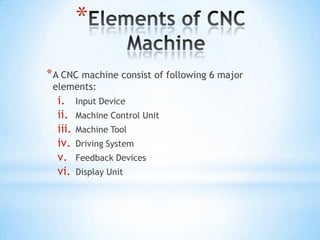

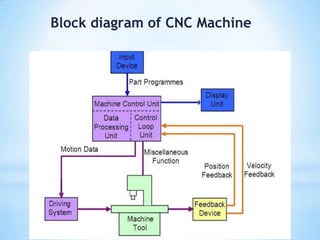

* The document presents information about computer numerical control (CNC) machines, including a brief history, how they work, common elements and programming.

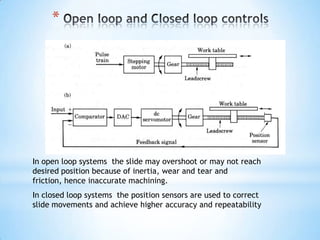

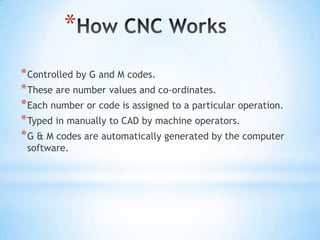

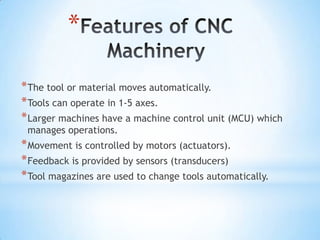

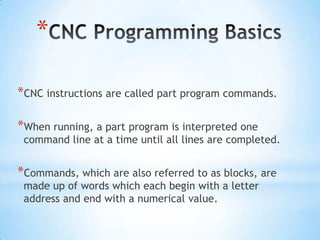

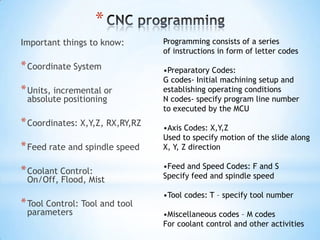

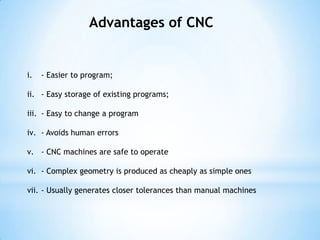

* CNC machines operate automatically according to programmed codes and have precision, consistency and reduced human errors compared to manual machines.

* They allow for complex geometries and closer tolerances at lower costs than manual machining. However, CNC machines require skilled operators and maintenance.