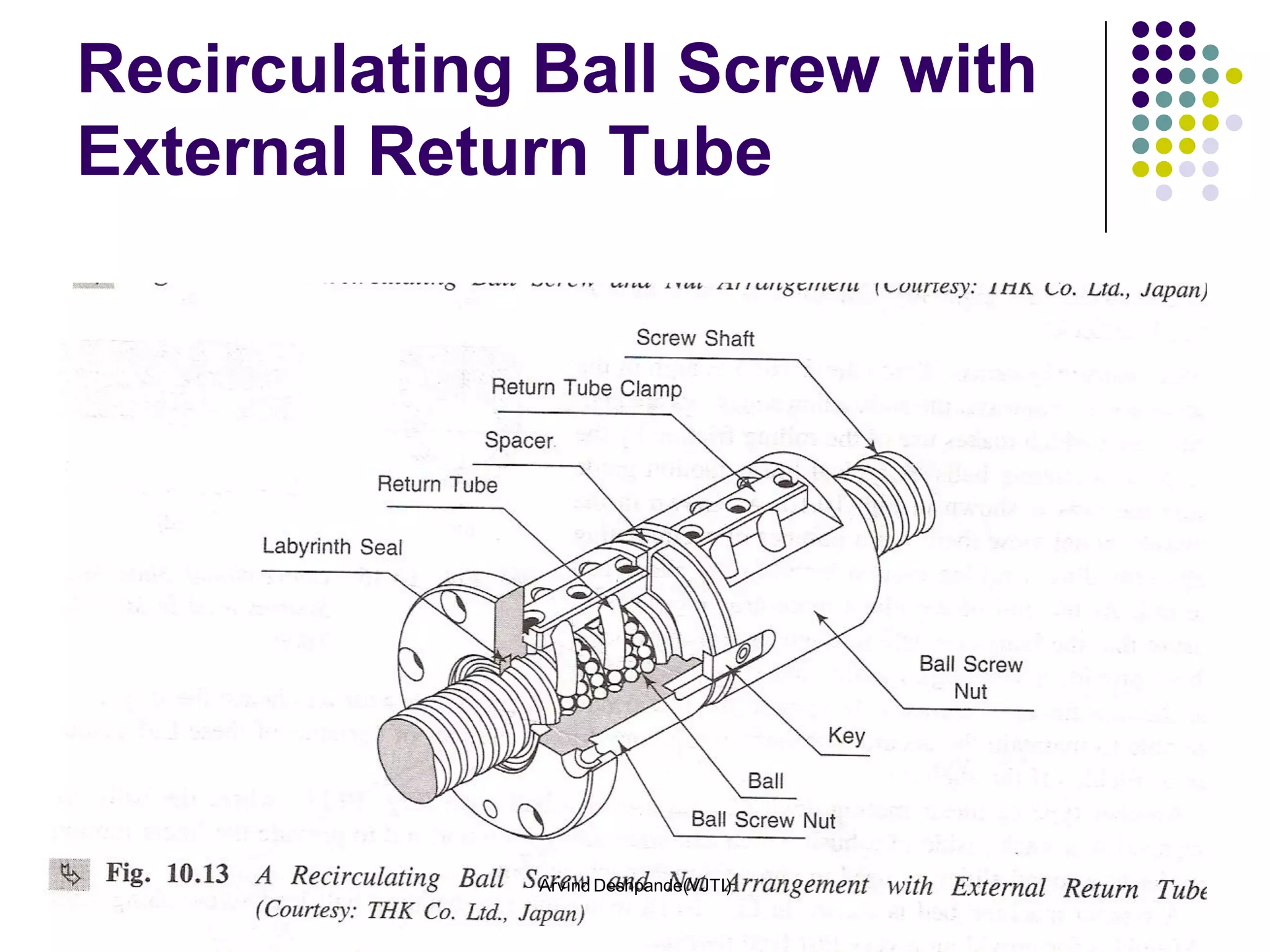

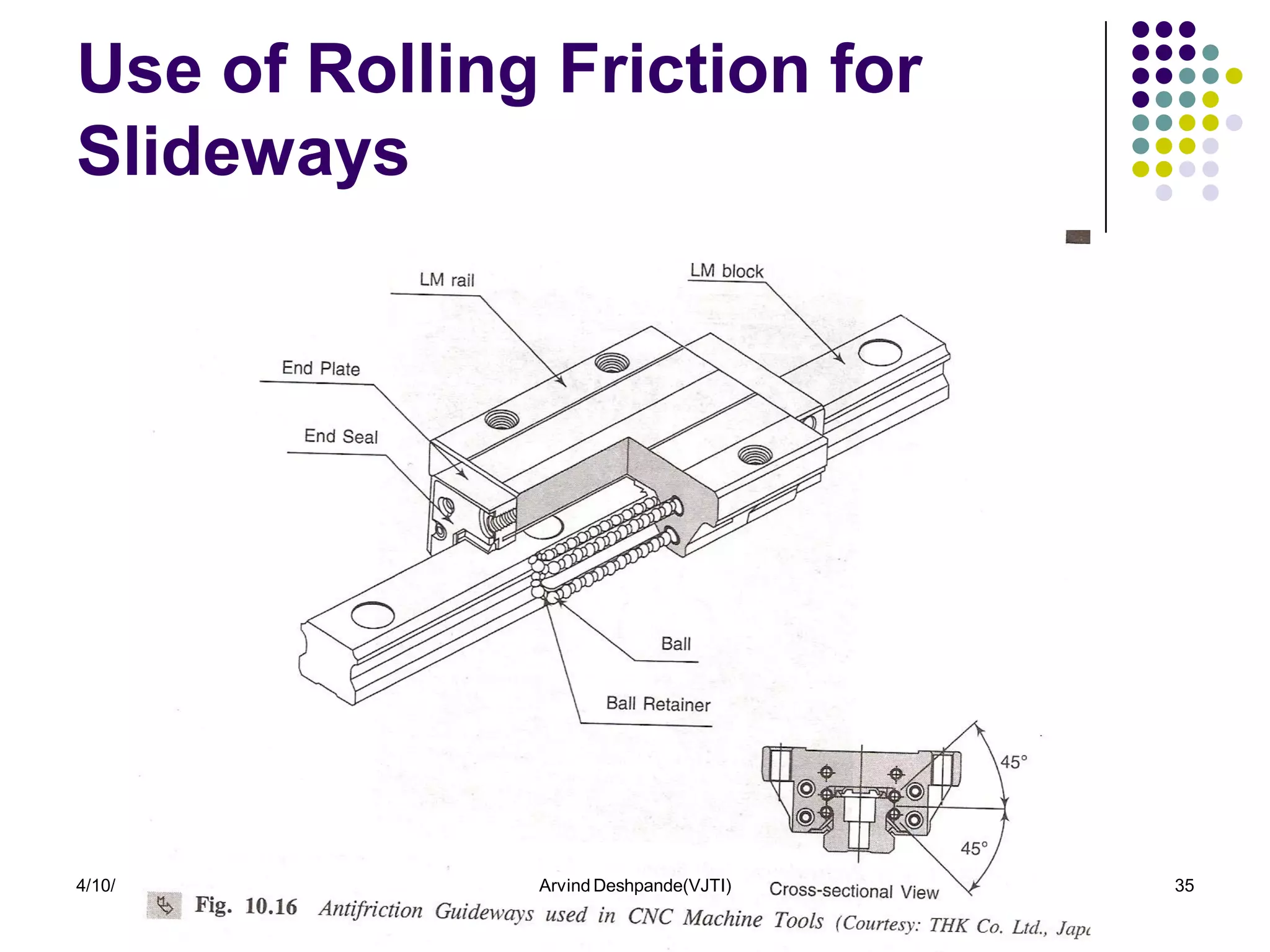

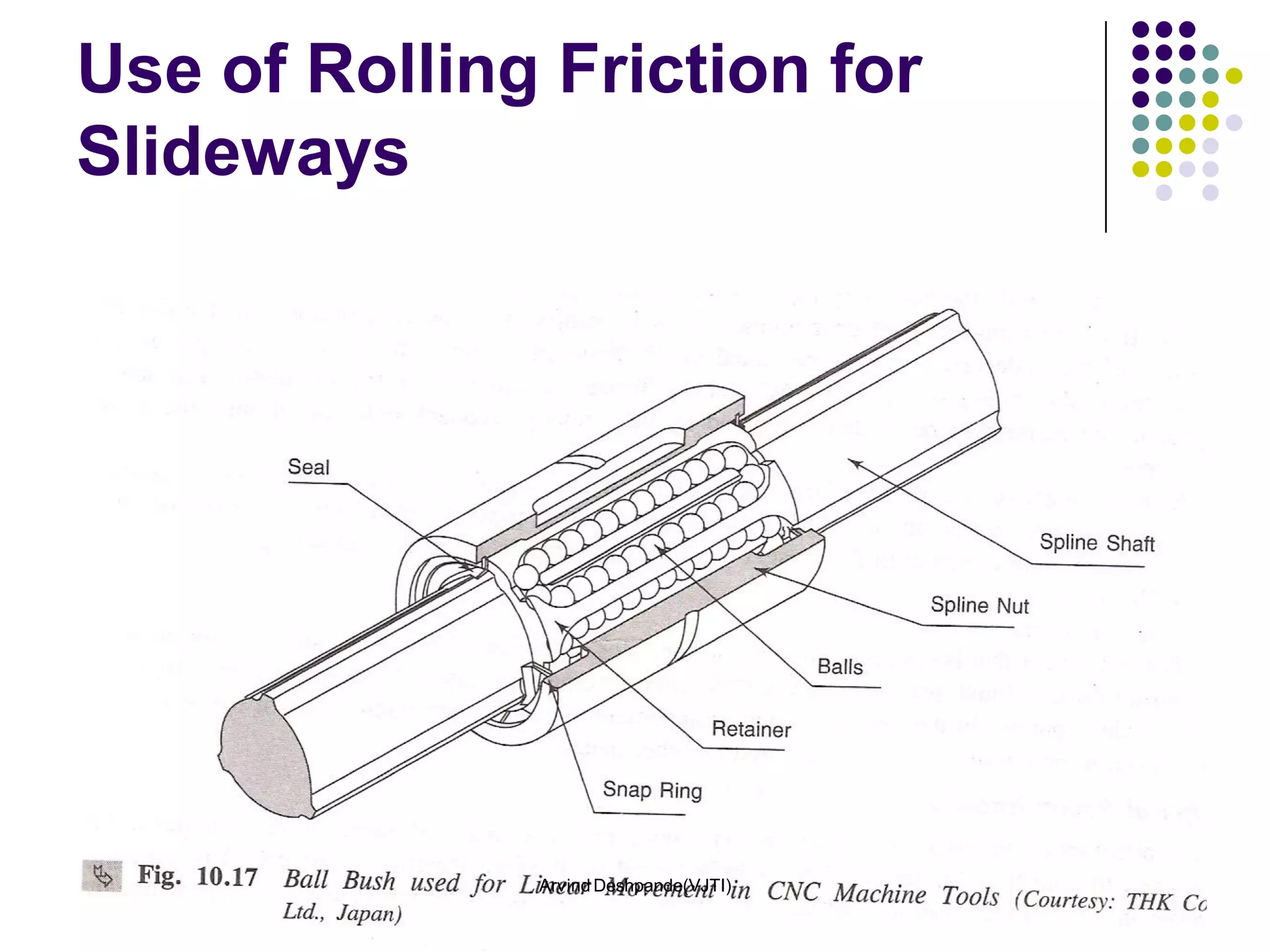

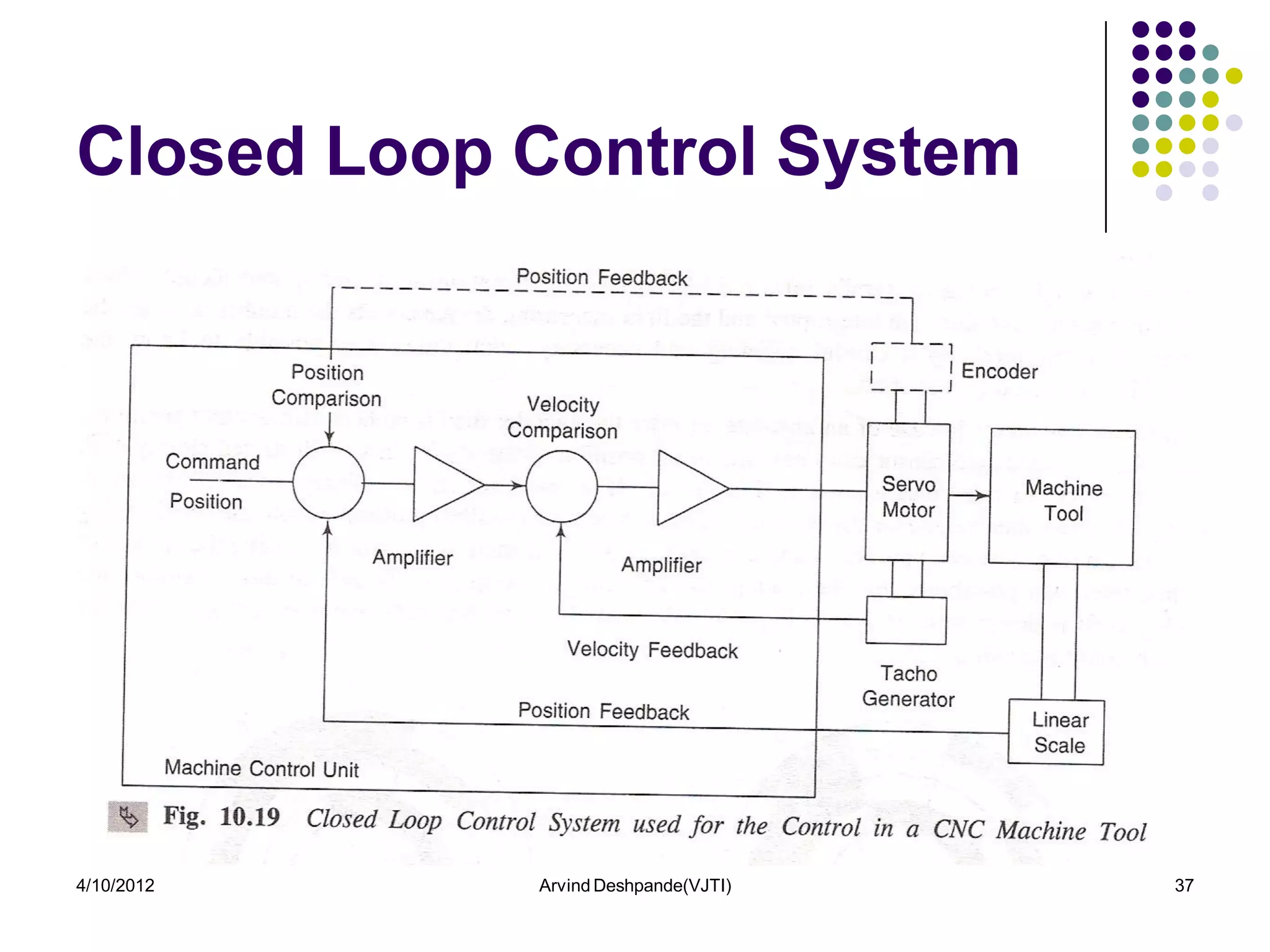

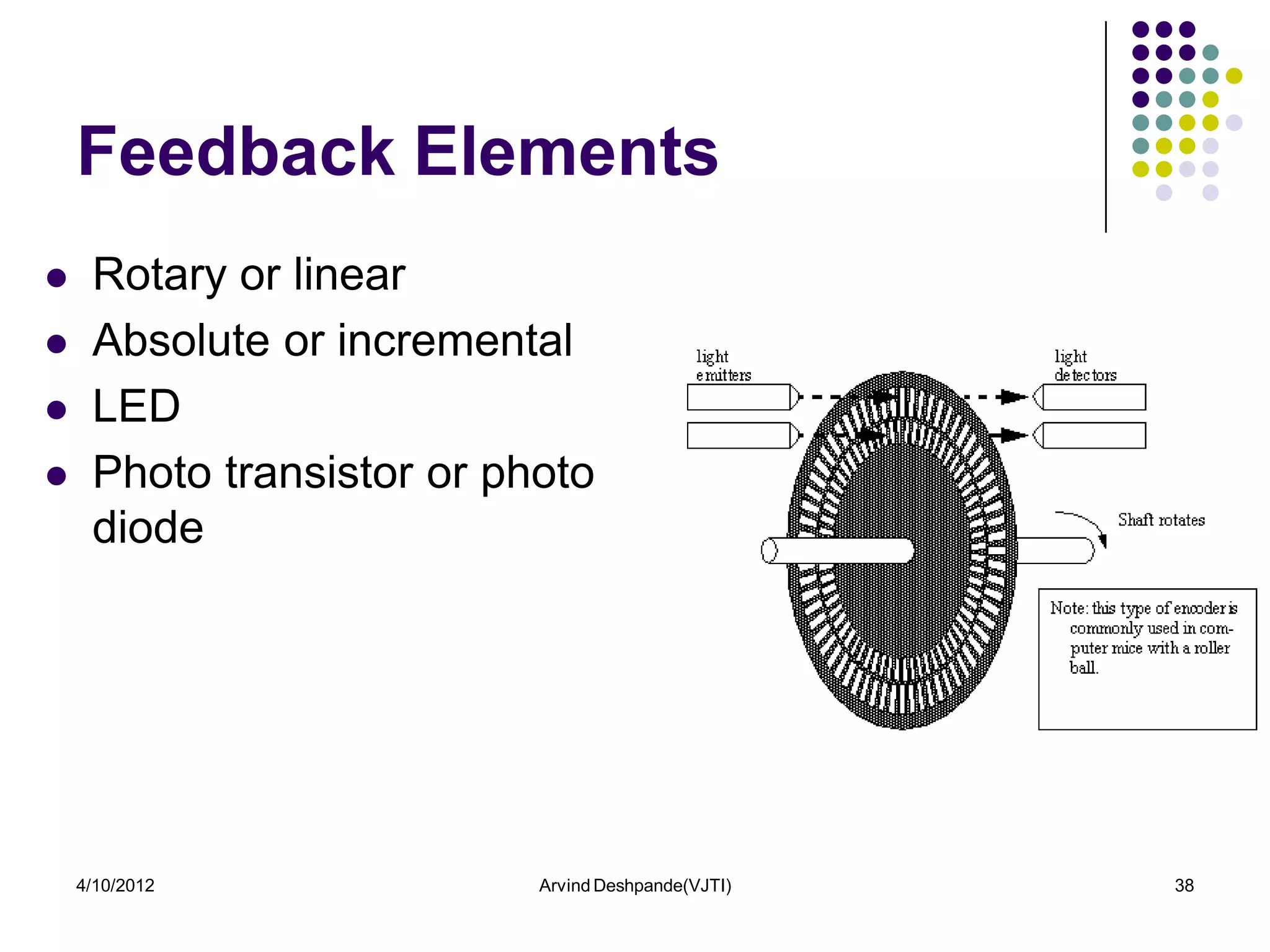

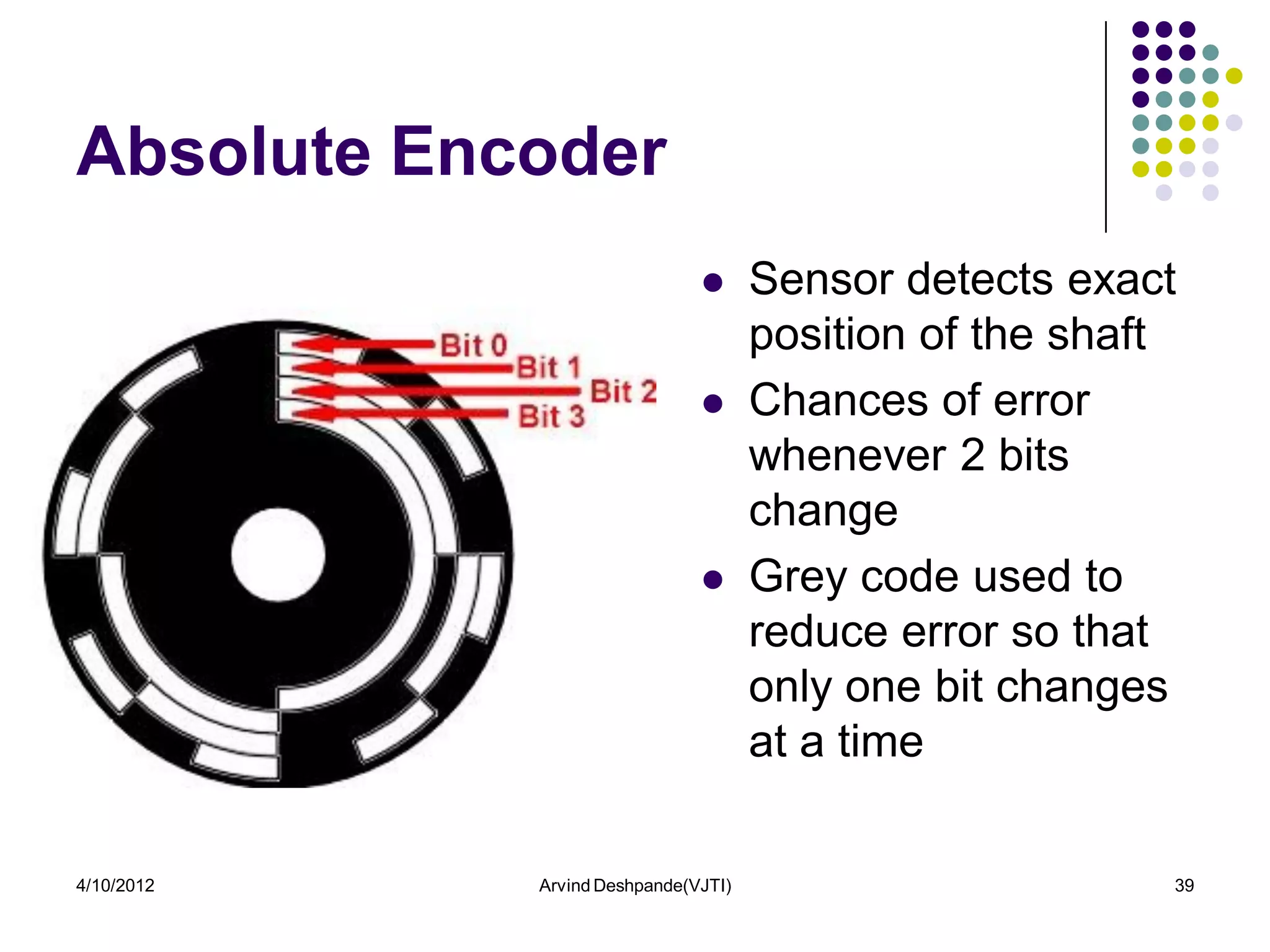

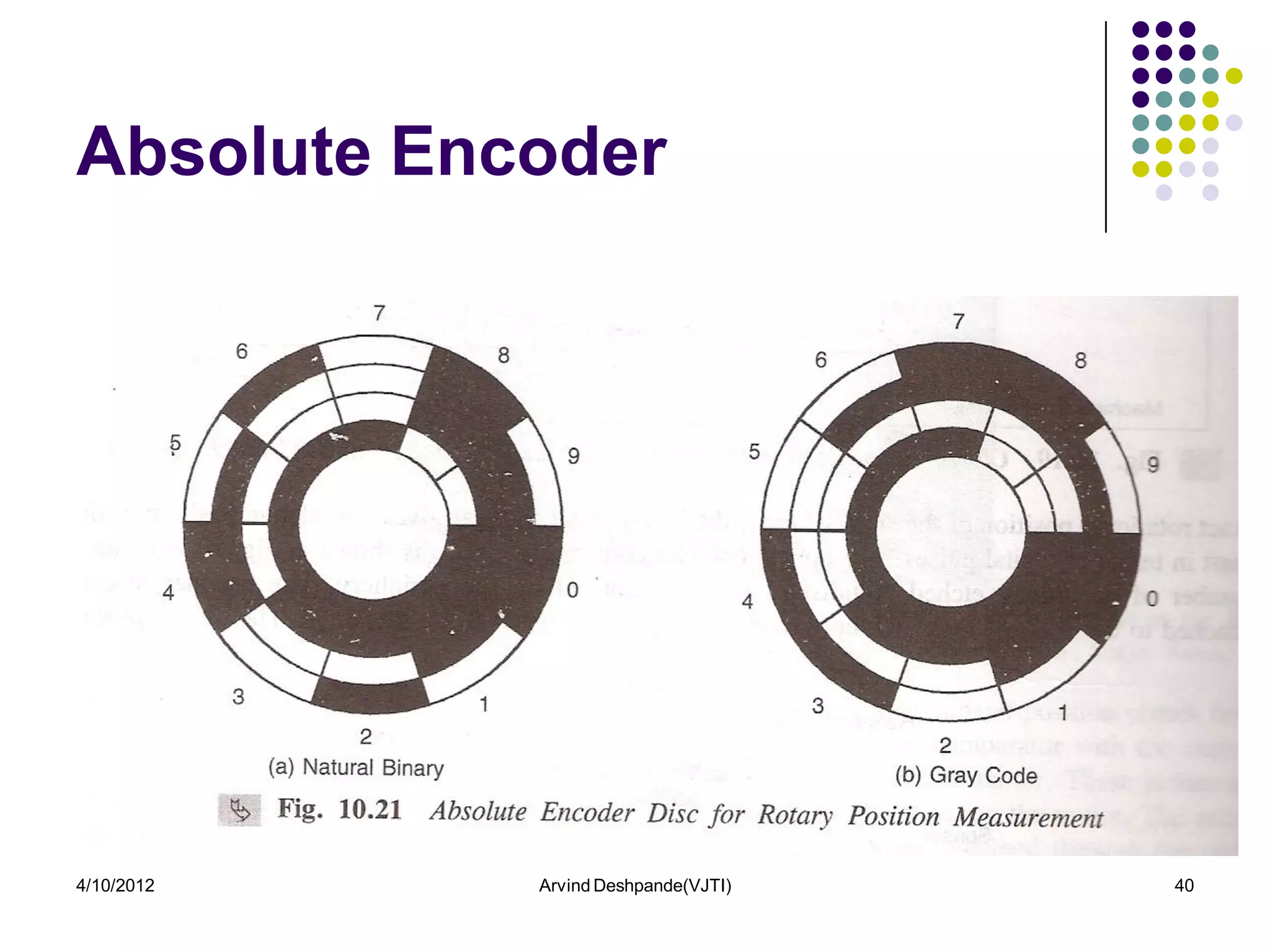

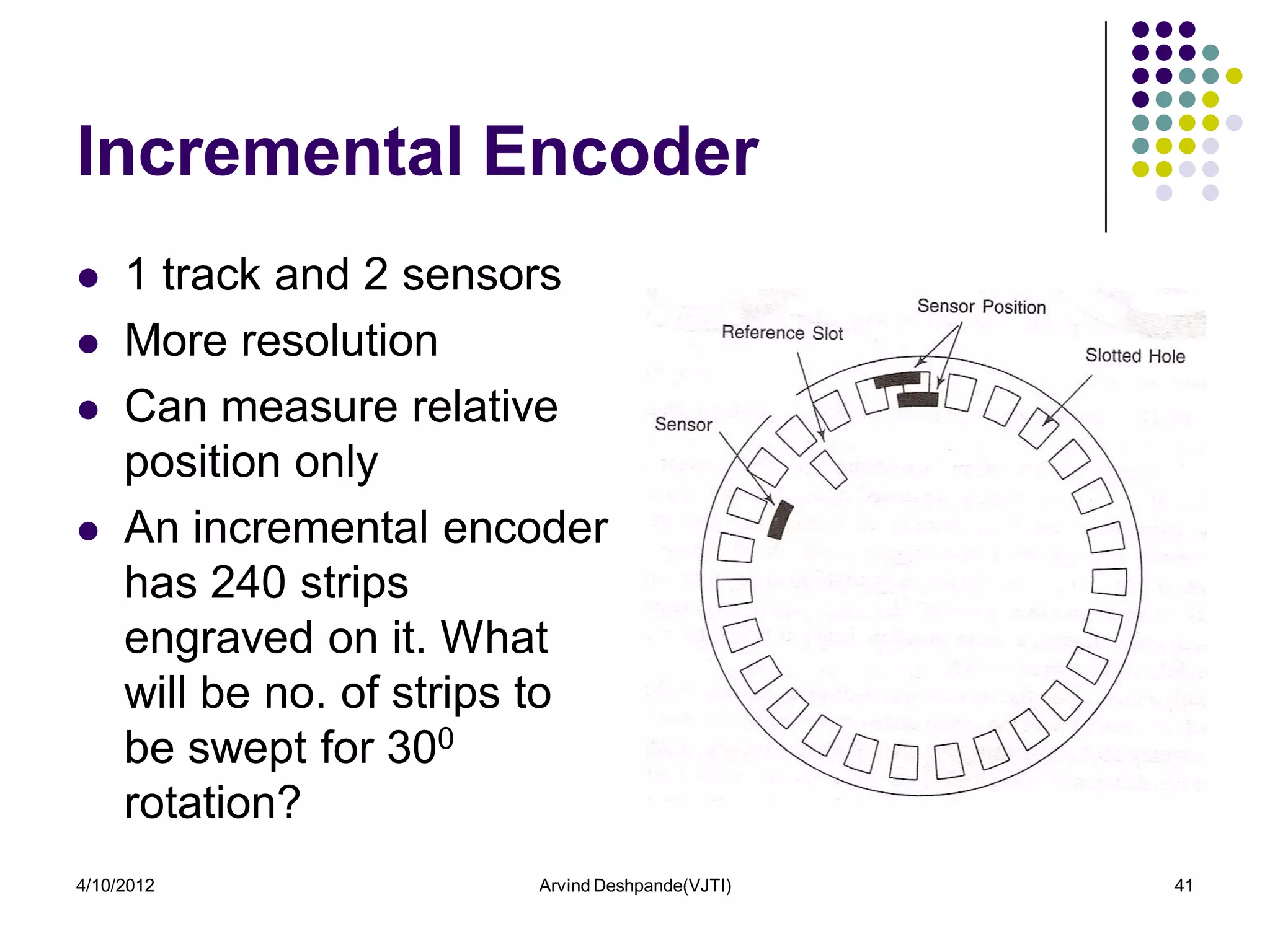

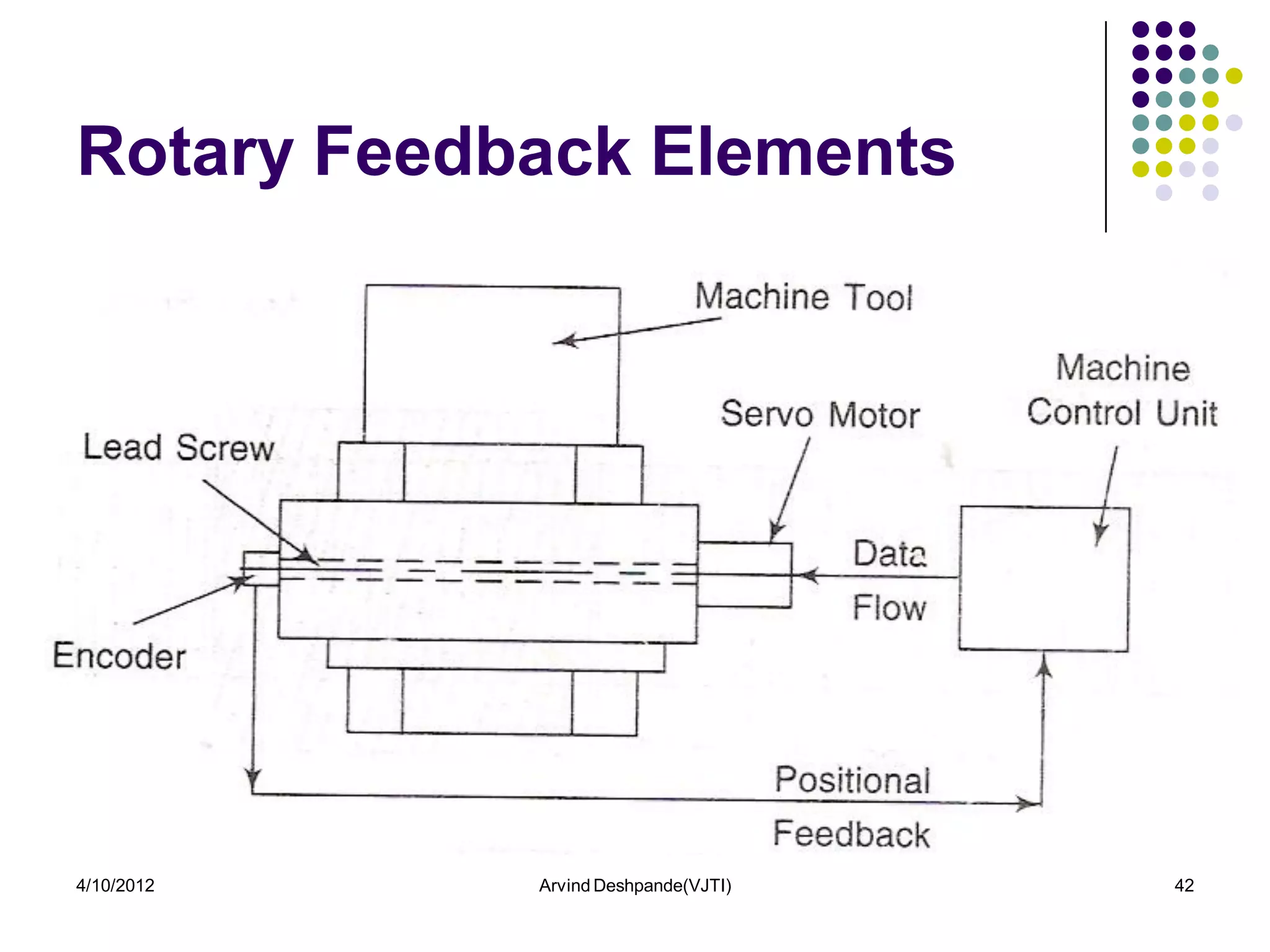

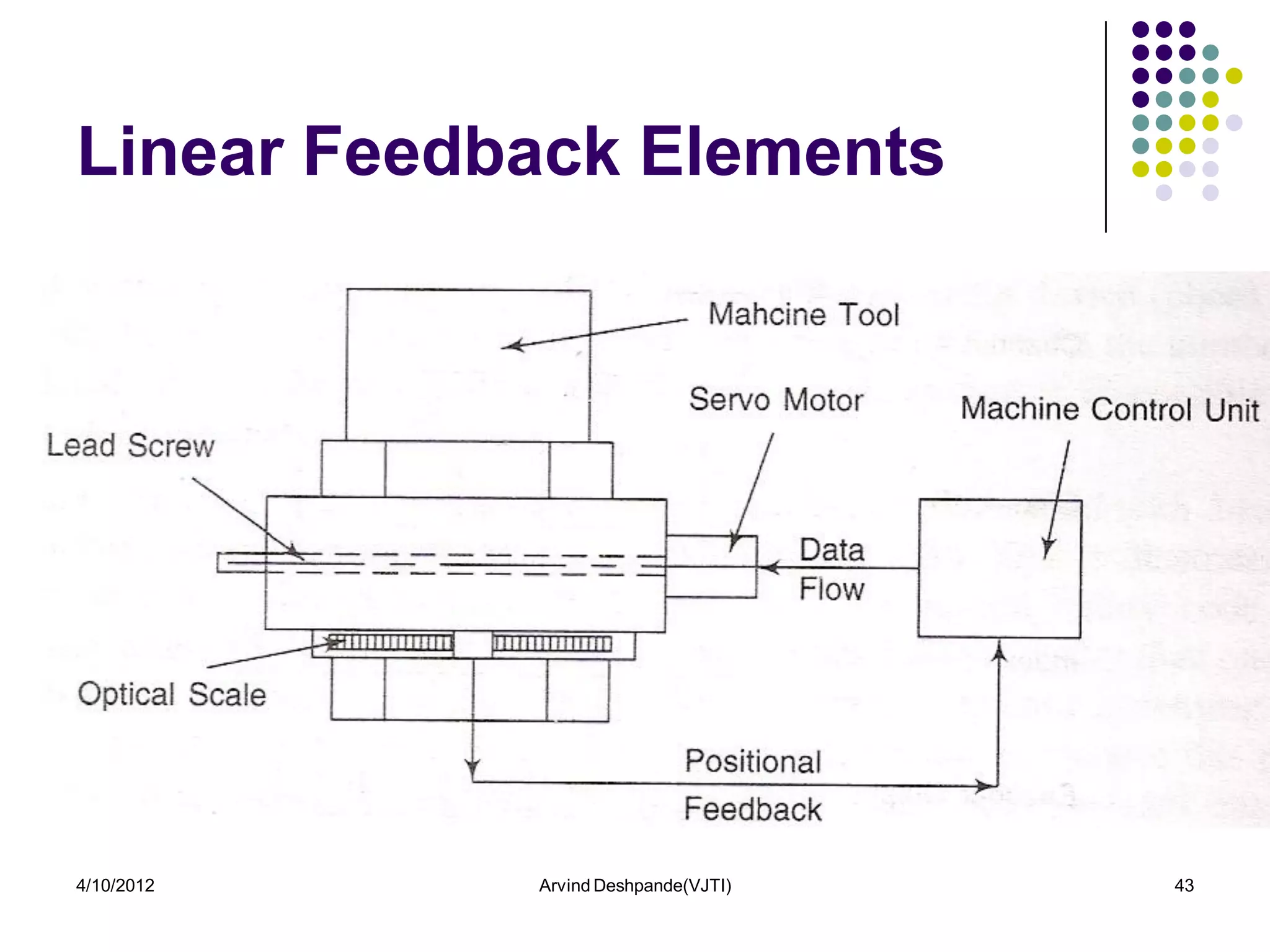

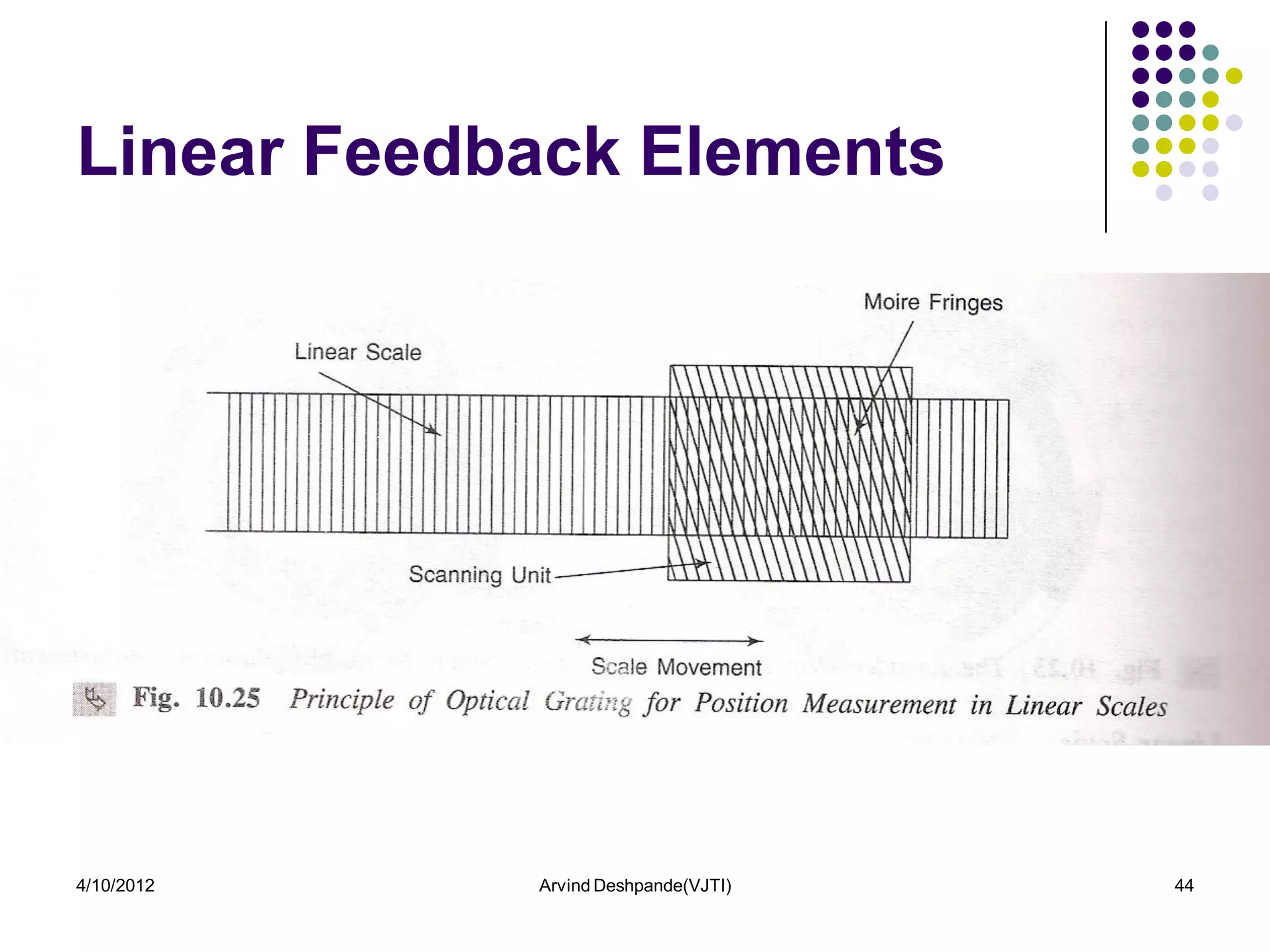

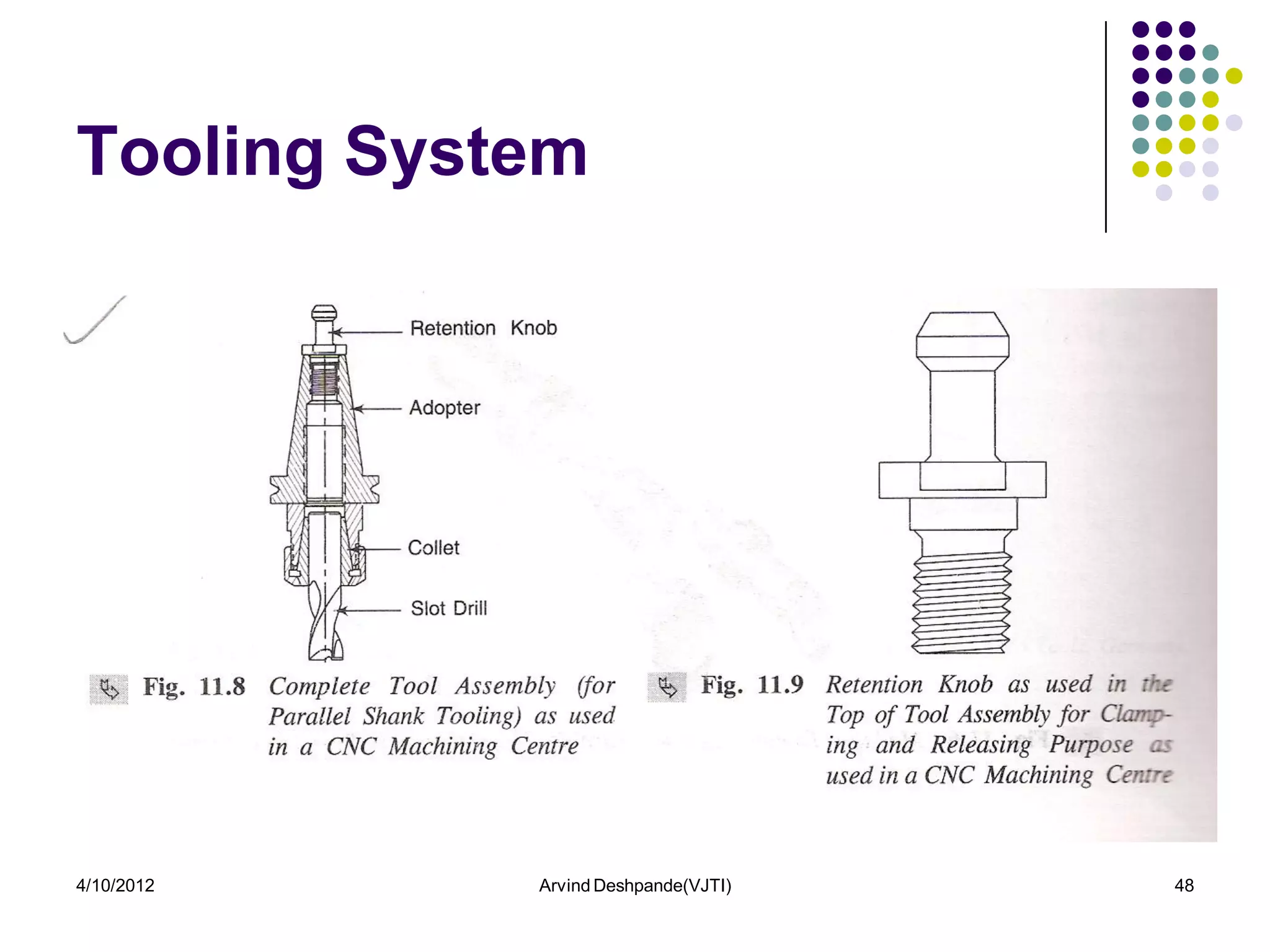

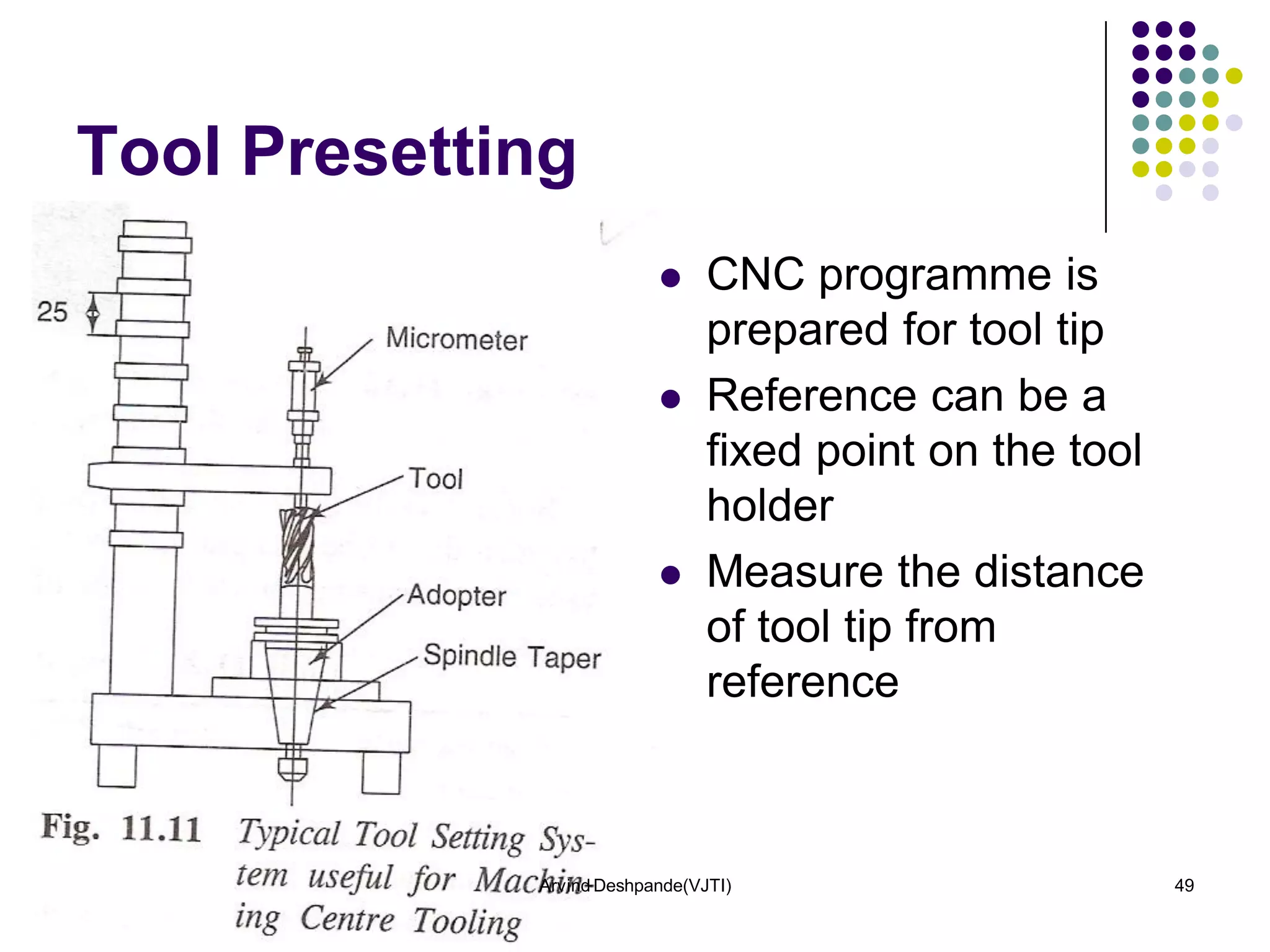

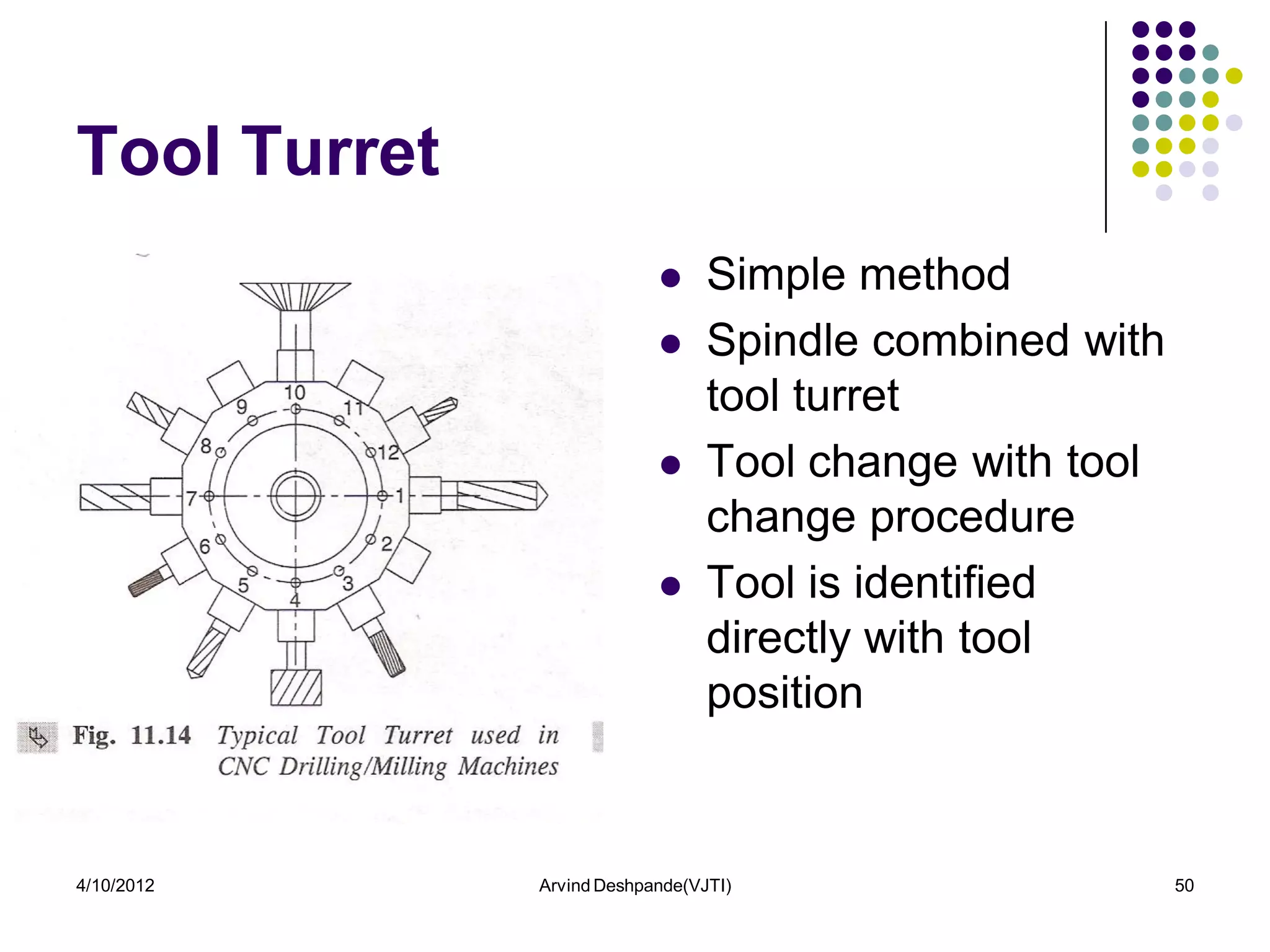

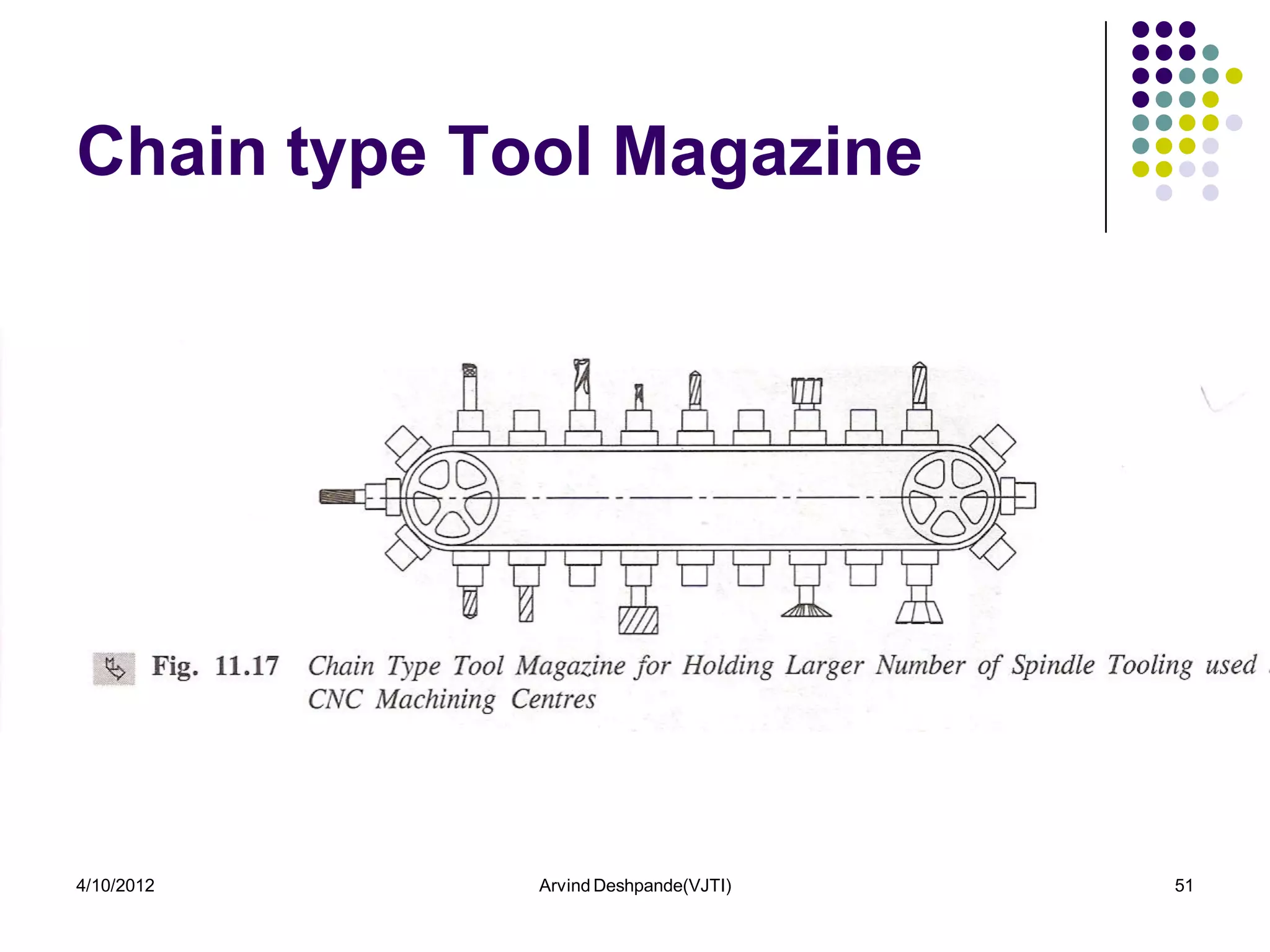

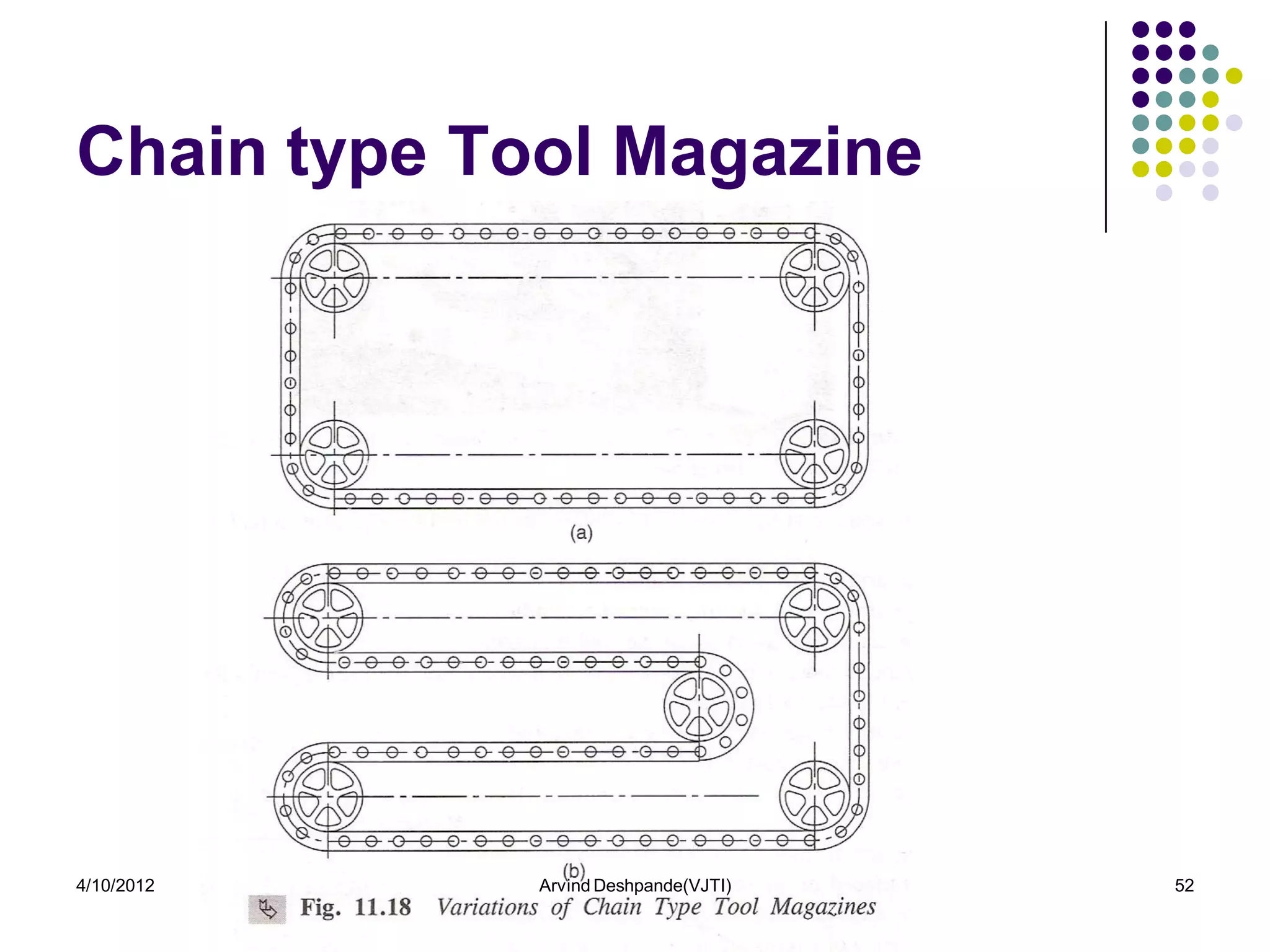

This document discusses the components and design considerations of computer numerical control (CNC) hardware. It describes the structure of CNC machine tools, including rigid beds, spindles, spindle drives, feed drives, and feedback control systems. Specific topics covered include stepper motors, servo motors, lead screws, ball screws, linear motors, encoders, and tooling systems. The goal of the design elements discussed is to enable CNC machine tools to achieve high stiffness, accuracy, and speeds for precision machining applications.