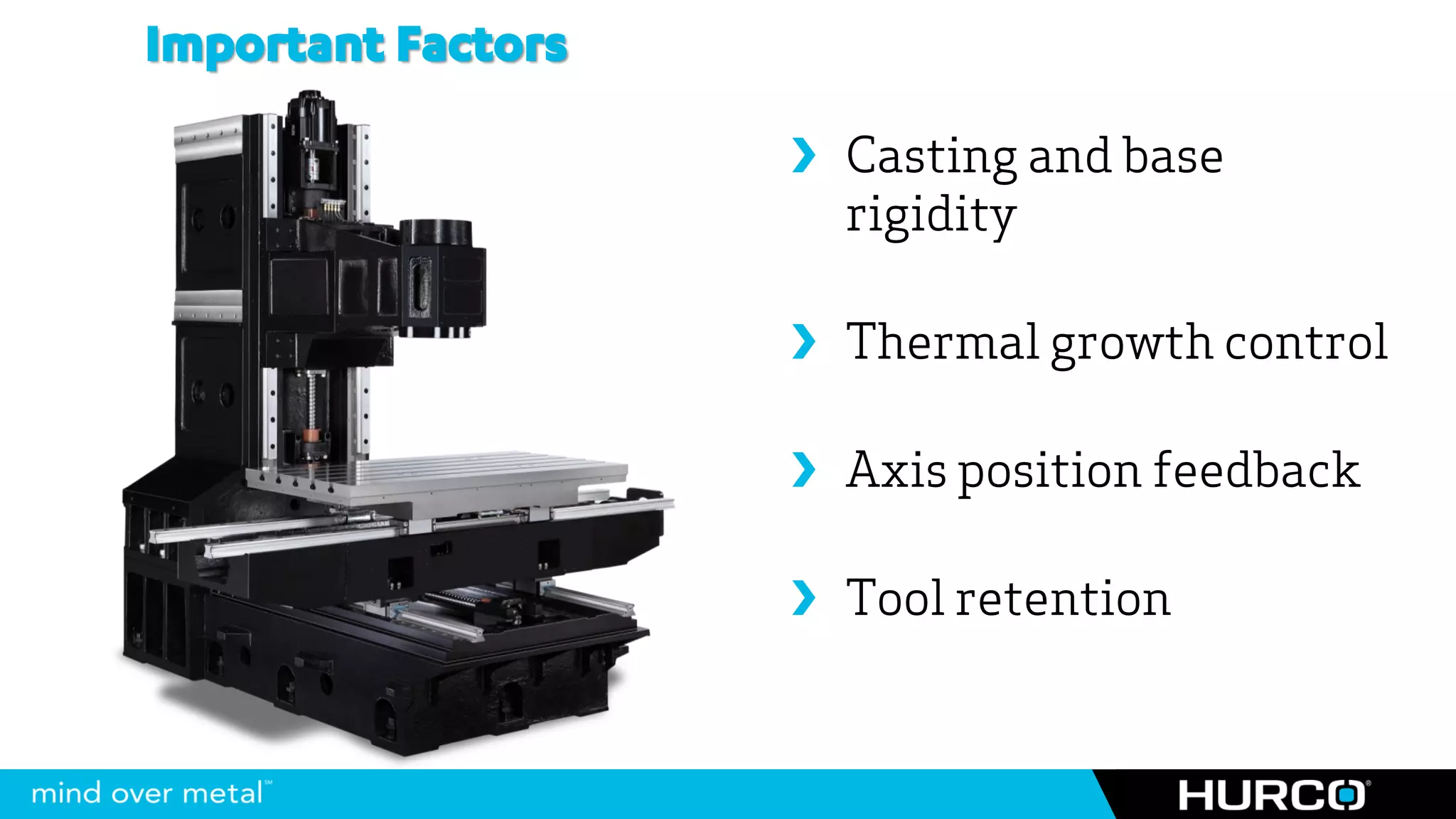

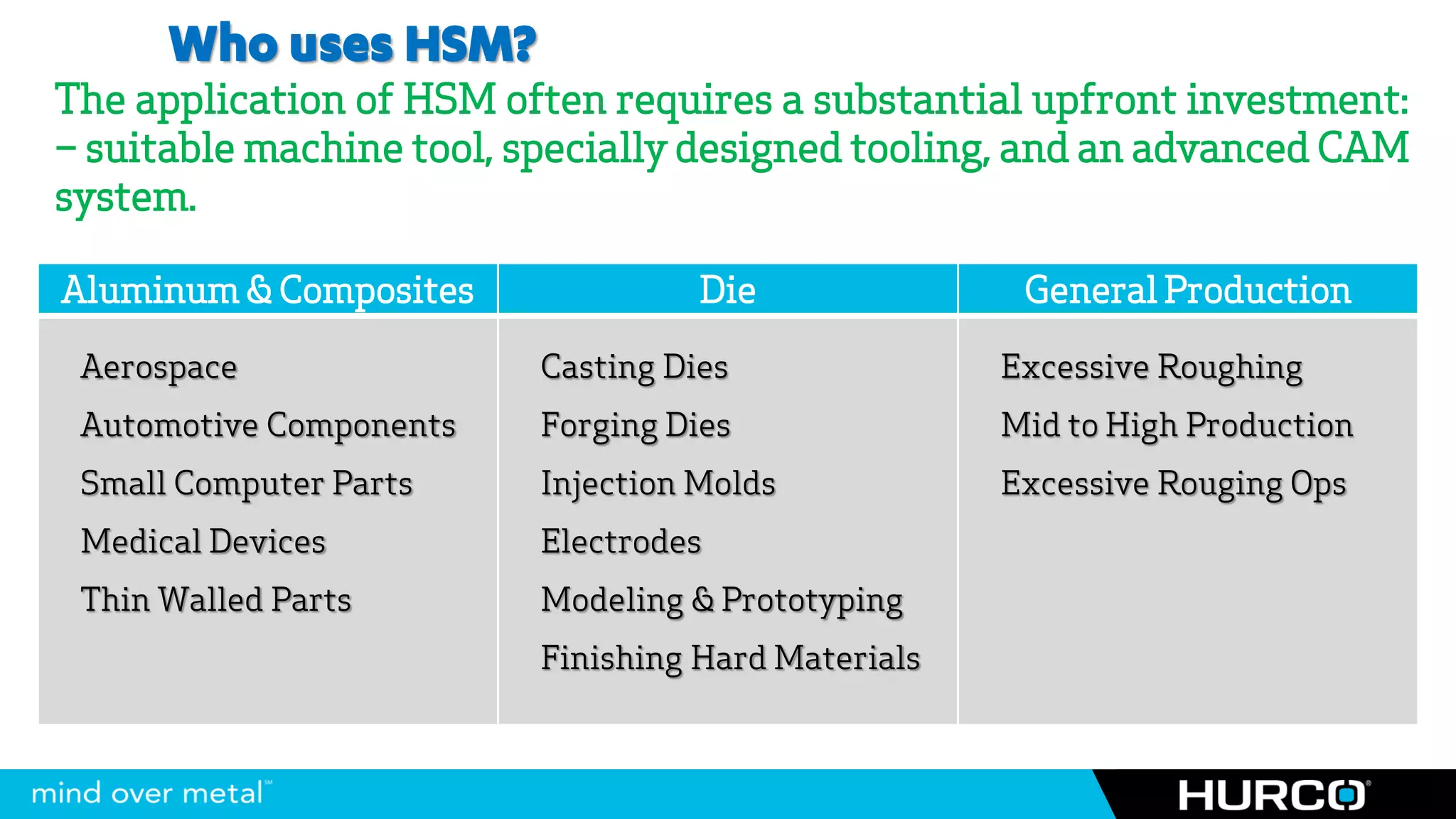

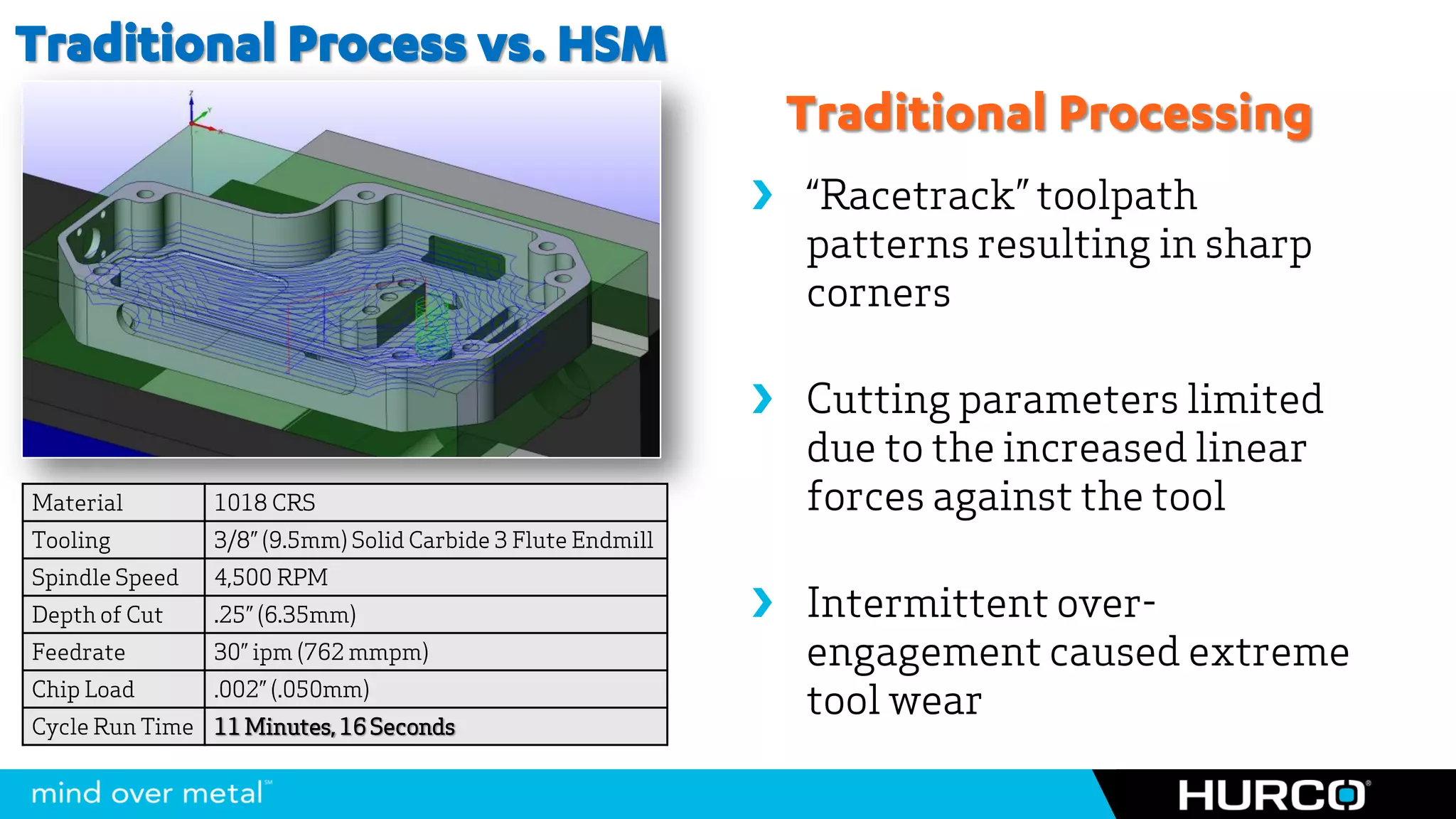

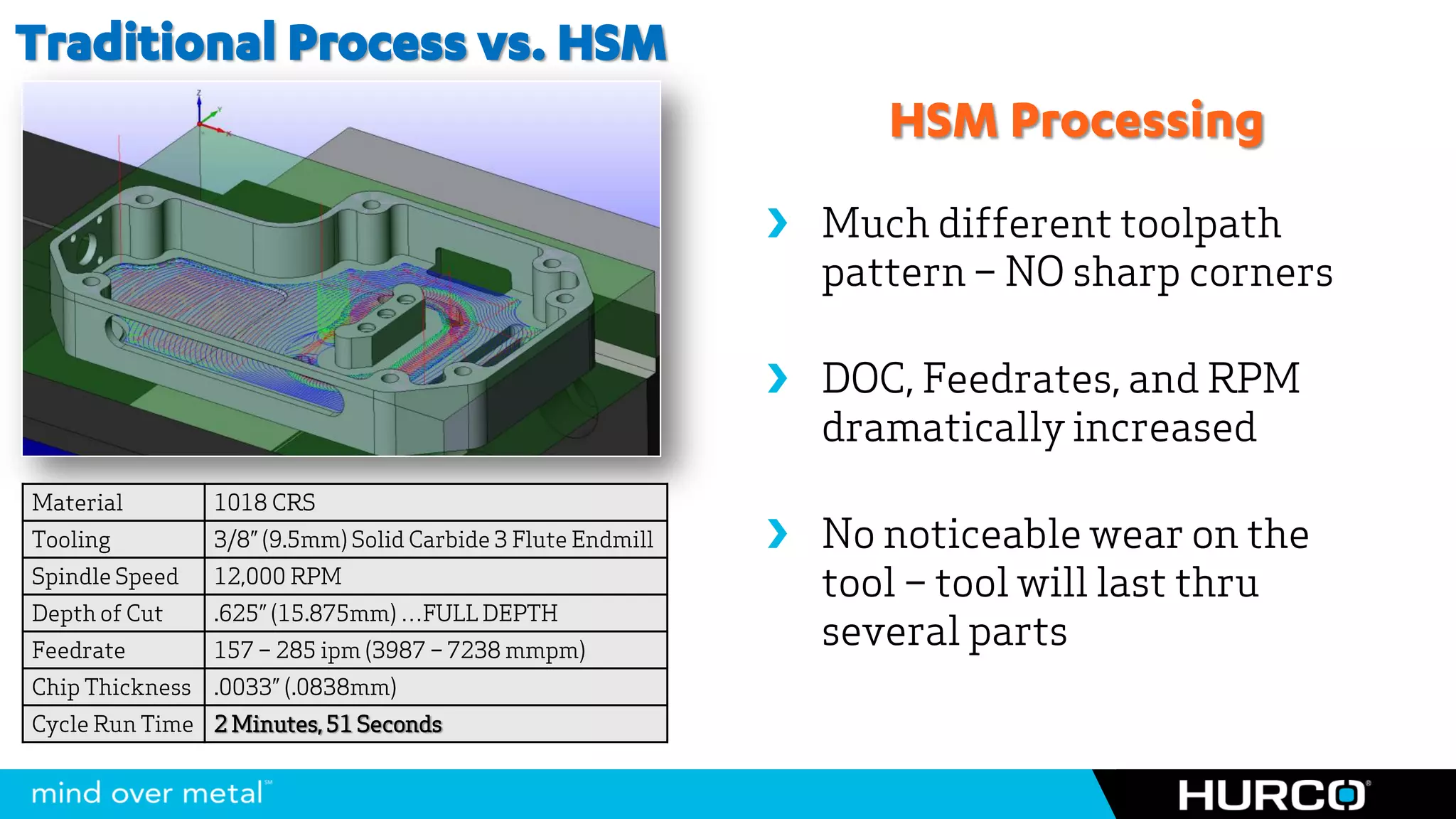

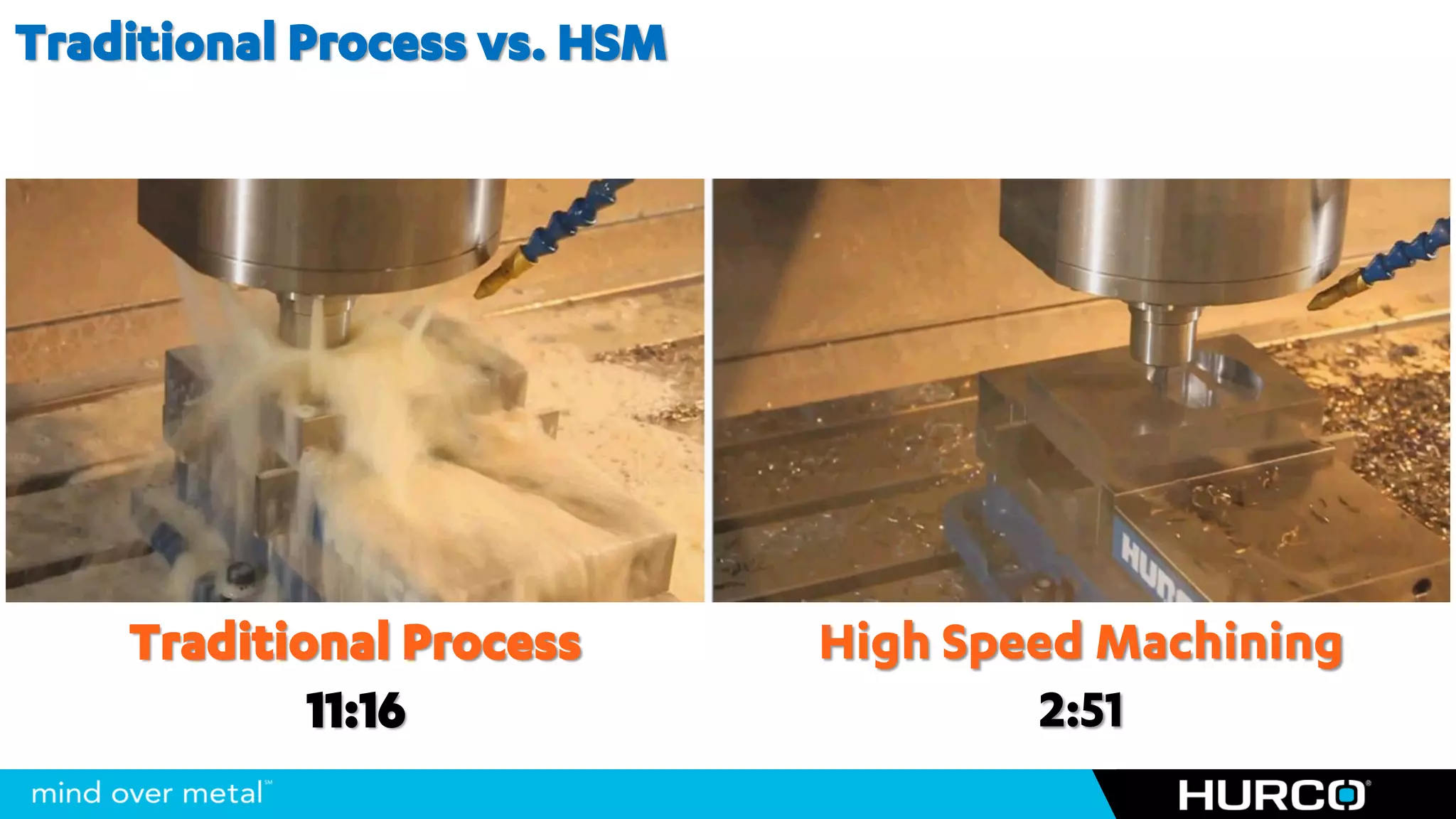

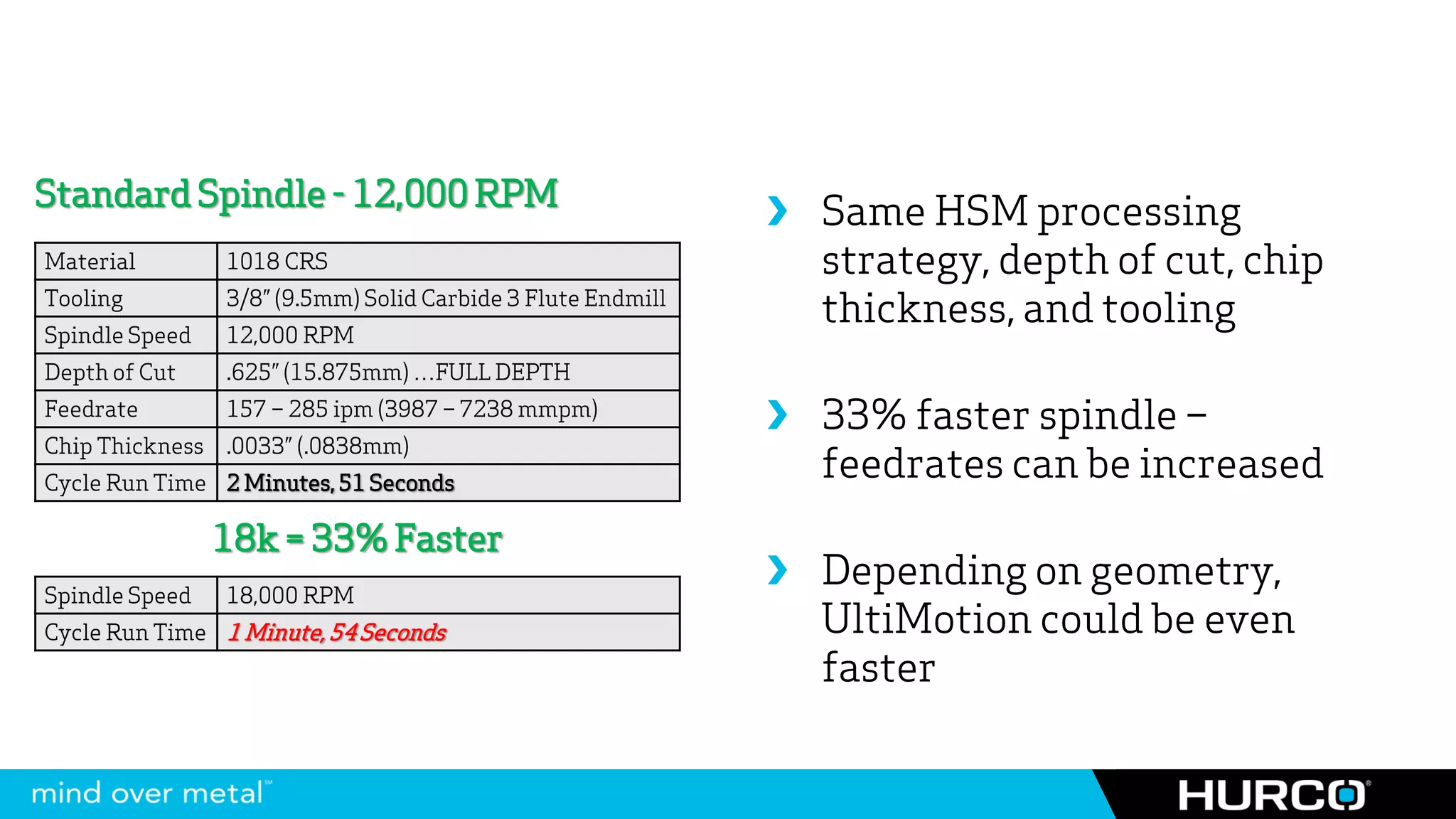

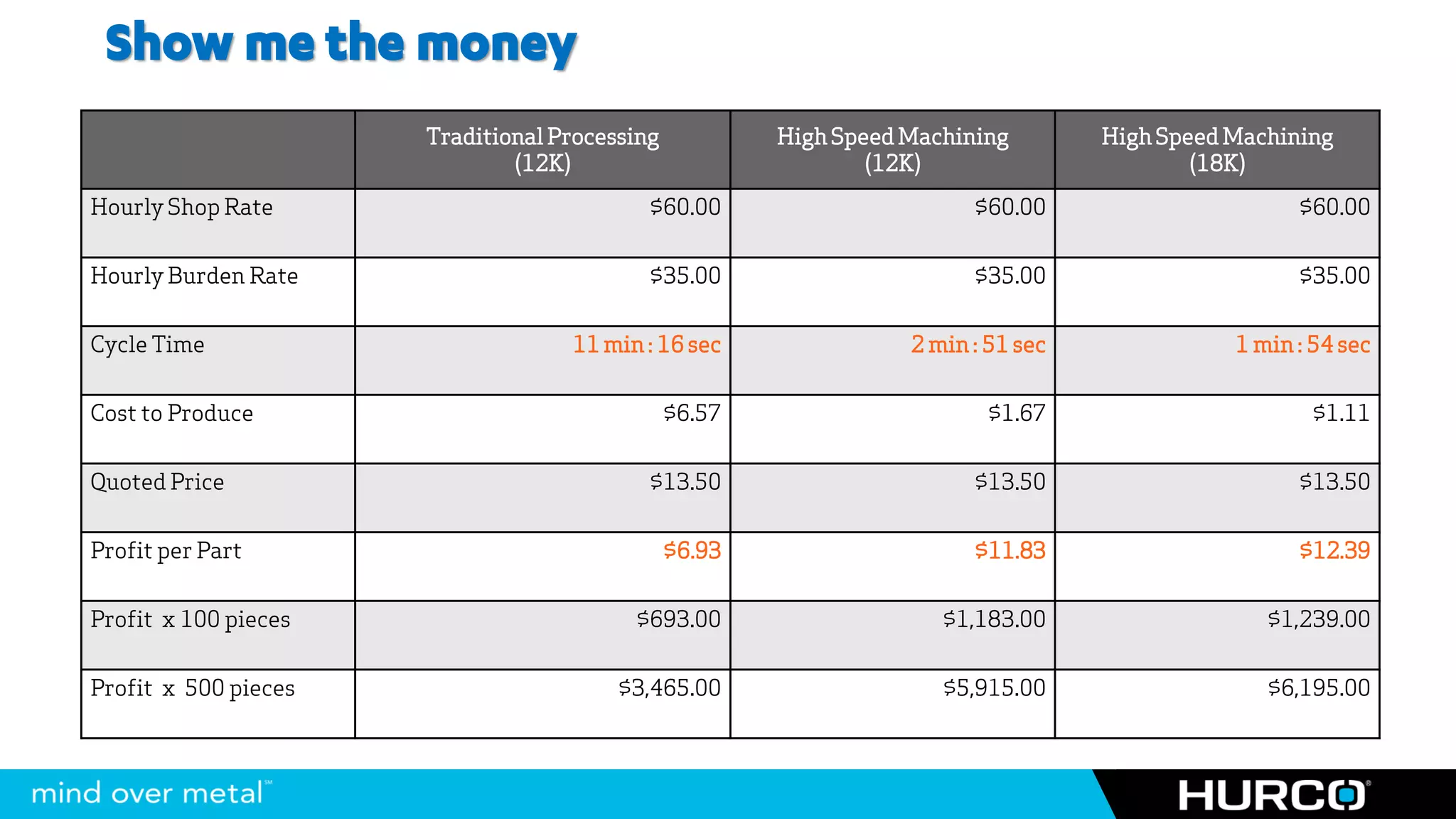

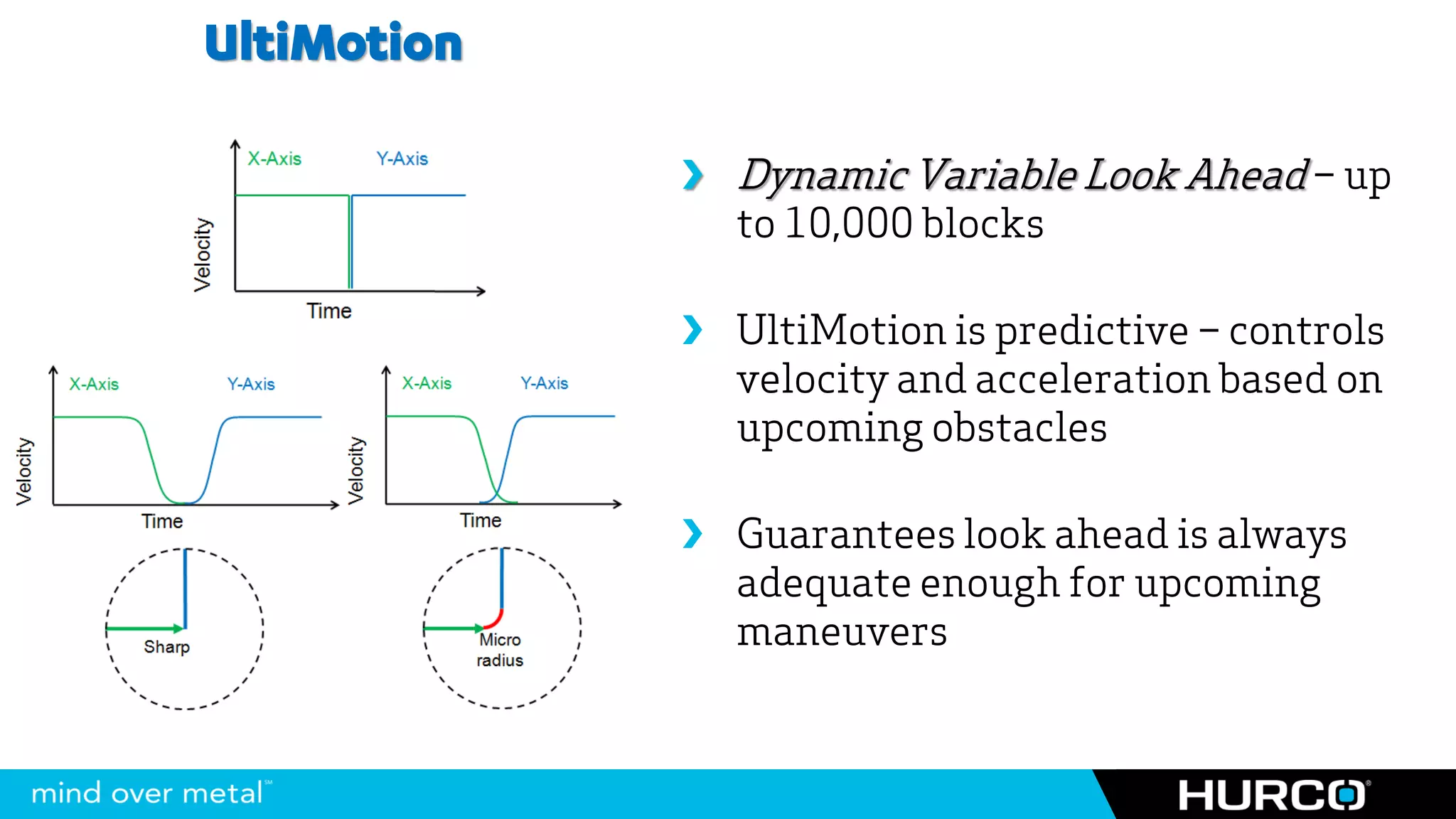

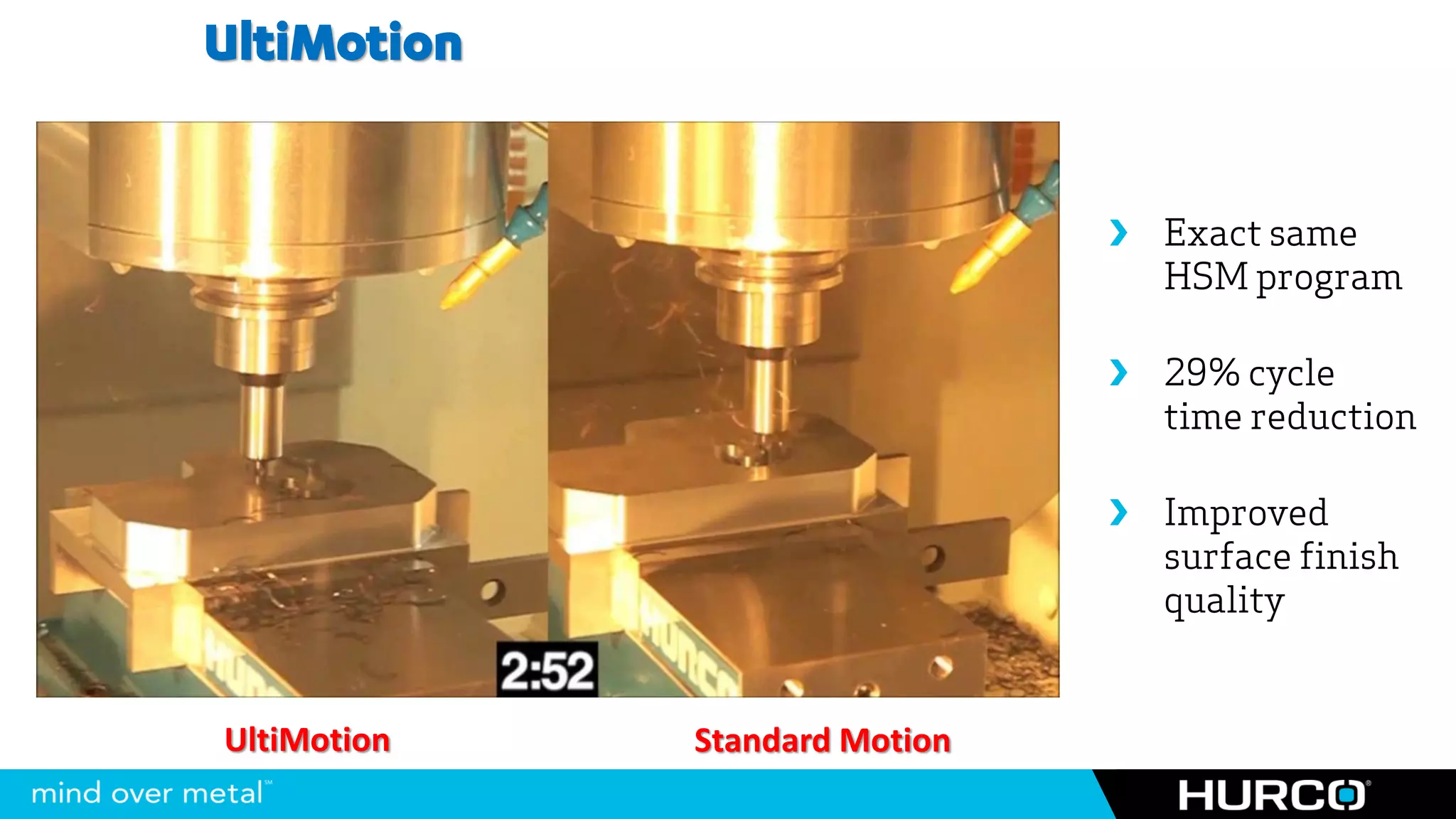

High-speed machining (HSM) involves spindle speeds above 15,000 RPM and focuses on enhancing overall machine performance through factors like rigidity and thermal control. It requires significant investment in specialized tools and offers advantages such as reduced cycle times and increased efficiency compared to traditional machining methods. HSM is increasingly used in various industries, including aerospace, automotive, and medical devices, yielding substantial profits per part due to lower production costs.