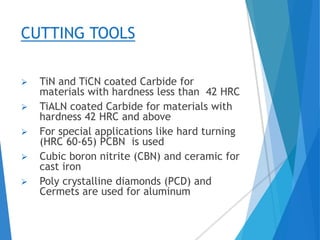

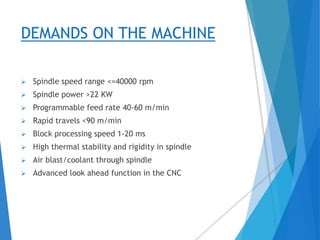

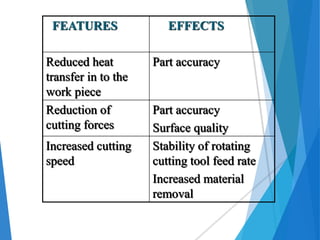

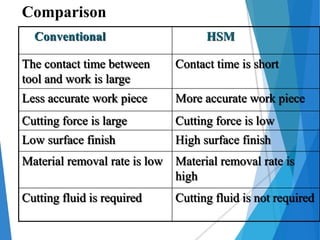

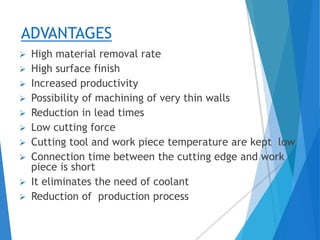

This seminar discusses high speed machining (HSM). HSM uses high spindle speeds combined with high feed rates, specialized tools, and tool paths. It allows for high material removal rates, improved surface finish and part accuracy, and reduced cutting forces compared to conventional machining. HSM is commonly used for machining aluminum automotive and aircraft parts, as well as hard metals like dies and molds. While HSM provides advantages like increased productivity, it requires expensive machine tools and advanced programming skills. Overall, HSM is an effective precision machining method when the proper conditions and equipment are used.